service interval NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 473 of 5883

CL-8

< SERVICE INFORMATION >

CLUTCH FLUID

CLUTCH FLUID

Air Bleeding ProcedureINFOID:0000000001375295

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

CAUTION:

Carefully monitor fluid level in reservoir tank during bleeding operation.

Keep painted surface of body and other parts free of clutch fluid. If it spills, wipe up immediately and

wash the affected area with water.

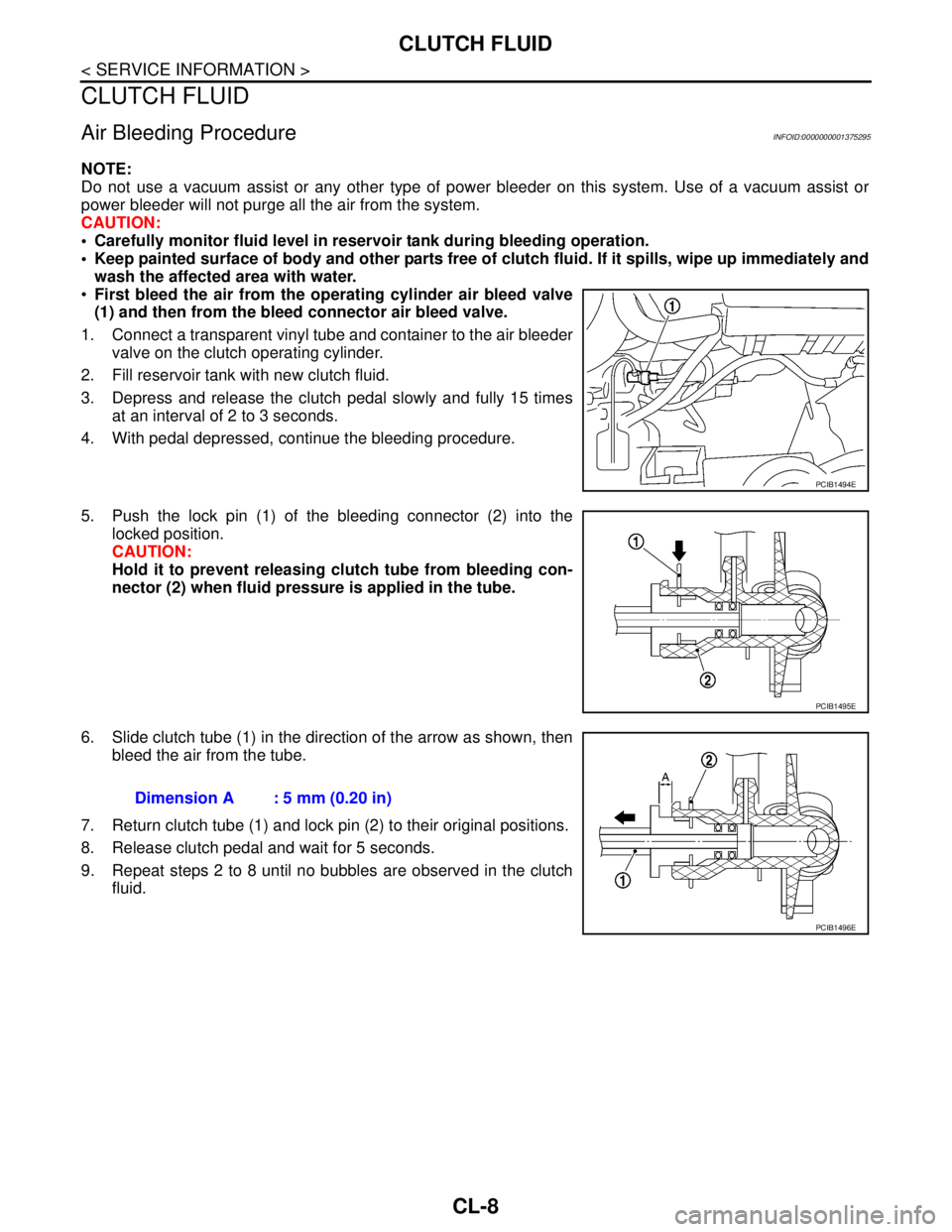

First bleed the air from the operating cylinder air bleed valve

(1) and then from the bleed connector air bleed valve.

1. Connect a transparent vinyl tube and container to the air bleeder

valve on the clutch operating cylinder.

2. Fill reservoir tank with new clutch fluid.

3. Depress and release the clutch pedal slowly and fully 15 times

at an interval of 2 to 3 seconds.

4. With pedal depressed, continue the bleeding procedure.

5. Push the lock pin (1) of the bleeding connector (2) into the

locked position.

CAUTION:

Hold it to prevent releasing clutch tube from bleeding con-

nector (2) when fluid pressure is applied in the tube.

