steering wheel adjustment NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 12 of 1833

7. The followingSYMBOLS AND ABBREVIATIONS are used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disassem- bly.

L.H., R.H.: Left-Hand, Right-Hand

FR, RR : Front, Rear

2WD : 2-Wheel Drive

4WD : 4-Wheel Drive

qP: Apply petroleum jelly.

: Apply A.T.F.

A.T.F. : Automatic Transmission Fluid

H : Select with proper thickness.

I : Adjustment is required.

M/T : Manual Transaxle/Transmission

A/C : Air Conditioner

P/S : Power Steering

S.S.T. : Special Service Tools

S.D.S. : Service Data and Specifications

SAE : Society of Automotive Engineers, Inc.

L.H.D. : Left-Hand Drive

R.H.D. : Right-Hand Drive

8. The UNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system. ªExampleºTightening torque:59-78N ×m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

9. TROUBLE DIAGNOSES are included in sections dealing with complicated components.

10. SERVICE DATA AND SPECIFICATIONS are contained at the end of each section for quick reference of

data.

11. The captions WARNINGandCAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

I WARNING indicates the possibility of personal injury if instructions are not followed.

I CAUTION indicates the possibility of component damage if instructions are not followed.

I BOLD TYPED STATEMENTS exceptWARNING andCAUTION give you helpful information.

HOW TO USE THIS MANUAL

GI-9

http://vnx.su/

Page 90 of 1833

Chassis and Body Maintenance

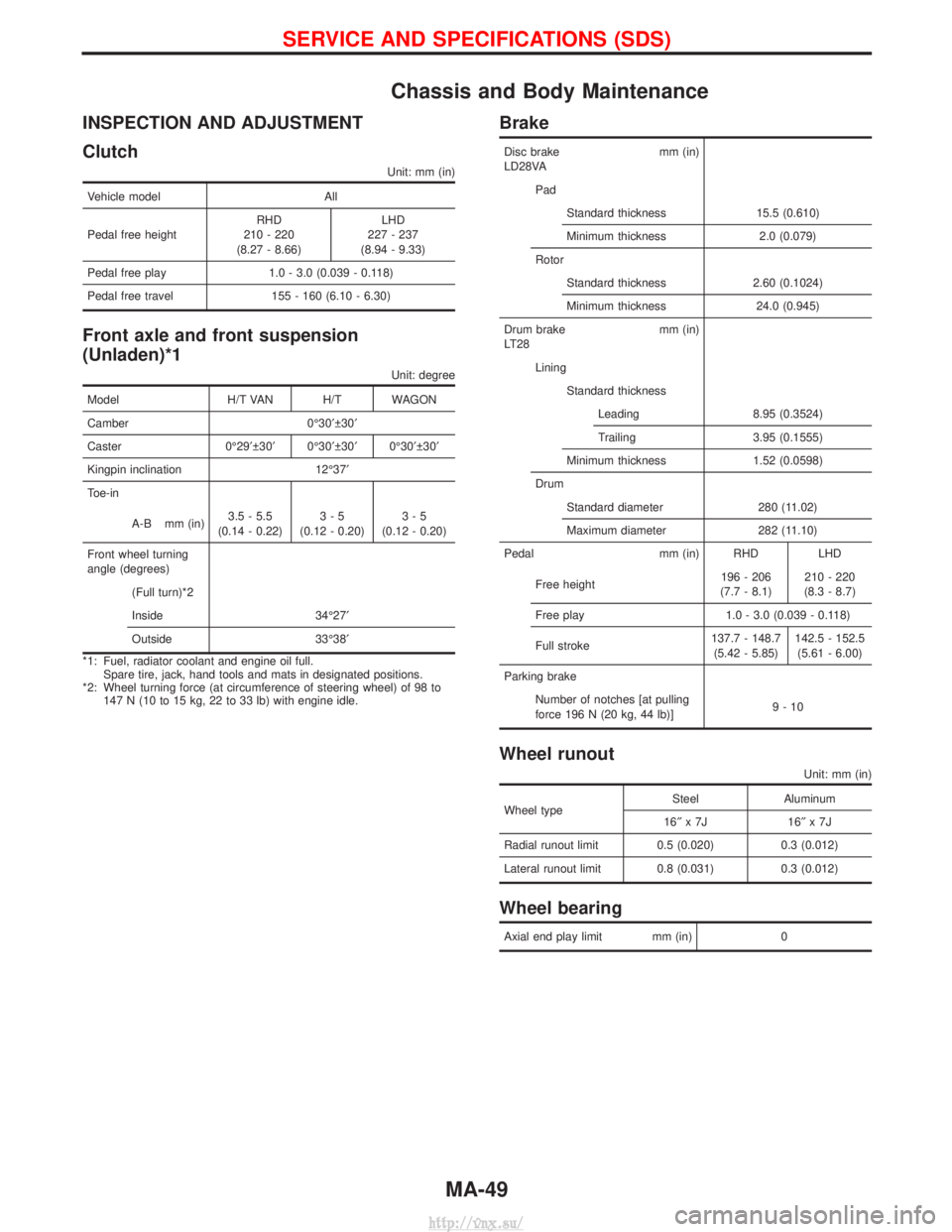

INSPECTION AND ADJUSTMENT

Clutch

Unit: mm (in)

