NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1241 of 2771

DTC P0101 MAF SENSOR

EC-167

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0101 MAF SENSOR

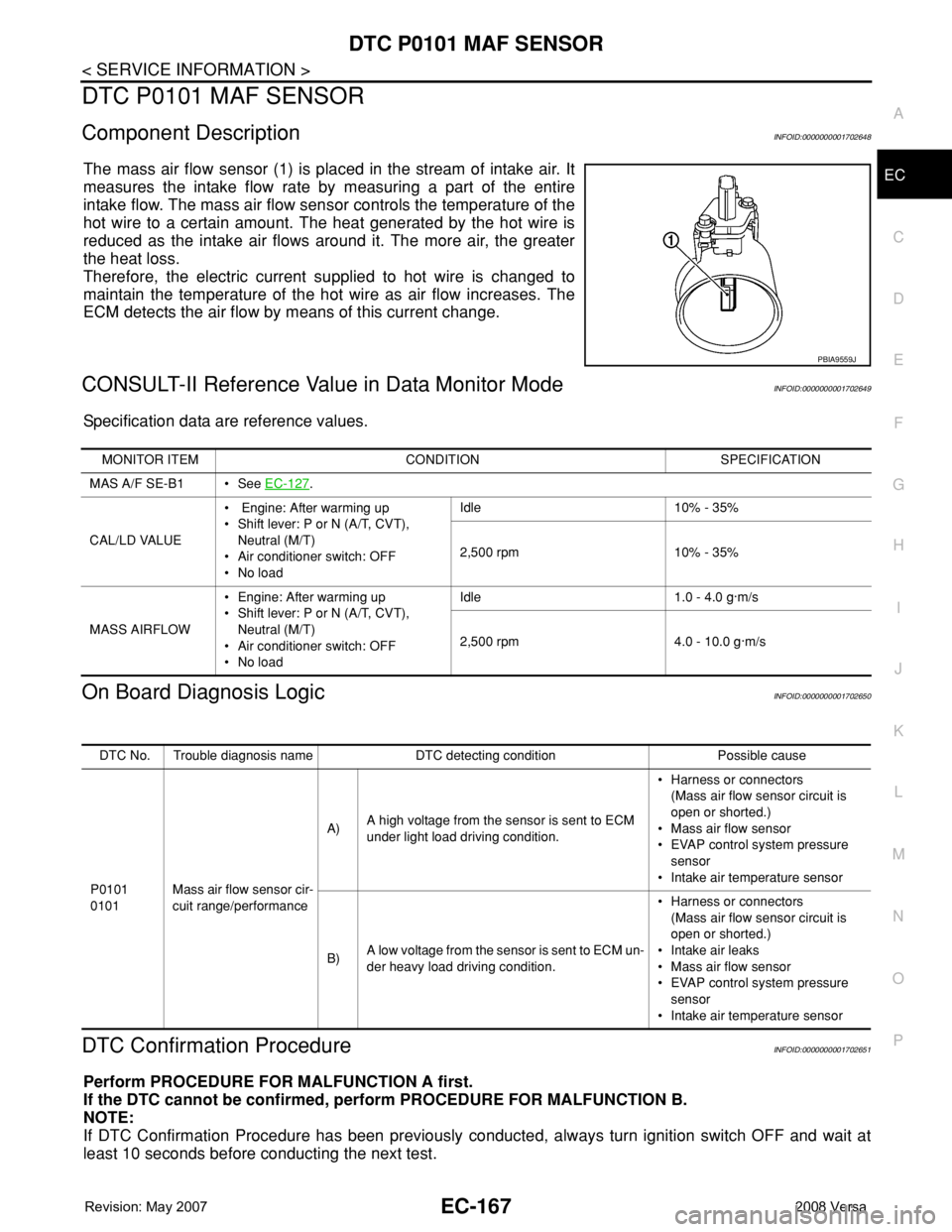

Component DescriptionINFOID:0000000001702648

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702649

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702650

DTC Confirmation ProcedureINFOID:0000000001702651

Perform PROCEDURE FOR MALFUNCTION A first.

If the DTC cannot be confirmed, perform PROCEDURE FOR MALFUNCTION B.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PBIA9559J

MONITOR ITEM CONDITION SPECIFICATION

MAS A/F SE-B1 • See EC-127

.

CAL/LD VALUE• Engine: After warming up

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• Air conditioner switch: OFF

•No loadIdle 10% - 35%

2,500 rpm 10% - 35%

MASS AIRFLOW• Engine: After warming up

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• Air conditioner switch: OFF

•No loadIdle 1.0 - 4.0 g·m/s

2,500 rpm 4.0 - 10.0 g·m/s

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0101

0101Mass air flow sensor cir-

cuit range/performanceA)A high voltage from the sensor is sent to ECM

under light load driving condition.• Harness or connectors

(Mass air flow sensor circuit is

open or shorted.)