6. Slide clutch tube (1) in the direction of the arrow as shown, then

bleed the air from the tube.

7. Return clutch tube (1) and lock pin (2) to their original positions.

8. Release clutch pedal and wait for 5 seconds.

9. Repeat steps 2 to 8 until no bubbles are observed in the clutch

fluid.

PCIB1494E

PCIB1495E

Dimension A : 5 mm (0.20 in)

PCIB1496E

Page 3496 of 5883

![NISSAN TIIDA 2007 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-163

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Componen NISSAN TIIDA 2007 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-163

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Componen](/img/5/57395/w960_57395-3495.png)

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-163

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component DescriptionINFOID:0000000001547446

COMPONENT DESCRIPTION

Front Air Control

The front air control has a built-in microcomputer which processes information sent from various sensors

needed for air conditioner operation. The air mix door motor, mode door motor, intake door motor, blower

motor and compressor are then controlled.

The front air control is unitized with control mechanisms. Signal from various switches and Potentio Tempera-

ture Control (PTC) are directly entered into front air control.

Self-diagnostic functions are also built into front air control to provide quick check of malfunctions in the auto

air conditioner system.

Potentio Temperature Control (PTC)

The PTC is built into the front air control. It can be set at an interval of 1°C (34°F) in the 18°C (64°F) to 32°C

(90°F) temperature range by turning temperature control switch. The set temperature is displayed.

Front Air Control Component Function CheckINFOID:0000000001547447

SYMPTOM: A/C system does not come on.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - AUTO MODE

1. Press the AUTO switch and A/C switch.

2. Display should indicate AUTO. Confirm that the compressor clutch engages (sound or visual inspection).

(Discharge air and blower speed will depend on ambient, in-vehicle and set temperatures.)

Can a symptom be duplicated?

YES >> GO TO 2.

NO >> Perform a complete operational check. Refer to HAC-87, "

Operational Check".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.CHECK POWER AND GROUND CIRCUIT

Check main power supply and ground circuit. Refer to HAC-163, "

Front Air Control Power and Ground Diag-

nosis Procedure".

Is the inspection result normal?

YES >> System OK.

NO >> Replace Front air control. Refer to XX.

Front Air Control Power and Ground Diagnosis ProcedureINFOID:0000000001547448

DIAGNOSTIC PROCEDURE FOR A/C SYSTEM

SYMPTOM: A/C system does not come on.

AWIIA0289GB

Page 3610 of 5883

![NISSAN TIIDA 2007 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-277

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component NISSAN TIIDA 2007 Service Repair Manual POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-277

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component](/img/5/57395/w960_57395-3609.png)

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

HAC-277

< COMPONENT DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

POWER SUPPLY AND GROUND CIRCUIT FOR CONTROLLER

Component DescriptionINFOID:0000000001547368

COMPONENT DESCRIPTION

Front air control

The front air control has a built-in microcomputer which processes information sent from various sensors

needed for air conditioner operation. The air mix door motor, mode door motor, intake door motor, blower

motor and compressor are then controlled.

The front air control is unitized with control mechanisms. Signal from various switches and Potentio Tempera-

ture Control (PTC) are directly entered into front air control

Self-diagnostic functions are also built into front air control to provide quick check of malfunctions in the auto

air conditioner system.

Potentio Temperature Control (PTC)

The PTC is built into the front air control It can be set at an interval of

1°C (34°F) in the 18°C (64°F) to 32°C (90°F) temperature range by

turning temperature control switch. The set temperature is displayed.

A/C Auto Amp. Component Function CheckINFOID:0000000001547369

SYMPTOM: A/C system does not come on.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - AUTO MODE

1. Rotate the mode dial to the AUTO position.

2. Display should indicate AUTO. Confirm that the compressor clutch engages (sound or visual inspection).

(Discharge air and blower speed will depend on ambient, in-vehicle and set temperatures.)

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to HAC-202, "

Operational Check".

Can a symptom be duplicated?

YES >> Refer to HAC-201, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK POWER AND GROUND CIRCUIT

Check main power supply and ground circuit. Refer to HAC-278, "

A/C Auto Amp Power and Ground Diagnosis

Procedure".

Is the inspection result normal?

YES >> System OK.

NO >> Replace Front air control. Refer to XXXX.