Vehicle modelAll

Pedal free height RHD

210 - 220

(8.27 - 8.66) LHD

227 - 237

(8.94 - 9.33)

Pedal free play 1.0 - 3.0 (0.039 - 0.118)

Pedal free travel 155 - 160 (6.10 - 6.30)

Front axle and front suspension

(Unladen)*1

Unit: degree

Model H/T VAN H/T WAGON

Camber 0É30¢ 30¢

Caster 0É29¢ 30¢ 0É30¢ 30¢ 0É30¢ 30¢

Kingpin inclination 12É37¢

Toe-in

A-B mm (in) 3.5 - 5.5

(0.14 - 0.22) 3-5

(0.12 - 0.20) 3-5

(0.12 - 0.20)

Front wheel turning

angle (degrees) (Full turn)*2

Inside 34É27¢

Outside 33É38¢

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with engine idle.

Brake

Disc brake mm (in)

LD28VA

PadStandard thickness 15.5 (0.610)

Minimum thickness 2.0 (0.079)

Rotor Standard thickness 2.60 (0.1024)

Minimum thickness 24.0 (0.945)

Drum brake mm (in)

LT28 LiningStandard thicknessLeading 8.95 (0.3524)

Trailing 3.95 (0.1555)

Minimum thickness 1.52 (0.0598)

Drum Standard diameter 280 (11.02)

Maximum diameter 282 (11.10)

Pedal mm (in) RHD LHD

Free height 196 - 206

(7.7 - 8.1) 210 - 220

(8.3 - 8.7)

Free play 1.0 - 3.0 (0.039 - 0.118)

Full stroke 137.7 - 148.7

(5.42 - 5.85) 142.5 - 152.5

(5.61 - 6.00)

Parking brake Number of notches [at pulling

force 196 N (20 kg, 44 lb)] 9-10

Wheel runout

Unit: mm (in)

Wheel typeSteel Aluminum

16² x7J 16 ²x7J

Radial runout limit 0.5 (0.020) 0.3 (0.012)

Lateral runout limit 0.8 (0.031) 0.3 (0.012)

Wheel bearing

Axial end play limit mm (in) 0

SERVICE AND SPECIFICATIONS (SDS)

