NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1271 of 2771

DTC P0122, P0123 TP SENSOR

EC-197

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

>>INSPECTION END

7.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

Component InspectionINFOID:0000000001702685

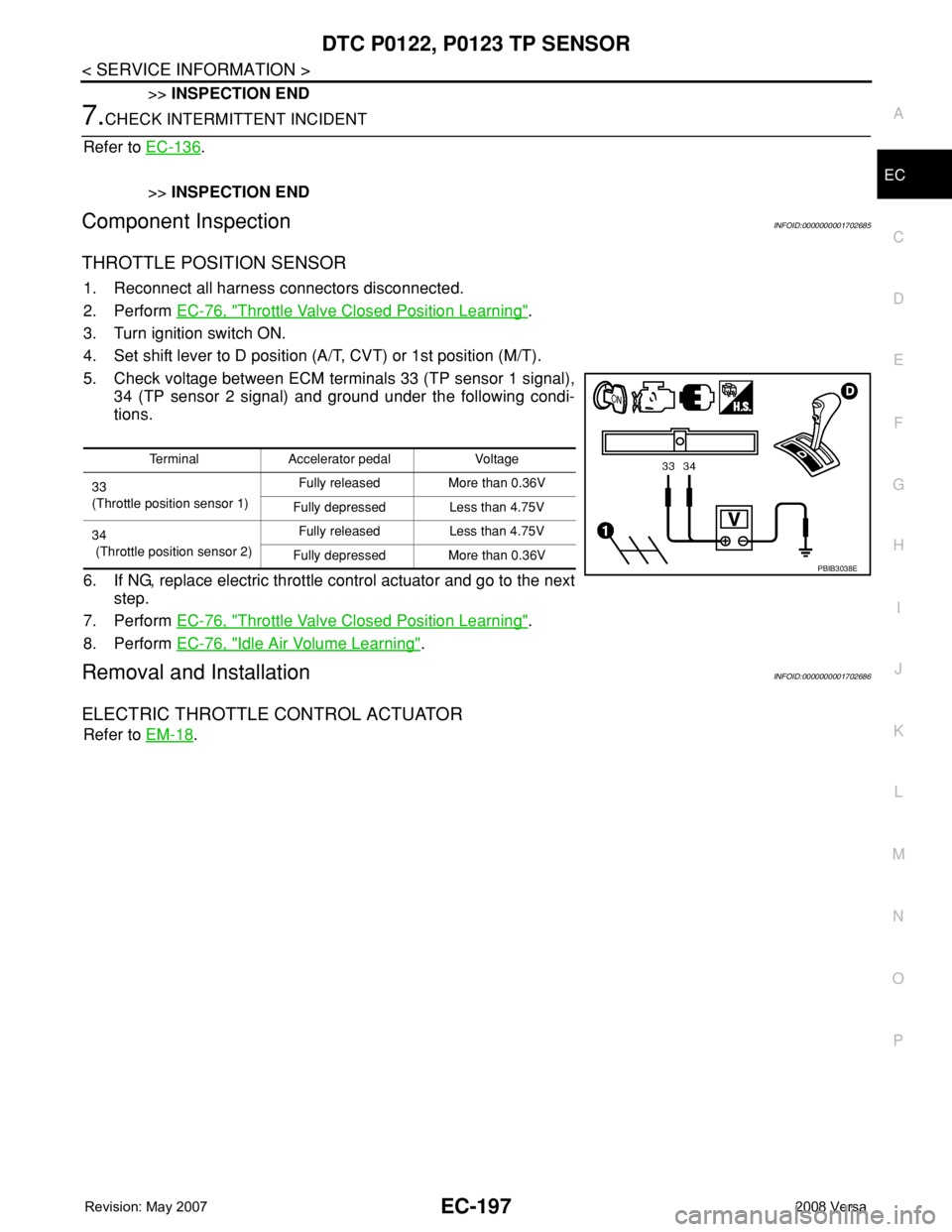

THROTTLE POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Perform EC-76, "

Throttle Valve Closed Position Learning".

3. Turn ignition switch ON.

4. Set shift lever to D position (A/T, CVT) or 1st position (M/T).

5. Check voltage between ECM terminals 33 (TP sensor 1 signal),

34 (TP sensor 2 signal) and ground under the following condi-

tions.

6. If NG, replace electric throttle control actuator and go to the next

step.

7. Perform EC-76, "

Throttle Valve Closed Position Learning".

8. Perform EC-76, "

Idle Air Volume Learning".

Removal and InstallationINFOID:0000000001702686

ELECTRIC THROTTLE CONTROL ACTUATOR

Refer to EM-18.

Terminal Accelerator pedal Voltage

33

(Throttle position sensor 1)Fully released More than 0.36V

Fully depressed Less than 4.75V

34

(Throttle position sensor 2)Fully released Less than 4.75V

Fully depressed More than 0.36V

PBIB3038E

Page 1272 of 2771

EC-198

< SERVICE INFORMATION >

DTC P0125 ECT SENSOR

DTC P0125 ECT SENSOR

DescriptionINFOID:0000000001702687

NOTE:

If DTC P0125 is displayed with P0117 or P0118, first perform the trouble diagnosis for DTC P0117 or

P0118. Refer to EC-187

.

