engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3047 of 5883

EXL-46

< COMPONENT DIAGNOSIS >

PARKING LAMP CIRCUIT

PARKING LAMP CIRCUIT

WITH DAYTIME LIGHT SYSTEM

WITH DAYTIME LIGHT SYSTEM : DescriptionINFOID:0000000001523268

The IPDM E/R (Intelligent Power Distribution Module Engine Room) controls the daytime light relay based on

inputs from the BCM via the CAN communication lines. When the daytime light relay is energized power flows

to the front and rear combination lamps and the license plate lamps.

WITH DAYTIME LIGHT SYSTEM : Component Function CheckINFOID:0000000001523269

1.CHECK PARKING LAMP OPERATION

CONSULT-III

1. Select "TAIL LAMP" of IPDM E/R active test item.

2. With test items operating, check that the parking lamps are turned ON.

Is the parking lamp turned ON?

YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-46, "

WITH DAYTIME LIGHT SYSTEM : Diagnosis Procedure".

WITH DAYTIME LIGHT SYSTEM : Diagnosis ProcedureINFOID:0000000001523270

1.CHECK PARKING LAMP FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2

2.CHECK DAYTIME LIGHT RELAY OUTPUT (VOLTAGE)

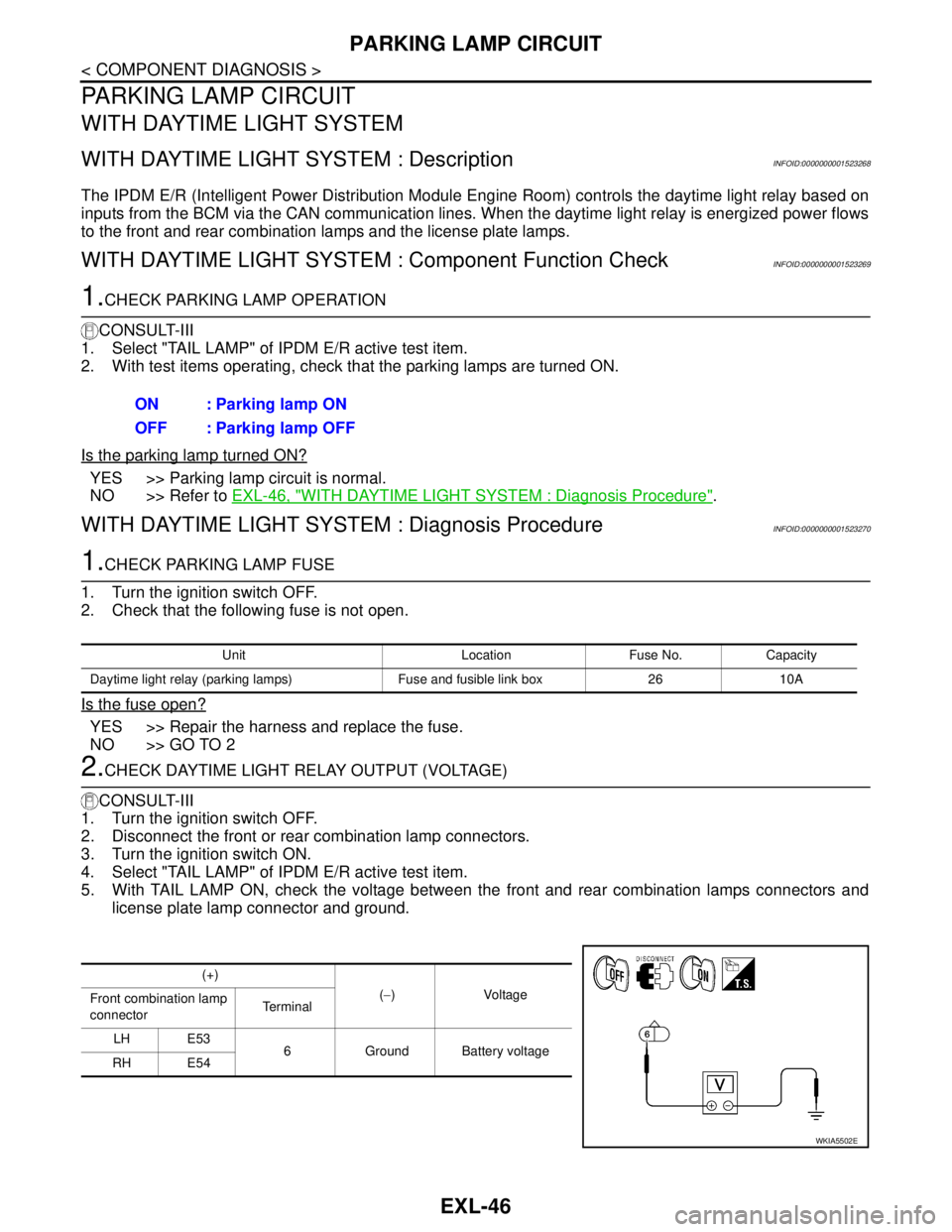

CONSULT-III

1. Turn the ignition switch OFF.

2. Disconnect the front or rear combination lamp connectors.

3. Turn the ignition switch ON.

4. Select "TAIL LAMP" of IPDM E/R active test item.

5. With TAIL LAMP ON, check the voltage between the front and rear combination lamps connectors and

license plate lamp connector and ground.ON : Parking lamp ON

OFF : Parking lamp OFF

Unit Location Fuse No. Capacity

Daytime light relay (parking lamps) Fuse and fusible link box 26 10A

(+)

