NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1591 of 2771

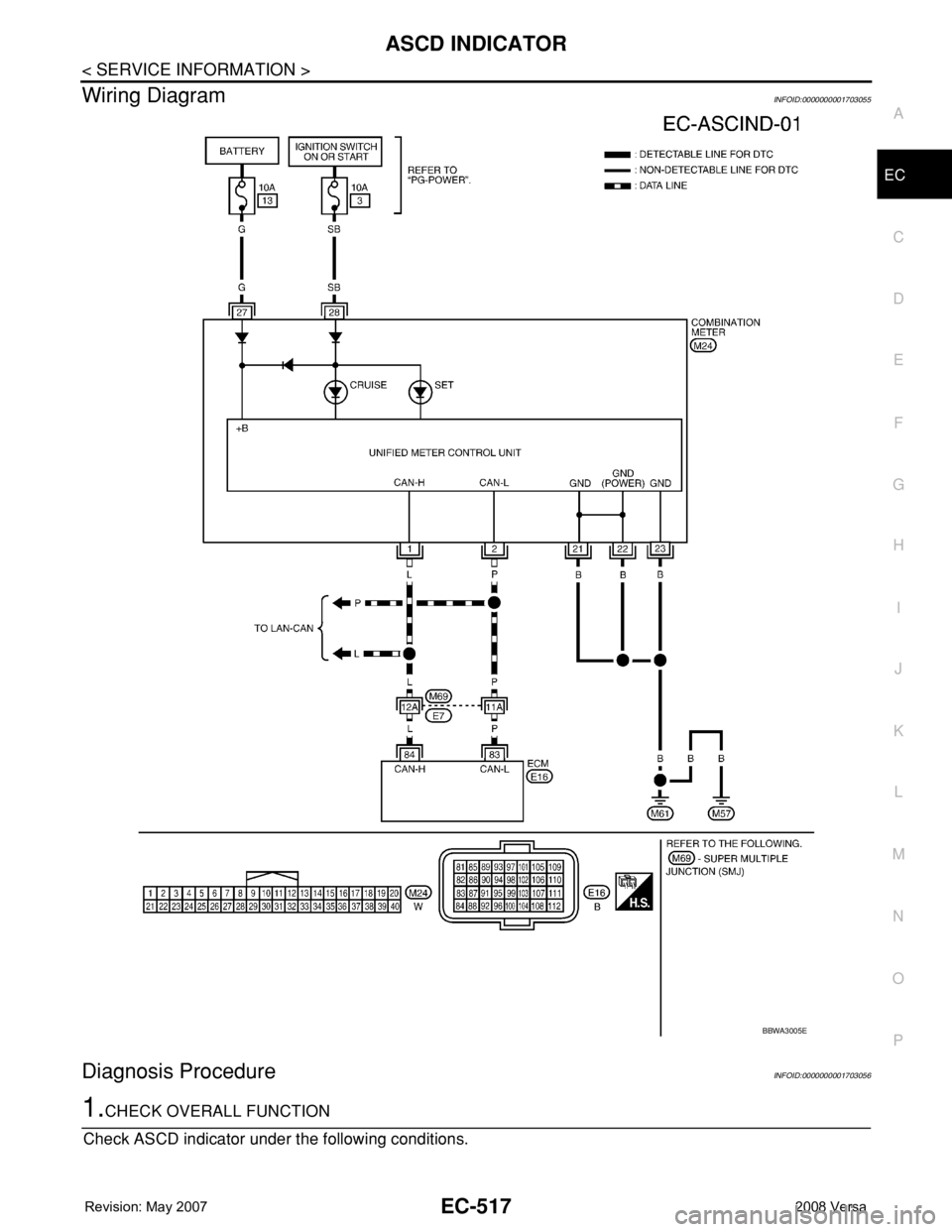

ASCD INDICATOR

EC-517

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Wiring DiagramINFOID:0000000001703055

Diagnosis ProcedureINFOID:0000000001703056

1.CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

BBWA3005E

Page 1592 of 2771

EC-518

< SERVICE INFORMATION >

ASCD INDICATOR

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC U1000 or U1001 is not displayed.

Ye s o r N o

Yes >> Perform trouble diagnoses for DTC U1000, U1001, refer to EC-143.

No >> GO TO 3.

3.CHECK COMBINATION METER OPERATION

Does combination meter operate normally?

Ye s o r N o

Ye s > > G O T O 4 .

No >> Check combination meter circuit. Refer to DI-4

.