• Mass air flow sensor

• EVAP control system pressure

sensor

• Intake air temperature sensor

B)A low voltage from the sensor is sent to ECM un-

der heavy load driving condition.• Harness or connectors

(Mass air flow sensor circuit is

open or shorted.)

• Intake air leaks

• Mass air flow sensor

• EVAP control system pressure

sensor

• Intake air temperature sensor

Page 1242 of 2771

EC-168

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

PROCEDURE FOR MALFUNCTION A

NOTE:

If engine will not start or stops soon, wait at least 10 seconds with engine stopped (Ignition switch ON) instead

of running engine at idle speed.

With CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and warm it up to normal operating temperature.

4. Run engine for at least 10 seconds at idle speed.

5. If 1st trip DTC is detected, go to EC-171, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

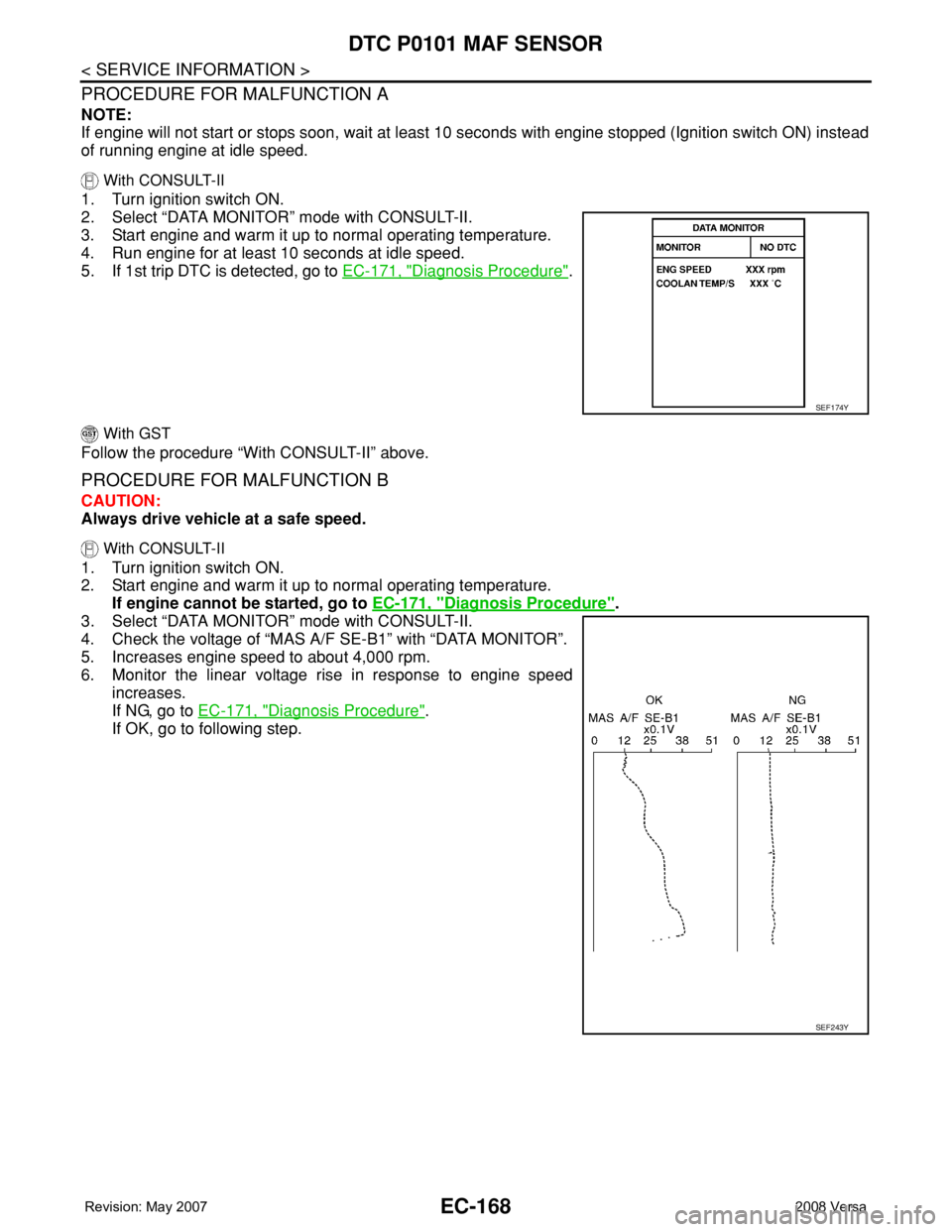

PROCEDURE FOR MALFUNCTION B

CAUTION:

Always drive vehicle at a safe speed.

With CONSULT-II

1. Turn ignition switch ON.

2. Start engine and warm it up to normal operating temperature.

If engine cannot be started, go to EC-171, "

Diagnosis Procedure".