(−)Voltage

Front combination lamp

connectorTe r m i n a l

LH E53

6 Ground Battery voltage

RH E54

WKIA5502E

Page 3049 of 5883

EXL-48

< COMPONENT DIAGNOSIS >

PARKING LAMP CIRCUIT

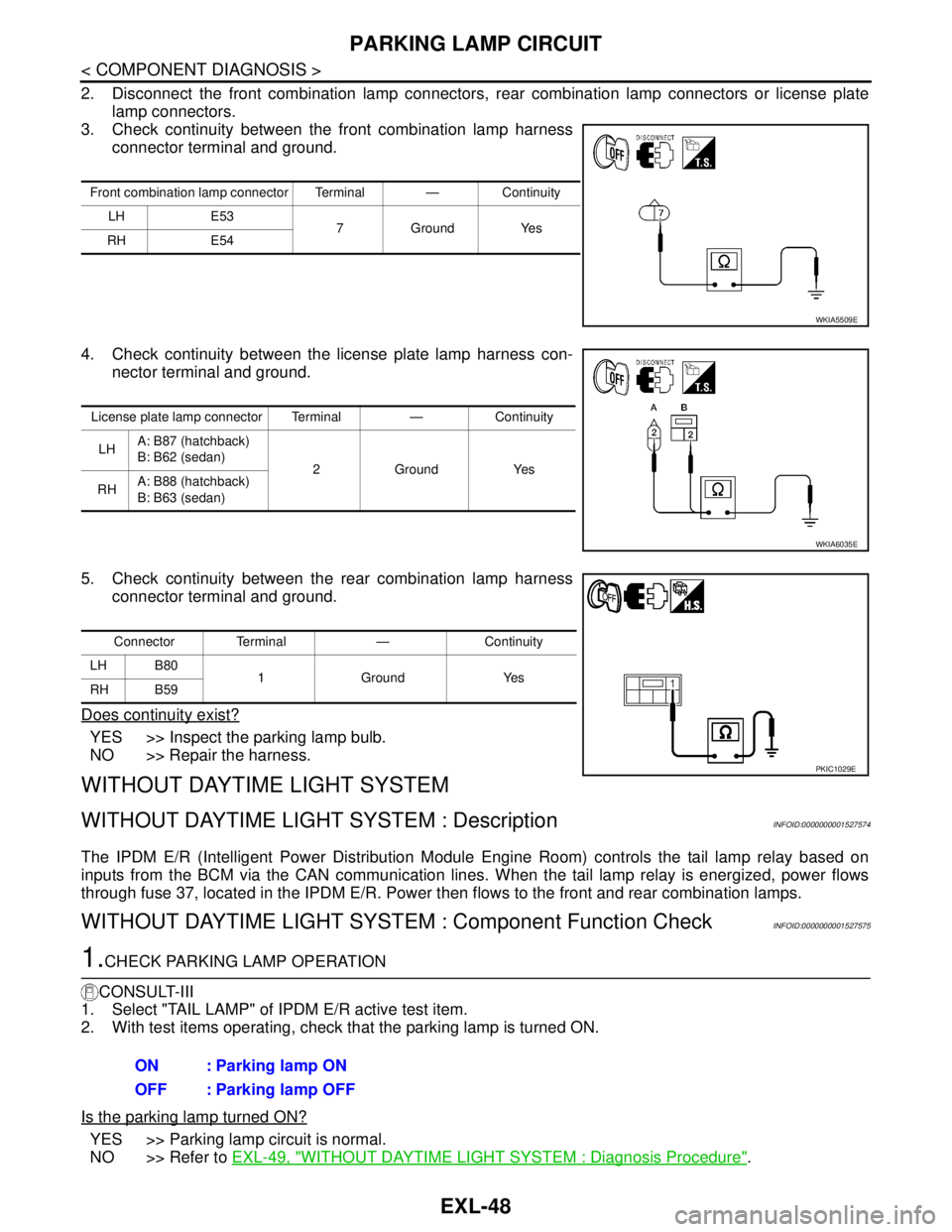

2. Disconnect the front combination lamp connectors, rear combination lamp connectors or license plate

lamp connectors.

3. Check continuity between the front combination lamp harness

connector terminal and ground.

4. Check continuity between the license plate lamp harness con-

nector terminal and ground.

5. Check continuity between the rear combination lamp harness

connector terminal and ground.

Does continuity exist?

YES >> Inspect the parking lamp bulb.

NO >> Repair the harness.

WITHOUT DAYTIME LIGHT SYSTEM

WITHOUT DAYTIME LIGHT SYSTEM : DescriptionINFOID:0000000001527574

The IPDM E/R (Intelligent Power Distribution Module Engine Room) controls the tail lamp relay based on

inputs from the BCM via the CAN communication lines. When the tail lamp relay is energized, power flows

through fuse 37, located in the IPDM E/R. Power then flows to the front and rear combination lamps.

WITHOUT DAYTIME LIGHT SYSTEM : Component Function CheckINFOID:0000000001527575

1.CHECK PARKING LAMP OPERATION

CONSULT-III

1. Select "TAIL LAMP" of IPDM E/R active test item.