SJIA0876E

Page 4247 of 5883

PERIODIC MAINTENANCE

MA-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

PERIODIC MAINTENANCE

Periodic MaintenanceINFOID:0000000001277598

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

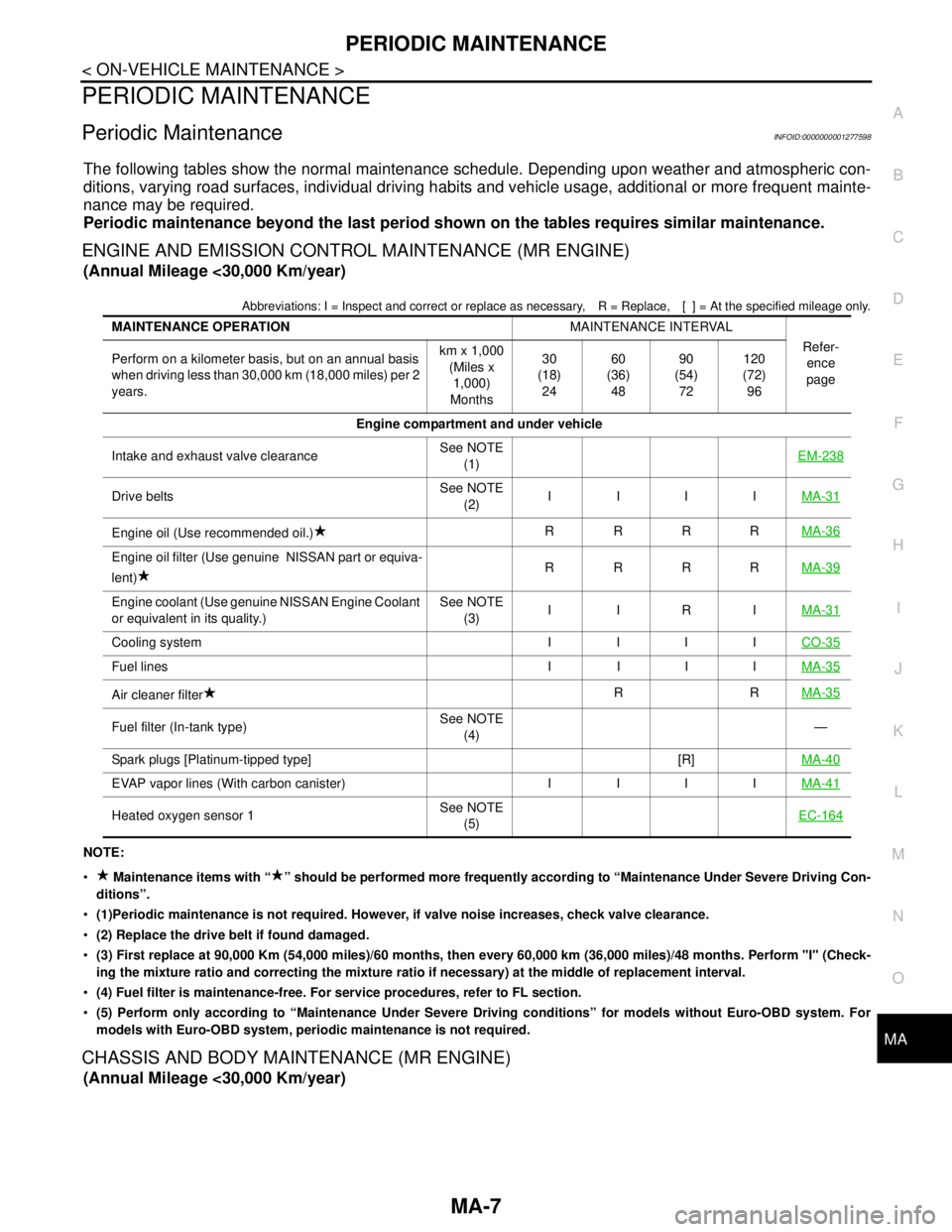

ENGINE AND EMISSION CONTROL MAINTENANCE (MR ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, [ ] = At the specified mileage only.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I" (Check-

ing the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (MR ENGINE)

(Annual Mileage <30,000 Km/year)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per 2