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Check the voltage of “MAS A/F SE-B1” with “DATA MONITOR”.

5. Increases engine speed to about 4,000 rpm.

6. Monitor the linear voltage rise in response to engine speed

increases.

If NG, go to EC-171, "

Diagnosis Procedure".

If OK, go to following step.

SEF174Y

SEF243Y

Page 1243 of 2771

DTC P0101 MAF SENSOR

EC-169

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

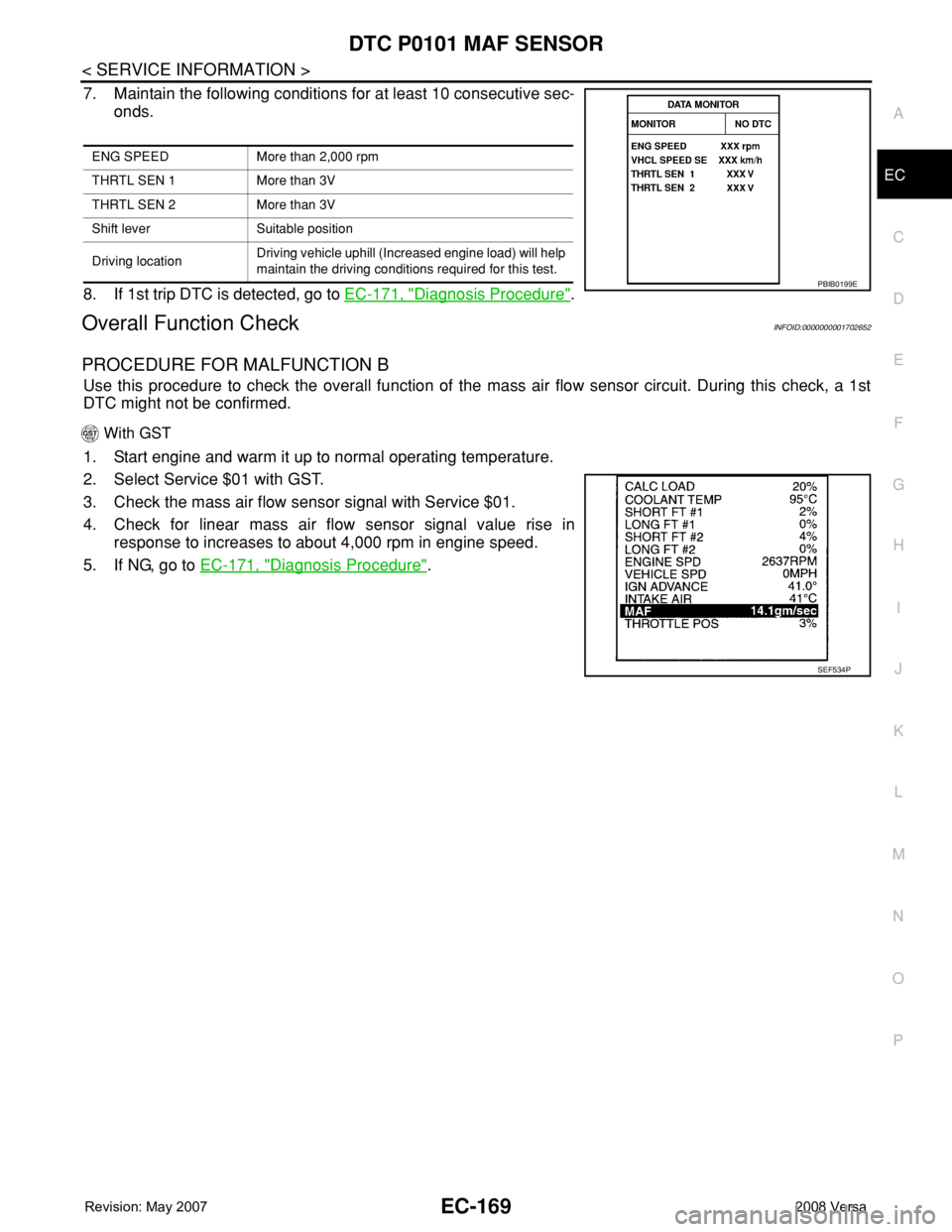

7. Maintain the following conditions for at least 10 consecutive sec-

onds.

8. If 1st trip DTC is detected, go to EC-171, "

Diagnosis Procedure".

Overall Function CheckINFOID:0000000001702652

PROCEDURE FOR MALFUNCTION B

Use this procedure to check the overall function of the mass air flow sensor circuit. During this check, a 1st

DTC might not be confirmed.

With GST

1. Start engine and warm it up to normal operating temperature.

2. Select Service $01 with GST.

3. Check the mass air flow sensor signal with Service $01.

4. Check for linear mass air flow sensor signal value rise in

response to increases to about 4,000 rpm in engine speed.