MA-49

http://vnx.su/

Page 1119 of 1833

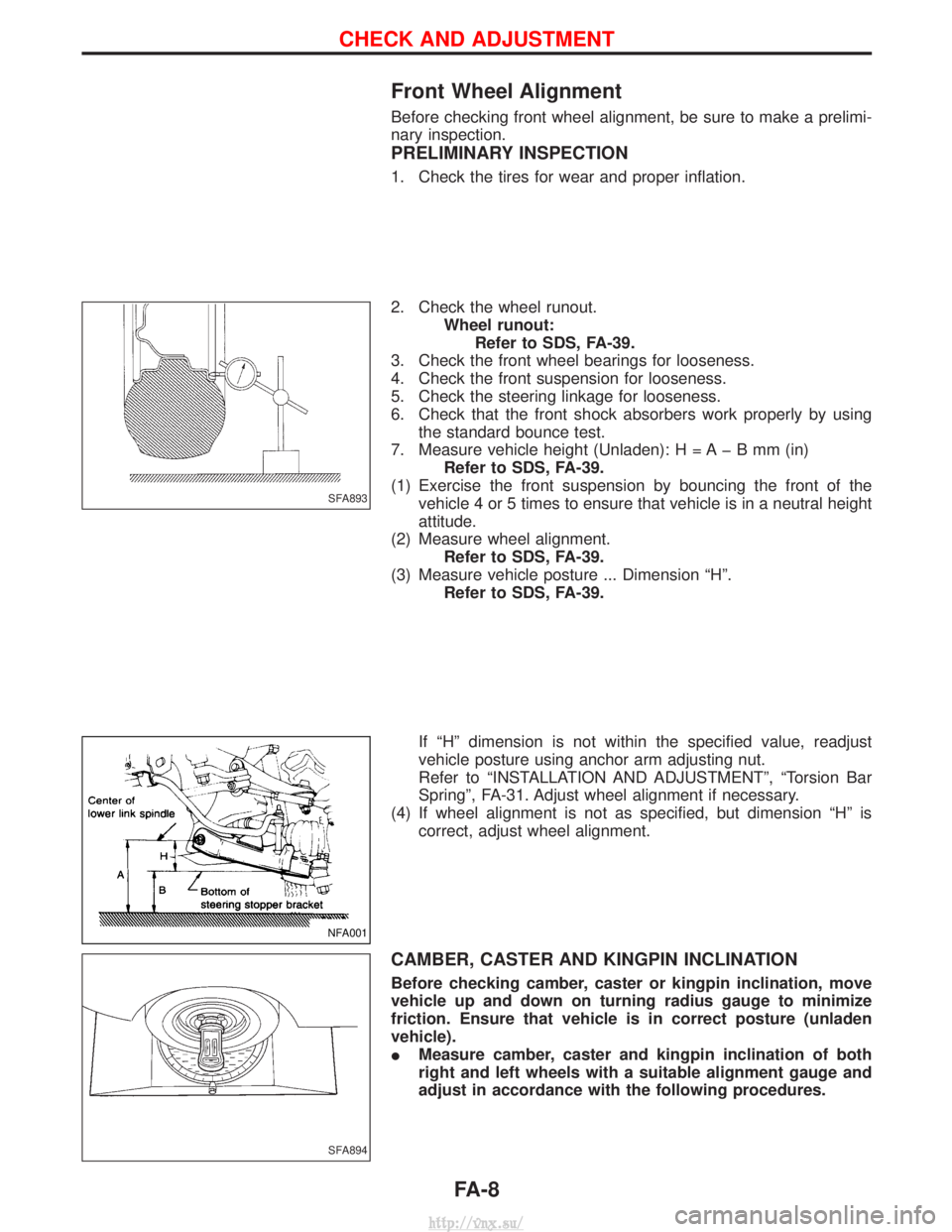

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a prelimi-

nary inspection.

PRELIMINARY INSPECTION

1. Check the tires for wear and proper inflation.

2. Check the wheel runout.Wheel runout:Refer to SDS, FA-39.

3. Check the front wheel bearings for looseness.

4. Check the front suspension for looseness.

5. Check the steering linkage for looseness.

6. Check that the front shock absorbers work properly by using the standard bounce test.

7. Measure vehicle height (Unladen): H = A þ B mm (in) Refer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the vehicle 4 or 5 times to ensure that vehicle is in a neutral height

attitude.

(2) Measure wheel alignment. Refer to SDS, FA-39.

(3) Measure vehicle posture ... Dimension ªHº. Refer to SDS, FA-39.

If ªHº dimension is not within the specified value, readjust

vehicle posture using anchor arm adjusting nut.

Refer to ªINSTALLATION AND ADJUSTMENTº, ªTorsion Bar

Springº, FA-31. Adjust wheel alignment if necessary.

(4) If wheel alignment is not as specified, but dimension ªHº is correct, adjust wheel alignment.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that vehicle is in correct posture (unladen

vehicle).

IMeasure camber, caster and kingpin inclination of both

right and left wheels with a suitable alignment gauge and

adjust in accordance with the following procedures.