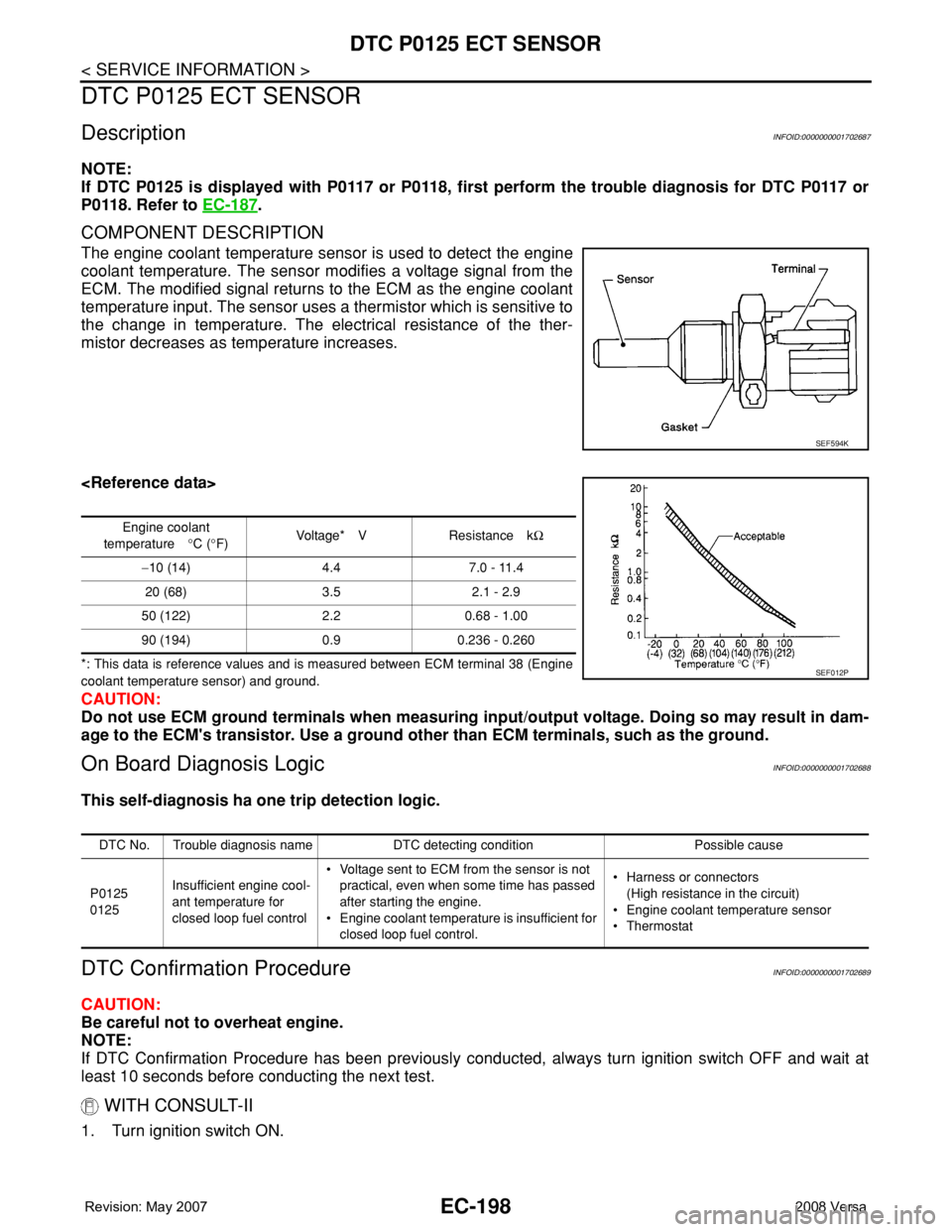

COMPONENT DESCRIPTION

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

*: This data is reference values and is measured between ECM terminal 38 (Engine

coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicINFOID:0000000001702688

This self-diagnosis ha one trip detection logic.

DTC Confirmation ProcedureINFOID:0000000001702689

CAUTION:

Be careful not to overheat engine.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

SEF594K

Engine coolant

temperature°C (°F)Voltage* V Resistance kΩ

−10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0125

0125Insufficient engine cool-

ant temperature for

closed loop fuel control• Voltage sent to ECM from the sensor is not

practical, even when some time has passed

after starting the engine.

• Engine coolant temperature is insufficient for

closed loop fuel control.• Harness or connectors

(High resistance in the circuit)

• Engine coolant temperature sensor

•Thermostat

Page 1273 of 2771

DTC P0125 ECT SENSOR

EC-199

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Check that “COOLAN TEMP/S” is above 10°C (50°F).

If it is above 10°C (50°F), the test result will be OK.

If it is below 10°C (50°F), go to following step.

4. Start engine and run it for 65 minutes at idle speed.

If “COOLAN TEMP/S” increases to more than 10°C (50°F)

within 65 minutes, stop engine because the test result will

be OK.

