NISSAN TIIDA 2008 Service Repair Manual

TIIDA 2008

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57399/w960_57399-0.png

NISSAN TIIDA 2008 Service Repair Manual

Trending: fuel cap, warning lamps, brake sensor, child lock, speedo, window motor, connector locations

Page 1051 of 2771

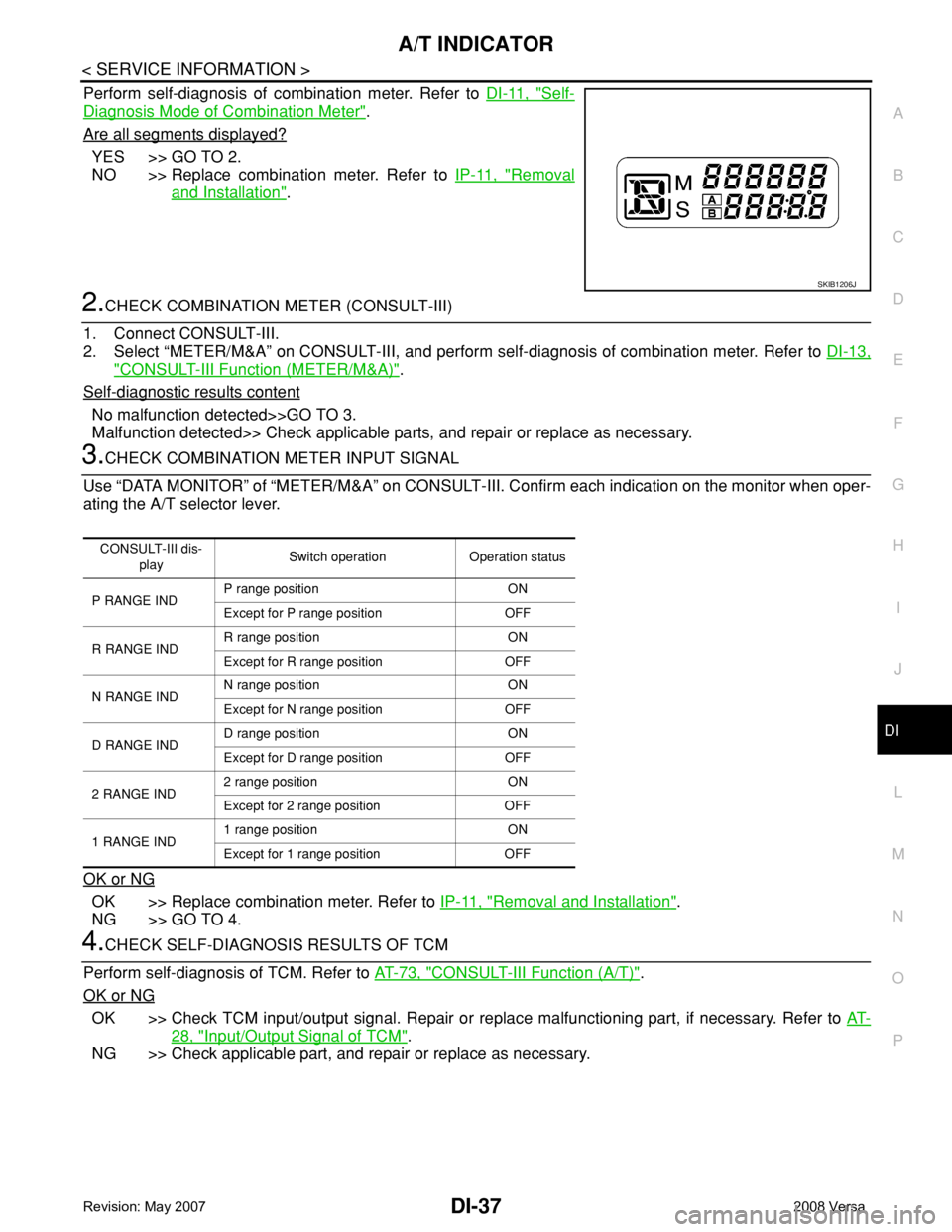

DI-30

< SERVICE INFORMATION >

WARNING LAMPS

Oil Pressure Warning Lamp Stays Off (Ignition Switch ON)

INFOID:0000000001704512

1.CHECK OIL PRESSURE WARNING LAMP OPERATION

Activate IPDM E/R auto active test. Refer to PG-19, "

Auto Active Test".

Does oil pressure warning lamp blink?

YES >> GO TO 2.

NO >> GO TO 5.