5. If NG, go to EC-171, "

Diagnosis Procedure".

ENG SPEED More than 2,000 rpm

THRTL SEN 1 More than 3V

THRTL SEN 2 More than 3V

Shift lever Suitable position

Driving locationDriving vehicle uphill (Increased engine load) will help

maintain the driving conditions required for this test.

PBIB0199E

SEF534P

Page 1244 of 2771

EC-170

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

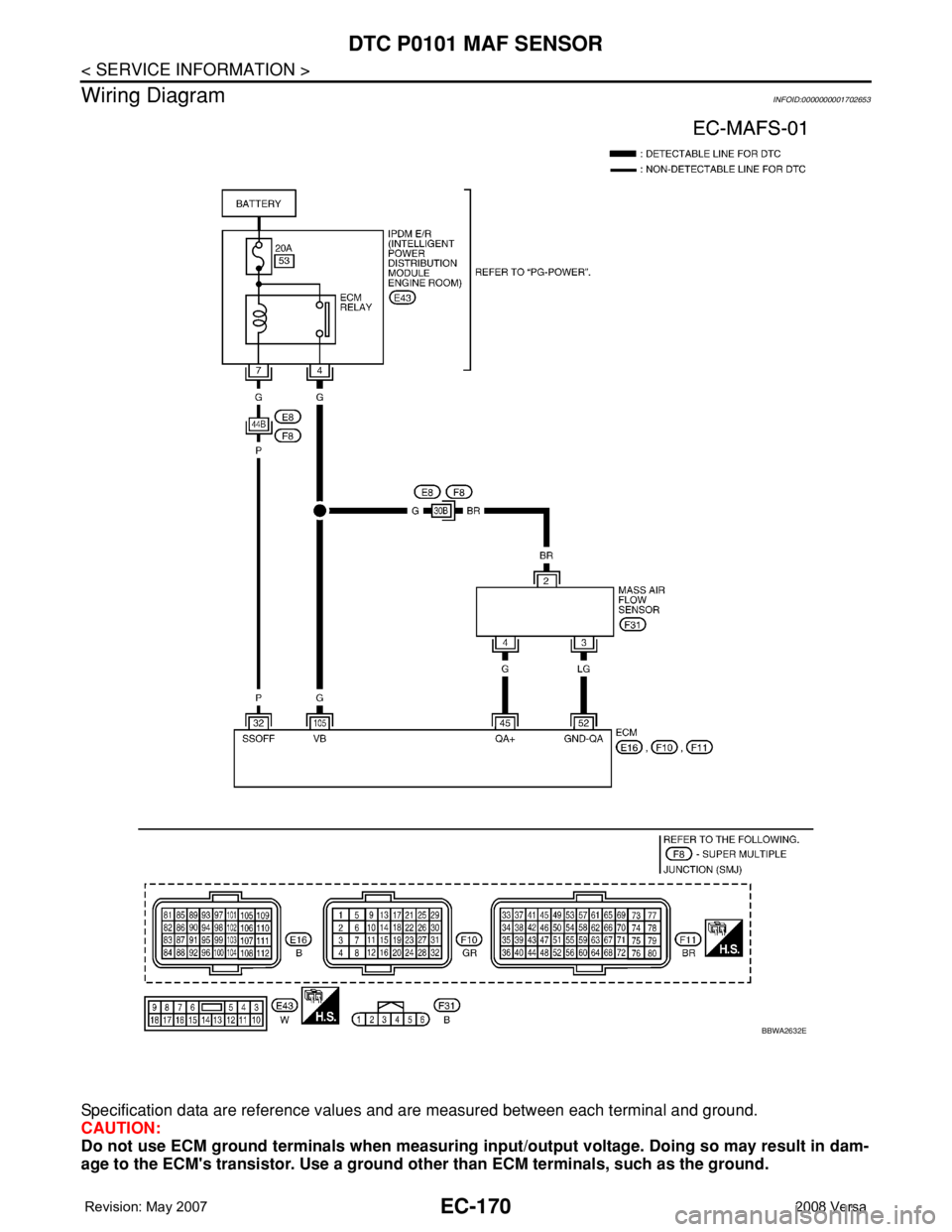

Wiring Diagram

INFOID:0000000001702653

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBWA2632E

Page 1245 of 2771

DTC P0101 MAF SENSOR

EC-171

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000001702654

1.INSPECTION START

Which malfunction (A or B) is duplicated?

A or B

A >> GO TO 3.

B >> GO TO 2.

2.CHECK INTAKE AIR LEAK

Check the following for connections.

• Air duct

• Vacuum hoses

• Intake air passage between air duct and intake manifold

OK or NG

OK >> GO TO 3.

NG >> Reconnect the parts.