4.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

ASCD INDICATOR CONDITION SPECIFICATION

CRUISE LAMP • Ignition switch: ONMAIN switch: Pressed at 1st

time → 2ndON → OFF

SET LAMP•MAIN switch: ON

• Vehicle: Between 40 km/h (25

MPH) and 144 km/h (89

MPH)ASCD: Operating ON

ASCD: Not operating OFF

Page 1593 of 2771

ELECTRICAL LOAD SIGNAL

EC-519

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

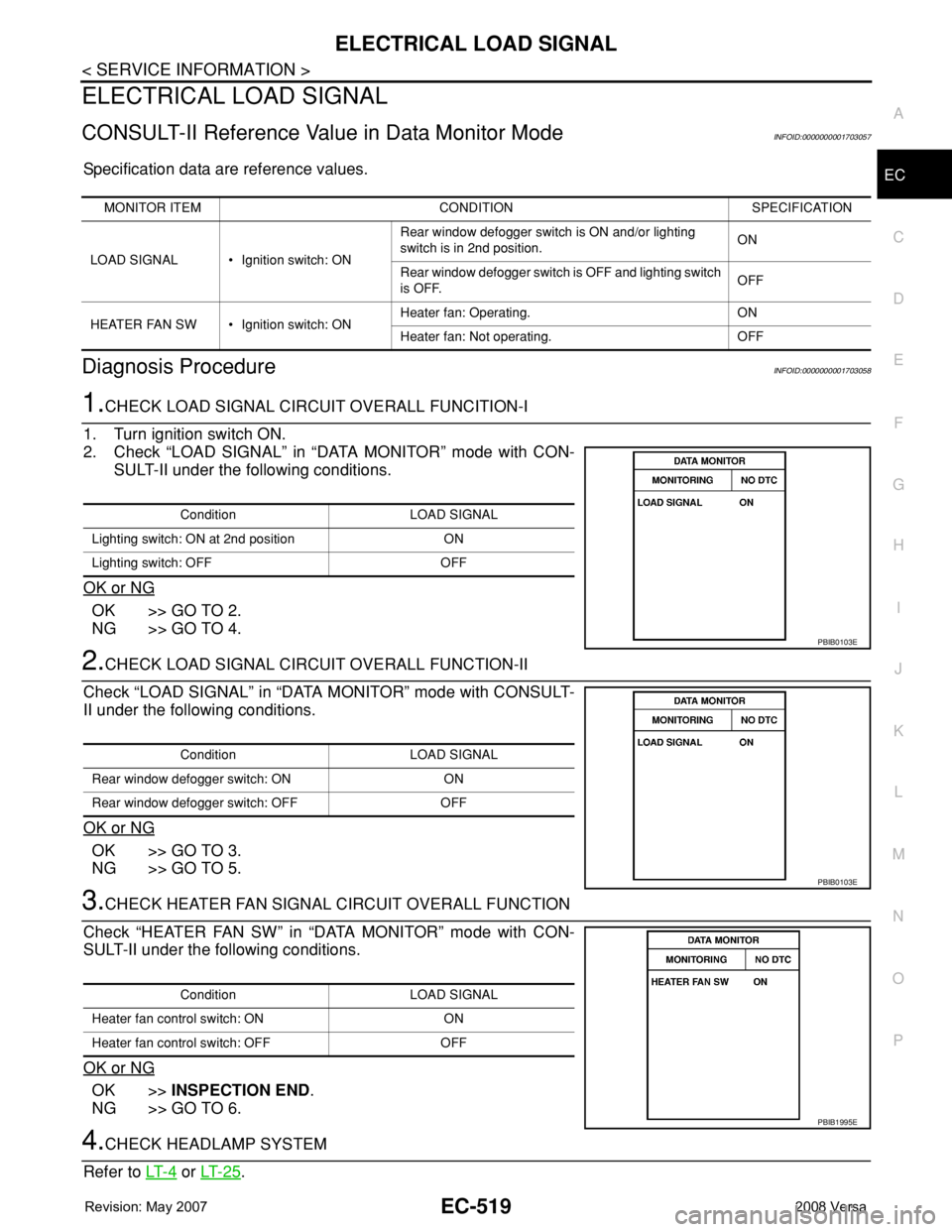

ELECTRICAL LOAD SIGNAL

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001703057

Specification data are reference values.

Diagnosis ProcedureINFOID:0000000001703058

1.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCITION-I

1. Turn ignition switch ON.

2. Check “LOAD SIGNAL” in “DATA MONITOR” mode with CON-

SULT-II under the following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Check “LOAD SIGNAL” in “DATA MONITOR” mode with CONSULT-

II under the following conditions.