LKWA0359E

Page 1052 of 2771

WARNING LAMPS

DI-31

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

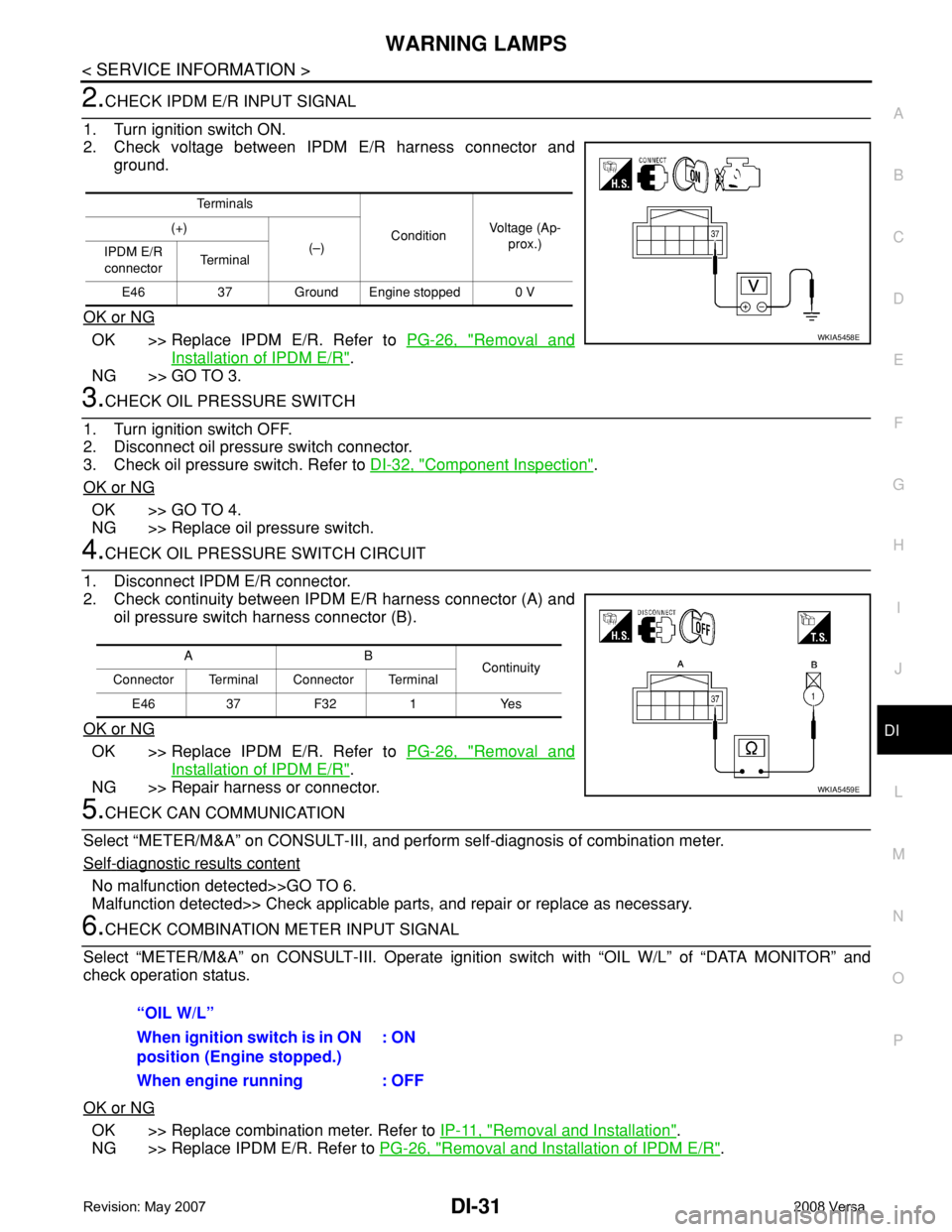

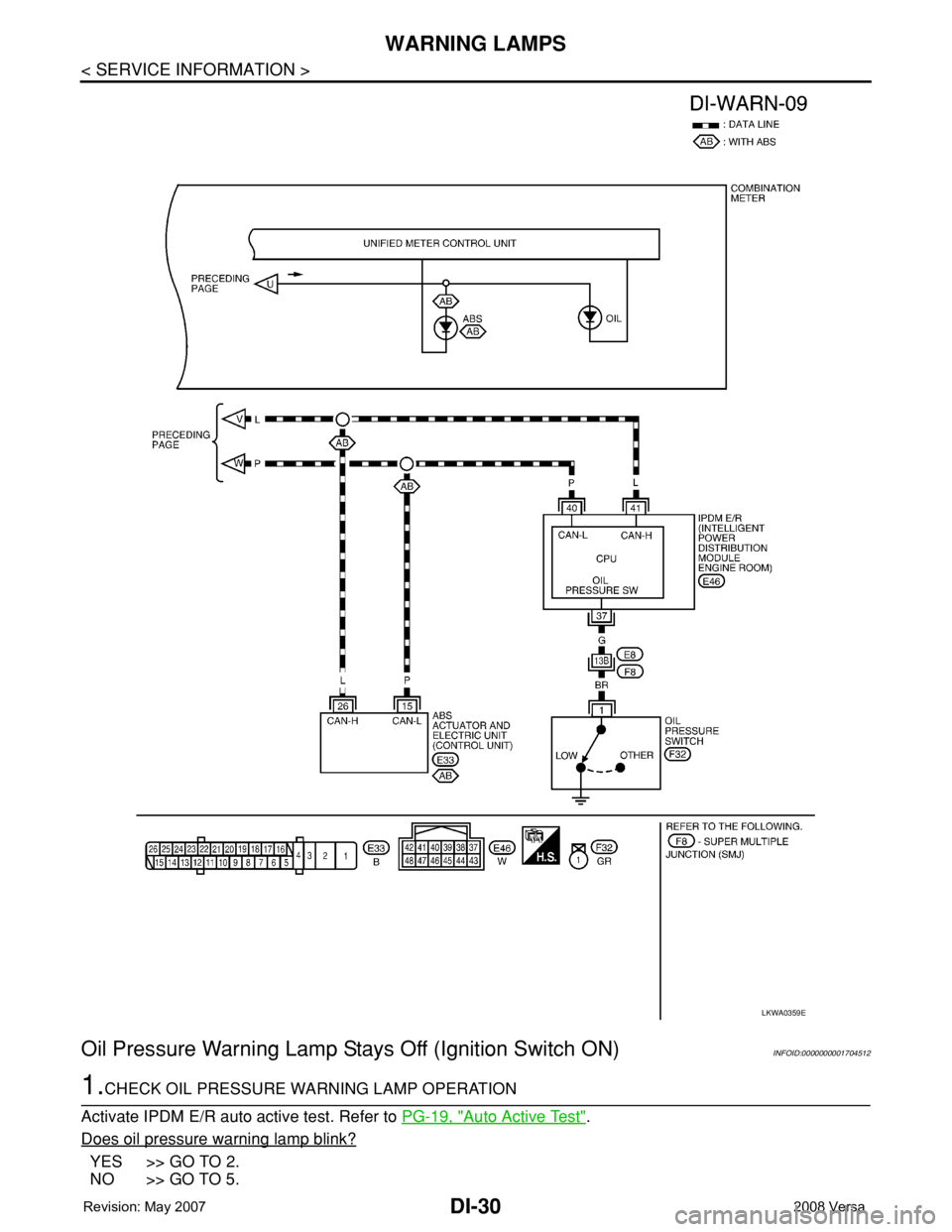

2.CHECK IPDM E/R INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R harness connector and

ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> GO TO 3.

3.CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Check oil pressure switch. Refer to DI-32, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace oil pressure switch.

4.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector (A) and

oil pressure switch harness connector (B).

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

5.CHECK CAN COMMUNICATION

Select “METER/M&A” on CONSULT-III, and perform self-diagnosis of combination meter.

Self

-diagnostic results content

No malfunction detected>>GO TO 6.

Malfunction detected>> Check applicable parts, and repair or replace as necessary.

6.CHECK COMBINATION METER INPUT SIGNAL

Select “METER/M&A” on CONSULT-III. Operate ignition switch with “OIL W/L” of “DATA MONITOR” and

check operation status.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal and Installation".

NG >> Replace IPDM E/R. Refer to PG-26, "

Removal and Installation of IPDM E/R".