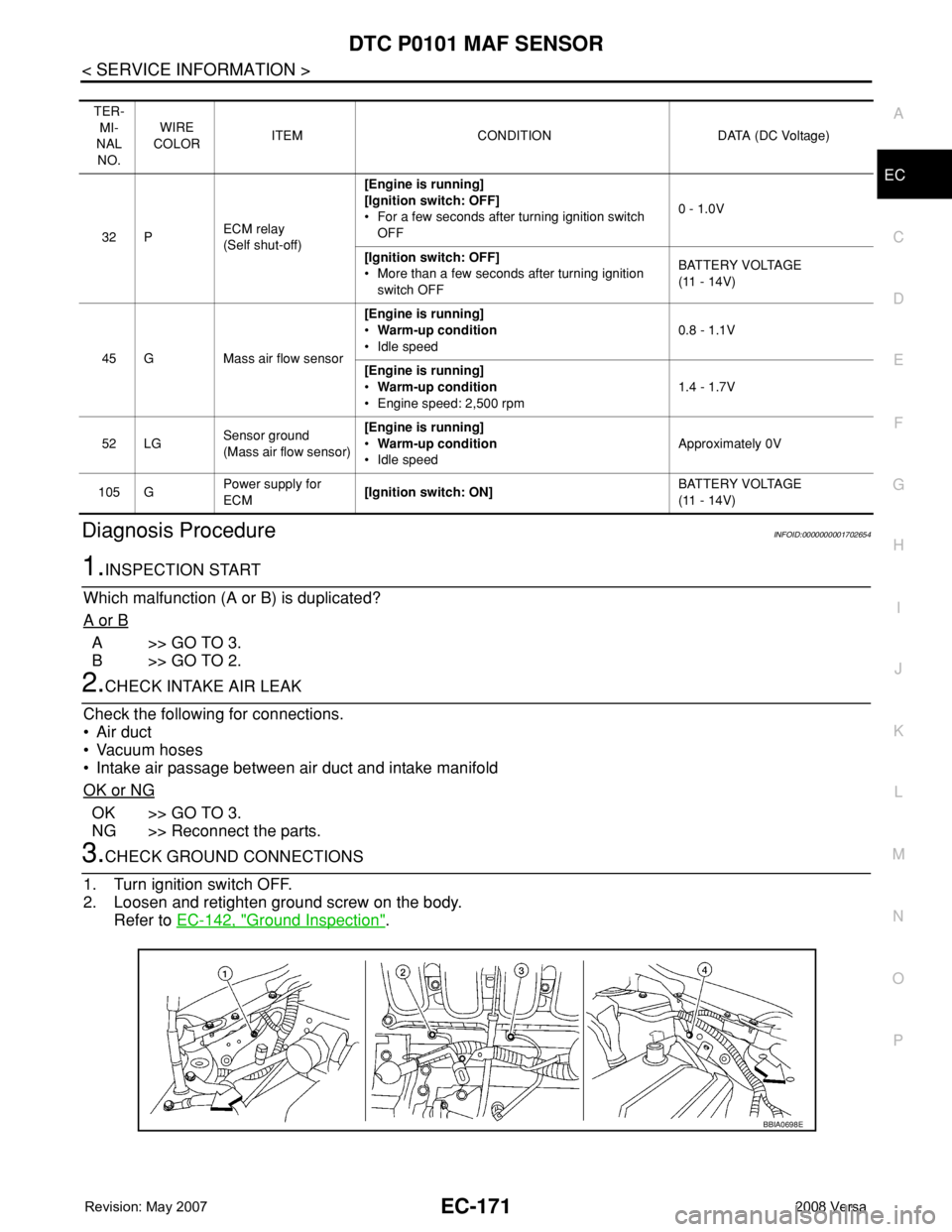

3.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition switch

OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

45 G Mass air flow sensor[Engine is running]

•Warm-up condition

• Idle speed0.8 - 1.1V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm1.4 - 1.7V

52 LGSensor ground

(Mass air flow sensor)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

105 GPower supply for

ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0698E

Page 1246 of 2771

EC-172

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

OK or NG

OK >> GO TO 4.

NG >> Repair or replace ground connections.