2. With test items operating, check that the parking lamp is turned ON.

Is the parking lamp turned ON?

YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-49, "

WITHOUT DAYTIME LIGHT SYSTEM : Diagnosis Procedure".

Front combination lamp connector Terminal — Continuity

LH E53

7GroundYes

RH E54

WKIA5509E

License plate lamp connector Terminal — Continuity

LHA: B87 (hatchback)

B: B62 (sedan)

2GroundYes

RHA: B88 (hatchback)

B: B63 (sedan)

WKIA6035E

Connector Terminal — Continuity

LH B80

1Ground Yes

RH B59

PKIC1029E

ON : Parking lamp ON

OFF : Parking lamp OFF

Page 3073 of 5883

EXL-72

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

DescriptionINFOID:0000000001523286

REFERENCE VALUES FOR IPDM E/R

For IPDM E/R reference values, refer to XX-XX, "*****".

TERMINAL LAYOUT FOR IPDM E/R

For the terminal layout for the IPDM E/R, refer to XX-XX, "*****".

PHYSICAL VALUES FOR IPDM E/R

For physical values for the IPDM E/R, refer to XX-XX, "*****".

WIRING DIAGRAM - IPDM E/R

For the IPDM E/R wiring diagram, refer to XX-XX, "*****".

FAIL SAFE - IPDM E/R

For IPDM E/R fail safe information, refer to XX-XX, "*****".

DTC INSPECTION PRIORITY CHART - IPDM E/R

For the IPDM E/R DTC inspection priority chart, refer to

DTC INDEX - IPDM E/R

For the IPDM E/R DTC index, refer to XX-XX, "*****".