Te r m i n a l s

ConditionVoltage (Ap-

prox.) (+)

(–)

IPDM E/R

connectorTe r m i n a l

E46 37 Ground Engine stopped 0 V

WKIA5458E

AB

Continuity

Connector Terminal Connector Terminal

E46 37 F32 1 Yes

WKIA5459E

“OIL W/L”

When ignition switch is in ON

position (Engine stopped.): ON

When engine running : OFF

Page 1053 of 2771

DI-32

< SERVICE INFORMATION >

WARNING LAMPS

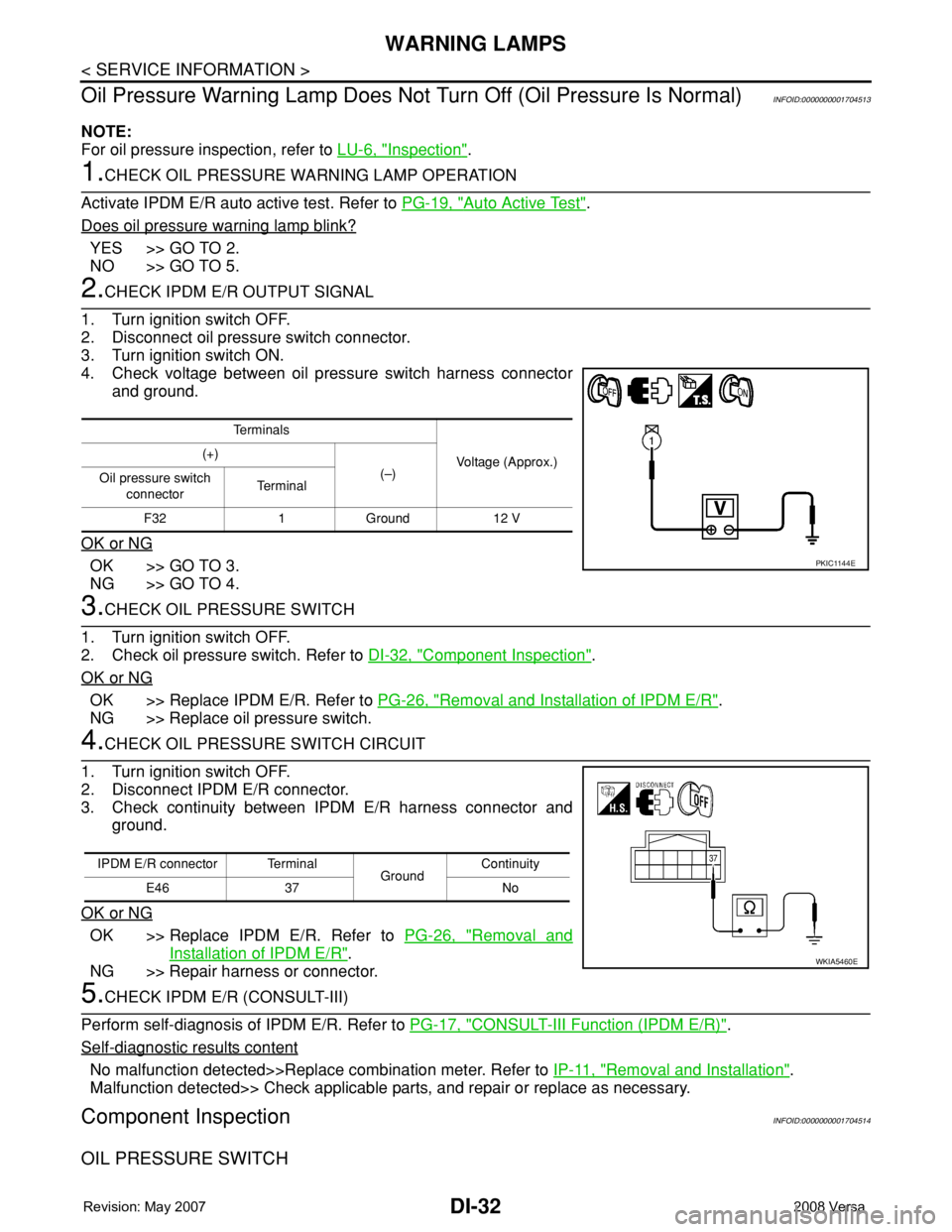

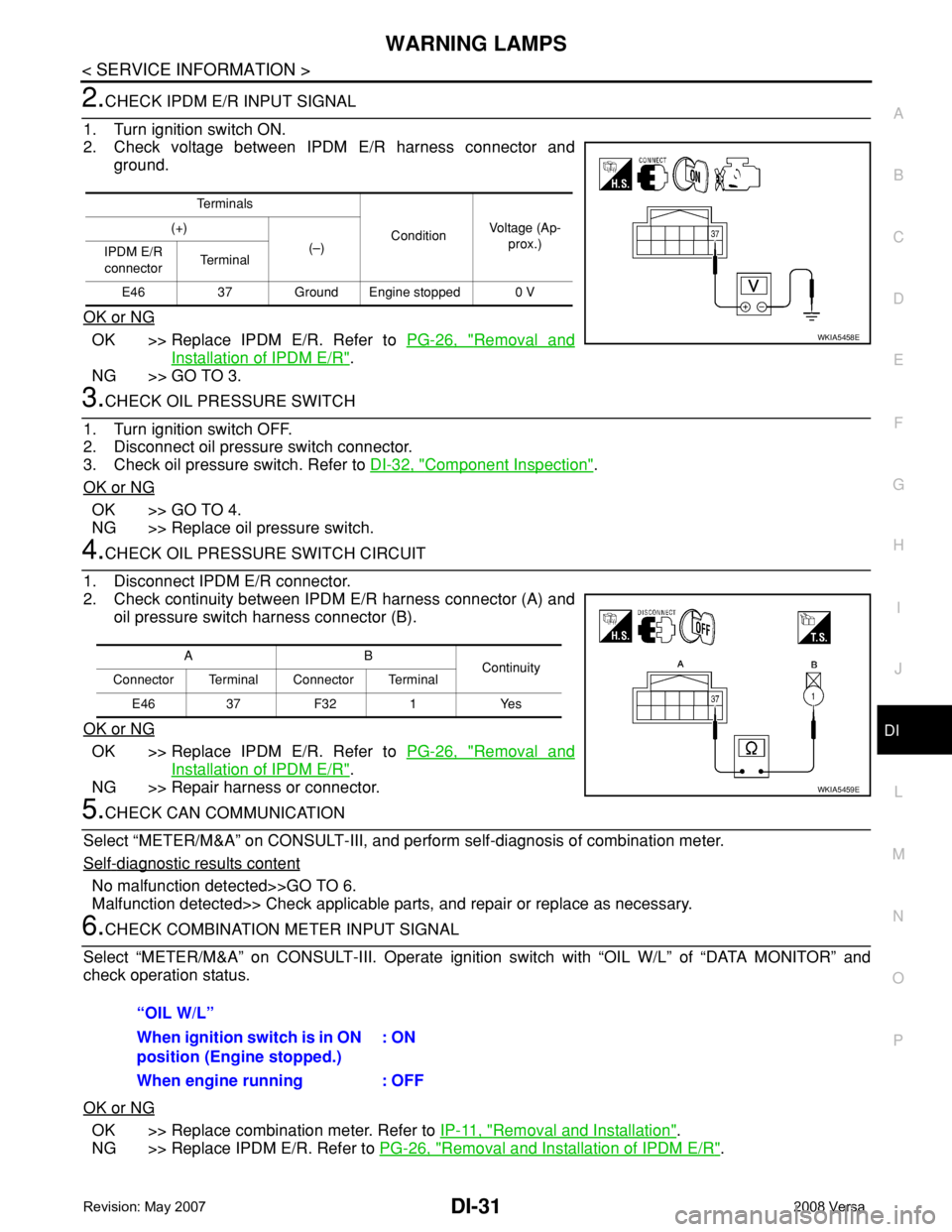

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)

INFOID:0000000001704513

NOTE:

For oil pressure inspection, refer to LU-6, "

Inspection".

1.CHECK OIL PRESSURE WARNING LAMP OPERATION

Activate IPDM E/R auto active test. Refer to PG-19, "

Auto Active Test".

Does oil pressure warning lamp blink?

YES >> GO TO 2.

NO >> GO TO 5.

2.CHECK IPDM E/R OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Turn ignition switch ON.

4. Check voltage between oil pressure switch harness connector

and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Check oil pressure switch. Refer to DI-32, "

Component Inspection".

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

4.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and

ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

5.CHECK IPDM E/R (CONSULT-III)

Perform self-diagnosis of IPDM E/R. Refer to PG-17, "