OK or NG

OK >> GO TO 3.

NG >> GO TO 5.

3.CHECK HEATER FAN SIGNAL CIRCUIT OVERALL FUNCTION

Check “HEATER FAN SW” in “DATA MONITOR” mode with CON-

SULT-II under the following conditions.

OK or NG

OK >>INSPECTION END.

NG >> GO TO 6.

4.CHECK HEADLAMP SYSTEM

Refer to LT- 4

or LT- 2 5.

MONITOR ITEM CONDITION SPECIFICATION

LOAD SIGNAL • Ignition switch: ONRear window defogger switch is ON and/or lighting

switch is in 2nd position.ON

Rear window defogger switch is OFF and lighting switch

is OFF.OFF

HEATER FAN SW • Ignition switch: ONHeater fan: Operating. ON

Heater fan: Not operating. OFF

Condition LOAD SIGNAL

Lighting switch: ON at 2nd position ON

Lighting switch: OFF OFF

PBIB0103E

Condition LOAD SIGNAL

Rear window defogger switch: ON ON

Rear window defogger switch: OFF OFF

PBIB0103E

Condition LOAD SIGNAL

Heater fan control switch: ON ON

Heater fan control switch: OFF OFF

PBIB1995E

Page 1594 of 2771

EC-520

< SERVICE INFORMATION >

ELECTRICAL LOAD SIGNAL

>>INSPECTION END

5.CHECK REAR WINDOW DEFOGGER SYSTEM

Refer to GW-49

.

>>INSPECTION END

6.CHECK HEATER FAN CONTROL SYSTEM

Refer to MTC-22

.