years.km x 1,000

(Miles x

1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee NOTE

(1)EM-238

Drive beltsSee NOTE

(2)IIIIMA-31

Engine oil (Use recommended oil.)RRRRMA-36

Engine oil filter (Use genuine NISSAN part or equiva-

lent)RRRRMA-39

Engine coolant (Use genuine NISSAN Engine Coolant

or equivalent in its quality.)See NOTE

(3)IIRIMA-31

Cooling system I I I ICO-35

Fuel lines I I I IMA-35

Air cleaner filterRRMA-35

Fuel filter (In-tank type)See NOTE

(4)—

Spark plugs [Platinum-tipped type] [R]MA-40

EVAP vapor lines (With carbon canister) I I I IMA-41

Heated oxygen sensor 1See NOTE

(5)EC-164

Page 4249 of 5883

PERIODIC MAINTENANCE

MA-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

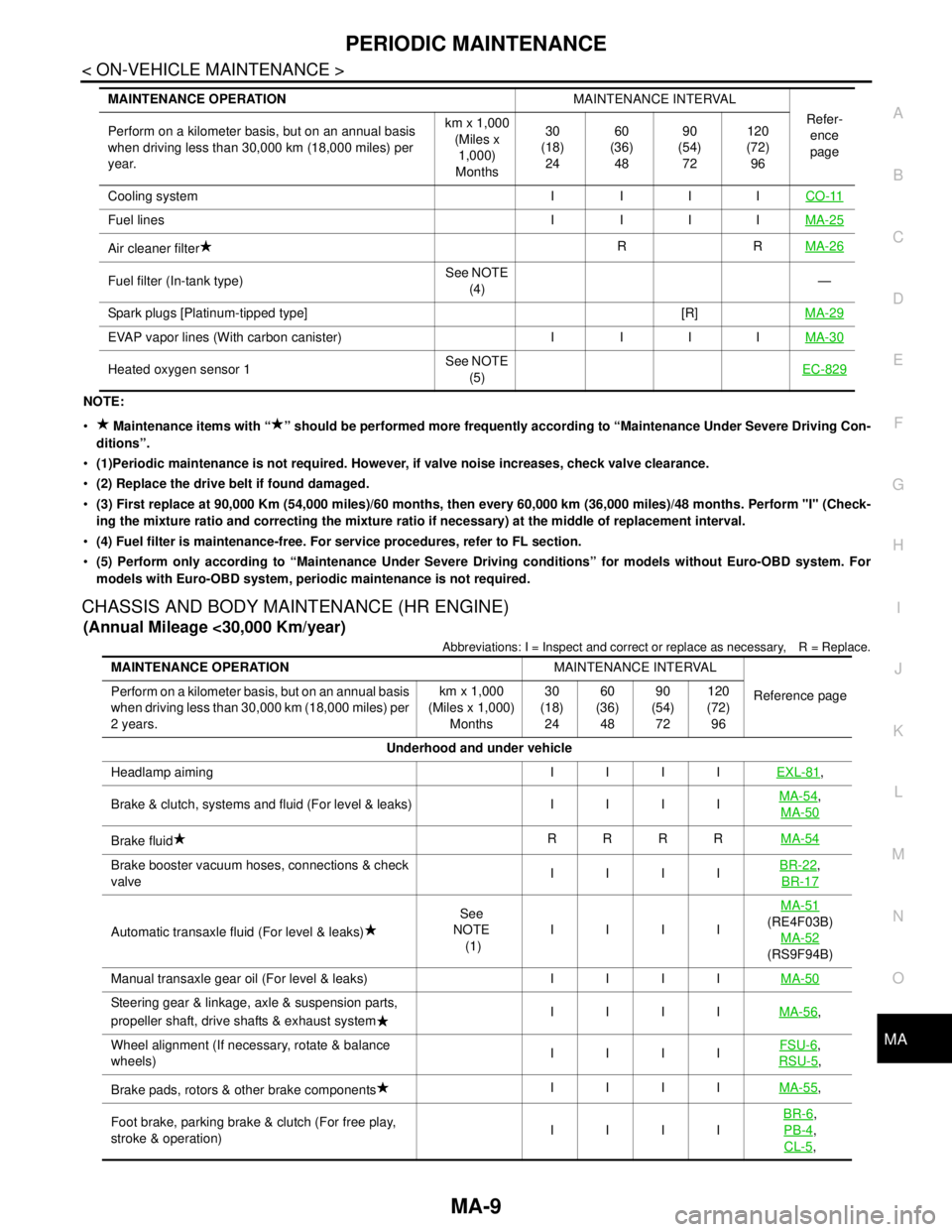

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I" (Check-

ing the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (HR ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace.

Cooling system I I I ICO-11

Fuel lines I I I IMA-25

Air cleaner filterRRMA-26

Fuel filter (In-tank type)See NOTE

(4)—

Spark plugs [Platinum-tipped type] [R]MA-29

EVAP vapor lines (With carbon canister) I I I IMA-30

Heated oxygen sensor 1See NOTE

(5)EC-829

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

year.km x 1,000

(Miles x

1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

2 years.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Headlamp aiming IIIIEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) IIIIMA-54

,

MA-50

Brake fluidRRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIIBR-22,

BR-17

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Manual transaxle gear oil (For level & leaks) IIIIMA-50

Steering gear & linkage, axle & suspension parts,

propeller shaft, drive shafts & exhaust systemIIIIMA-56,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIFSU-6