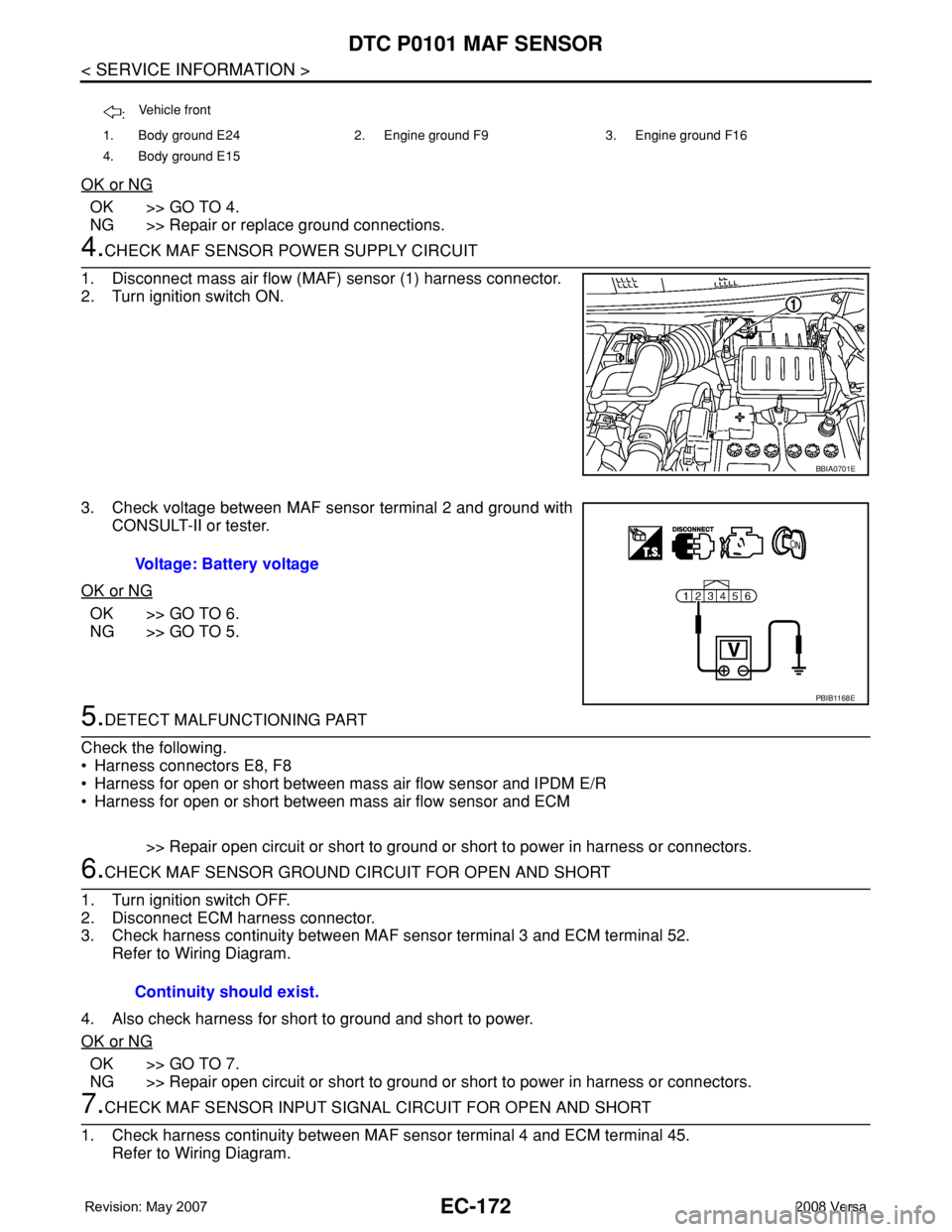

4.CHECK MAF SENSOR POWER SUPPLY CIRCUIT

1. Disconnect mass air flow (MAF) sensor (1) harness connector.

2. Turn ignition switch ON.

3. Check voltage between MAF sensor terminal 2 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between mass air flow sensor and IPDM E/R

• Harness for open or short between mass air flow sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK MAF SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between MAF sensor terminal 3 and ECM terminal 52.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK MAF SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between MAF sensor terminal 4 and ECM terminal 45.

Refer to Wiring Diagram.

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0701E

Voltage: Battery voltage

PBIB1168E

Continuity should exist.

Page 1247 of 2771

DTC P0101 MAF SENSOR

EC-173

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short or short to power in harness or connectors.

8.CHECK INTAKE AIR TEMPERATURE SENSOR

Refer to EC-202, "

Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Replace intake air temperature sensor.

9.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-353, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace EVAP control system pressure sensor.

10.CHECK MASS AIR FLOW SENSOR

Refer to EC-173, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace mass air flow sensor.

11 .CHECK INTERMITTENT INCIDENT

Perform EC-136

.