CONSULT-III Function (IPDM E/R)".

Self

-diagnostic results content

No malfunction detected>>Replace combination meter. Refer to IP-11, "Removal and Installation".

Malfunction detected>> Check applicable parts, and repair or replace as necessary.

Component InspectionINFOID:0000000001704514

OIL PRESSURE SWITCH

Te r m i n a l s

Voltage (Approx.) (+)

(–)

Oil pressure switch

connectorTe r m i n a l

F32 1 Ground 12 V

PKIC1144E

IPDM E/R connector Terminal

GroundContinuity

E46 37 No

WKIA5460E

Page 1054 of 2771

WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Check continuity between oil pressure switch and ground.

Condition

Oil pressure [kPa (bar, kg/cm2, psi)]Continuity

Engine stopped Less than 29 (0.3, 0.3, 4) Yes

Engine running More than 29 (0.3, 0.3, 4) No

ELF0044D

Page 1055 of 2771

DI-34

< SERVICE INFORMATION >

A/T INDICATOR

A/T INDICATOR

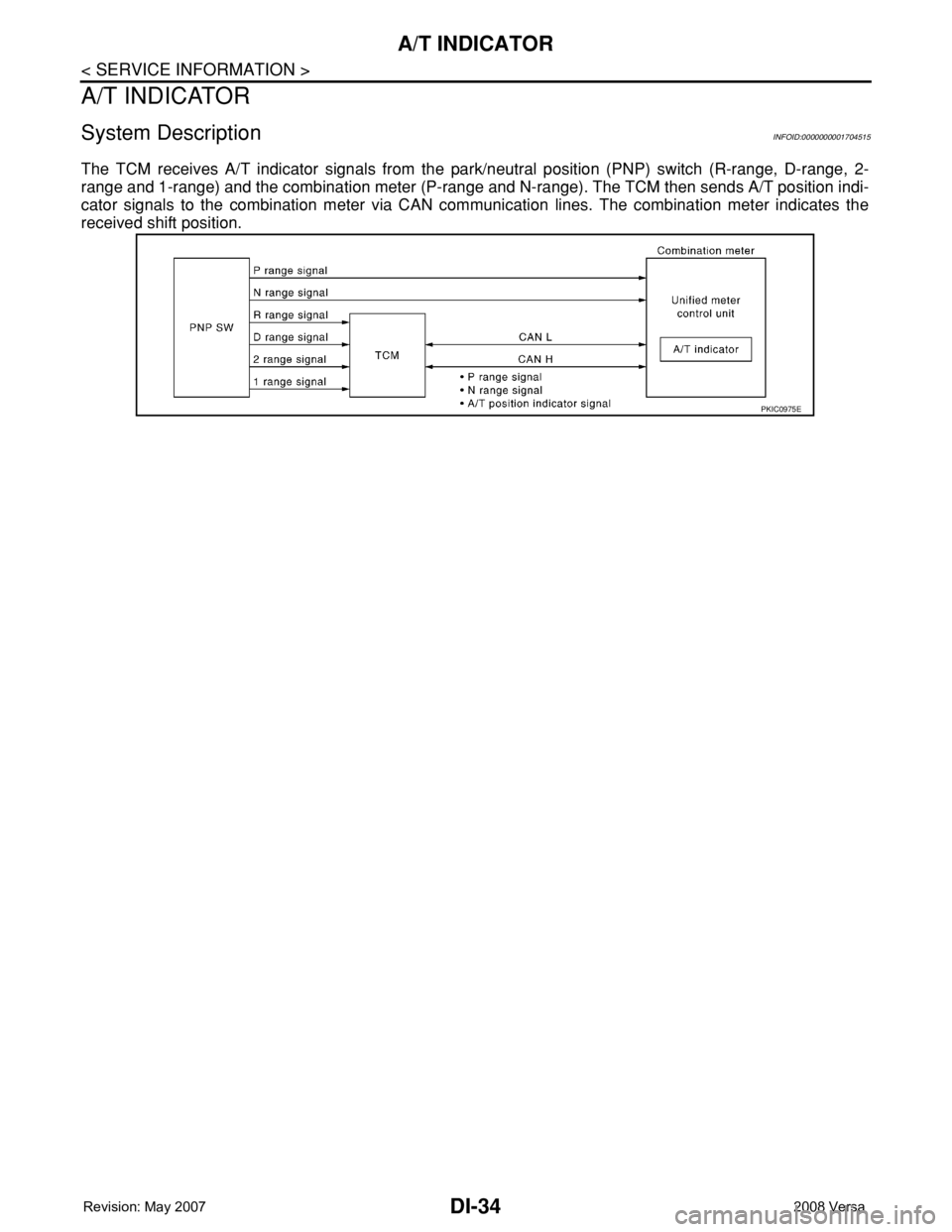

System DescriptionINFOID:0000000001704515

The TCM receives A/T indicator signals from the park/neutral position (PNP) switch (R-range, D-range, 2-

range and 1-range) and the combination meter (P-range and N-range). The TCM then sends A/T position indi-

cator signals to the combination meter via CAN communication lines. The combination meter indicates the

received shift position.