5. If DTC is detected, go to EC-199, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000001702690

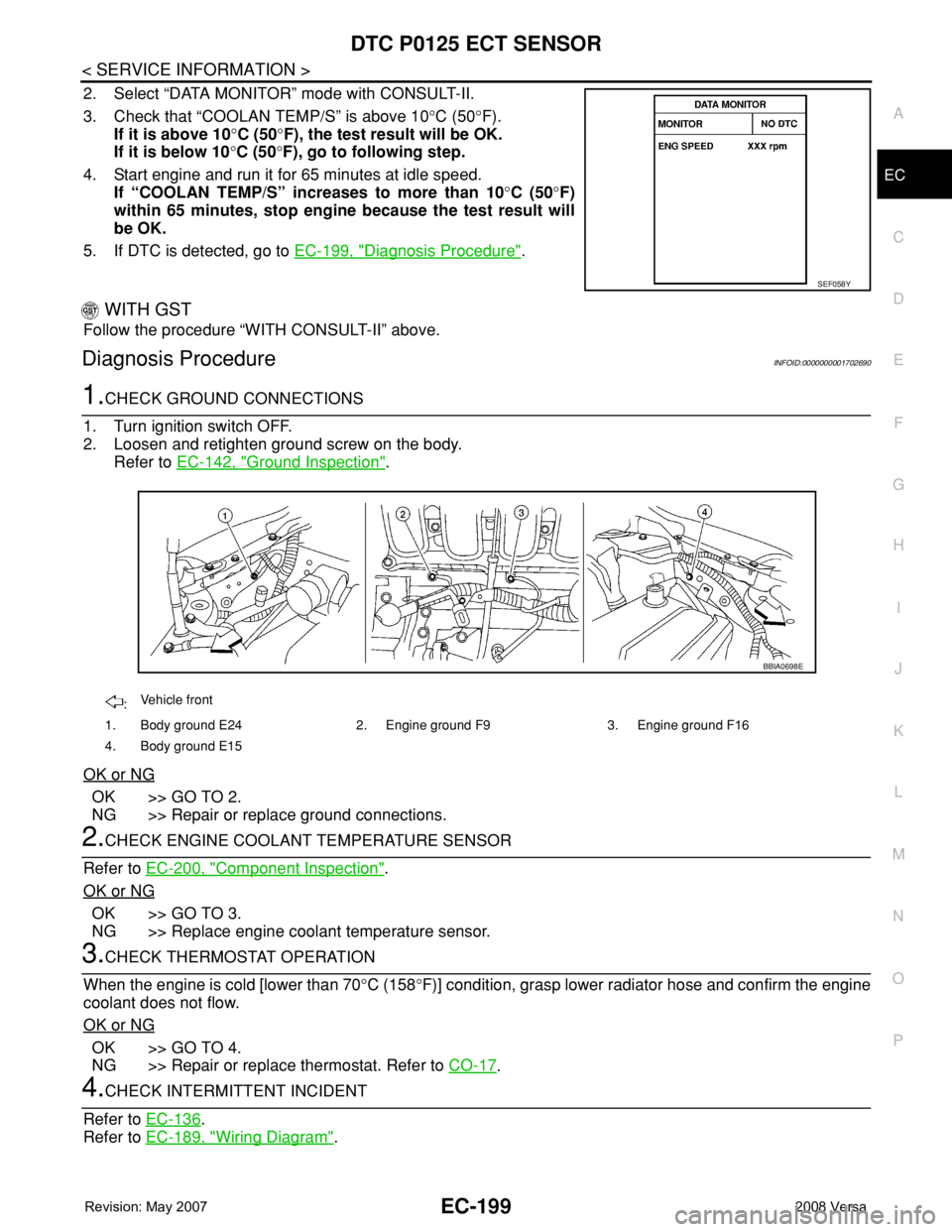

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-200, "

Component Inspection".

OK or NG

OK >> GO TO 3.

NG >> Replace engine coolant temperature sensor.

3.CHECK THERMOSTAT OPERATION

When the engine is cold [lower than 70°C (158°F)] condition, grasp lower radiator hose and confirm the engine

coolant does not flow.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace thermostat. Refer to CO-17

.

4.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

Refer to EC-189, "

Wiring Diagram".

SEF058Y

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Page 1274 of 2771

EC-200

< SERVICE INFORMATION >

DTC P0125 ECT SENSOR

>>INSPECTION END

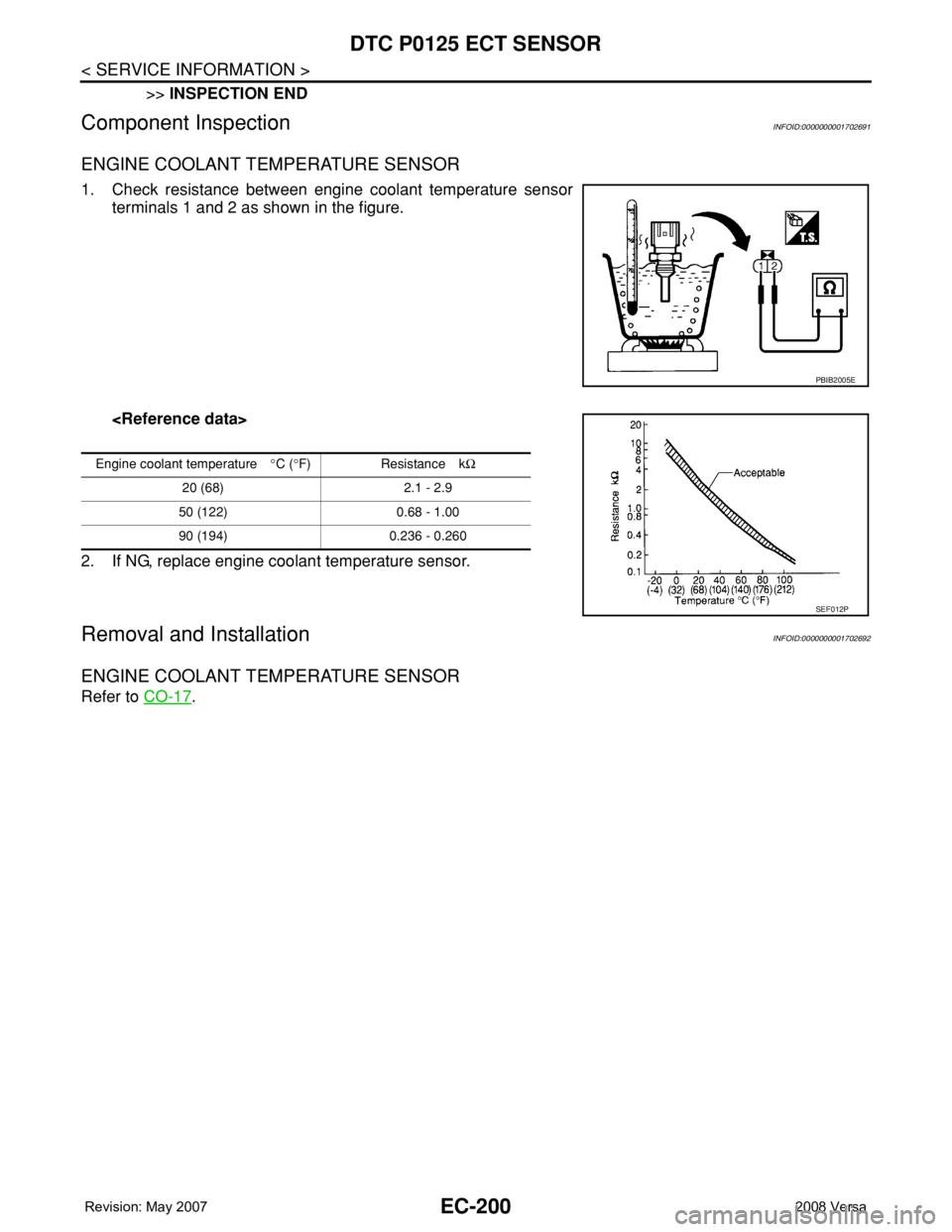

Component InspectionINFOID:0000000001702691

ENGINE COOLANT TEMPERATURE SENSOR

1. Check resistance between engine coolant temperature sensor

terminals 1 and 2 as shown in the figure.