Page 3082 of 5883

HEADLAMP

EXL-81

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

ON-VEHICLE MAINTENANCE

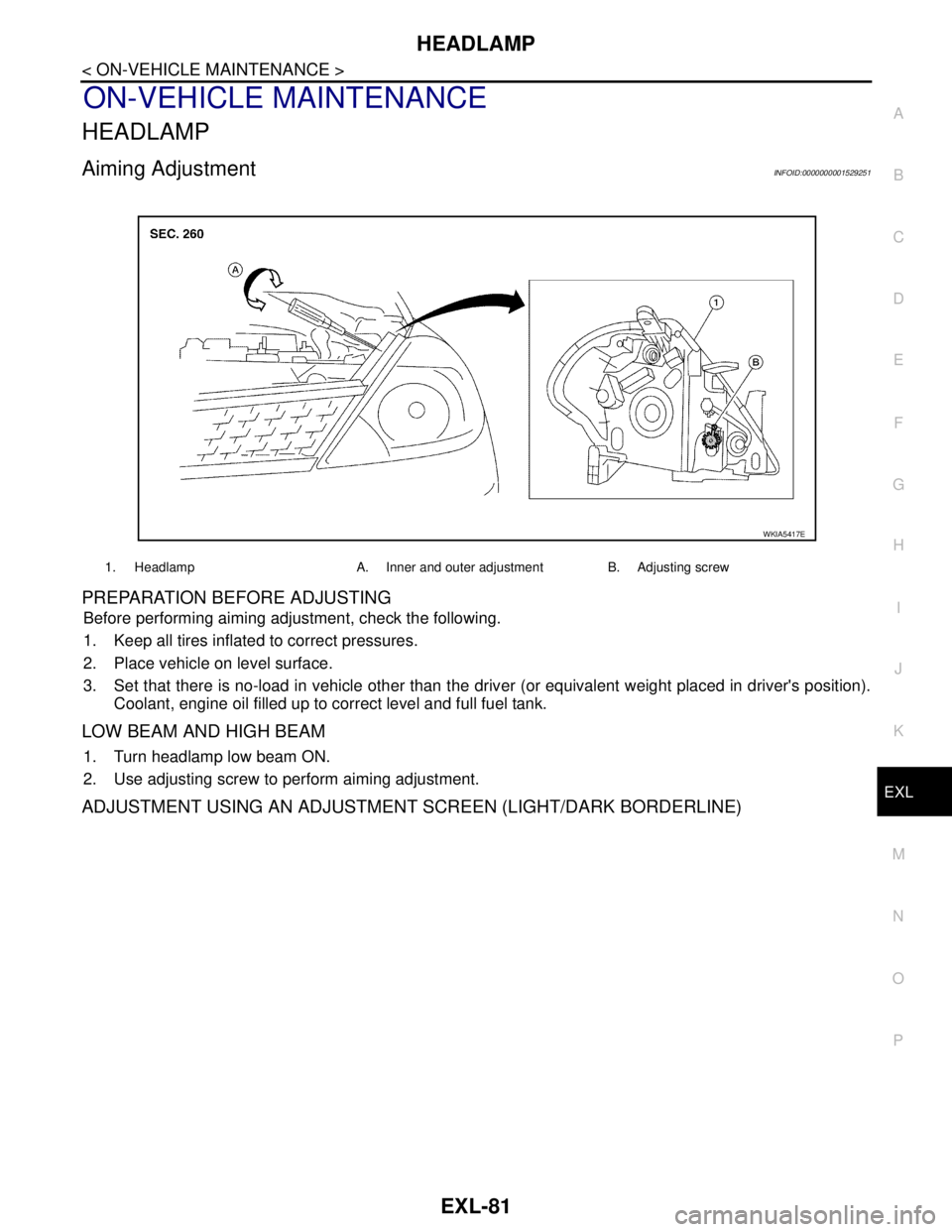

HEADLAMP

Aiming AdjustmentINFOID:0000000001529251

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level surface.

3. Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screw to perform aiming adjustment.