PKIC0975E

Page 1056 of 2771

A/T INDICATOR

DI-35

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

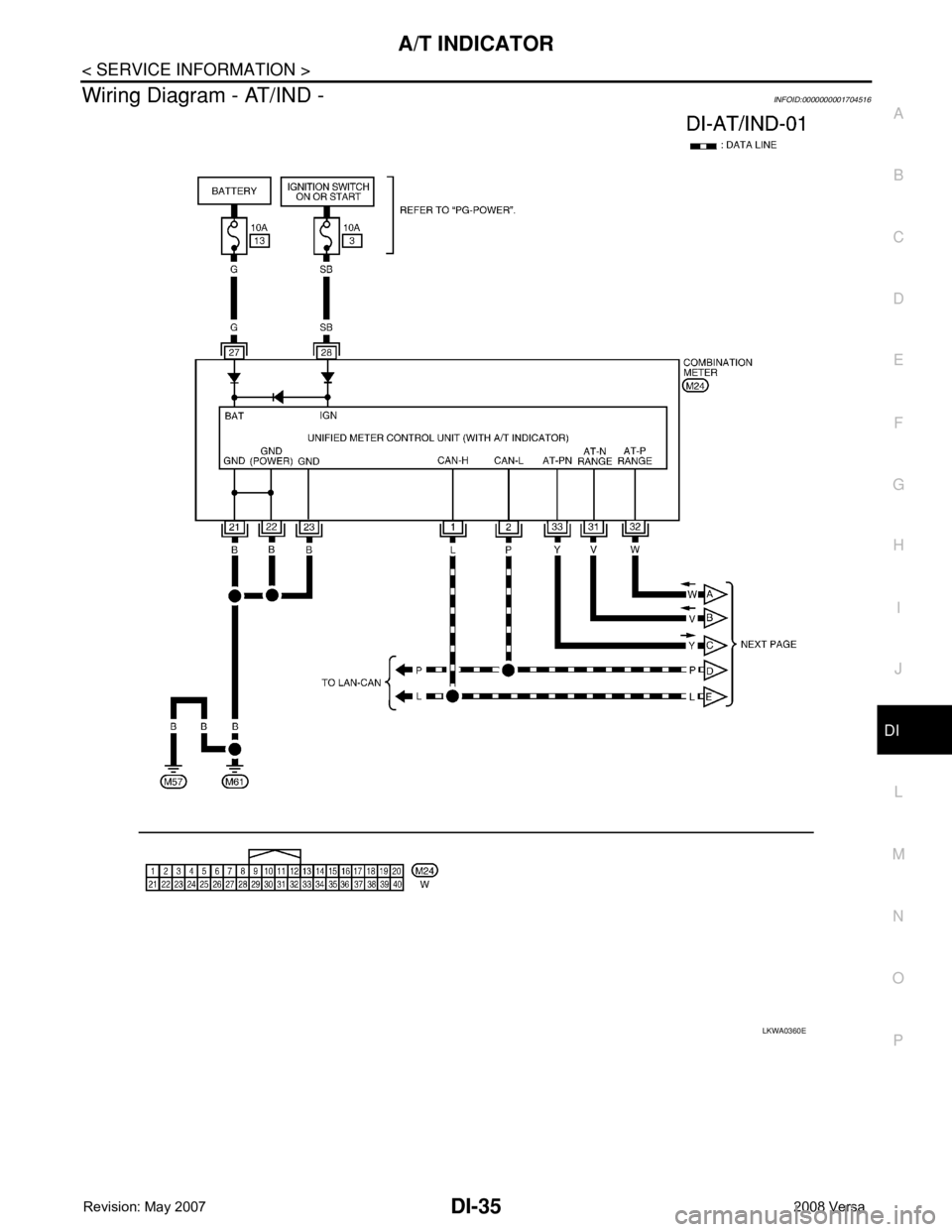

Wiring Diagram - AT/IND -INFOID:0000000001704516

LKWA0360E

Page 1057 of 2771

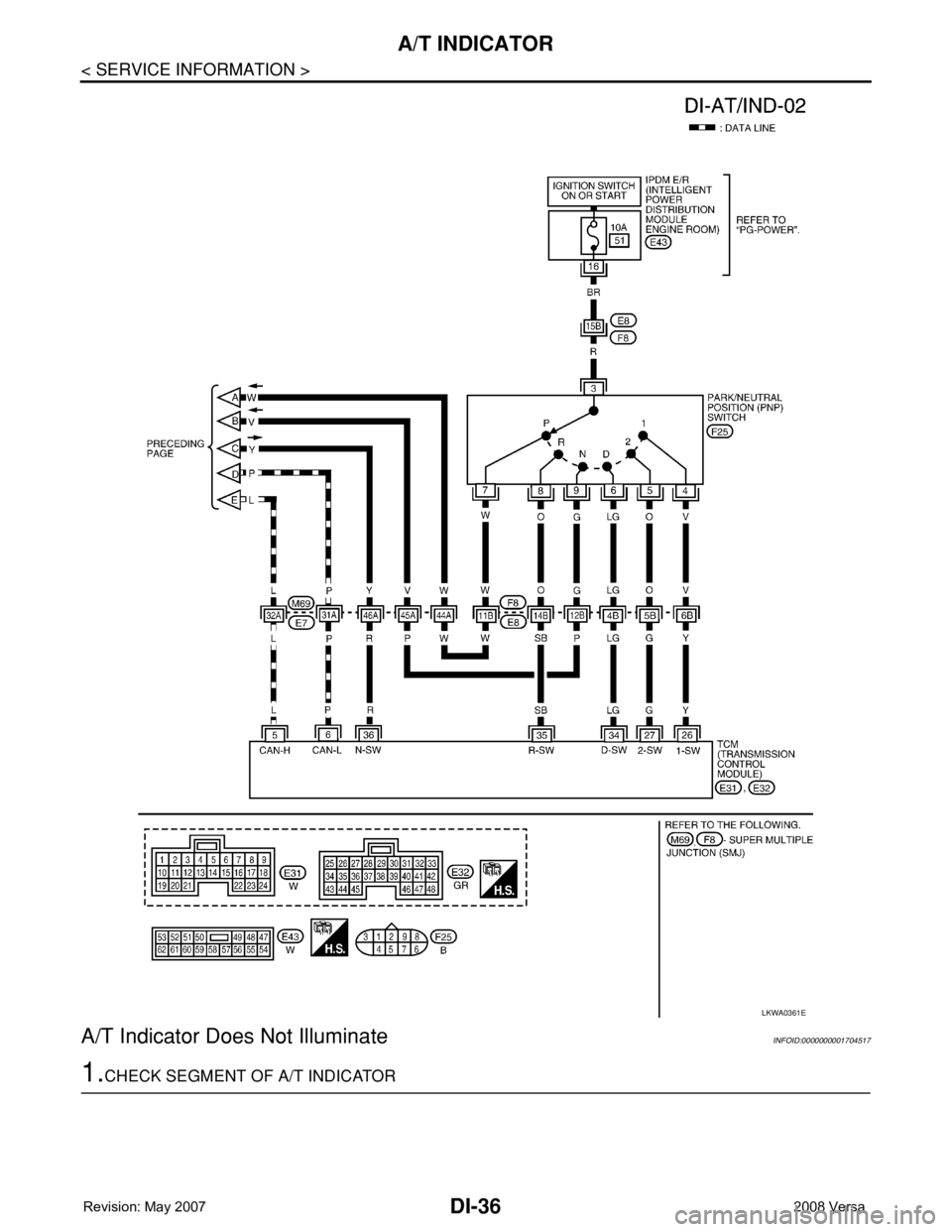

DI-36

< SERVICE INFORMATION >

A/T INDICATOR

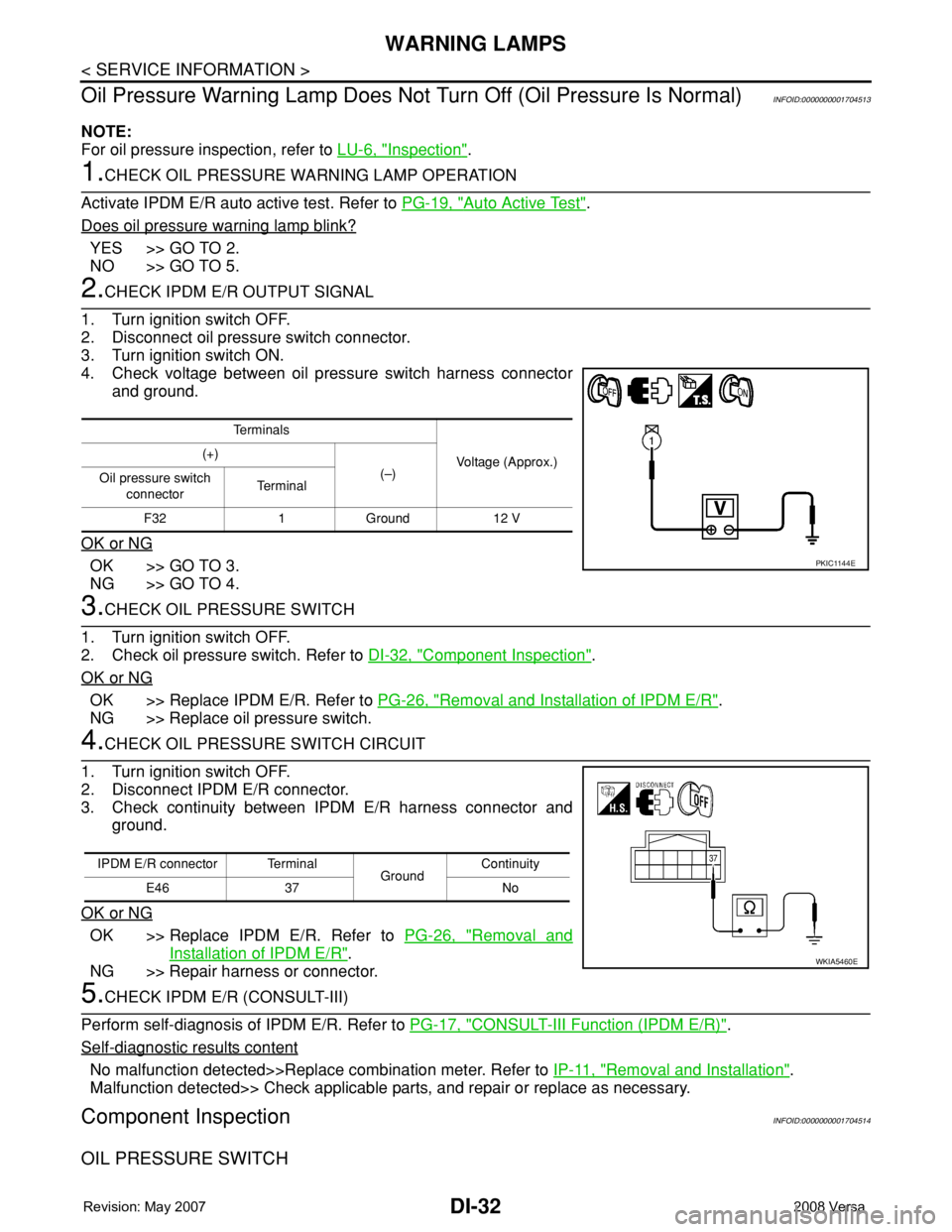

A/T Indicator Does Not Illuminate

INFOID:0000000001704517

1.CHECK SEGMENT OF A/T INDICATOR

LKWA0361E

Page 1058 of 2771

A/T INDICATOR

DI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

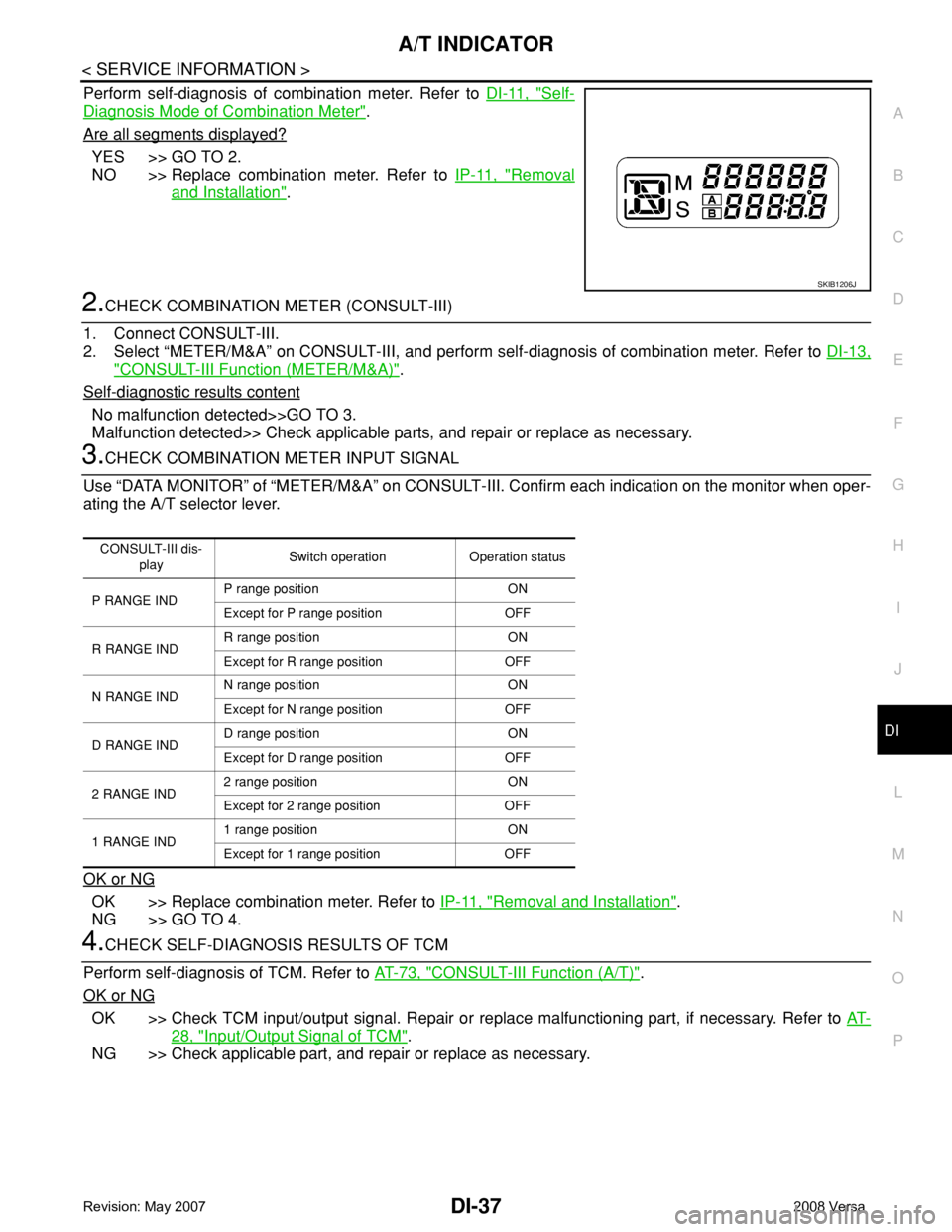