SFA893

NFA001

SFA894

CHECK AND ADJUSTMENT

FA-8

http://vnx.su/

Page 1122 of 1833

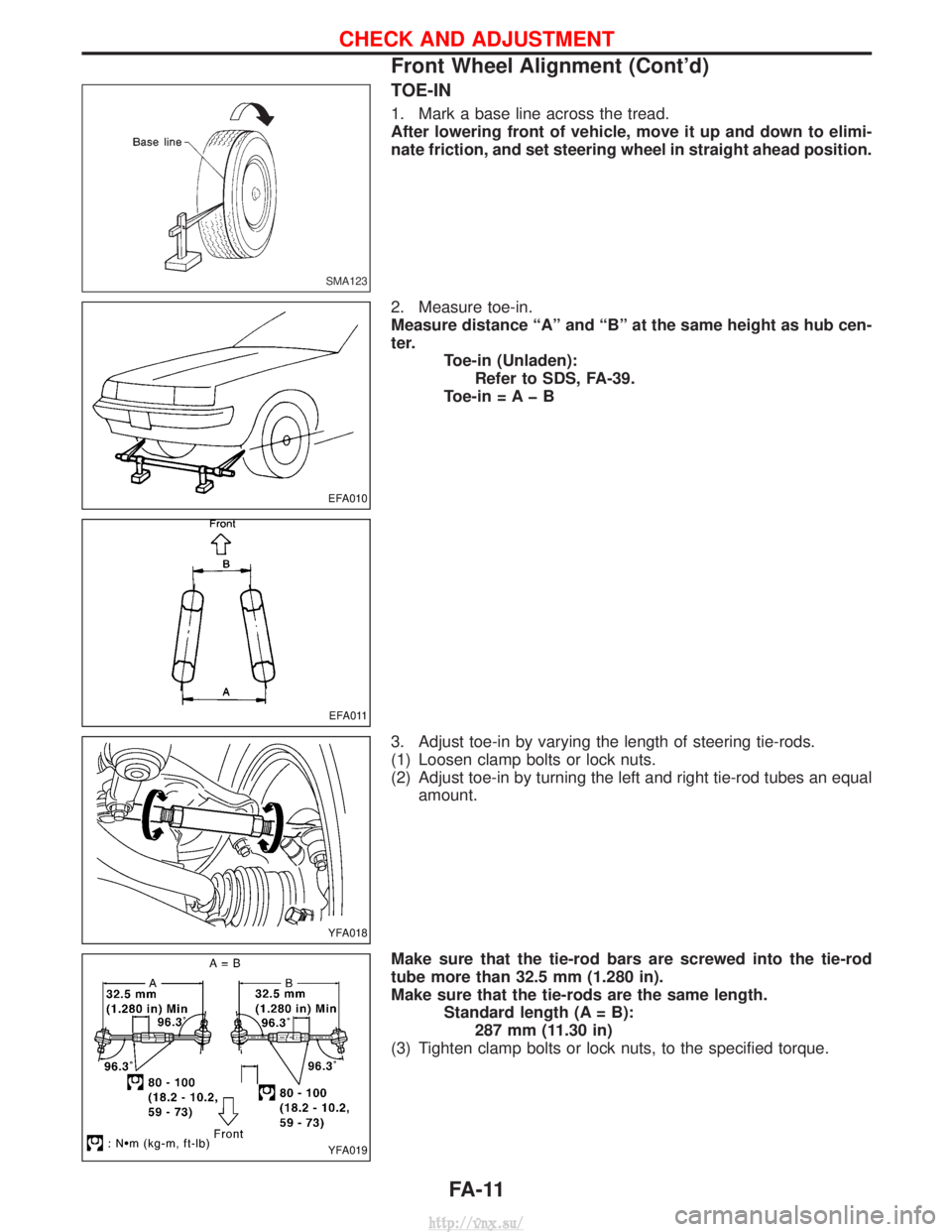

TOE-IN

1. Mark a base line across the tread.

After lowering front of vehicle, move it up and down to elimi-

nate friction, and set steering wheel in straight ahead position.

2. Measure toe-in.

Measure distance ªAº and ªBº at the same height as hub cen-

ter.Toe-in (Unladen):Refer to SDS, FA-39.

Toe-in = A þ B

3. Adjust toe-in by varying the length of steering tie-rods.

(1) Loosen clamp bolts or lock nuts.

(2) Adjust toe-in by turning the left and right tie-rod tubes an equal amount.

Make sure that the tie-rod bars are screwed into the tie-rod

tube more than 32.5 mm (1.280 in).

Make sure that the tie-rods are the same length. Standard length (A = B):287 mm (11.30 in)

(3) Tighten clamp bolts or lock nuts, to the specified torque.