>>INSPECTION END

Page 1595 of 2771

FUEL INJECTOR

EC-521

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

FUEL INJECTOR

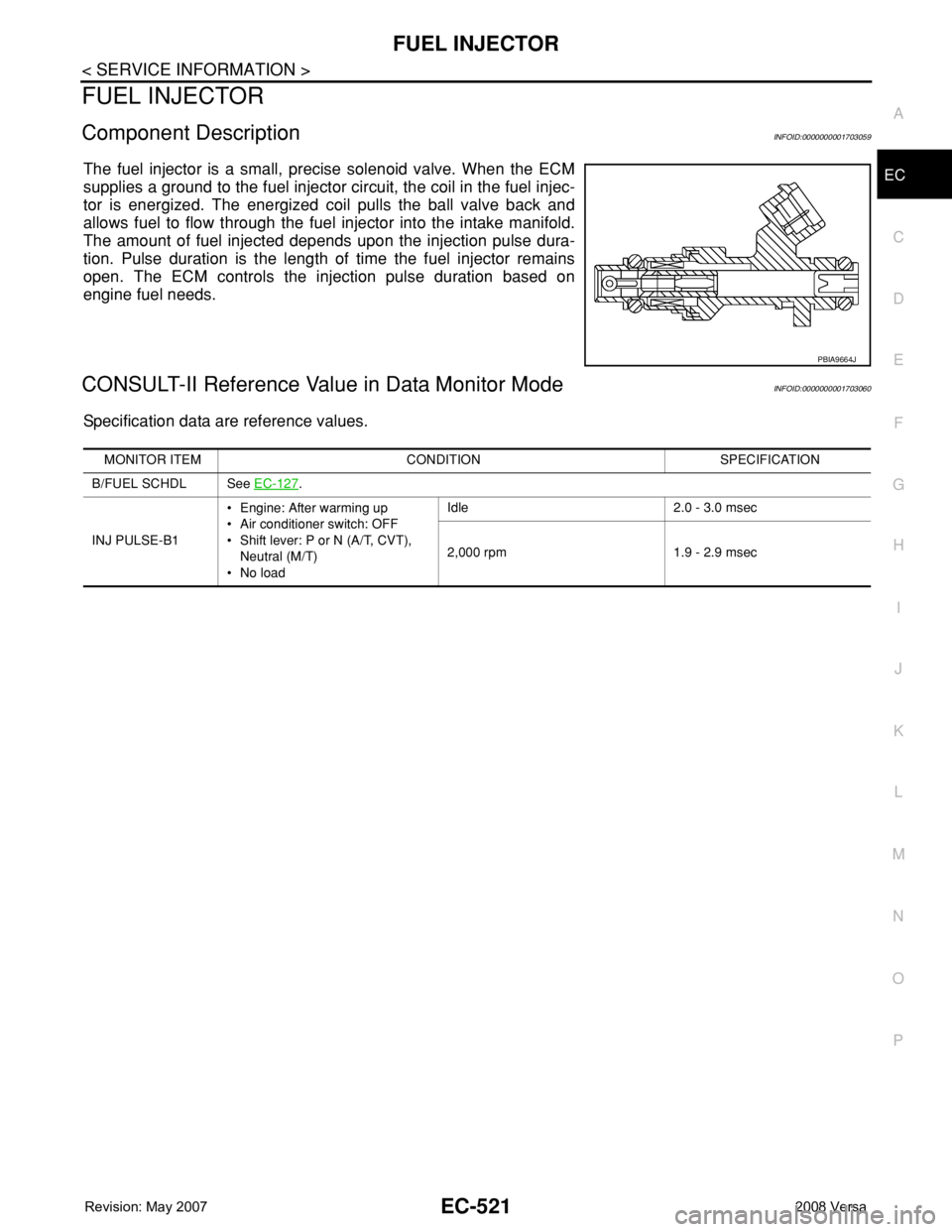

Component DescriptionINFOID:0000000001703059

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001703060

Specification data are reference values.

PBIA9664J

MONITOR ITEM CONDITION SPECIFICATION

B/FUEL SCHDL See EC-127

.