,

RSU-5

,

Brake pads, rotors & other brake componentsIIIIMA-55

,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,

Page 4253 of 5883

PERIODIC MAINTENANCE

MA-13

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

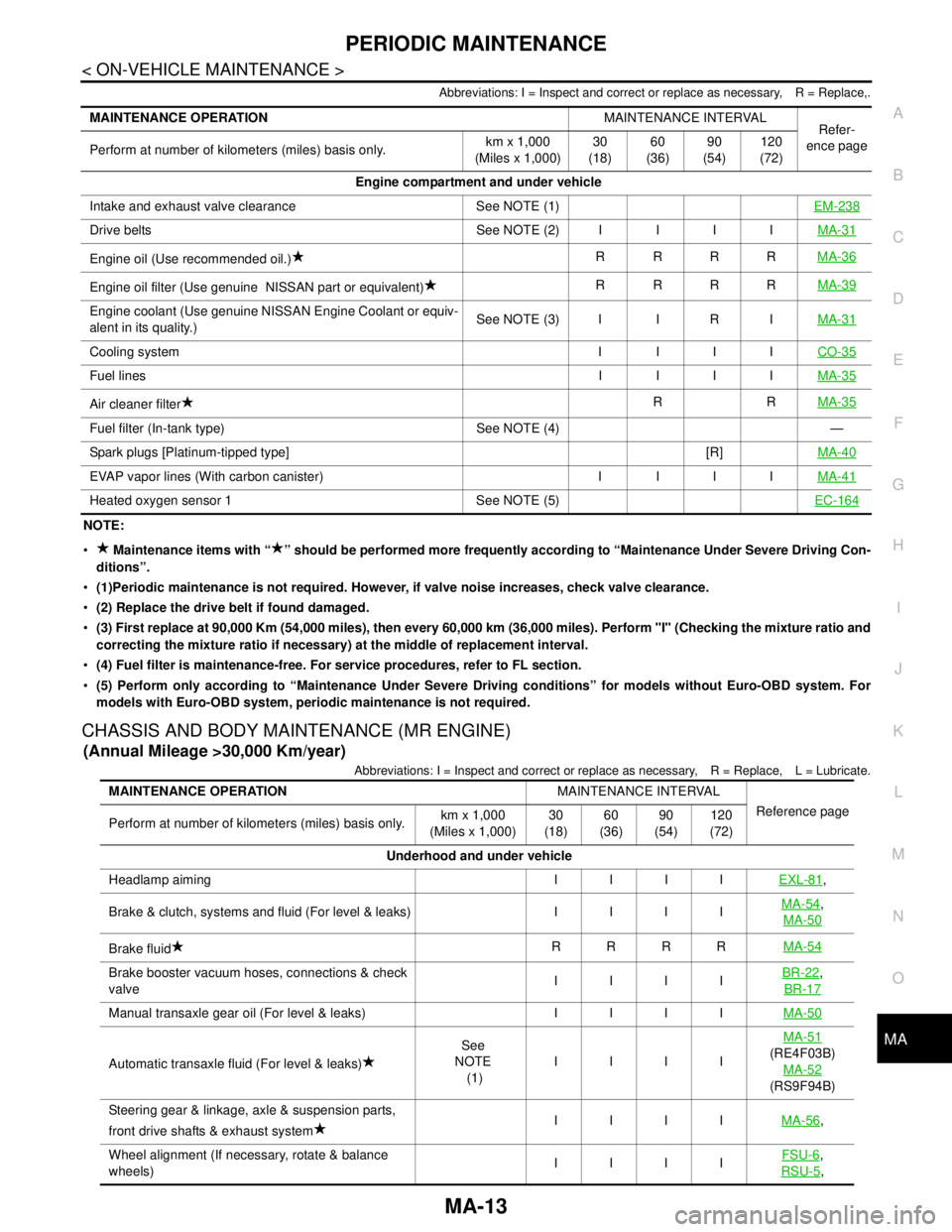

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (MR ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

Engine compartment and under vehicle

Intake and exhaust valve clearance See NOTE (1)EM-238

Drive belts See NOTE (2) I I I IMA-31

Engine oil (Use recommended oil.)RRRRMA-36

Engine oil filter (Use genuine NISSAN part or equivalent)RRRRMA-39

Engine coolant (Use genuine NISSAN Engine Coolant or equiv-

alent in its quality.)See NOTE (3) I I R IMA-31

Cooling system I I I ICO-35

Fuel linesI IIIMA-35

Air cleaner filterRRMA-35

Fuel filter (In-tank type) See NOTE (4) —

Spark plugs [Platinum-tipped type] [R]MA-40

EVAP vapor lines (With carbon canister) I I I IMA-41

Heated oxygen sensor 1 See NOTE (5)EC-164

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

Underhood and under vehicle

Headlamp aiming I I I IEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) I I I IMA-54