2. If NG, replace engine coolant temperature sensor.

Removal and InstallationINFOID:0000000001702692

ENGINE COOLANT TEMPERATURE SENSOR

Refer to CO-17.

PBIB2005E

Engine coolant temperature°C (°F) Resistance kΩ

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

SEF012P

Page 1275 of 2771

DTC P0127 IAT SENSOR

EC-201

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

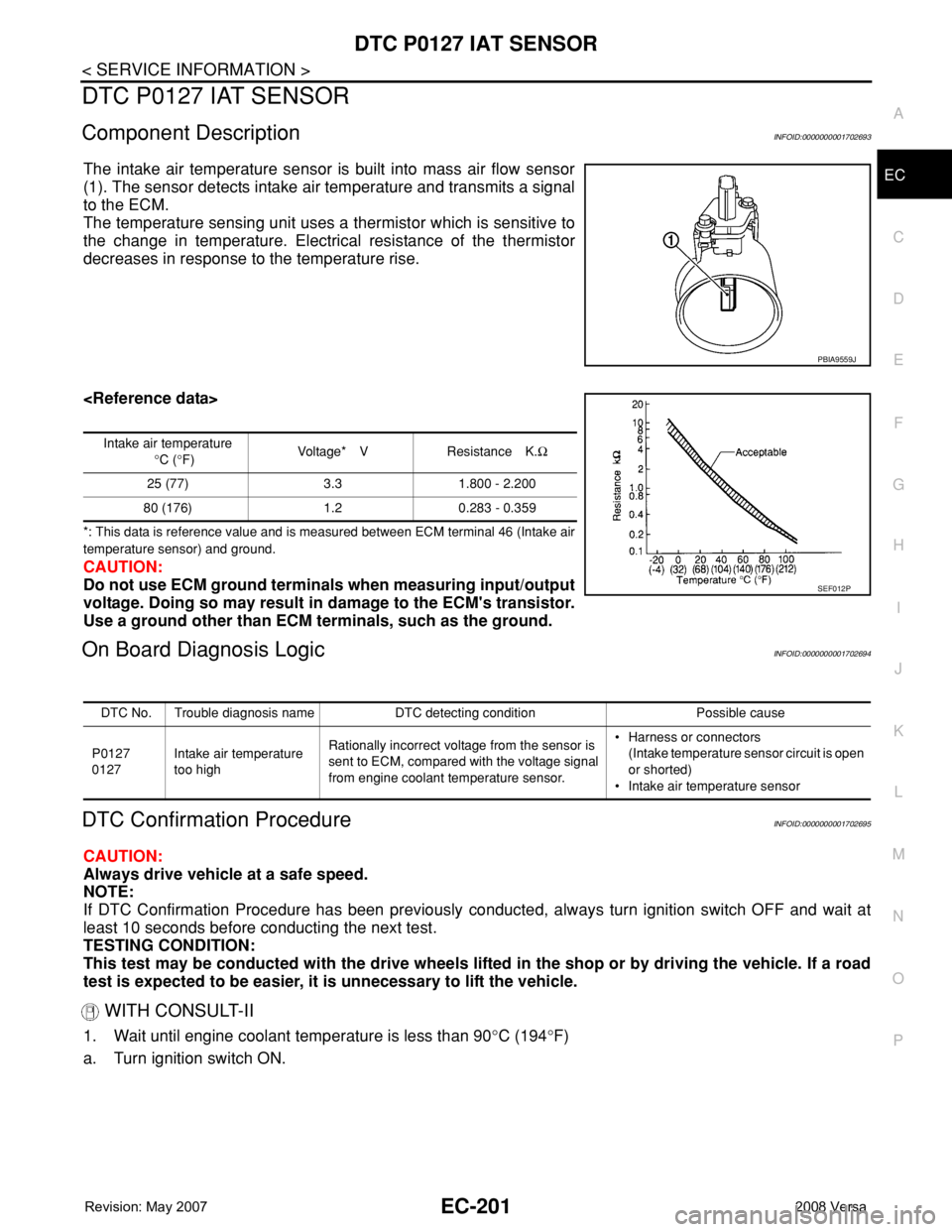

DTC P0127 IAT SENSOR

Component DescriptionINFOID:0000000001702693

The intake air temperature sensor is built into mass air flow sensor

(1). The sensor detects intake air temperature and transmits a signal

to the ECM.

The temperature sensing unit uses a thermistor which is sensitive to

the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

*: This data is reference value and is measured between ECM terminal 46 (Intake air

temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result in damage to the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicINFOID:0000000001702694

DTC Confirmation ProcedureINFOID:0000000001702695

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

This test may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a road

test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Wait until engine coolant temperature is less than 90°C (194°F)

a. Turn ignition switch ON.