>>INSPECTION END

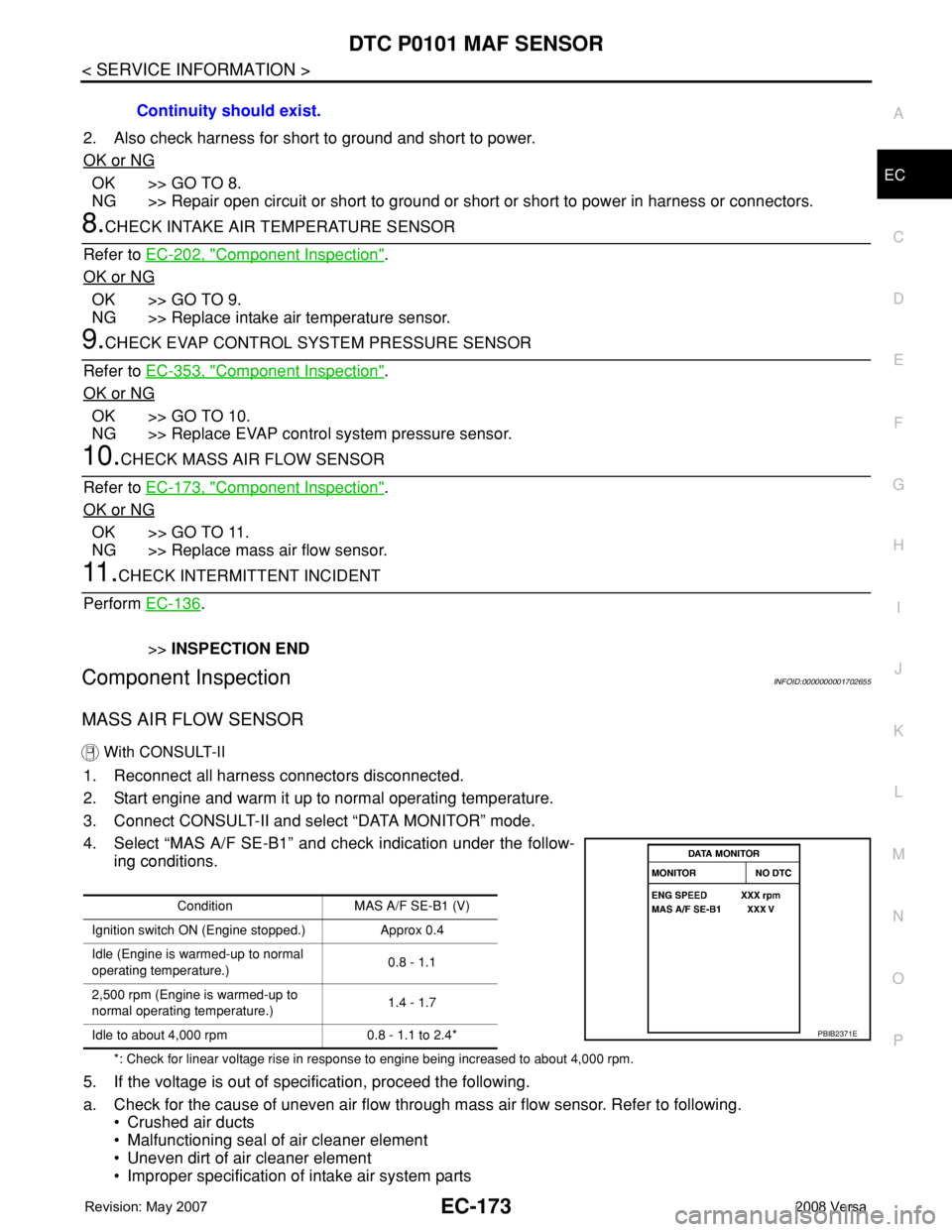

Component InspectionINFOID:0000000001702655

MASS AIR FLOW SENSOR

With CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-II and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check indication under the follow-

ing conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system partsContinuity should exist.

