NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1421 of 2771

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

EC-347

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

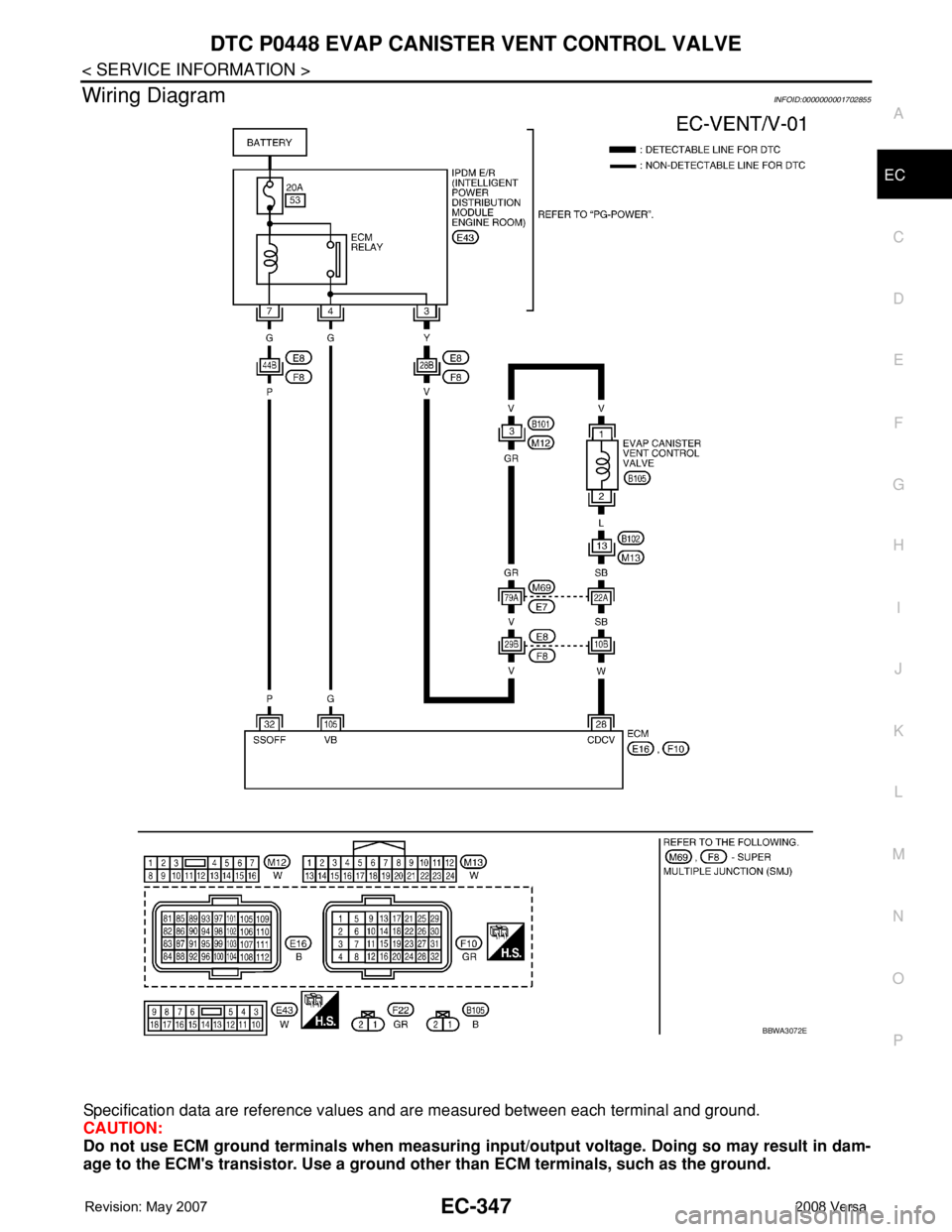

Wiring DiagramINFOID:0000000001702855

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBWA3072E

Page 1422 of 2771

EC-348

< SERVICE INFORMATION >

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

Diagnosis Procedure

INFOID:0000000001702856

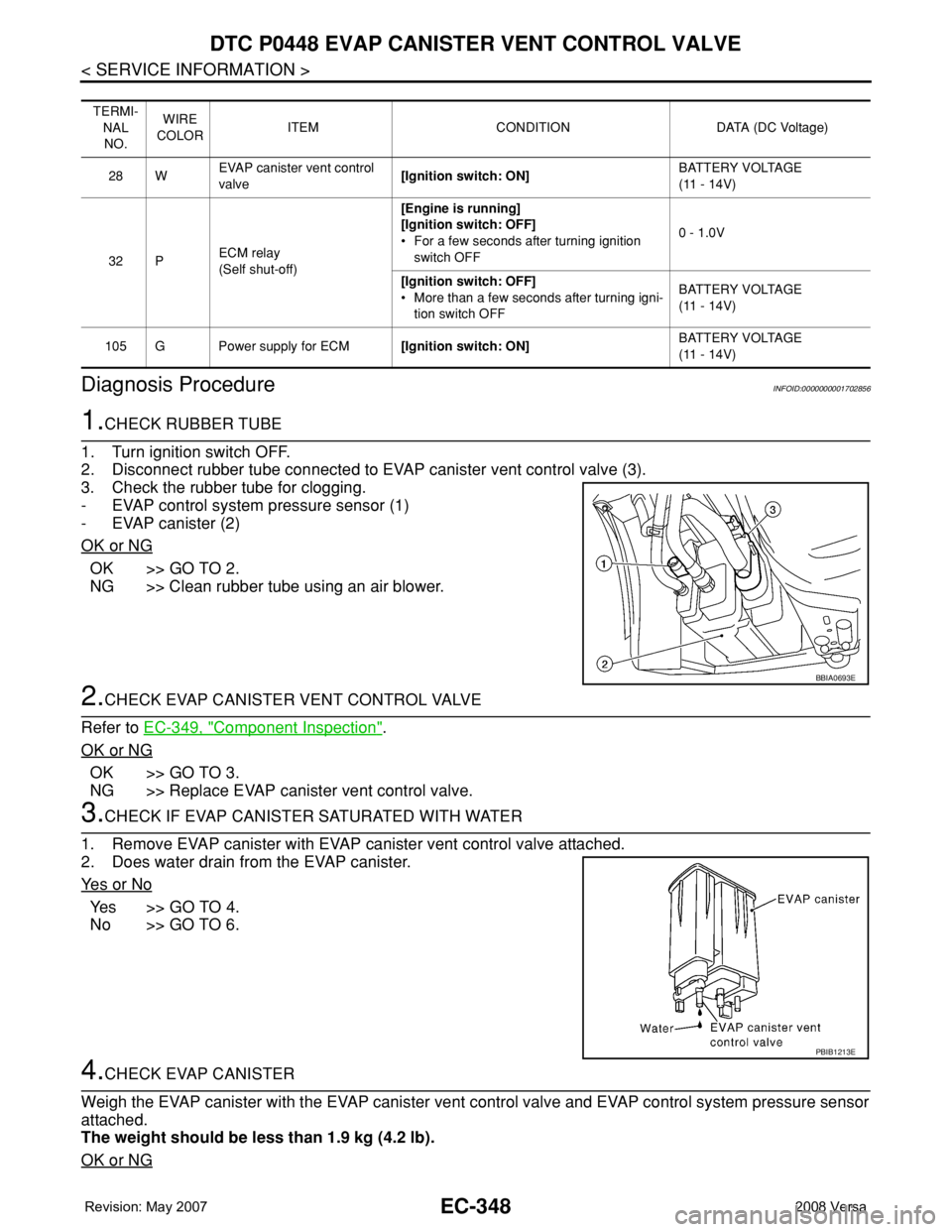

1.CHECK RUBBER TUBE

1. Turn ignition switch OFF.

2. Disconnect rubber tube connected to EVAP canister vent control valve (3).

3. Check the rubber tube for clogging.

- EVAP control system pressure sensor (1)

- EVAP canister (2)

OK or NG

OK >> GO TO 2.

NG >> Clean rubber tube using an air blower.

2.CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-349, "

Component Inspection".

OK or NG

OK >> GO TO 3.

NG >> Replace EVAP canister vent control valve.

3.CHECK IF EVAP CANISTER SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve attached.

2. Does water drain from the EVAP canister.

Ye s o r N o

Ye s > > G O T O 4 .

No >> GO TO 6.

4.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

OK or NG

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

28 WEVAP canister vent control

valve[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0693E

PBIB1213E

Page 1423 of 2771

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

EC-349

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister.