PBIA9559J

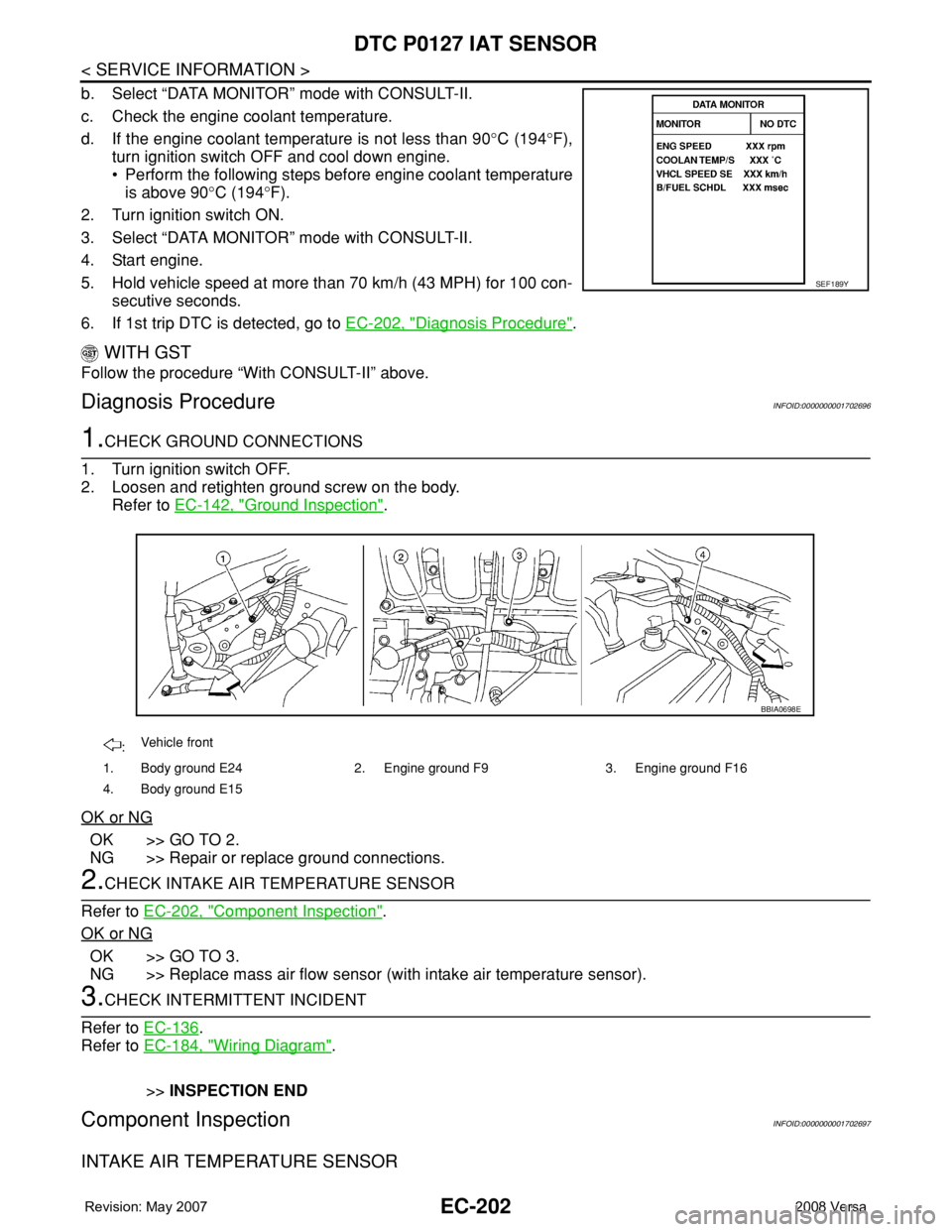

Intake air temperature

°C (°F)Voltage* V Resistance K.Ω

25 (77) 3.3 1.800 - 2.200

80 (176) 1.2 0.283 - 0.359

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0127

0127Intake air temperature

too highRationally incorrect voltage from the sensor is

sent to ECM, compared with the voltage signal

from engine coolant temperature sensor.• Harness or connectors

(Intake temperature sensor circuit is open

or shorted)

• Intake air temperature sensor

Page 1276 of 2771

EC-202

< SERVICE INFORMATION >

DTC P0127 IAT SENSOR

b. Select “DATA MONITOR” mode with CONSULT-II.

c. Check the engine coolant temperature.

d. If the engine coolant temperature is not less than 90°C (194°F),

turn ignition switch OFF and cool down engine.

• Perform the following steps before engine coolant temperature

is above 90°C (194°F).

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Start engine.

5. Hold vehicle speed at more than 70 km/h (43 MPH) for 100 con-

secutive seconds.