Condition MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.) Approx 0.4

Idle (Engine is warmed-up to normal

operating temperature.)0.8 - 1.1

2,500 rpm (Engine is warmed-up to

normal operating temperature.)1.4 - 1.7

Idle to about 4,000 rpm 0.8 - 1.1 to 2.4*

PBIB2371E

Page 1248 of 2771

EC-174

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

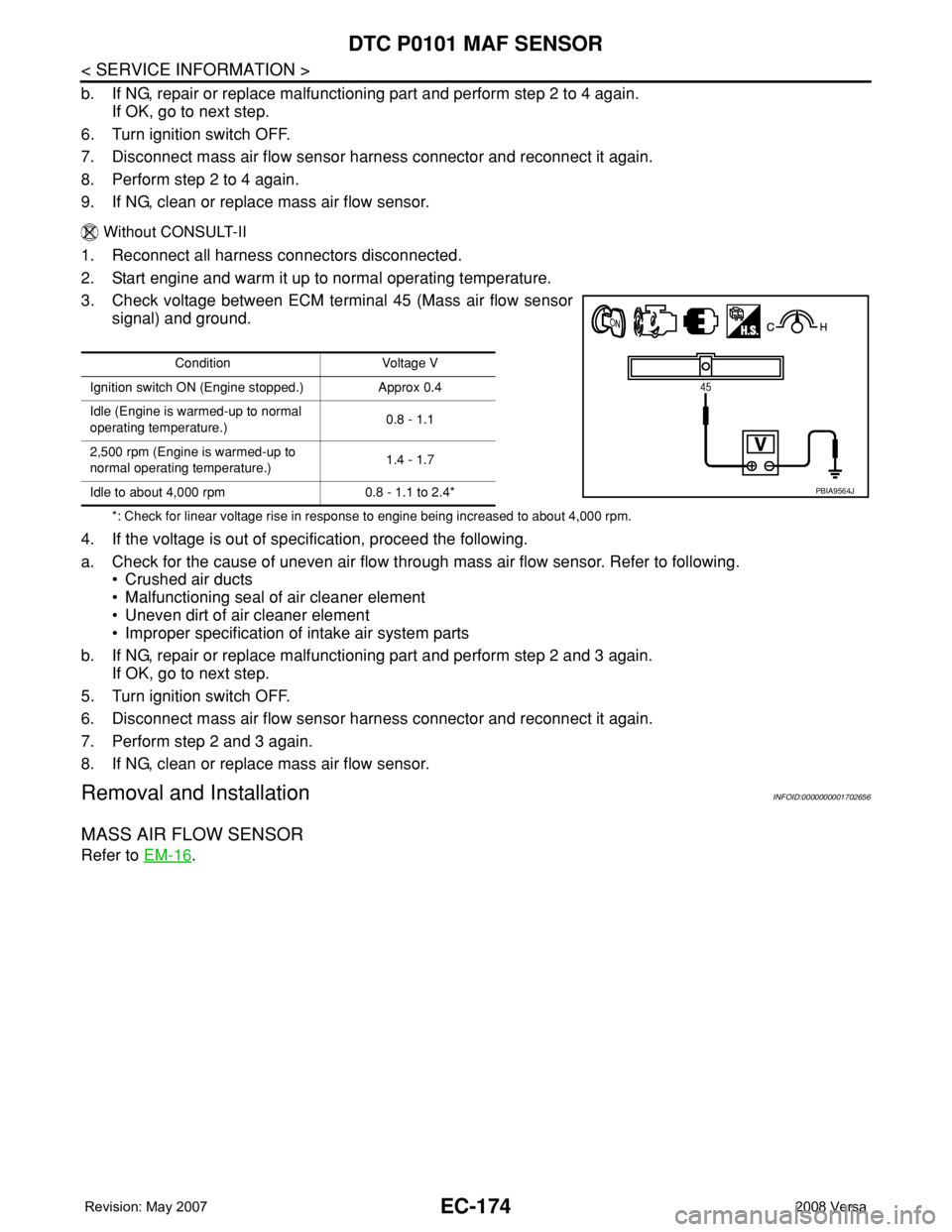

Without CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 45 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

4. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 and 3 again.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and InstallationINFOID:0000000001702656

MASS AIR FLOW SENSOR

Refer to EM-16.

Condition Voltage V

Ignition switch ON (Engine stopped.) Approx 0.4

Idle (Engine is warmed-up to normal

operating temperature.)0.8 - 1.1

2,500 rpm (Engine is warmed-up to

normal operating temperature.)1.4 - 1.7

Idle to about 4,000 rpm 0.8 - 1.1 to 2.4*

PBIA9564J

Page 1249 of 2771

DTC P0102, P0103 MAF SENSOR

EC-175

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0102, P0103 MAF SENSOR

Component DescriptionINFOID:0000000001702657

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702658

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702659

These self-diagnoses have the one trip detection logic.

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters fail-safe mode and the MIL lights up.

DTC Confirmation ProcedureINFOID:0000000001702660

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PBIA9559J

MONITOR ITEM CONDITION SPECIFICATION

MAS A/F SE-B1 See EC-127

.

CAL/LD VALUE• Engine: After warming up

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• Air conditioner switch: OFF

•No loadIdle 10% - 35%

2,500 rpm 10% - 35%

MASS AIRFLOW• Engine: After warming up

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• Air conditioner switch: OFF

•No loadIdle 1.0 - 4.0 g·m/s

2,500 rpm 4.0 - 10.0 g·m/s

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

P0102

0102Mass air flow sensor

circuit low inputAn excessively low voltage from the sensor is sent

to ECM.• Harness or connectors

(Mass air flow sensor circuit is open or short-

ed.)

• Intake air leaks

• Mass air flow sensor

P0103

0103Mass air flow sensor

circuit high inputAn excessively high voltage from the sensor is

sent to ECM.• Harness or connectors

(Mass air flow sensor circuit is open or short-

ed.)

• Mass air flow sensor

Detected items Engine operating condition in fail-safe mode

Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

Page 1250 of 2771

EC-176

< SERVICE INFORMATION >

DTC P0102, P0103 MAF SENSOR

PROCEDURE FOR DTC P0102

With CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and wait at least 5 seconds.

4. If DTC is detected, go to EC-178, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

PROCEDURE FOR DTC P0103

With CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go to EC-178, "

Diagnosis Procedure".

If DTC is not detected, go to next step.

5. Start engine and wait at least 5 seconds.

6. If DTC is detected, go to EC-178, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

SEF058Y

SEF058Y