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

1. Headlamp A. Inner and outer adjustment B. Adjusting screw

WKIA5417E

Page 3084 of 5883

FRONT FOG LAMP

EXL-83

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

FRONT FOG LAMP

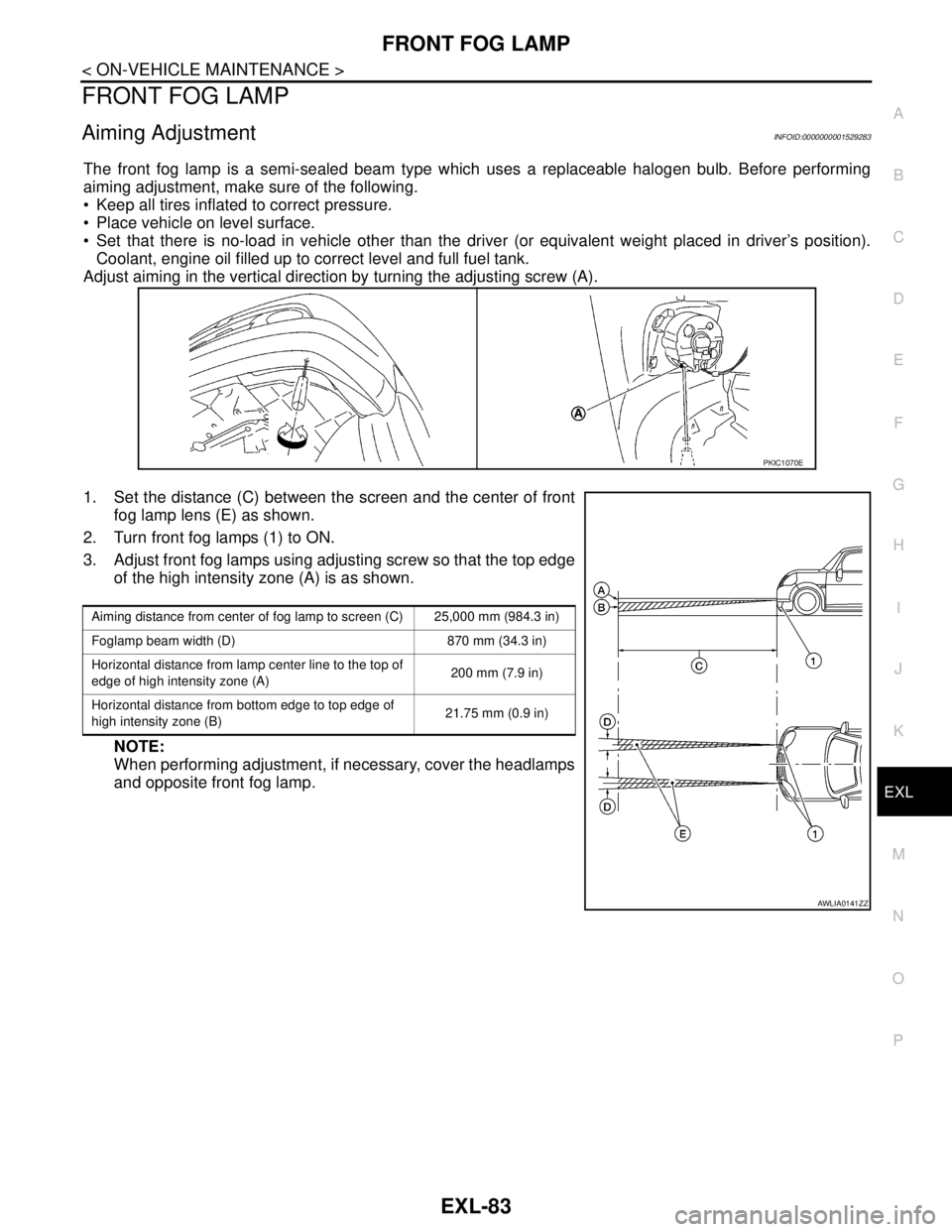

Aiming AdjustmentINFOID:0000000001529283

The front fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing

aiming adjustment, make sure of the following.

Keep all tires inflated to correct pressure.

Place vehicle on level surface.

Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver’s position).

Coolant, engine oil filled up to correct level and full fuel tank.

Adjust aiming in the vertical direction by turning the adjusting screw (A).

1. Set the distance (C) between the screen and the center of front

fog lamp lens (E) as shown.

2. Turn front fog lamps (1) to ON.

3. Adjust front fog lamps using adjusting screw so that the top edge

of the high intensity zone (A) is as shown.

NOTE:

When performing adjustment, if necessary, cover the headlamps

and opposite front fog lamp.

PKIC1070E

Aiming distance from center of fog lamp to screen (C) 25,000 mm (984.3 in)

Foglamp beam width (D) 870 mm (34.3 in)

Horizontal distance from lamp center line to the top of

edge of high intensity zone (A)200 mm (7.9 in)

Horizontal distance from bottom edge to top edge of

high intensity zone (B)21.75 mm (0.9 in)