6. If 1st trip DTC is detected, go to EC-202, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000001702696

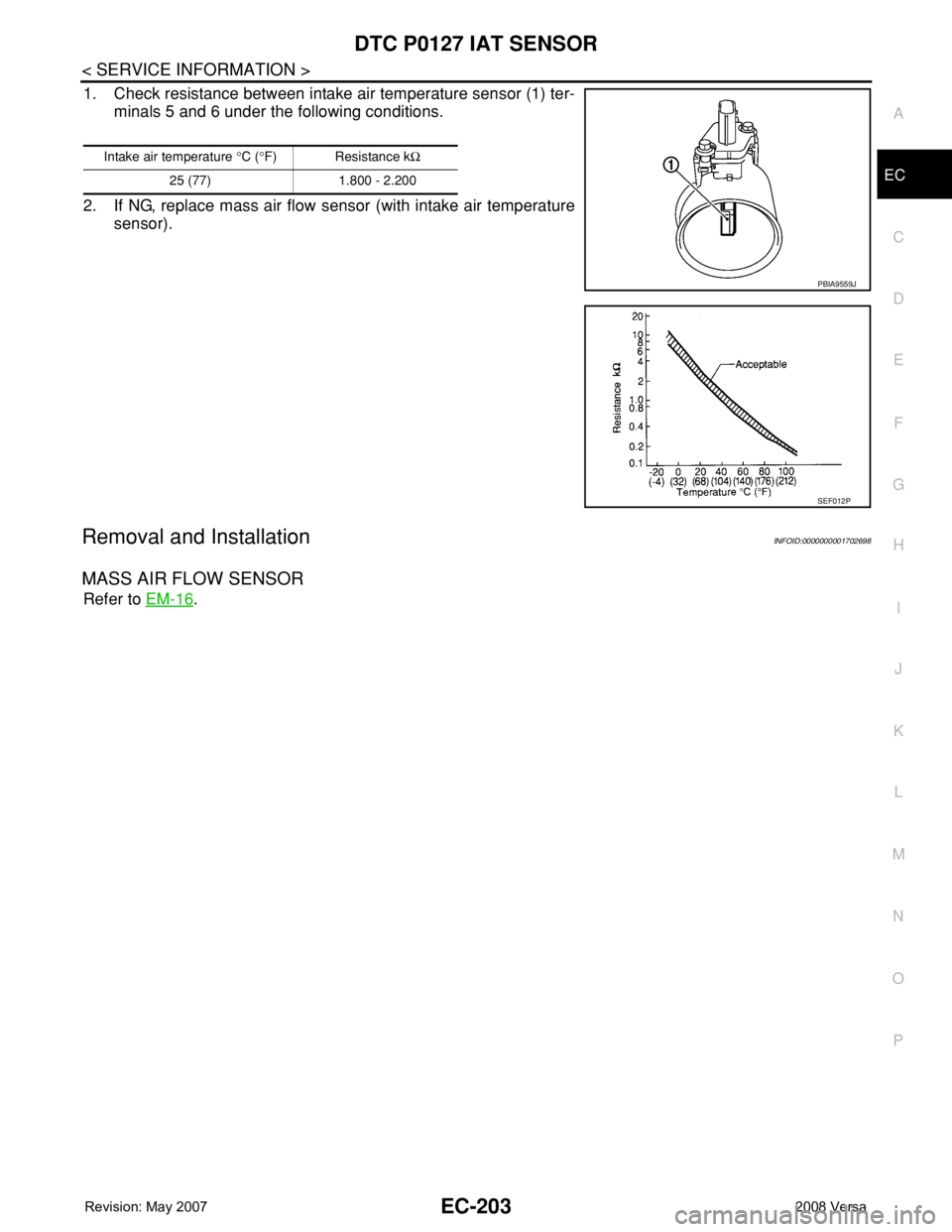

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK INTAKE AIR TEMPERATURE SENSOR

Refer to EC-202, "

Component Inspection".

OK or NG

OK >> GO TO 3.

NG >> Replace mass air flow sensor (with intake air temperature sensor).

3.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

Refer to EC-184, "

Wiring Diagram".

>>INSPECTION END

Component InspectionINFOID:0000000001702697

INTAKE AIR TEMPERATURE SENSOR

SEF189Y

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Page 1277 of 2771

DTC P0127 IAT SENSOR

EC-203

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

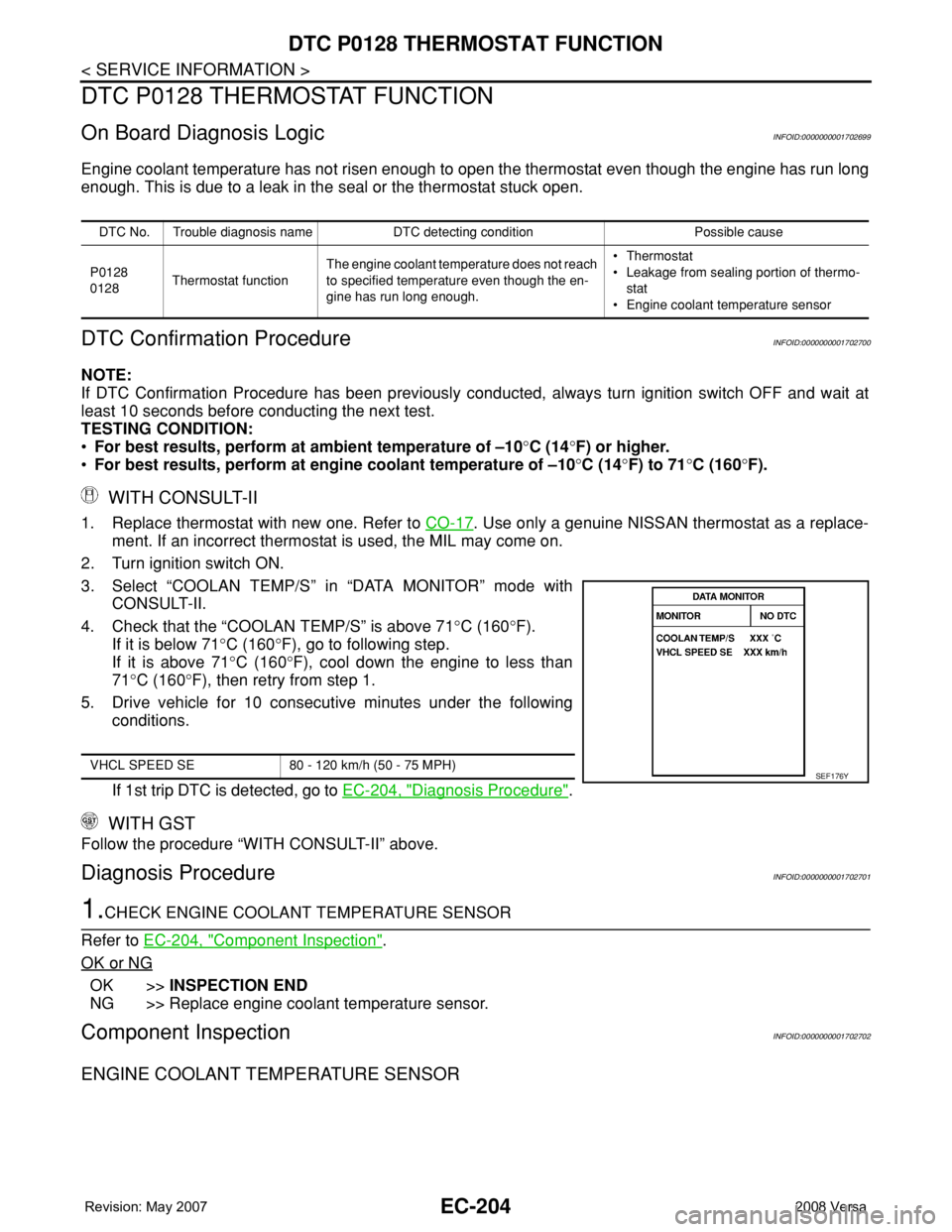

1. Check resistance between intake air temperature sensor (1) ter-

minals 5 and 6 under the following conditions.