Perform self-diagnosis of combination meter. Refer to DI-11, "Self-

Diagnosis Mode of Combination Meter".

Are all segments displayed?

YES >> GO TO 2.

NO >> Replace combination meter. Refer to IP-11, "

Removal

and Installation".

2.CHECK COMBINATION METER (CONSULT-III)

1. Connect CONSULT-III.

2. Select “METER/M&A” on CONSULT-III, and perform self-diagnosis of combination meter. Refer to DI-13,

"CONSULT-III Function (METER/M&A)".

Self

-diagnostic results content

No malfunction detected>>GO TO 3.

Malfunction detected>> Check applicable parts, and repair or replace as necessary.

3.CHECK COMBINATION METER INPUT SIGNAL

Use “DATA MONITOR” of “METER/M&A” on CONSULT-III. Confirm each indication on the monitor when oper-

ating the A/T selector lever.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal and Installation".

NG >> GO TO 4.

4.CHECK SELF-DIAGNOSIS RESULTS OF TCM

Perform self-diagnosis of TCM. Refer to AT-73, "

CONSULT-III Function (A/T)".

OK or NG

OK >> Check TCM input/output signal. Repair or replace malfunctioning part, if necessary. Refer to AT-

28, "Input/Output Signal of TCM".

NG >> Check applicable part, and repair or replace as necessary.