AWLIA0141ZZ

Page 3107 of 5883

PREPARATION

EXT-3

< PREPARATION >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

PREPARATION

PREPARATION

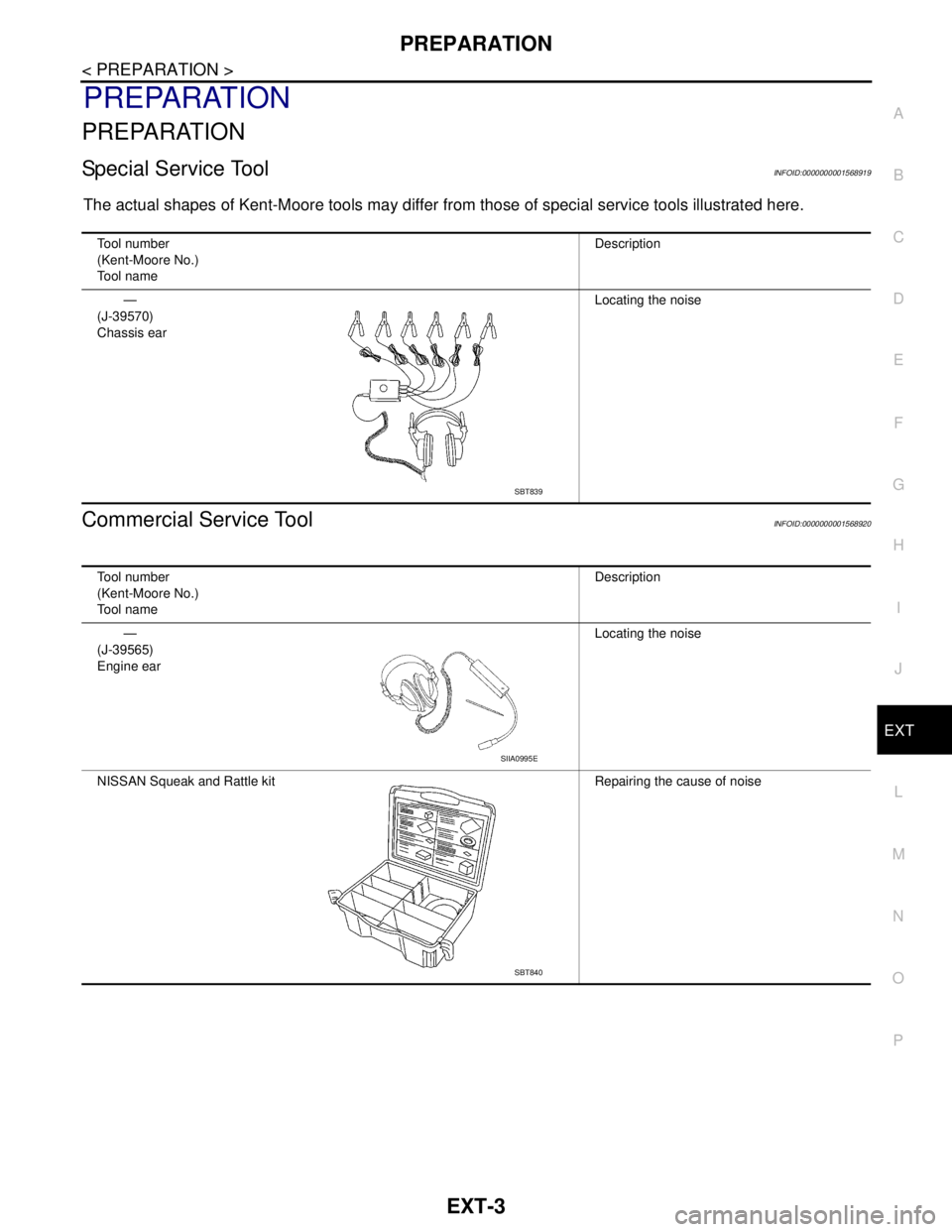

Special Service ToolINFOID:0000000001568919

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001568920

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39570)

Chassis earLocating the noise

SBT839

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39565)

Engine earLocating the noise

NISSAN Squeak and Rattle kit Repairing the cause of noise

SIIA0995E

SBT840

Page 3109 of 5883

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

EXT-5

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

Close a door.

Tap or push/pull around the area where the noise appears to be coming from.

Rev the engine.

Use a floor jack to recreate vehicle “twist”.

At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners

can be broken or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be elimi-

nated only temporarily.

Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing

the noise.

Placing a piece of paper between components that you suspect are causing the noise.

Looking for loose components and contact marks.

Refer to EXT-6, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Squeak and Rattle Kit is available through your authorized NISSAN Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Squeak and Rattle Kit. Each item can be ordered separately as

needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 x 135 mm (3.94 x 5.31 in)/76884-71L01: 60 x 85 mm (2.36 x 3.35 in)/76884-71L02: 15 x 25

mm (0.59 x 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 x 50 mm (1.97 x 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50 x 50

mm (1.97 x 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 x 50 mm (1.18 x 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