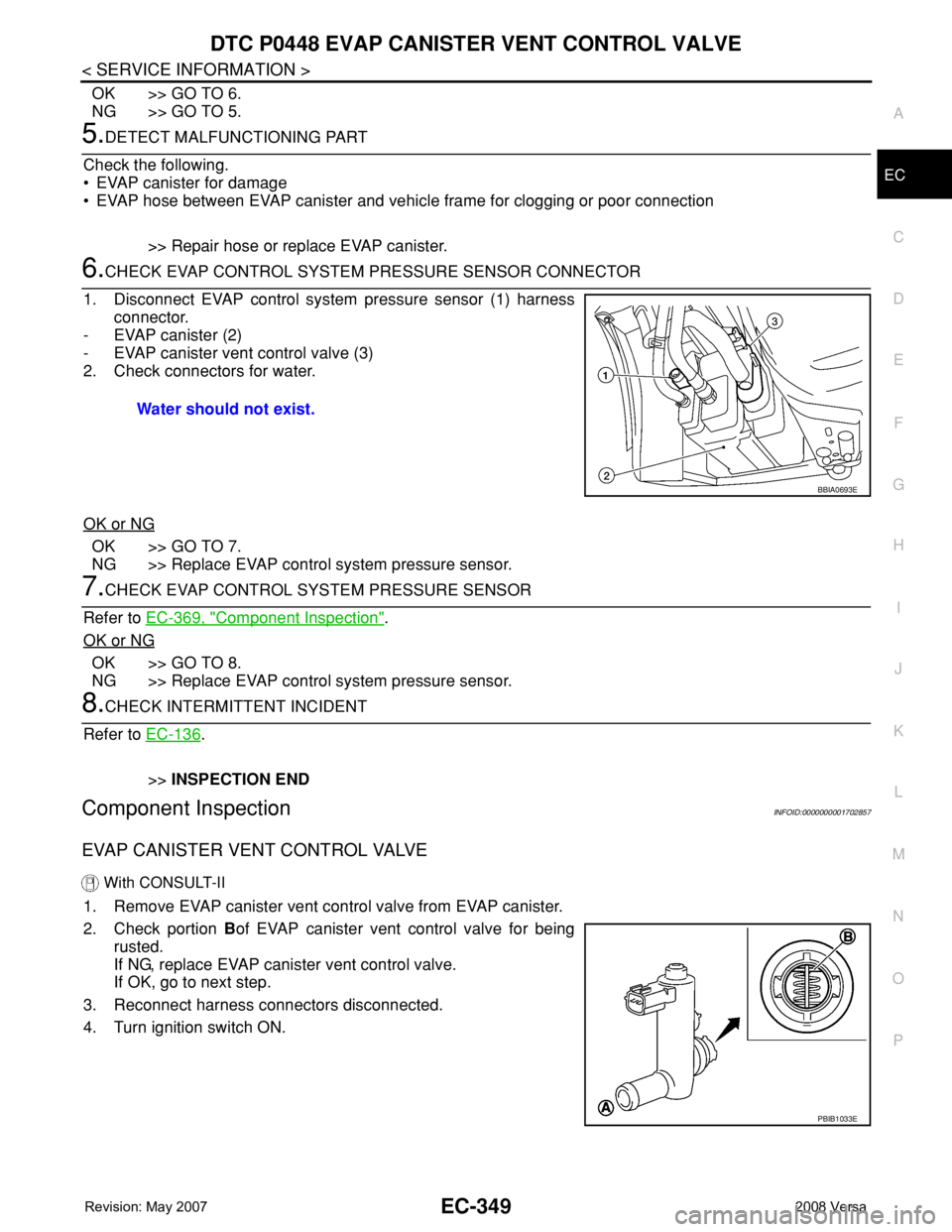

6.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor (1) harness

connector.

- EVAP canister (2)

- EVAP canister vent control valve (3)

2. Check connectors for water.

OK or NG

OK >> GO TO 7.

NG >> Replace EVAP control system pressure sensor.

7.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-369, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace EVAP control system pressure sensor.

8.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

Component InspectionINFOID:0000000001702857

EVAP CANISTER VENT CONTROL VALVE

With CONSULT-II

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portion Bof EVAP canister vent control valve for being

rusted.

If NG, replace EVAP canister vent control valve.

If OK, go to next step.

3. Reconnect harness connectors disconnected.

4. Turn ignition switch ON.Water should not exist.

BBIA0693E

PBIB1033E

Page 1424 of 2771

EC-350

< SERVICE INFORMATION >

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

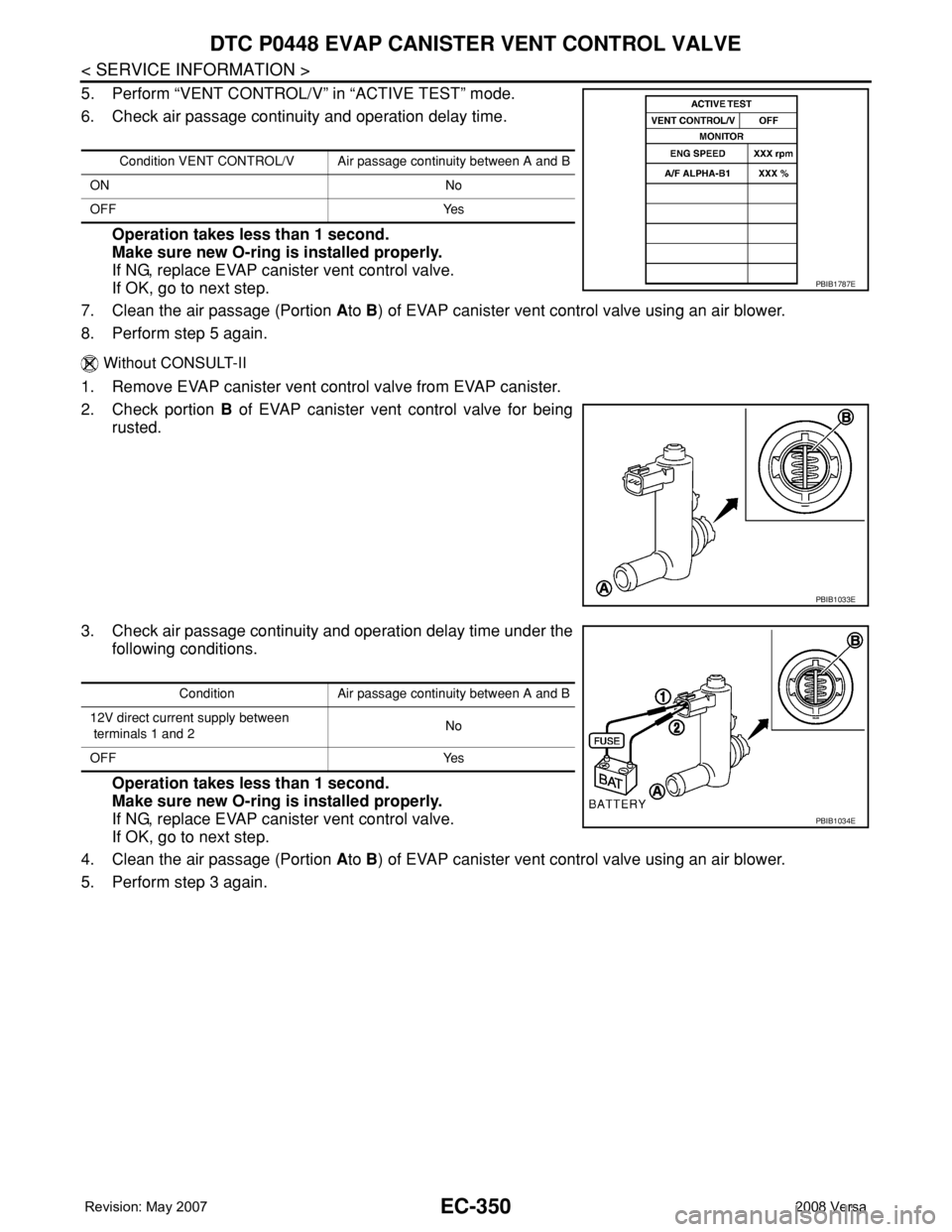

5. Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

6. Check air passage continuity and operation delay time.

Operation takes less than 1 second.

Make sure new O-ring is installed properly.

If NG, replace EVAP canister vent control valve.

If OK, go to next step.

7. Clean the air passage (Portion Ato B) of EVAP canister vent control valve using an air blower.

8. Perform step 5 again.

Without CONSULT-II

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portion B of EVAP canister vent control valve for being

rusted.