SMA123

EFA010

EFA011

YFA018

YFA019

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-11

http://vnx.su/

Page 1123 of 1833

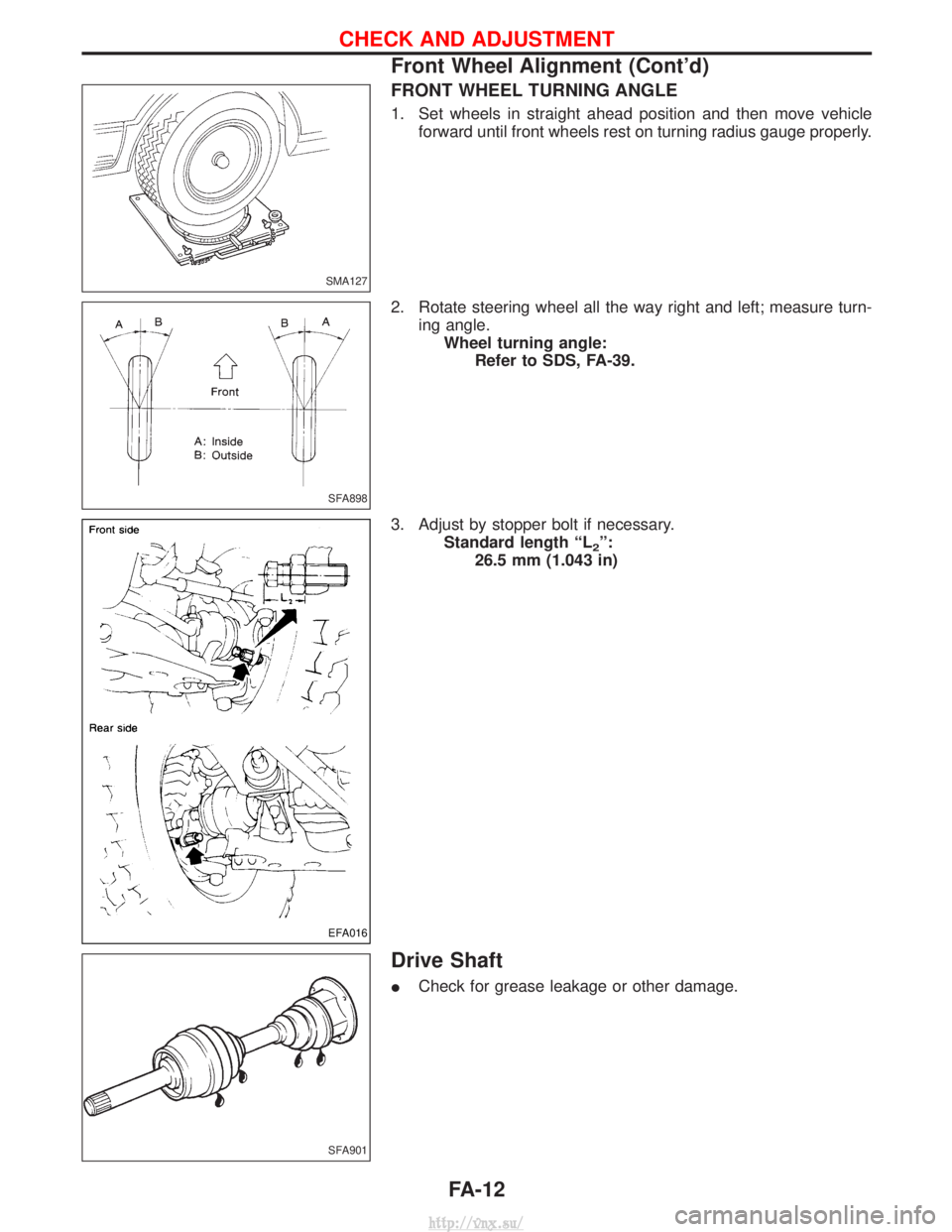

FRONT WHEEL TURNING ANGLE

1. Set wheels in straight ahead position and then move vehicleforward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turn- ing angle.Wheel turning angle: Refer to SDS, FA-39.

3. Adjust by stopper bolt if necessary. Standard length ªL

2º:

26.5 mm (1.043 in)

Drive Shaft

I Check for grease leakage or other damage.

SMA127

SFA898

EFA016

SFA901

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-12

http://vnx.su/

Page 1170 of 1833

Supplement Restraint System (SRS) ªAIR BAGº

and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt, help

to reduce the risk or severity or injury to the driver and front passenger in a collision. The Supplemental

Restraint System consists of an air bag module (located in the center of the steering wheel and on the instru-

ment panel on the passenger side, where fitted), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

BT sectionof this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation), all maintenance must be per-

formed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT-TENSIONERº connector) can be iden-

tified with yellow harness connector and with yellow harness protector or yellow insulation tape

before the harness connectors.

Precautions

IUse only ªDOT 4º fluid from a sealed container.

I Never reuse drained brake fluid.

I Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

I To clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake fluid.

I Never use mineral oils such as Petrol or kerosene. They

will ruin rubber parts of hydraulic system.

I Use flare nut wrench when removing and installing brake

tubes.

I Always torque brake lines when installing.

I Burnish the brake contact surfaces after refinishing or

replacing drums or rotors, after replacing pads or linings,

or if a soft pedal occurs at very low speed. Refer to ªBrake

Burnishing Procedureº, ªCheck and Adjustmentº, BR-5.

WARNING:

I Clean brakes with a vacuum dust collector to minimize risk

of health hazard from airborne materials.

I Avoid prolonged and repeated skin contact with brake

fluid.

I Wear protective clothing, including impervious gloves.

I Where there is a risk of eye contact, eye protection should

be worn Ð for example chemical goggles or face shield.