Page 3111 of 5883

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

EXT-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3117 of 5883

FRONT BUMPER

EXT-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

FRONT BUMPER

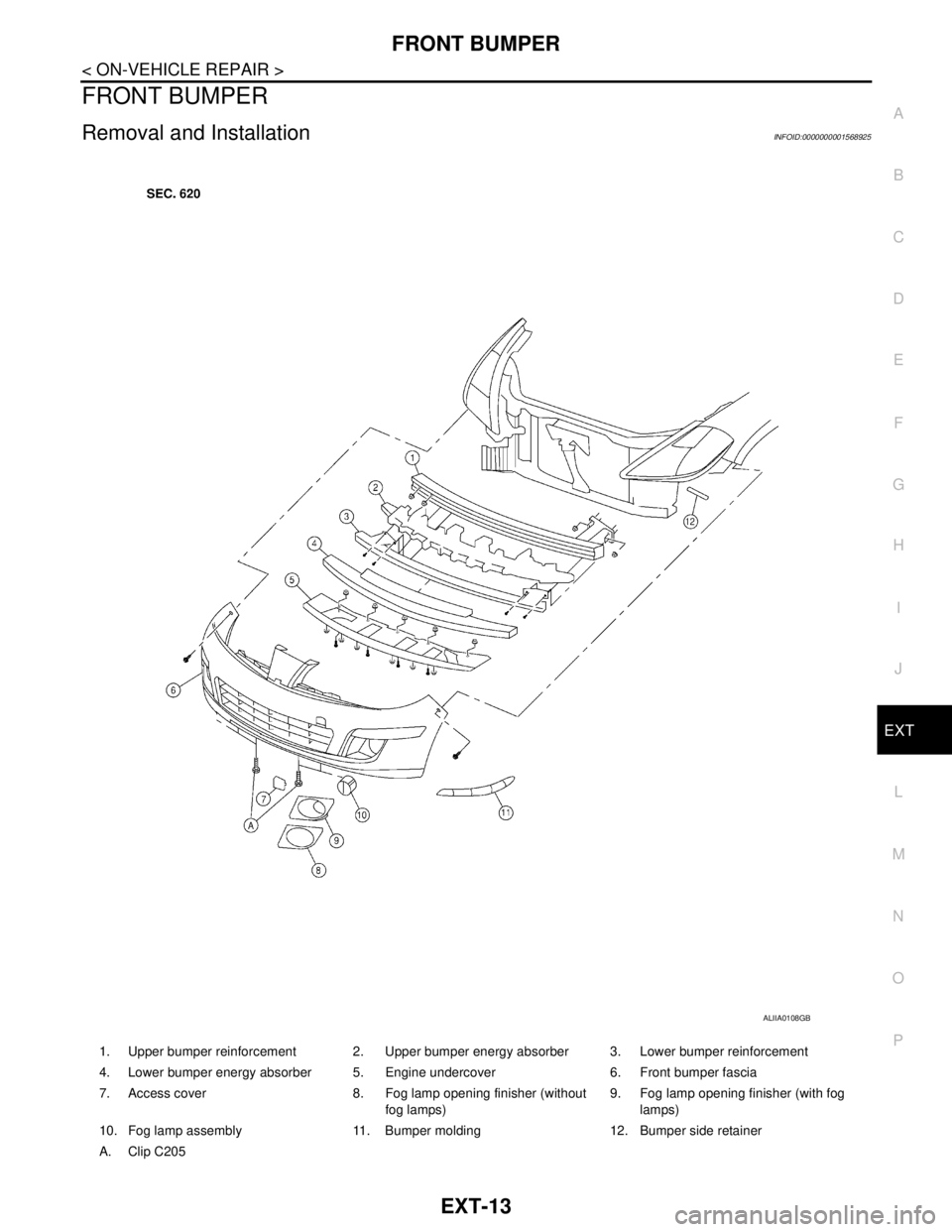

Removal and InstallationINFOID:0000000001568925

1. Upper bumper reinforcement 2. Upper bumper energy absorber 3. Lower bumper reinforcement

4. Lower bumper energy absorber 5. Engine undercover 6. Front bumper fascia

7. Access cover 8. Fog lamp opening finisher (without

fog lamps)9. Fog lamp opening finisher (with fog

lamps)