2. If NG, replace mass air flow sensor (with intake air temperature

sensor).

Removal and InstallationINFOID:0000000001702698

MASS AIR FLOW SENSOR

Refer to EM-16.

Intake air temperature °C (°F) Resistance kΩ

25 (77) 1.800 - 2.200

PBIA9559J

SEF012P

Page 1278 of 2771

EC-204

< SERVICE INFORMATION >

DTC P0128 THERMOSTAT FUNCTION

DTC P0128 THERMOSTAT FUNCTION

On Board Diagnosis LogicINFOID:0000000001702699

Engine coolant temperature has not risen enough to open the thermostat even though the engine has run long

enough. This is due to a leak in the seal or the thermostat stuck open.

DTC Confirmation ProcedureINFOID:0000000001702700

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

•For best results, perform at ambient temperature of –10°C (14°F) or higher.

•For best results, perform at engine coolant temperature of –10°C (14°F) to 71°C (160°F).

WITH CONSULT-II

1. Replace thermostat with new one. Refer to CO-17. Use only a genuine NISSAN thermostat as a replace-

ment. If an incorrect thermostat is used, the MIL may come on.

2. Turn ignition switch ON.

3. Select “COOLAN TEMP/S” in “DATA MONITOR” mode with

CONSULT-II.

4. Check that the “COOLAN TEMP/S” is above 71°C (160°F).

If it is below 71°C (160°F), go to following step.

If it is above 71°C (160°F), cool down the engine to less than

71°C (160°F), then retry from step 1.

5. Drive vehicle for 10 consecutive minutes under the following

conditions.

If 1st trip DTC is detected, go to EC-204, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000001702701

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-204, "

Component Inspection".

OK or NG

OK >>INSPECTION END

NG >> Replace engine coolant temperature sensor.

Component InspectionINFOID:0000000001702702

ENGINE COOLANT TEMPERATURE SENSOR

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0128

0128Thermostat functionThe engine coolant temperature does not reach

to specified temperature even though the en-

gine has run long enough.•Thermostat

• Leakage from sealing portion of thermo-

stat

• Engine coolant temperature sensor

VHCL SPEED SE 80 - 120 km/h (50 - 75 MPH)SEF176Y

Page 1279 of 2771

DTC P0128 THERMOSTAT FUNCTION

EC-205

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

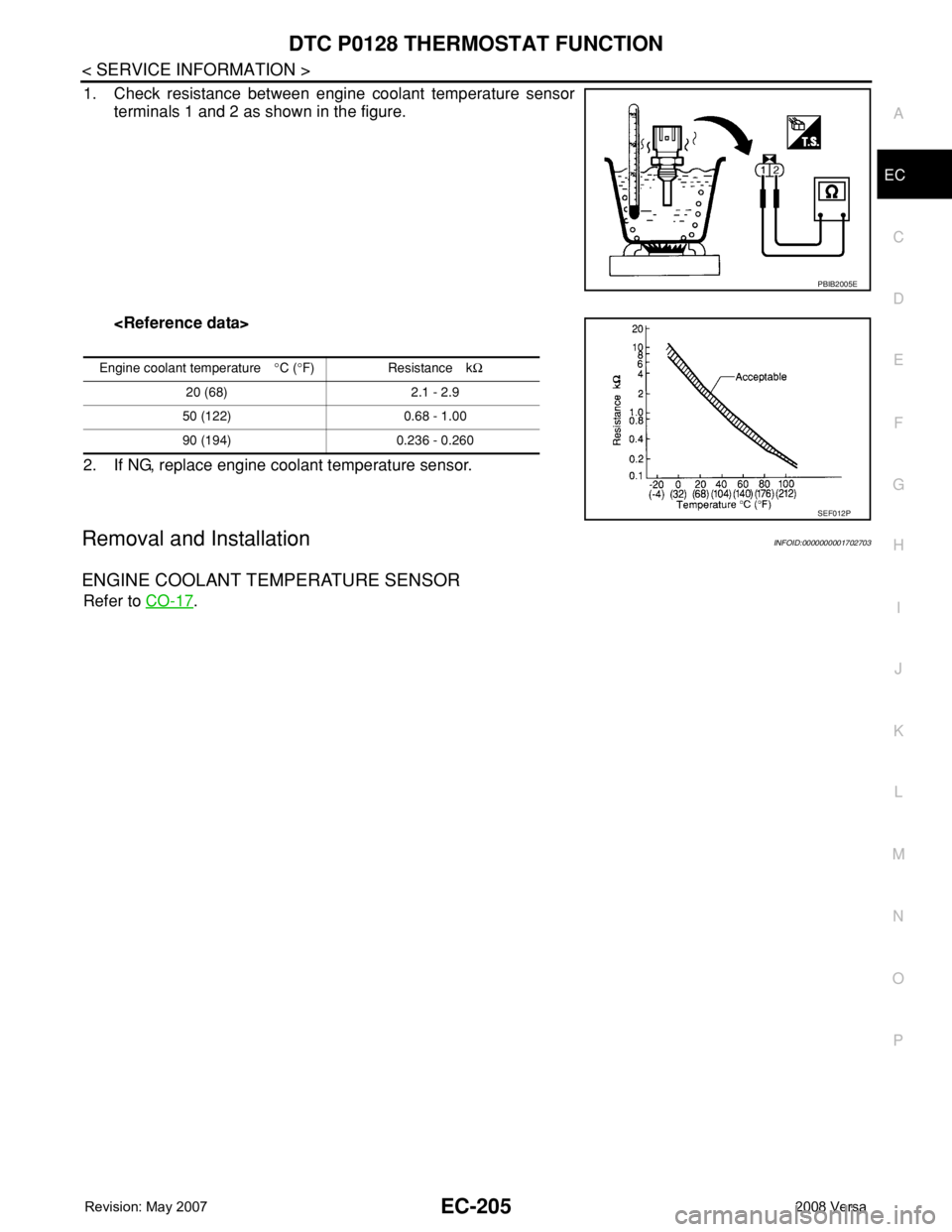

1. Check resistance between engine coolant temperature sensor

terminals 1 and 2 as shown in the figure.