INJ PULSE-B1• Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

•No loadIdle 2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

Page 1596 of 2771

EC-522

< SERVICE INFORMATION >

FUEL INJECTOR

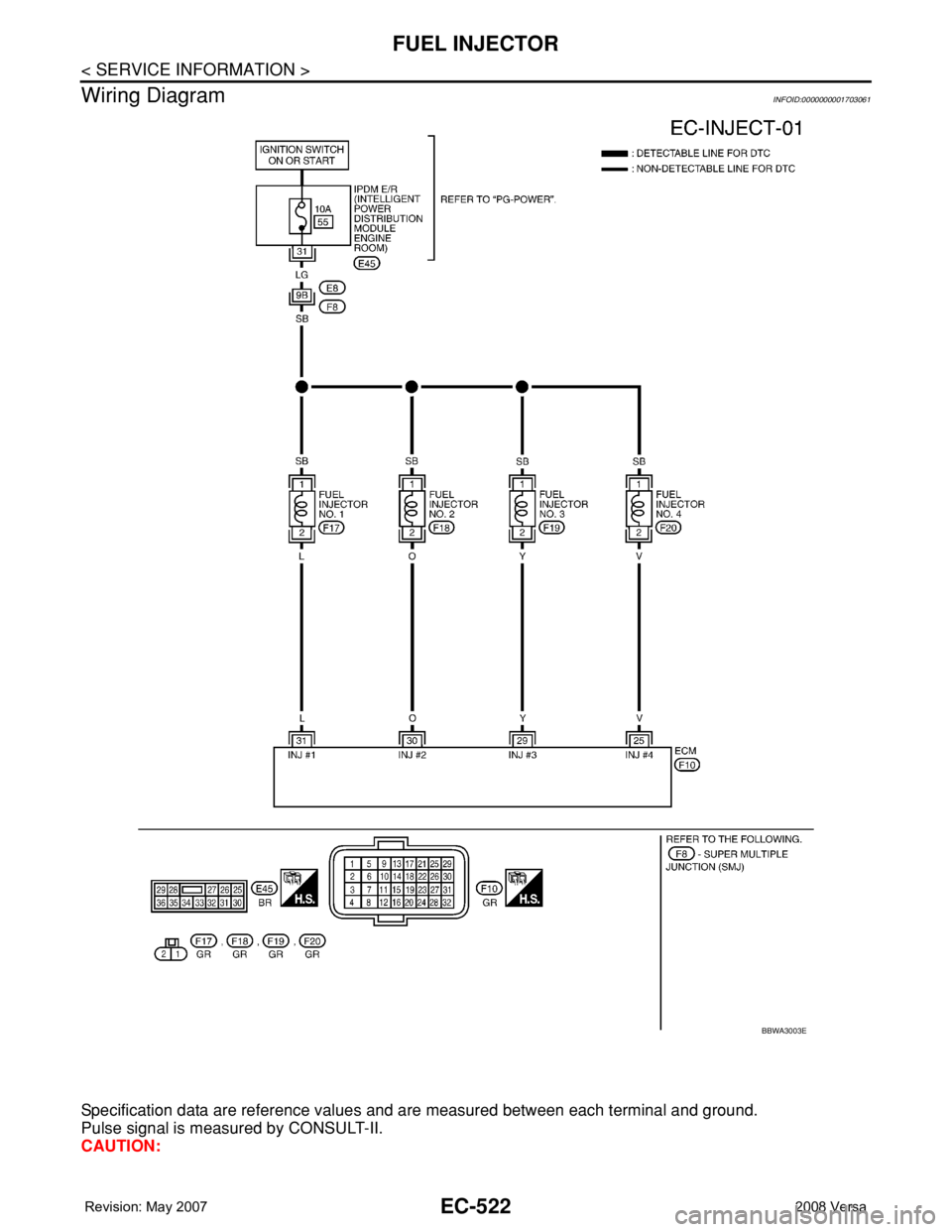

Wiring Diagram

INFOID:0000000001703061

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

BBWA3003E

Page 1597 of 2771

FUEL INJECTOR

EC-523

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

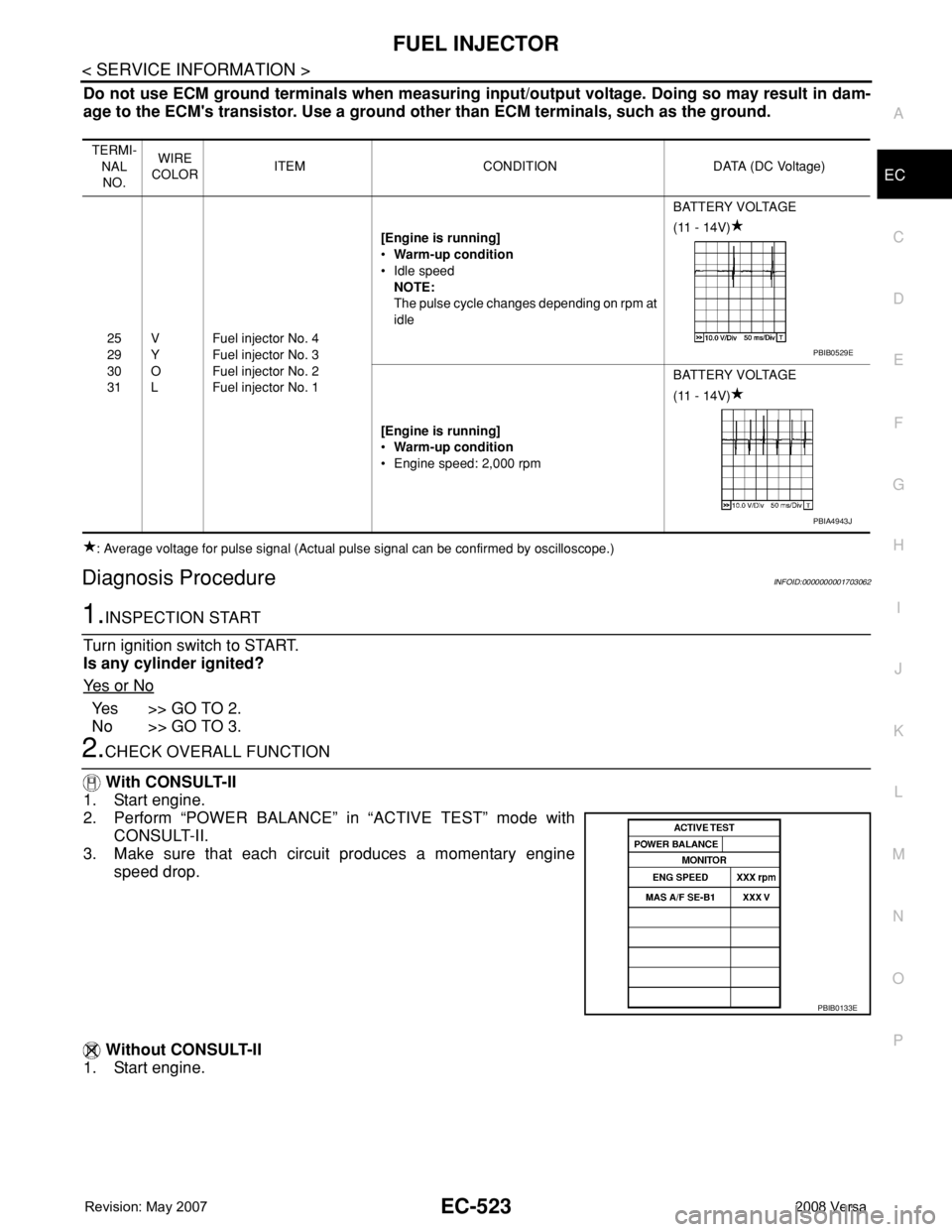

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001703062

1.INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited?