10. Fog lamp assembly 11. Bumper molding 12. Bumper side retainer

A. Clip C205

ALIIA0108GB

Page 3118 of 5883

EXT-14

< ON-VEHICLE REPAIR >

FRONT BUMPER

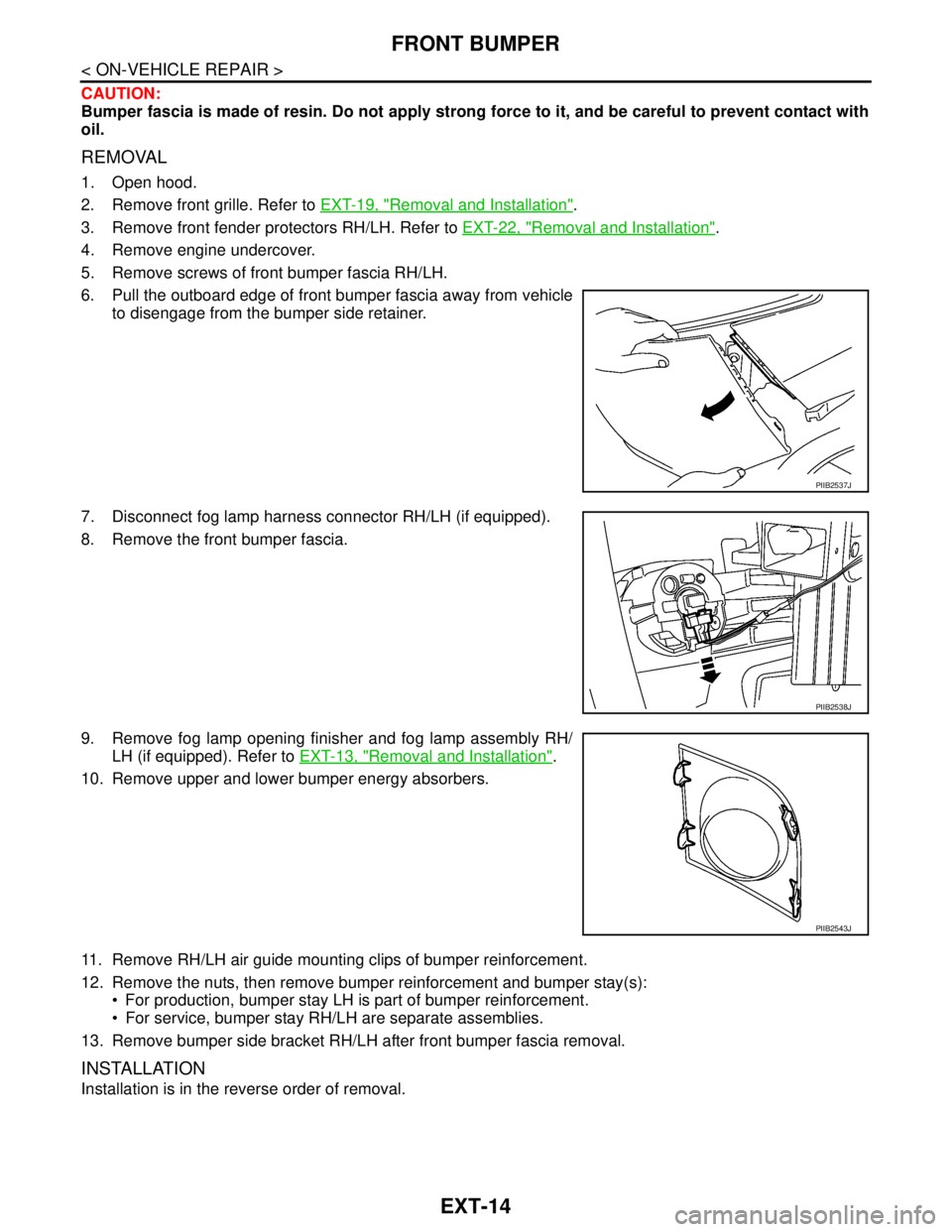

CAUTION:

Bumper fascia is made of resin. Do not apply strong force to it, and be careful to prevent contact with

oil.

REMOVAL

1. Open hood.

2. Remove front grille. Refer to EXT-19, "

Removal and Installation".

3. Remove front fender protectors RH/LH. Refer to EXT-22, "

Removal and Installation".

4. Remove engine undercover.

5. Remove screws of front bumper fascia RH/LH.

6. Pull the outboard edge of front bumper fascia away from vehicle

to disengage from the bumper side retainer.

7. Disconnect fog lamp harness connector RH/LH (if equipped).

8. Remove the front bumper fascia.

9. Remove fog lamp opening finisher and fog lamp assembly RH/

LH (if equipped). Refer to EXT-13, "

Removal and Installation".

10. Remove upper and lower bumper energy absorbers.

11. Remove RH/LH air guide mounting clips of bumper reinforcement.

12. Remove the nuts, then remove bumper reinforcement and bumper stay(s):

For production, bumper stay LH is part of bumper reinforcement.

For service, bumper stay RH/LH are separate assemblies.

13. Remove bumper side bracket RH/LH after front bumper fascia removal.

INSTALLATION

Installation is in the reverse order of removal.

PIIB2537J

PIIB2538J

PIIB2543J