2. If NG, replace engine coolant temperature sensor.

Removal and InstallationINFOID:0000000001702703

ENGINE COOLANT TEMPERATURE SENSOR

Refer to CO-17.

PBIB2005E

Engine coolant temperature°C (°F) Resistance kΩ

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

SEF012P

Page 1280 of 2771

EC-206

< SERVICE INFORMATION >

DTC P0130 A/F SENSOR 1

DTC P0130 A/F SENSOR 1

Component DescriptionINFOID:0000000001702704

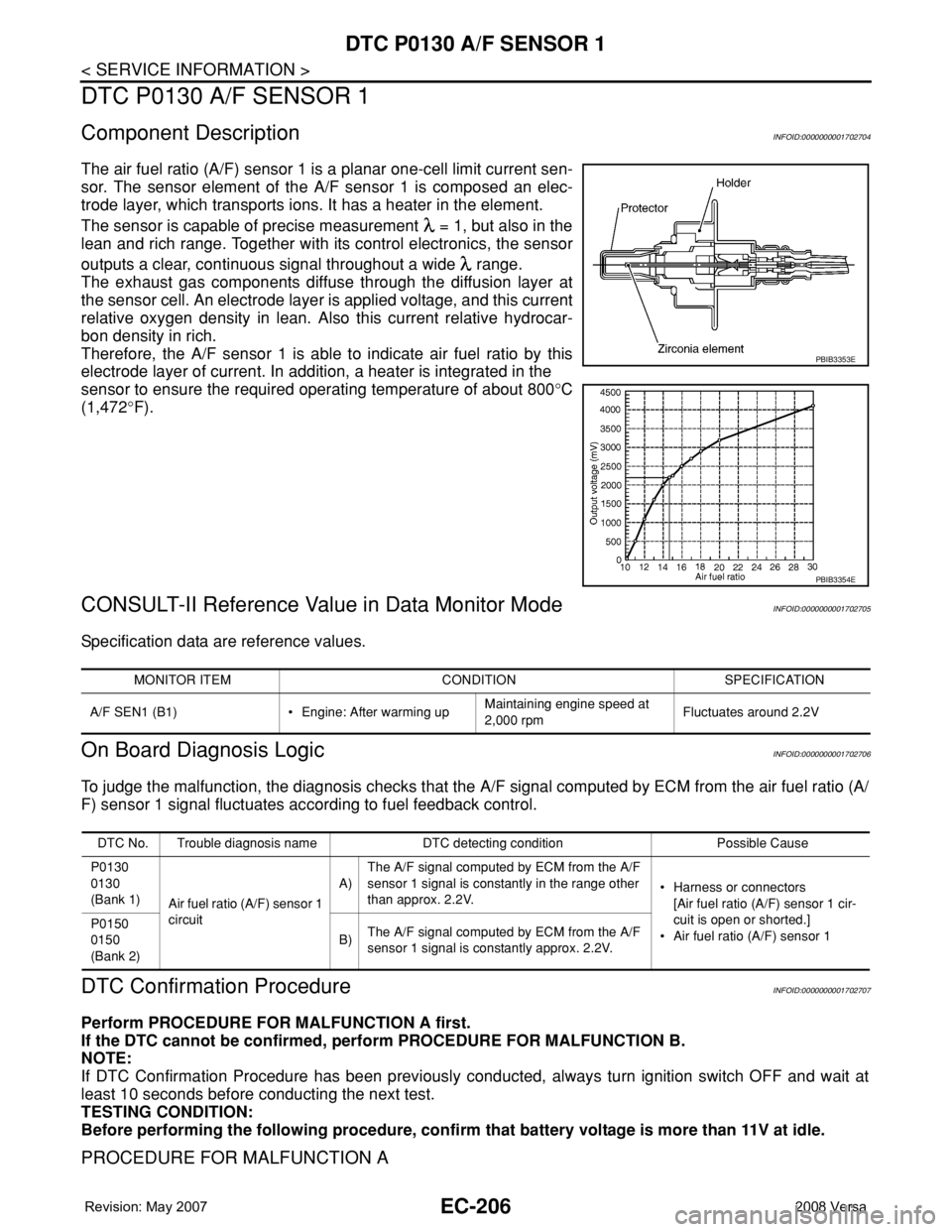

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800°C

(1,472°F).

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702705

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702706

To judge the malfunction, the diagnosis checks that the A/F signal computed by ECM from the air fuel ratio (A/

F) sensor 1 signal fluctuates according to fuel feedback control.

DTC Confirmation ProcedureINFOID:0000000001702707

Perform PROCEDURE FOR MALFUNCTION A first.

If the DTC cannot be confirmed, perform PROCEDURE FOR MALFUNCTION B.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

PROCEDURE FOR MALFUNCTION A

PBIB3353E

PBIB3354E

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1) • Engine: After warming upMaintaining engine speed at

2,000 rpmFluctuates around 2.2V

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0130

0130

(Bank 1)

Air fuel ratio (A/F) sensor 1

circuitA)The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly in the range other

than approx. 2.2V.• Harness or connectors

[Air fuel ratio (A/F) sensor 1 cir-

cuit is open or shorted.]

• Air fuel ratio (A/F) sensor 1 P0150

0150

(Bank 2)B)The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly approx. 2.2V.