,

MA-50

Brake fluidRRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIIBR-22,

BR-17

Manual transaxle gear oil (For level & leaks) I I I IMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Steering gear & linkage, axle & suspension parts,

front drive shafts & exhaust systemIIIIMA-56

,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIFSU-6

,

RSU-5

,

Page 4254 of 5883

MA-14

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

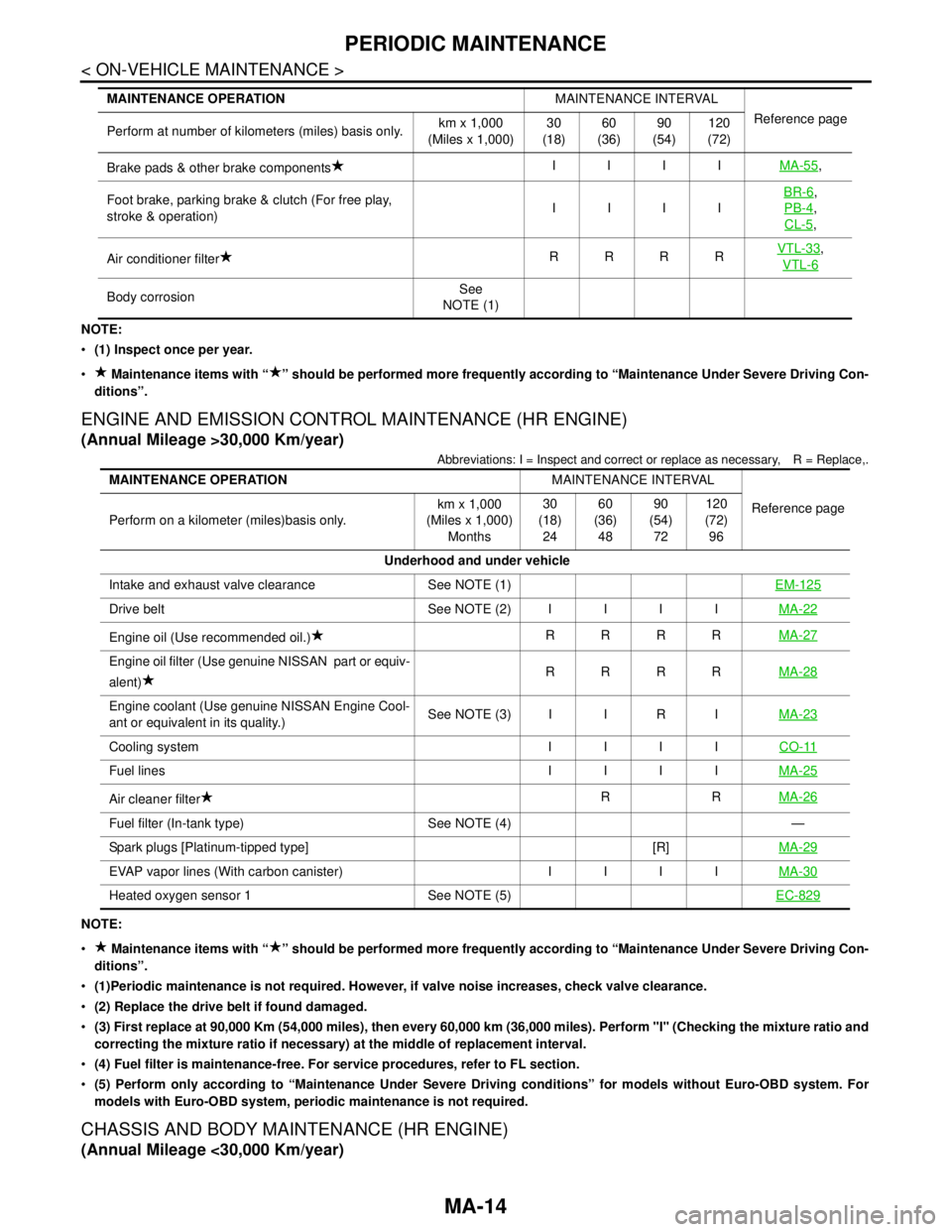

ENGINE AND EMISSION CONTROL MAINTENANCE (HR ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (HR ENGINE)

(Annual Mileage <30,000 Km/year)

Brake pads & other brake componentsIIIIMA-55,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1) MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform on a kilometer (miles)basis only.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Intake and exhaust valve clearance See NOTE (1)EM-125