Ye s o r N o

Yes >> GO TO 2.

No >> GO TO 3.

2.CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

3. Make sure that each circuit produces a momentary engine

speed drop.

Without CONSULT-II

1. Start engine.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

25

29

30

31V

Y

O

LFuel injector No. 4

Fuel injector No. 3

Fuel injector No. 2

Fuel injector No. 1[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm at

idleBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

PBIB0529E

PBIA4943J

PBIB0133E

Page 1598 of 2771

EC-524

< SERVICE INFORMATION >

FUEL INJECTOR

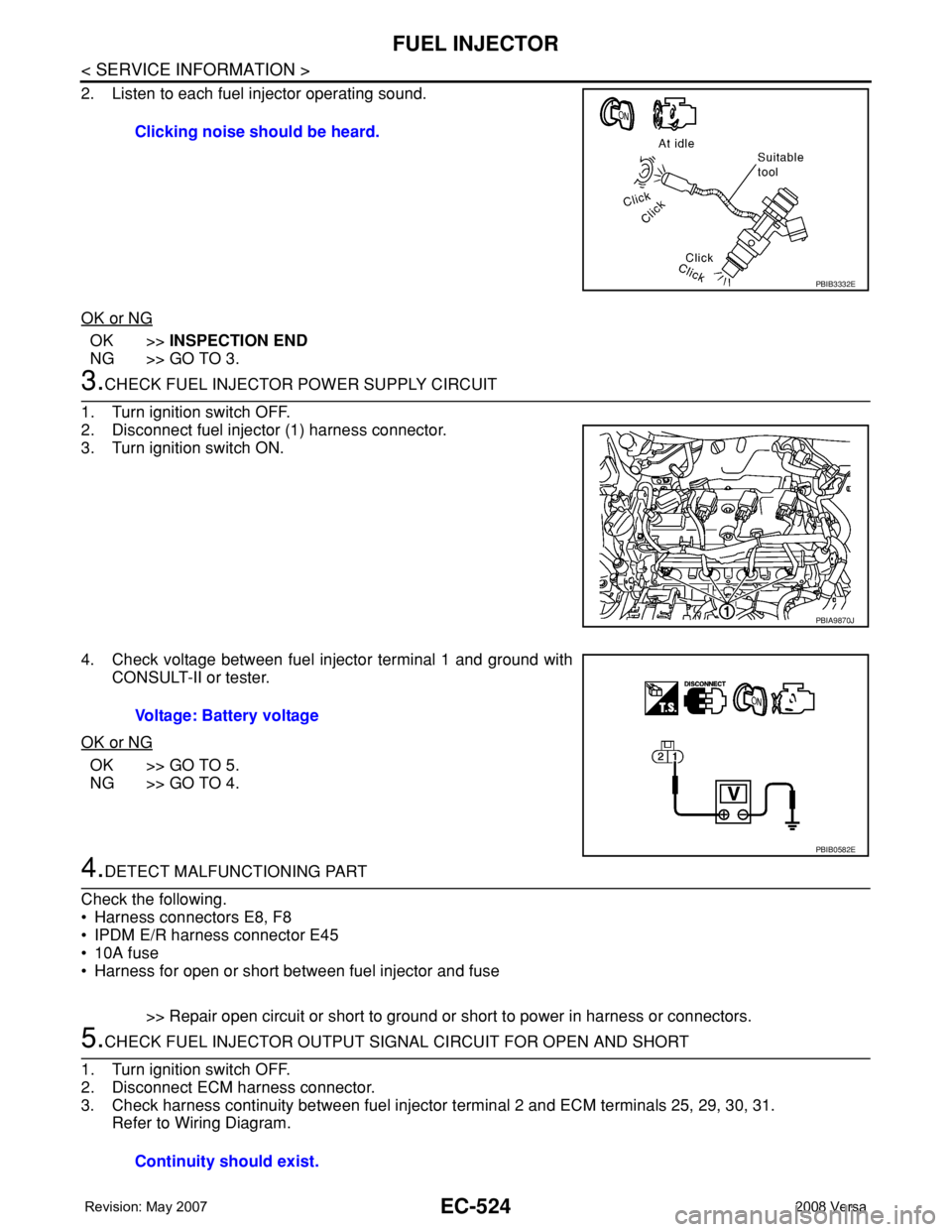

2. Listen to each fuel injector operating sound.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuel injector (1) harness connector.