YBR293

PRECAUTIONS AND PREPARATION

BR-3

http://vnx.su/

Page 1254 of 1833

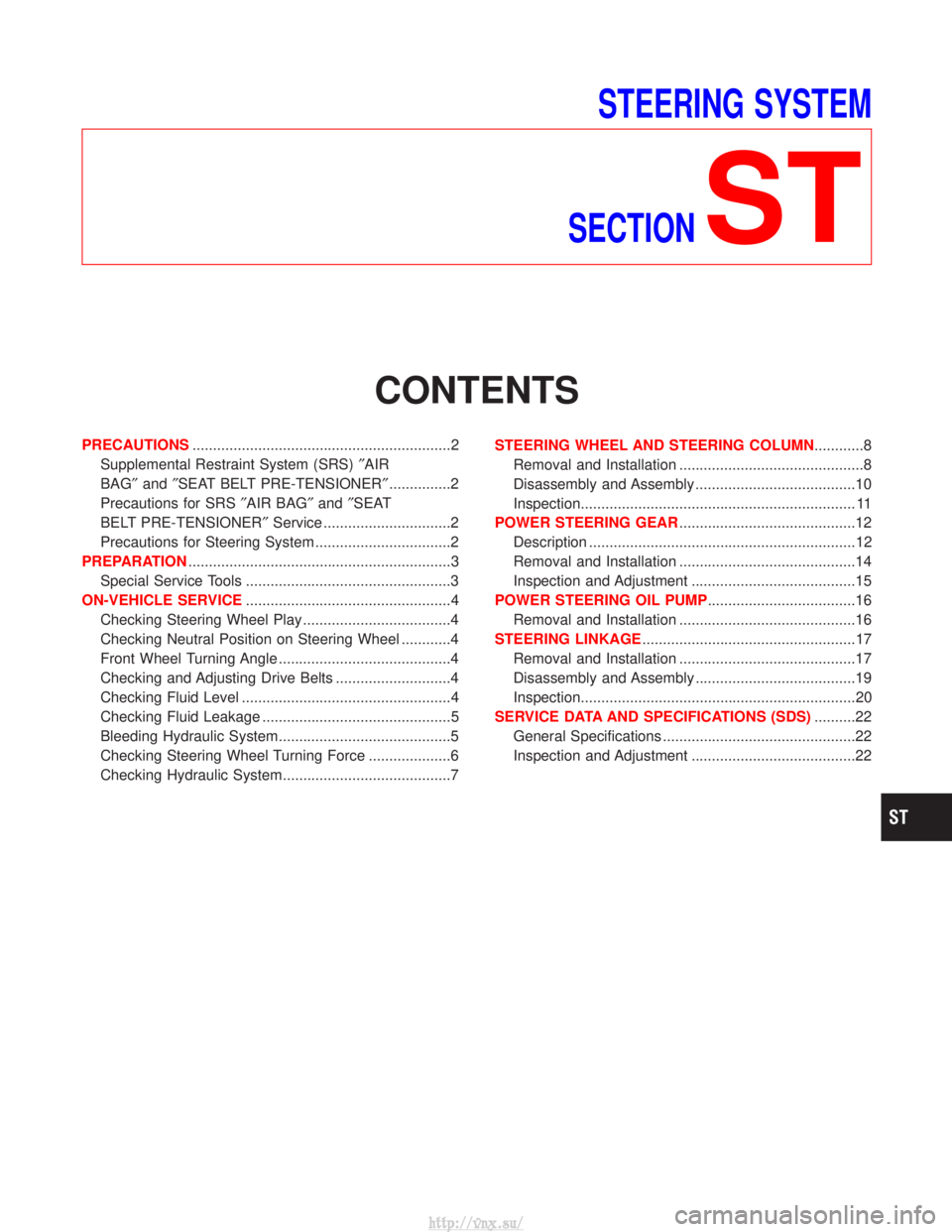

STEERING SYSTEM

SECTION

ST

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ²AIR

BAG² and²SEAT BELT PRE-TENSIONER² ...............2

Precautions for SRS ²AIR BAG² and²SEAT

BELT PRE-TENSIONER² Service ...............................2

Precautions for Steering System .................................2

PREPARATION ................................................................3

Special Service Tools ..................................................3

ON-VEHICLE SERVICE ..................................................4

Checking Steering Wheel Play ....................................4

Checking Neutral Position on Steering Wheel ............4

Front Wheel Turning Angle ..........................................4

Checking and Adjusting Drive Belts ............................4

Checking Fluid Level ...................................................4

Checking Fluid Leakage ..............................................5

Bleeding Hydraulic System..........................................5

Checking Steering Wheel Turning Force ....................6

Checking Hydraulic System.........................................7 STEERING WHEEL AND STEERING COLUMN