Drive belt See NOTE (2)IIIIMA-22

Engine oil (Use recommended oil.)RRRRMA-27

Engine oil filter (Use genuine NISSAN part or equiv-

alent)RRRRMA-28

Engine coolant (Use genuine NISSAN Engine Cool-

ant or equivalent in its quality.)See NOTE (3) I I R IMA-23

Cooling system IIIICO-11

Fuel lines IIIIMA-25

Air cleaner filterRRMA-26

Fuel filter (In-tank type) See NOTE (4) —

Spark plugs [Platinum-tipped type] [R]MA-29

EVAP vapor lines (With carbon canister) IIIIMA-30

Heated oxygen sensor 1 See NOTE (5)EC-829

Page 4293 of 5883

CHASSIS AND BODY MAINTENANCE

MA-53

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

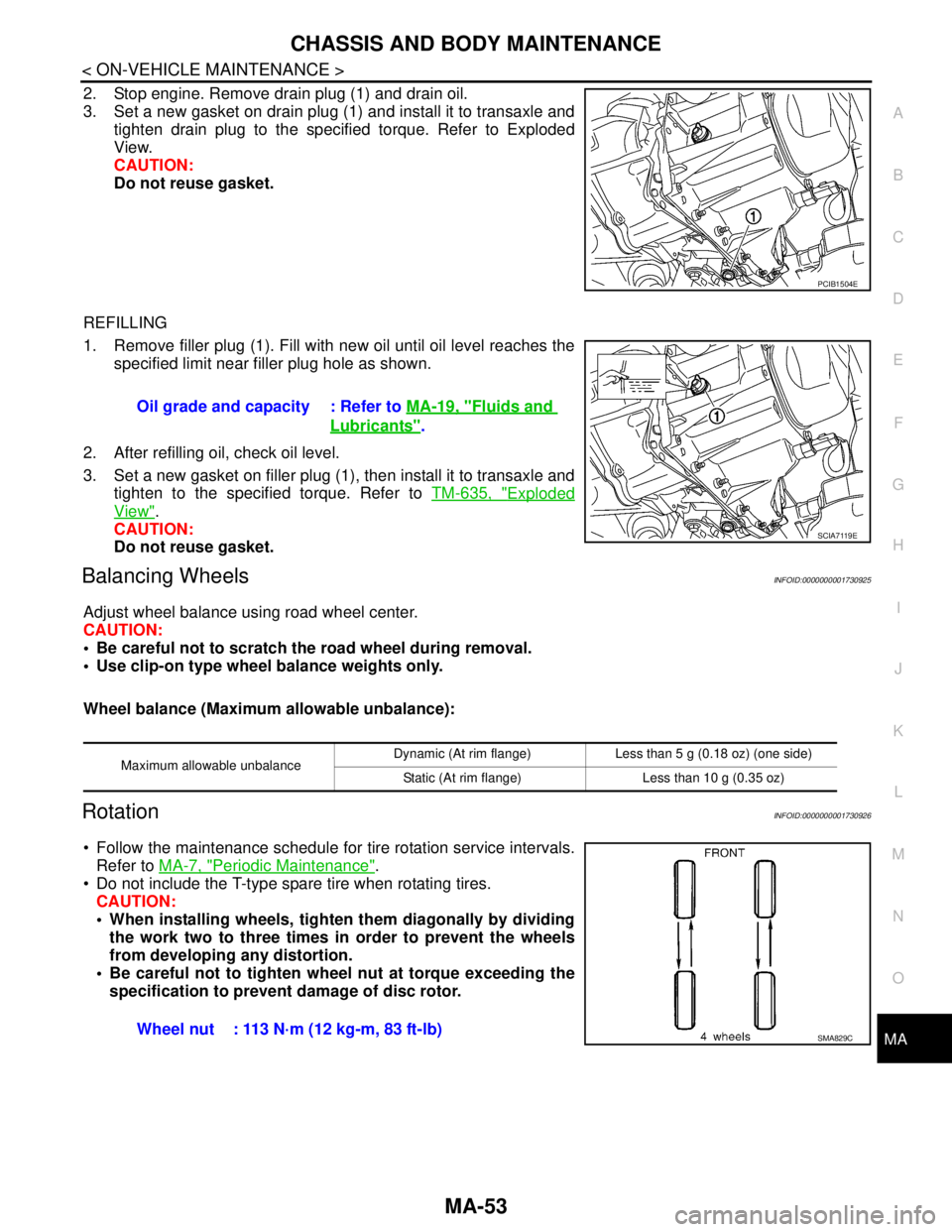

2. Stop engine. Remove drain plug (1) and drain oil.

3. Set a new gasket on drain plug (1) and install it to transaxle and

tighten drain plug to the specified torque. Refer to Exploded

View.

CAUTION:

Do not reuse gasket.

REFILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit near filler plug hole as shown.

2. After refilling oil, check oil level.

3. Set a new gasket on filler plug (1), then install it to transaxle and

tighten to the specified torque. Refer to TM-635, "

Exploded

View".

CAUTION:

Do not reuse gasket.

Balancing WheelsINFOID:0000000001730925

Adjust wheel balance using road wheel center.

CAUTION:

Be careful not to scratch the road wheel during removal.

Use clip-on type wheel balance weights only.

Wheel balance (Maximum allowable unbalance):

RotationINFOID:0000000001730926

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "

Periodic Maintenance".

Do not include the T-type spare tire when rotating tires.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

specification to prevent damage of disc rotor.

PCIB1504E

Oil grade and capacity : Refer to MA-19, "Fluids and

Lubricants".