3. Check air passage continuity and operation delay time under the

following conditions.

Operation takes less than 1 second.

Make sure new O-ring is installed properly.

If NG, replace EVAP canister vent control valve.

If OK, go to next step.

4. Clean the air passage (Portion Ato B) of EVAP canister vent control valve using an air blower.

5. Perform step 3 again.

Condition VENT CONTROL/V Air passage continuity between A and B

ON No

OFF Yes

PBIB1787E

PBIB1033E

Condition Air passage continuity between A and B

12V direct current supply between

terminals 1 and 2No

OFF Yes

PBIB1034E

Page 1425 of 2771

DTC P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-351

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

Component DescriptionINFOID:0000000001702858

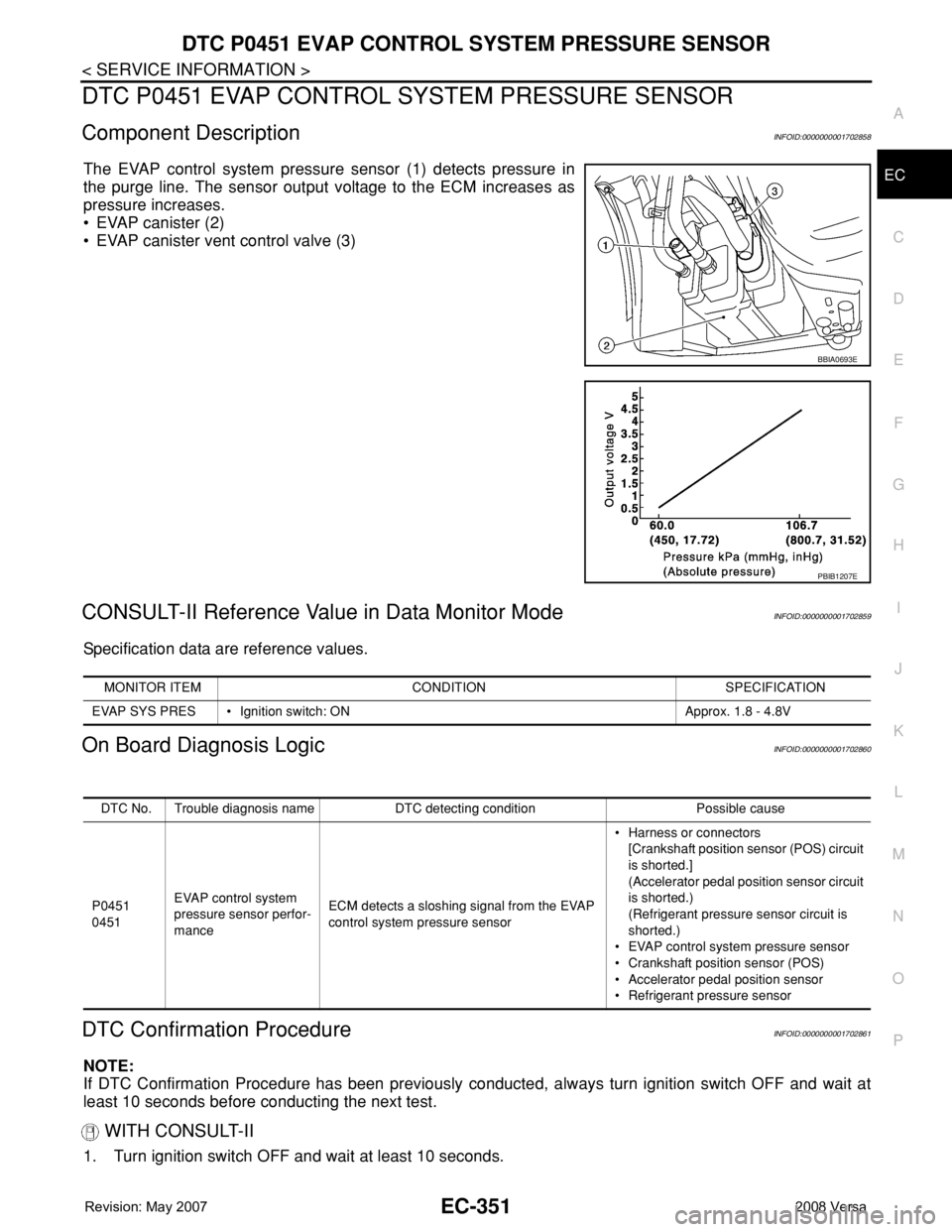

The EVAP control system pressure sensor (1) detects pressure in

the purge line. The sensor output voltage to the ECM increases as

pressure increases.

• EVAP canister (2)

• EVAP canister vent control valve (3)

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702859

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702860

DTC Confirmation ProcedureINFOID:0000000001702861

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch OFF and wait at least 10 seconds.

BBIA0693E

PBIB1207E

MONITOR ITEM CONDITION SPECIFICATION

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8V

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0451

0451EVAP control system

pressure sensor perfor-

manceECM detects a sloshing signal from the EVAP

control system pressure sensor• Harness or connectors

[Crankshaft position sensor (POS) circuit

is shorted.]

(Accelerator pedal position sensor circuit

is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

• EVAP control system pressure sensor

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

Page 1426 of 2771

EC-352

< SERVICE INFORMATION >

DTC P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

2. Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

3. Start engine and wait at least 40 seconds.

NOTE:

Do not depress accelerator pedal even slightly.

If 1st trip DTC is detected, go to EC-352, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000001702862

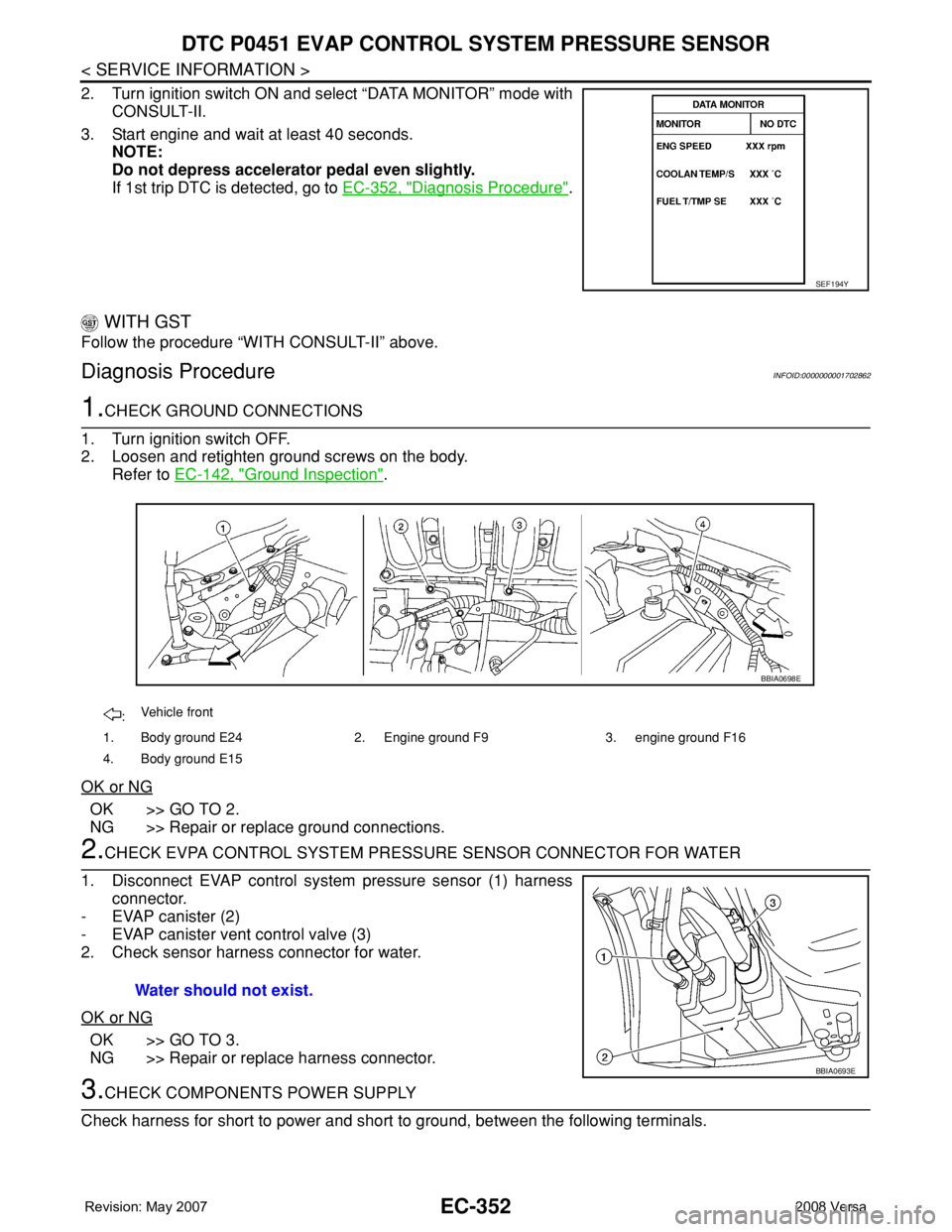

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK EVPA CONTROL SYSTEM PRESSURE SENSOR CONNECTOR FOR WATER

1. Disconnect EVAP control system pressure sensor (1) harness

connector.

- EVAP canister (2)

- EVAP canister vent control valve (3)

2. Check sensor harness connector for water.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness connector.

3.CHECK COMPONENTS POWER SUPPLY

Check harness for short to power and short to ground, between the following terminals.

SEF194Y

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. engine ground F16

4. Body ground E15

BBIA0698E

Water should not exist.

BBIA0693E

Page 1427 of 2771

DTC P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-353

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

OK or NG

OK >> GO TO 4.

NG >> Repair short to ground or short to power in harness or connectors.

4.CHECK COMPONENTS

Check the following.

• Refrigerant pressure sensor (Refer to MTC-22

.)

• Crankshaft position sensor (POS) (Refer to EC-301, "

Component Inspection".)

OK or NG

OK >> GO TO 5.

NG >> Replace malfunctioning components.

5.CHECK APP SENSOR

Refer to EC-485, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-76, "

Accelerator Pedal Released Position Learning".

3. Perform EC-76, "

Throttle Valve Closed Position Learning".

4. Perform EC-76, "

Idle Air Volume Learning".

>>INSPECTION END

7.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-353, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace EVAP control system pressure sensor.

8.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

For wiring diagram, refer to EC-357, "

Wiring Diagram".

>>INSPECTION END

Component InspectionINFOID:0000000001702863

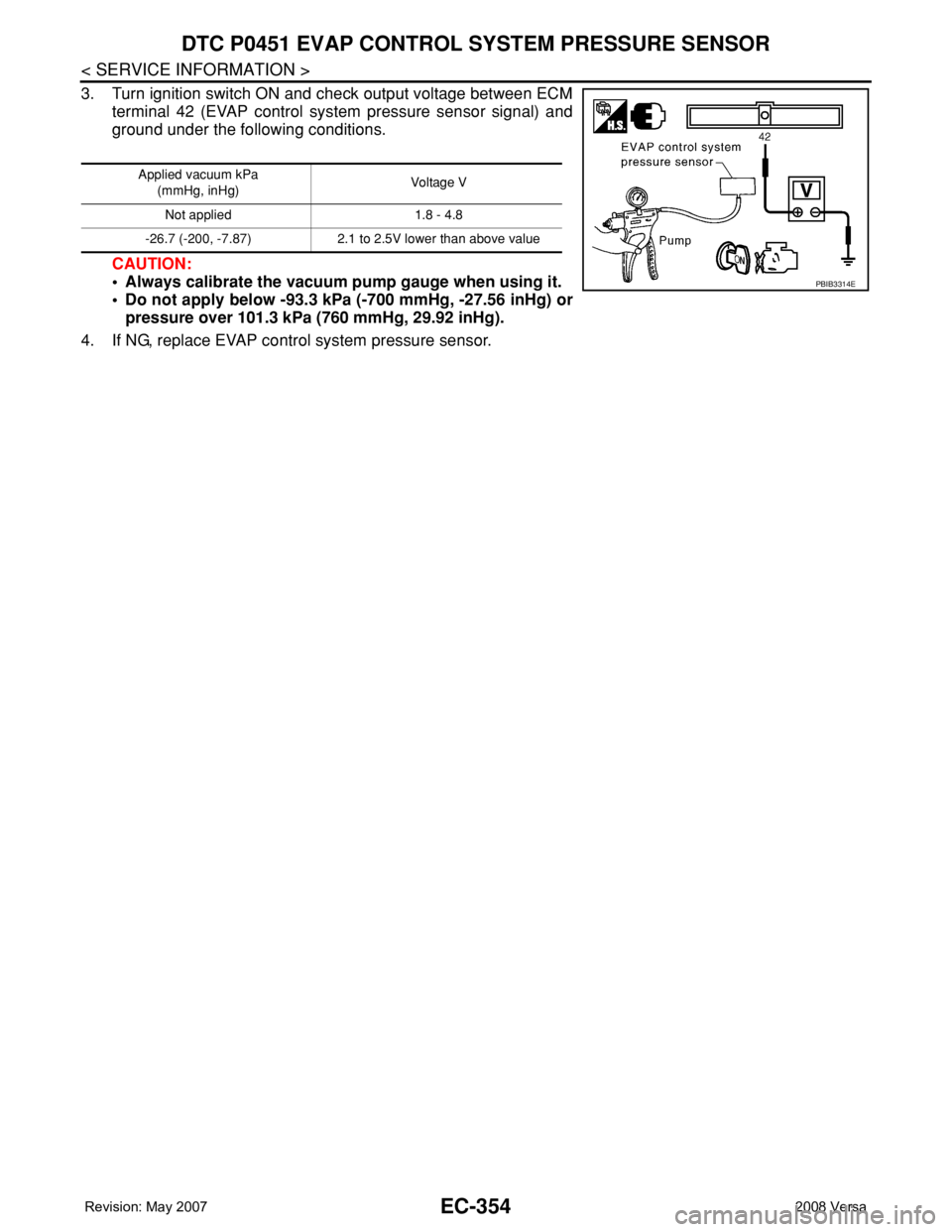

EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Remove EVAP control system pressure sensor with its harness connector connected from EVAP canister.

Always replace O-ring with a new one.

2. Install a vacuum pump to EVAP control system pressure sensor.

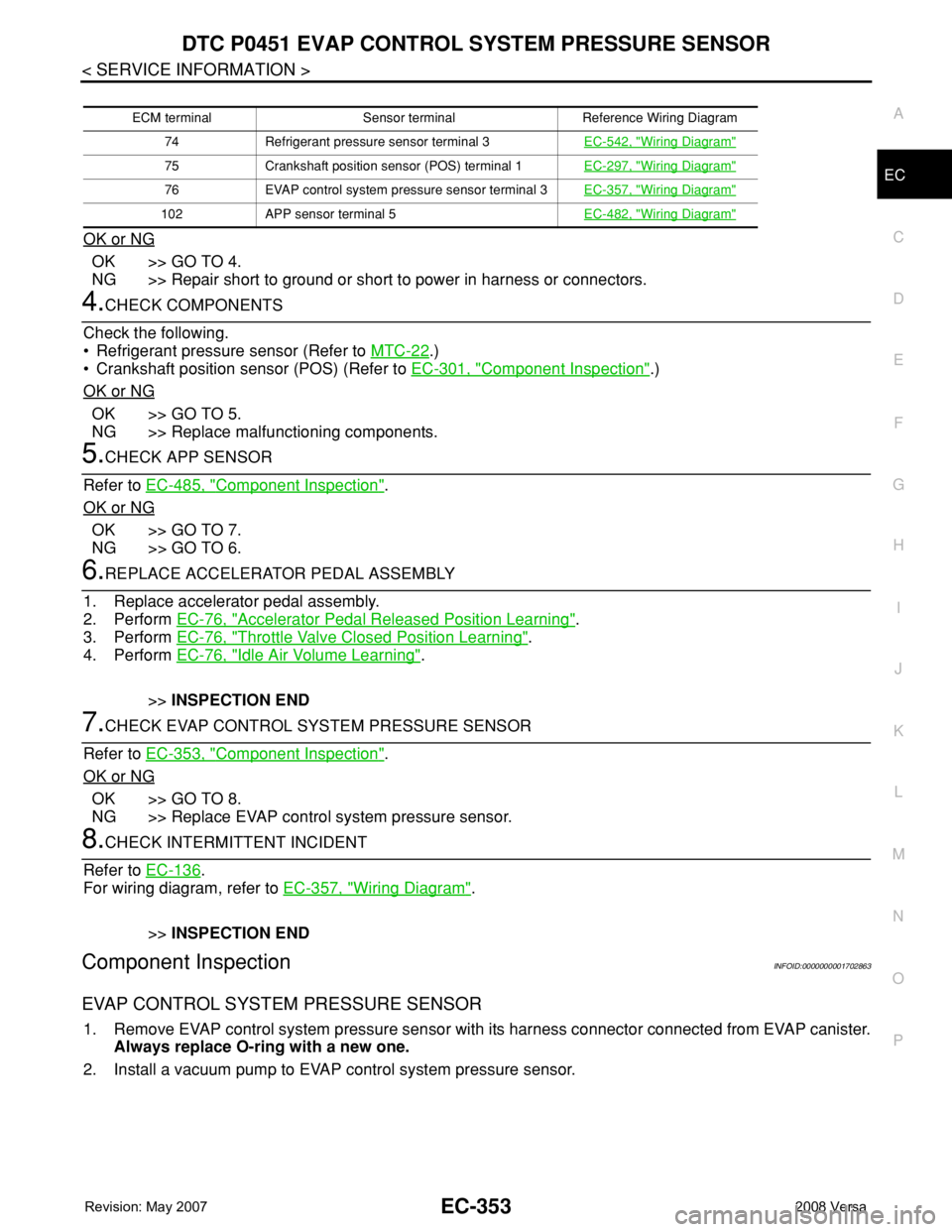

ECM terminal Sensor terminal Reference Wiring Diagram

74 Refrigerant pressure sensor terminal 3EC-542, "

Wiring Diagram"

75 Crankshaft position sensor (POS) terminal 1EC-297, "Wiring Diagram"

76 EVAP control system pressure sensor terminal 3EC-357, "Wiring Diagram"

102 APP sensor terminal 5EC-482, "Wiring Diagram"

Page 1428 of 2771

EC-354

< SERVICE INFORMATION >

DTC P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

3. Turn ignition switch ON and check output voltage between ECM

terminal 42 (EVAP control system pressure sensor signal) and

ground under the following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Do not apply below -93.3 kPa (-700 mmHg, -27.56 inHg) or

pressure over 101.3 kPa (760 mmHg, 29.92 inHg).

4. If NG, replace EVAP control system pressure sensor.

Applied vacuum kPa

(mmHg, inHg)Voltage V

Not applied 1.8 - 4.8

-26.7 (-200, -7.87) 2.1 to 2.5V lower than above value

PBIB3314E

Page 1429 of 2771

DTC P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-355

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

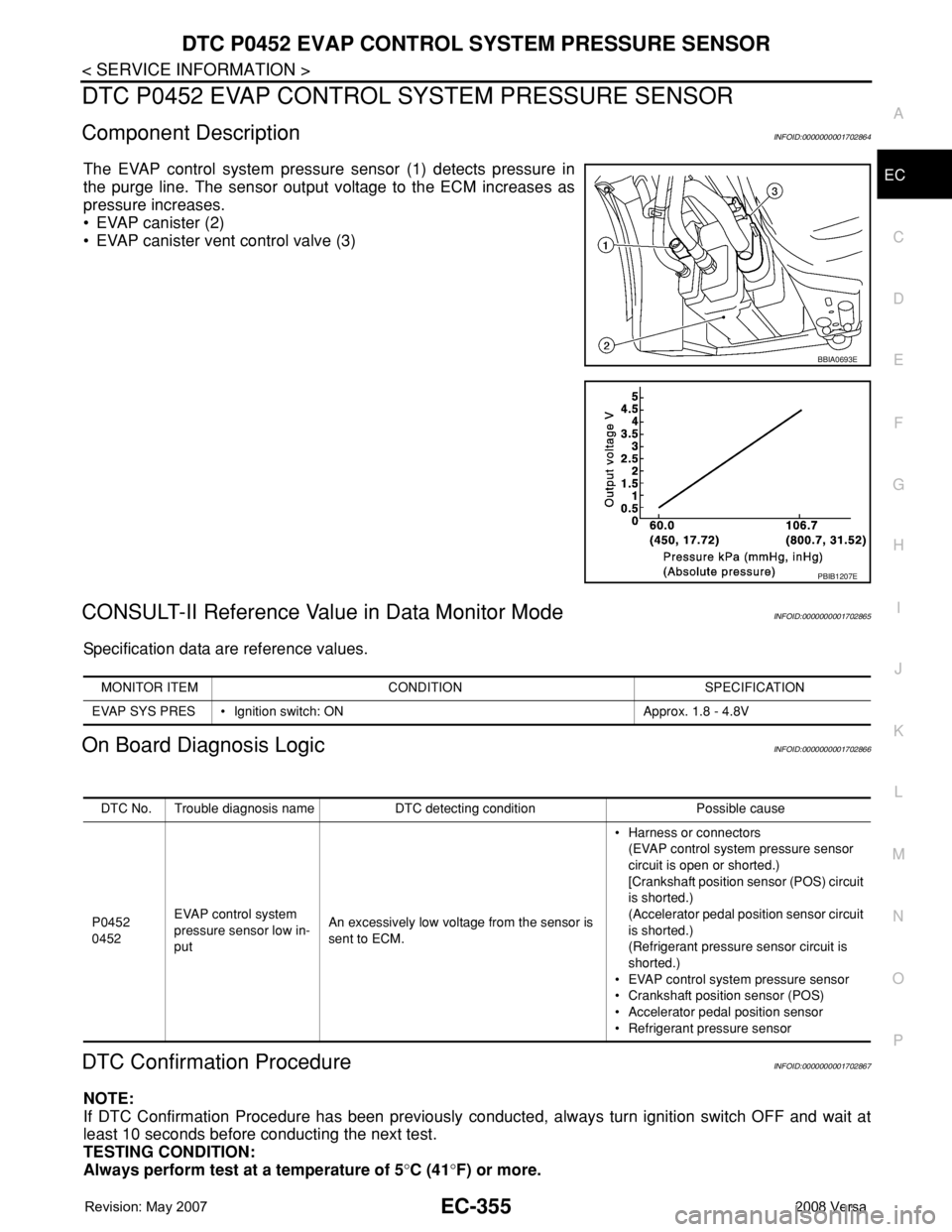

Component DescriptionINFOID:0000000001702864

The EVAP control system pressure sensor (1) detects pressure in

the purge line. The sensor output voltage to the ECM increases as

pressure increases.

• EVAP canister (2)

• EVAP canister vent control valve (3)

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702865

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702866

DTC Confirmation ProcedureINFOID:0000000001702867

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Always perform test at a temperature of 5°C (41°F) or more.

BBIA0693E

PBIB1207E

MONITOR ITEM CONDITION SPECIFICATION

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8V

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0452

0452EVAP control system

pressure sensor low in-

putAn excessively low voltage from the sensor is

sent to ECM.• Harness or connectors

(EVAP control system pressure sensor

circuit is open or shorted.)

[Crankshaft position sensor (POS) circuit

is shorted.)

(Accelerator pedal position sensor circuit

is shorted.)

(Refrigerant pressure sensor circuit is

shorted.)

• EVAP control system pressure sensor

• Crankshaft position sensor (POS)

• Accelerator pedal position sensor

• Refrigerant pressure sensor

Page 1430 of 2771

EC-356

< SERVICE INFORMATION >

DTC P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

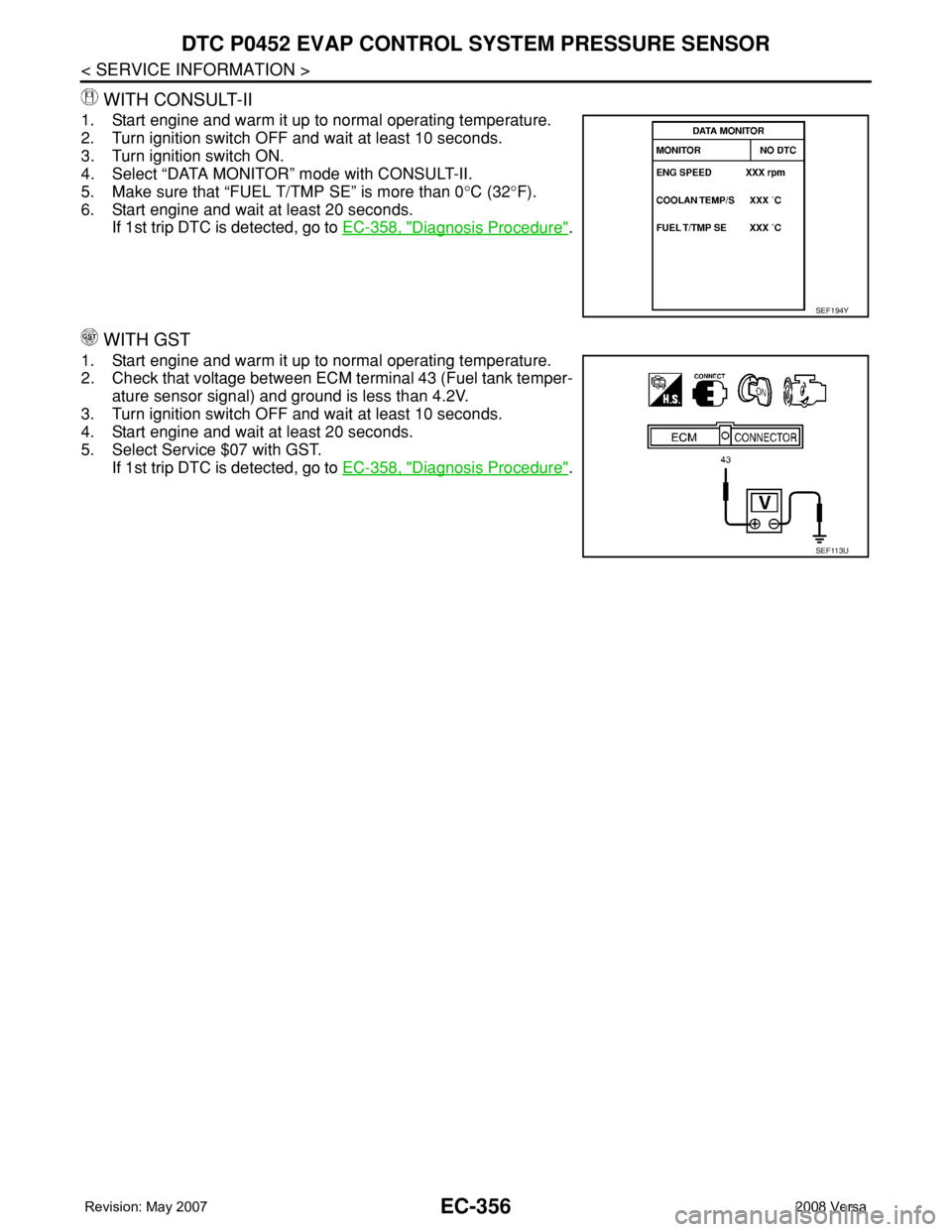

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Select “DATA MONITOR” mode with CONSULT-II.

5. Make sure that “FUEL T/TMP SE” is more than 0°C (32°F).

6. Start engine and wait at least 20 seconds.

If 1st trip DTC is detected, go to EC-358, "

Diagnosis Procedure".

WITH GST

1. Start engine and warm it up to normal operating temperature.

2. Check that voltage between ECM terminal 43 (Fuel tank temper-

ature sensor signal) and ground is less than 4.2V.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and wait at least 20 seconds.

5. Select Service $07 with GST.

If 1st trip DTC is detected, go to EC-358, "

Diagnosis Procedure".

SEF194Y

SEF113U