............8

Removal and Installation .............................................8

Disassembly and Assembly .......................................10

Inspection................................................................... 11

POWER STEERING GEAR ...........................................12

Description .................................................................12

Removal and Installation ...........................................14

Inspection and Adjustment ........................................15

POWER STEERING OIL PUMP ....................................16

Removal and Installation ...........................................16

STEERING LINKAGE ....................................................17

Removal and Installation ...........................................17

Disassembly and Assembly .......................................19

Inspection...................................................................20

SERVICE DATA AND SPECIFICATIONS (SDS) ..........22

General Specifications ...............................................22

Inspection and Adjustment ........................................22

http://vnx.su/

Page 1259 of 1833

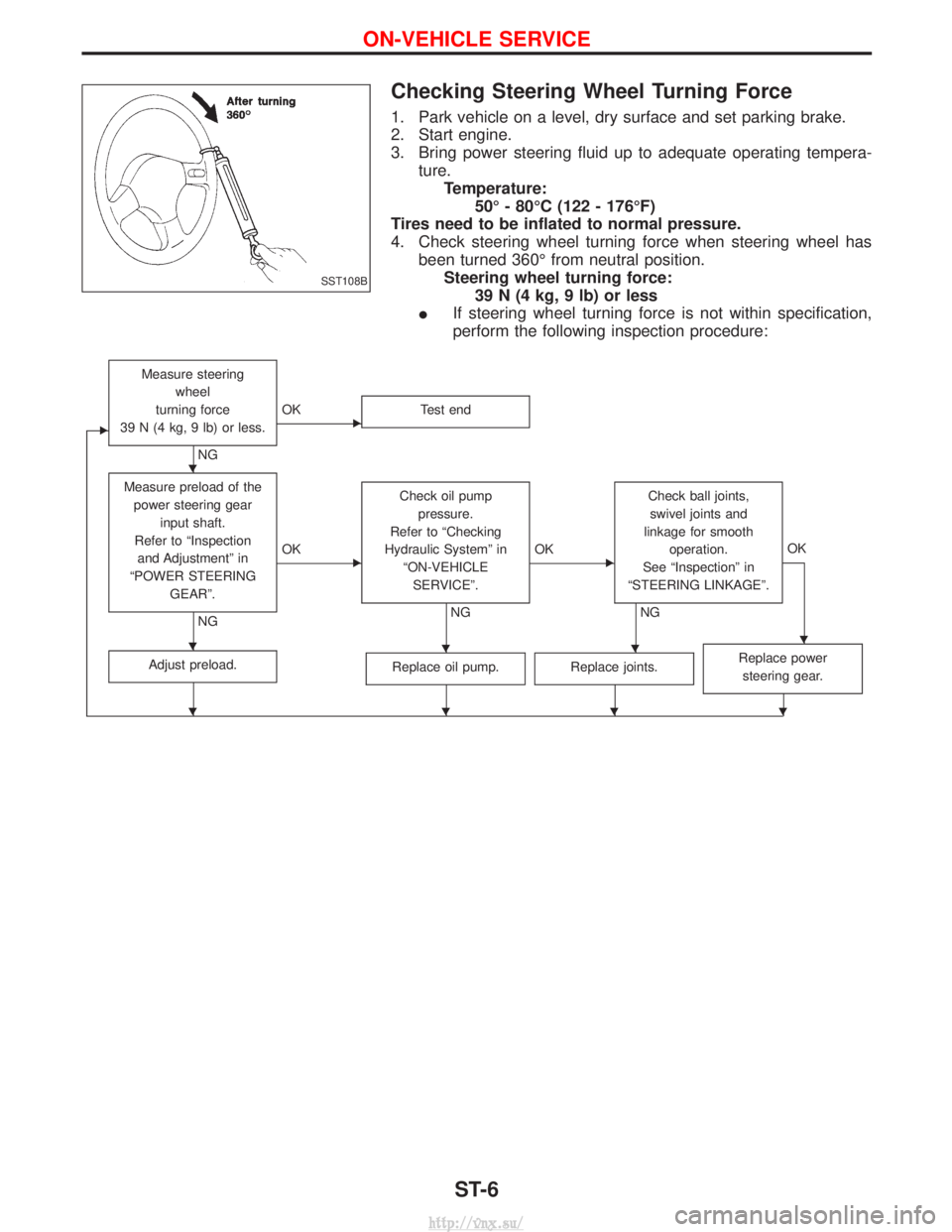

Checking Steering Wheel Turning Force

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-ture.Temperature: 50É - 80ÉC (122 - 176ÉF)

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has been turned 360É from neutral position.Steering wheel turning force: 39 N (4 kg, 9 lb) or less

I If steering wheel turning force is not within specification,

perform the following inspection procedure:

E

Measure steering

wheel

turning force

39 N (4 kg, 9 lb) or less.

NG

EOK Test end

Measure preload of the

power steering gear input shaft.

Refer to ªInspection and Adjustmentº in

ªPOWER STEERING GEARº.

NG

EOK Check oil pump

pressure.

Refer to ªChecking

Hydraulic Systemº in ªON-VEHICLESERVICEº.

NG

EOK Check ball joints,

swivel joints and

linkage for smooth operation.

See ªInspectionº in

ªSTEERING LINKAGEº.

NG OK

Adjust preload.Replace oil pump.Replace joints.Replace power

steering gear.

SST108B

H

HHHH

HHHH

ON-VEHICLE SERVICE

ST-6

http://vnx.su/

Page 1275 of 1833

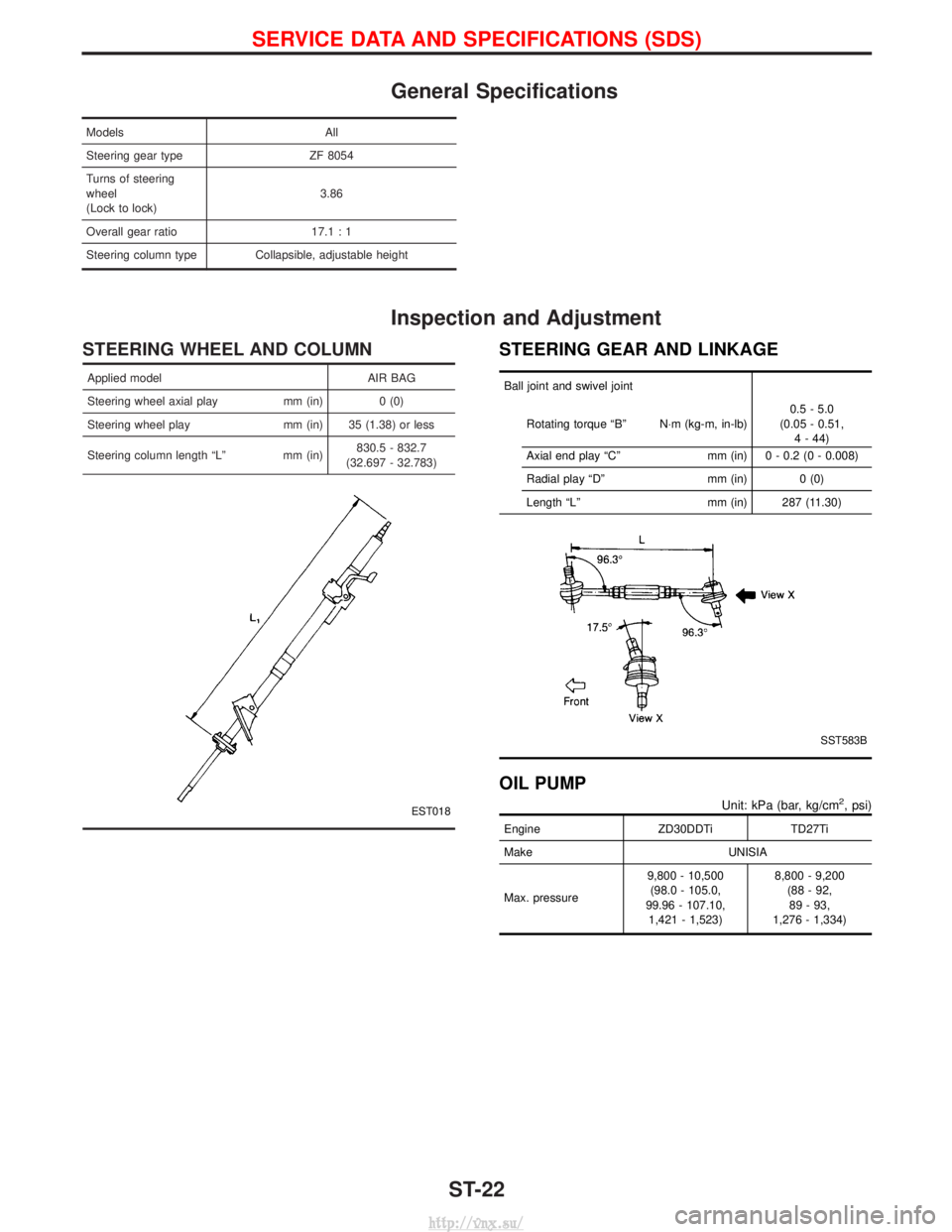

General Specifications

ModelsAll

Steering gear type ZF 8054

Turns of steering

wheel

(Lock to lock) 3.86

Overall gear ratio 17.1 : 1

Steering column type Collapsible, adjustable height

Inspection and Adjustment

STEERING WHEEL AND COLUMN

Applied model AIR BAG

Steering wheel axial play mm (in) 0 (0)

Steering wheel play mm (in) 35 (1.38) or less

Steering column length ªLº mm (in) 830.5 - 832.7

(32.697 - 32.783)

EST018

STEERING GEAR AND LINKAGE

Ball joint and swivel joint

Rotating torque ªBº N×m (kg-m, in-lb) 0.5 - 5.0

(0.05 - 0.51, 4 - 44)

Axial end play ªCº mm (in) 0 - 0.2 (0 - 0.008)

Radial play ªDº mm (in) 0 (0)

Length ªLº mm (in) 287 (11.30)

SST583B

OIL PUMP

Unit: kPa (bar, kg/cm2, psi)

EngineZD30DDTiTD27Ti

Make UNISIA

Max. pressure 9,800 - 10,500

(98.0 - 105.0,

99.96 - 107.10, 1,421 - 1,523) 8,800 - 9,200

(88 - 92,89 - 93,

1,276 - 1,334)

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-22

http://vnx.su/