SKIB1206J

CONSULT-III dis-

playSwitch operation Operation status

P RANGE INDP range position ON

Except for P range position OFF

R RANGE INDR range position ON

Except for R range position OFF

N RANGE INDN range position ON

Except for N range position OFF

D RANGE INDD range position ON

Except for D range position OFF

2 RANGE IND2 range position ON

Except for 2 range position OFF

1 RANGE IND1 range position ON

Except for 1 range position OFF

Page 1059 of 2771

DI-38

< SERVICE INFORMATION >

CVT INDICATOR

CVT INDICATOR

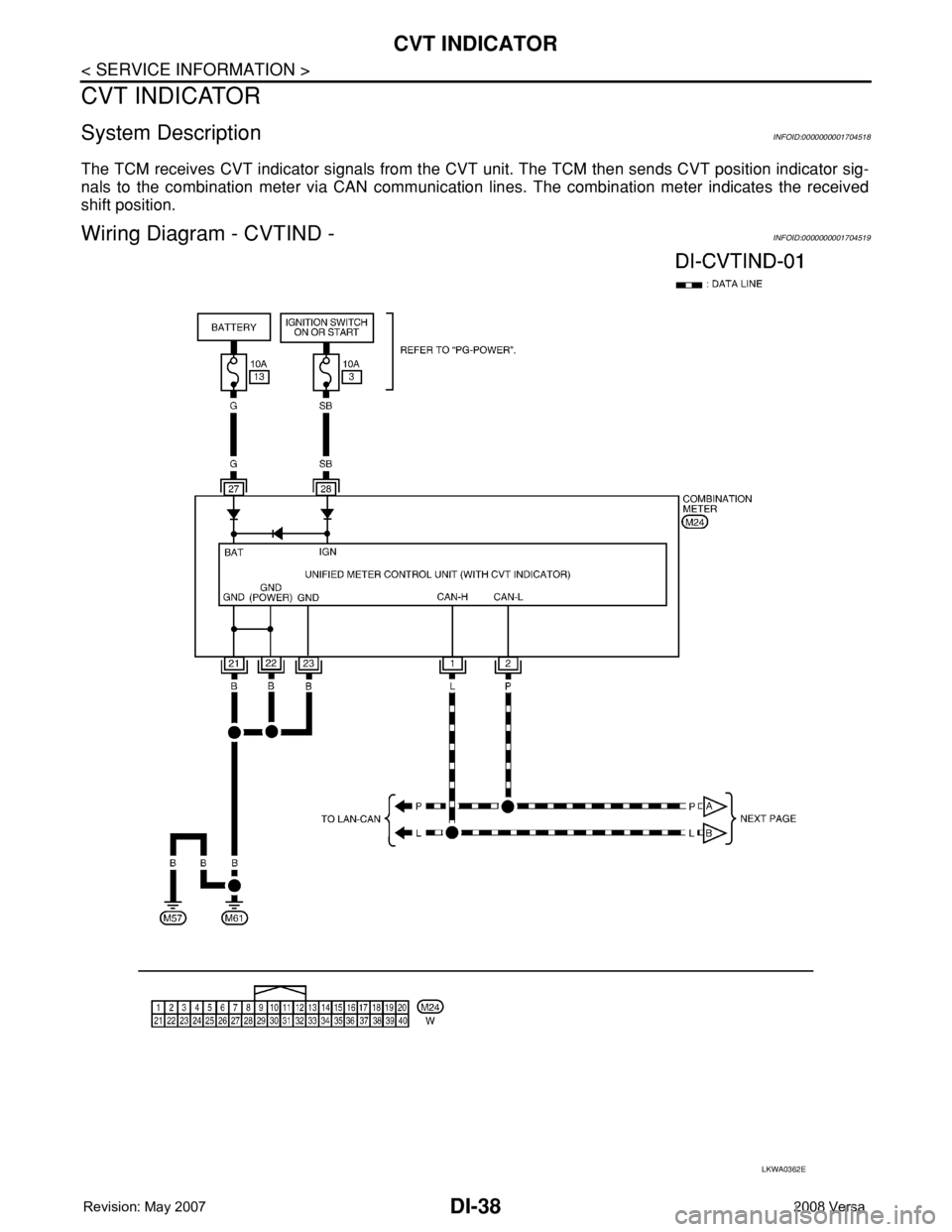

System DescriptionINFOID:0000000001704518

The TCM receives CVT indicator signals from the CVT unit. The TCM then sends CVT position indicator sig-

nals to the combination meter via CAN communication lines. The combination meter indicates the received

shift position.

Wiring Diagram - CVTIND -INFOID:0000000001704519

LKWA0362E

Page 1060 of 2771

CVT INDICATOR

DI-39

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

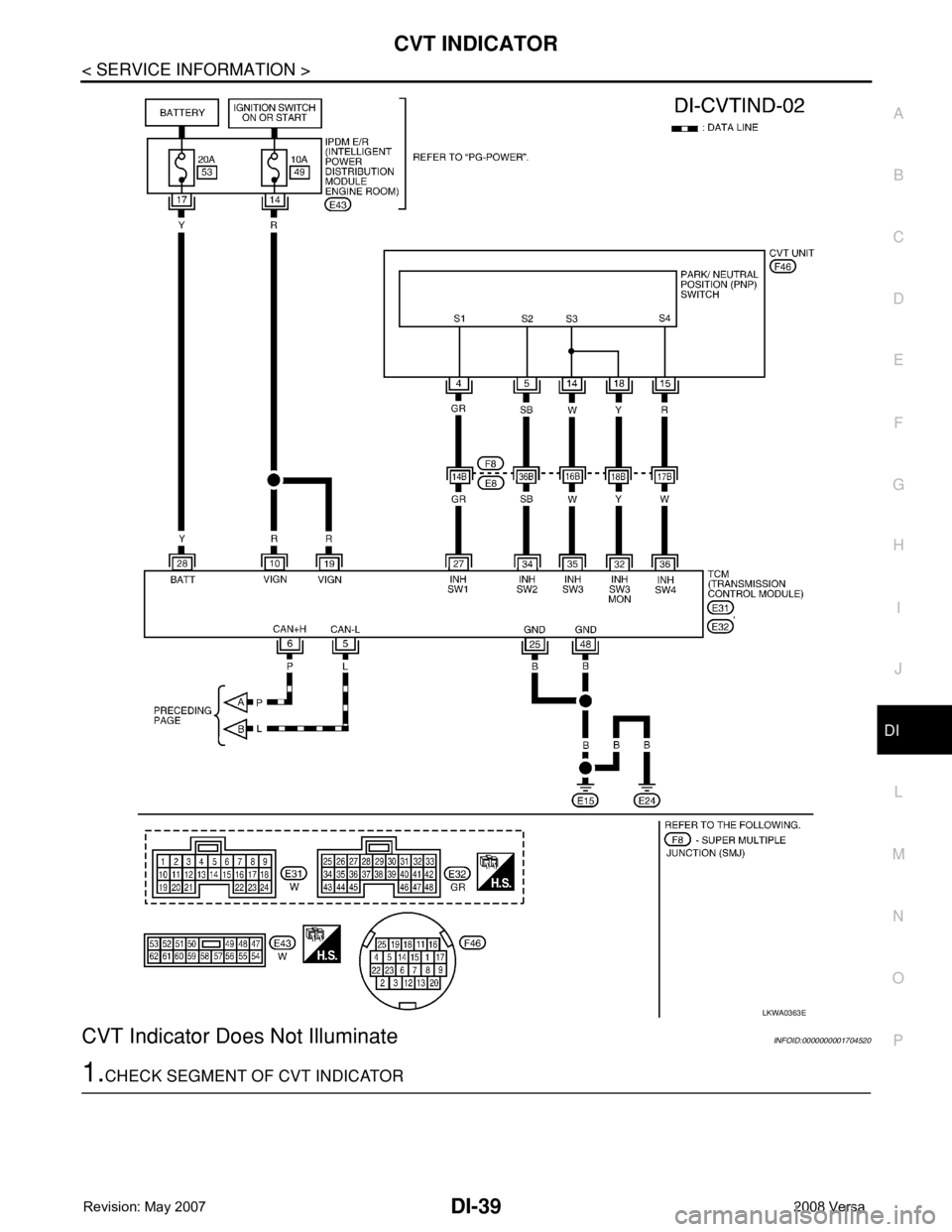

CVT Indicator Does Not IlluminateINFOID:0000000001704520

1.CHECK SEGMENT OF CVT INDICATOR

LKWA0363E

Trending: Coil, fuel reserve, lan system, rsu, Auxiliary, Body, Gear oil type

![NISSAN TIIDA 2008 Service Repair Manual WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Check continuity between oil pressure switch and ground.

Condition

Oil pressure [kPa (bar, kg/cm2, psi)]Continuity

Engine st NISSAN TIIDA 2008 Service Repair Manual WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Check continuity between oil pressure switch and ground.

Condition

Oil pressure [kPa (bar, kg/cm2, psi)]Continuity

Engine st](/img/5/57399/w960_57399-1053.png)