SCIA7119E

Maximum allowable unbalanceDynamic (At rim flange) Less than 5 g (0.18 oz) (one side)

Static (At rim flange) Less than 10 g (0.35 oz)

Wheel nut : 113 N·m (12 kg-m, 83 ft-lb)SMA829C

Page 5801 of 5883

WT-6

< ON-VEHICLE REPAIR >

ROAD WHEEL TIRE ASSEMBLY

ON-VEHICLE REPAIR

ROAD WHEEL TIRE ASSEMBLY

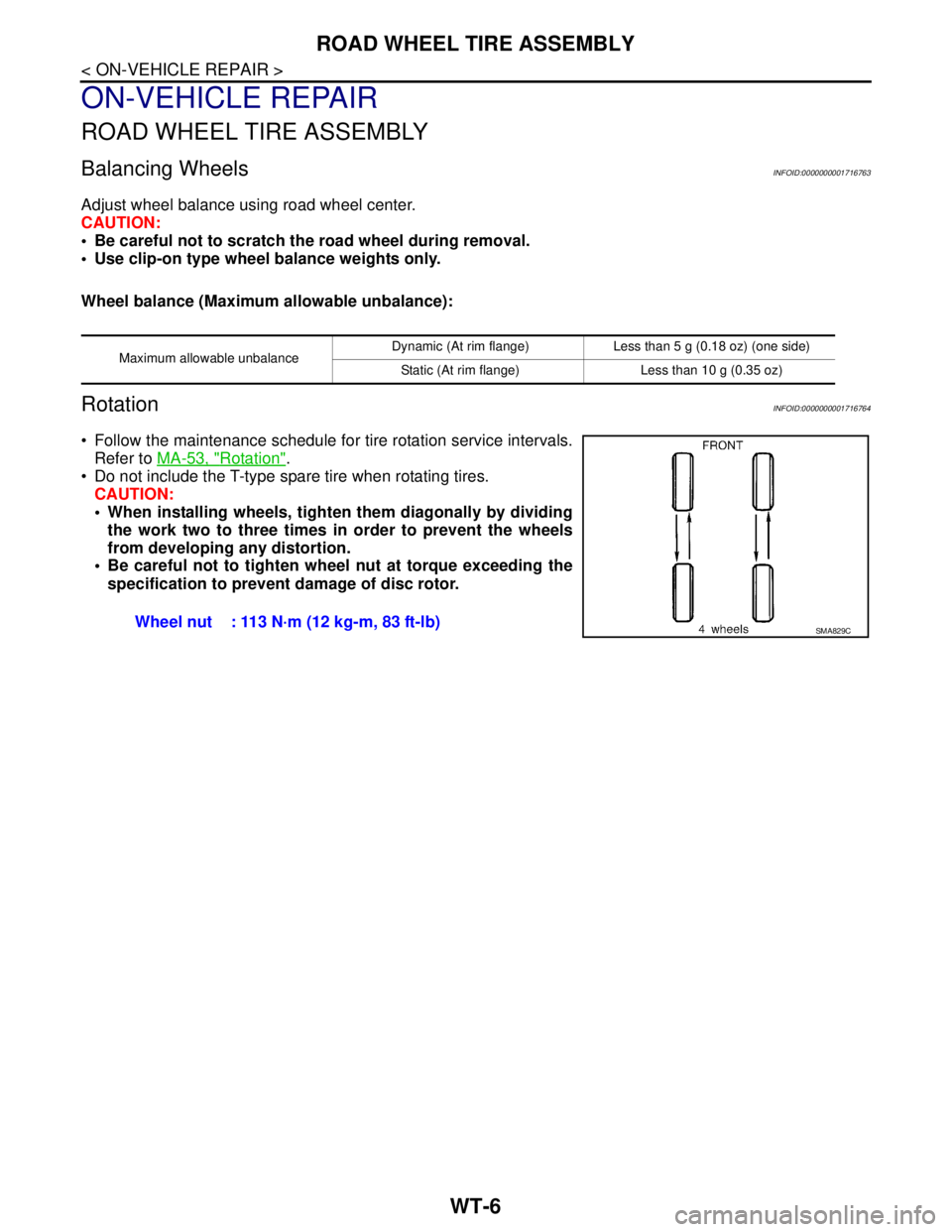

Balancing WheelsINFOID:0000000001716763

Adjust wheel balance using road wheel center.

CAUTION:

Be careful not to scratch the road wheel during removal.

Use clip-on type wheel balance weights only.

Wheel balance (Maximum allowable unbalance):

RotationINFOID:0000000001716764

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-53, "

Rotation".

Do not include the T-type spare tire when rotating tires.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

specification to prevent damage of disc rotor.

Maximum allowable unbalanceDynamic (At rim flange) Less than 5 g (0.18 oz) (one side)

Static (At rim flange) Less than 10 g (0.35 oz)

Wheel nut : 113 N·m (12 kg-m, 83 ft-lb)SMA829C