3. Turn ignition switch ON.

4. Check voltage between fuel injector terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• IPDM E/R harness connector E45

• 10A fuse

• Harness for open or short between fuel injector and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK FUEL INJECTOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between fuel injector terminal 2 and ECM terminals 25, 29, 30, 31.

Refer to Wiring Diagram.Clicking noise should be heard.

PBIB3332E

PBIA9870J

Voltage: Battery voltage

PBIB0582E

Continuity should exist.

Page 1599 of 2771

FUEL INJECTOR

EC-525

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK FUEL INJECTOR

Refer to EC-525, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace fuel injector.

7.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

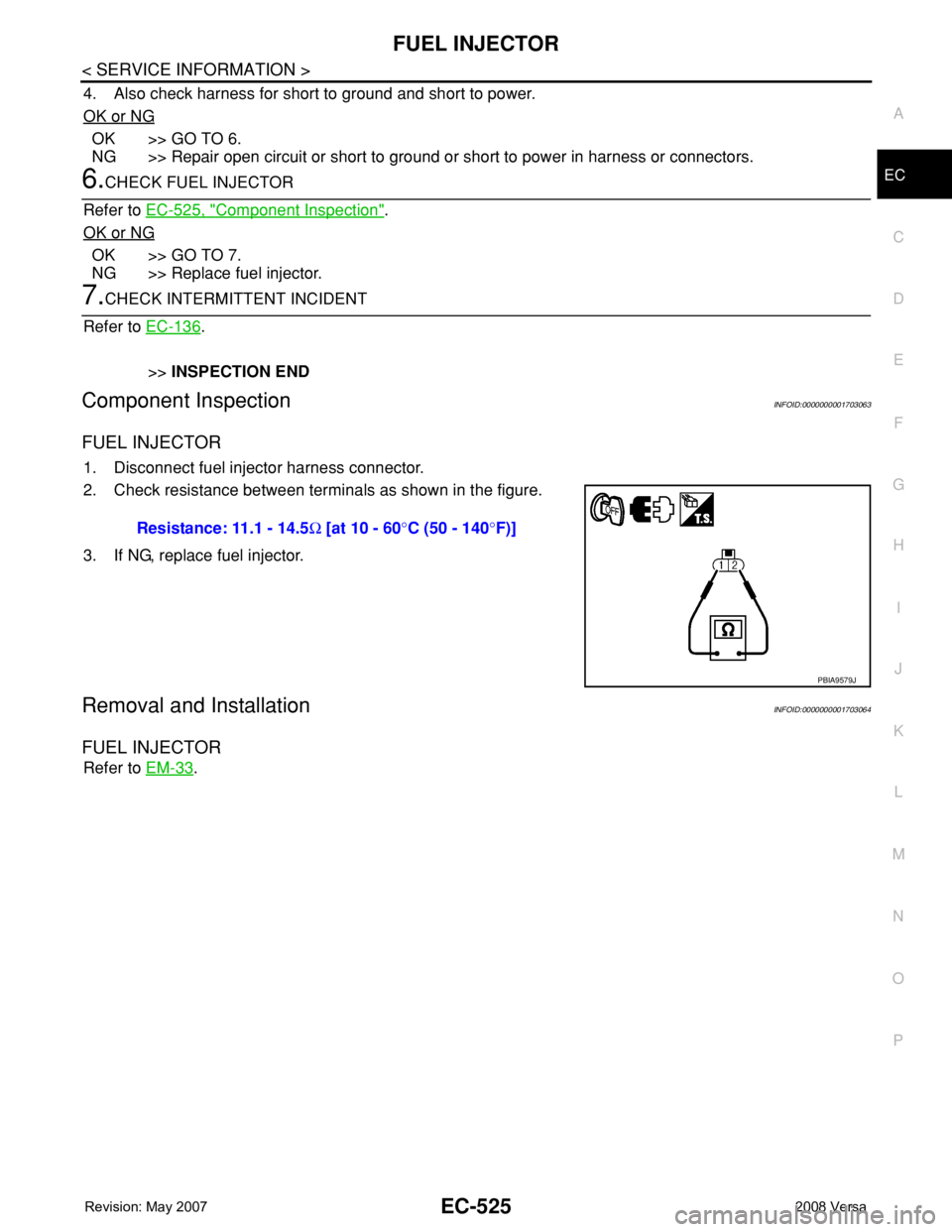

Component InspectionINFOID:0000000001703063

FUEL INJECTOR

1. Disconnect fuel injector harness connector.

2. Check resistance between terminals as shown in the figure.

3. If NG, replace fuel injector.

Removal and InstallationINFOID:0000000001703064

FUEL INJECTOR

Refer to EM-33. Resistance: 11.1 - 14.5Ω [at 10 - 60°C (50 - 140°F)]

PBIA9579J

Page 1600 of 2771

EC-526

< SERVICE INFORMATION >

FUEL PUMP

FUEL PUMP

DescriptionINFOID:0000000001703065

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

startability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engine is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition switch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel

pump. It controls the ON/OFF fuel pump relay, which in turn controls the fuel pump.

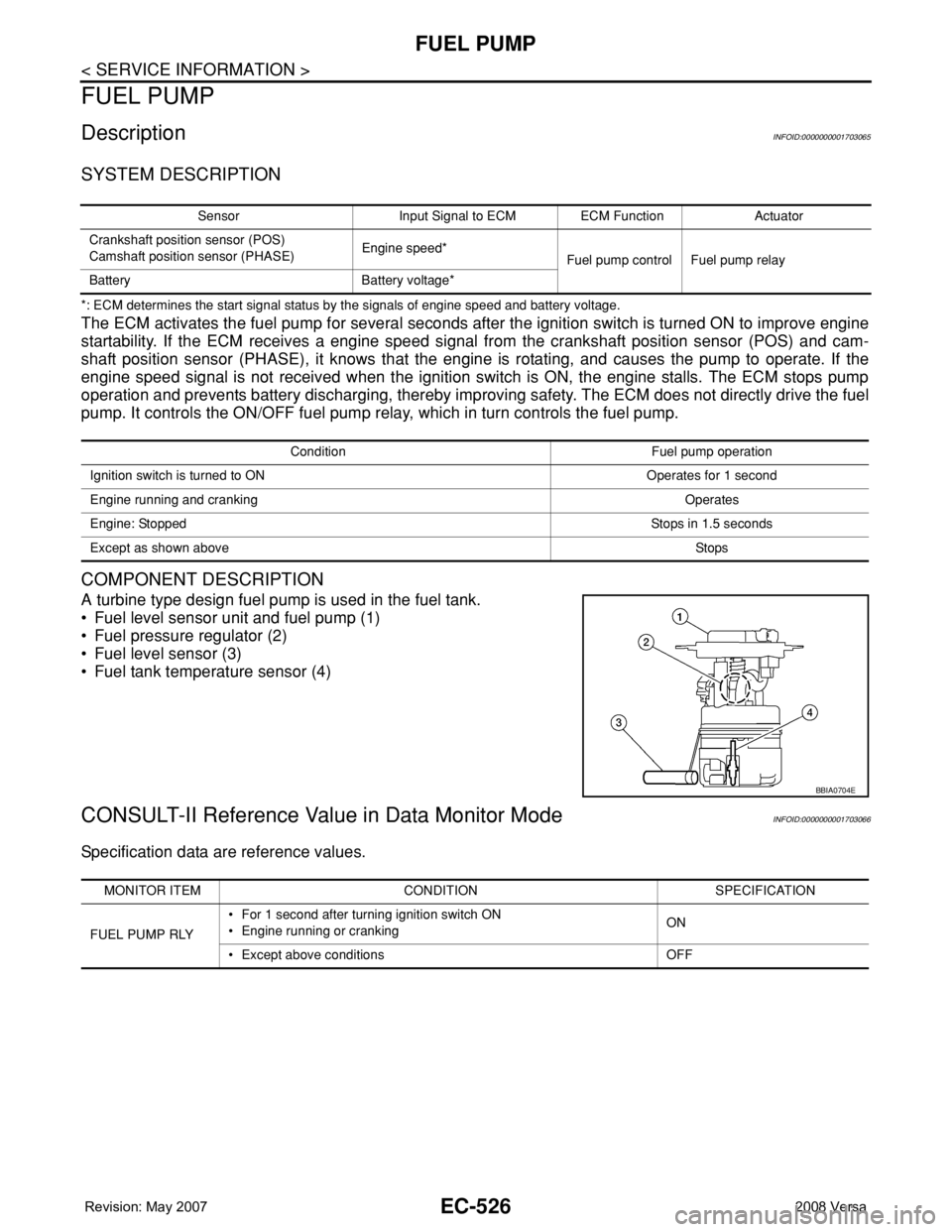

COMPONENT DESCRIPTION

A turbine type design fuel pump is used in the fuel tank.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

• Fuel tank temperature sensor (4)

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001703066

Specification data are reference values.

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON Operates for 1 second

Engine running and crankingOperates

Engine: StoppedStops in 1.5 seconds

Except as shown aboveSt ops

BBIA0704E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF