NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1601 of 2771

FUEL PUMP

EC-527

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

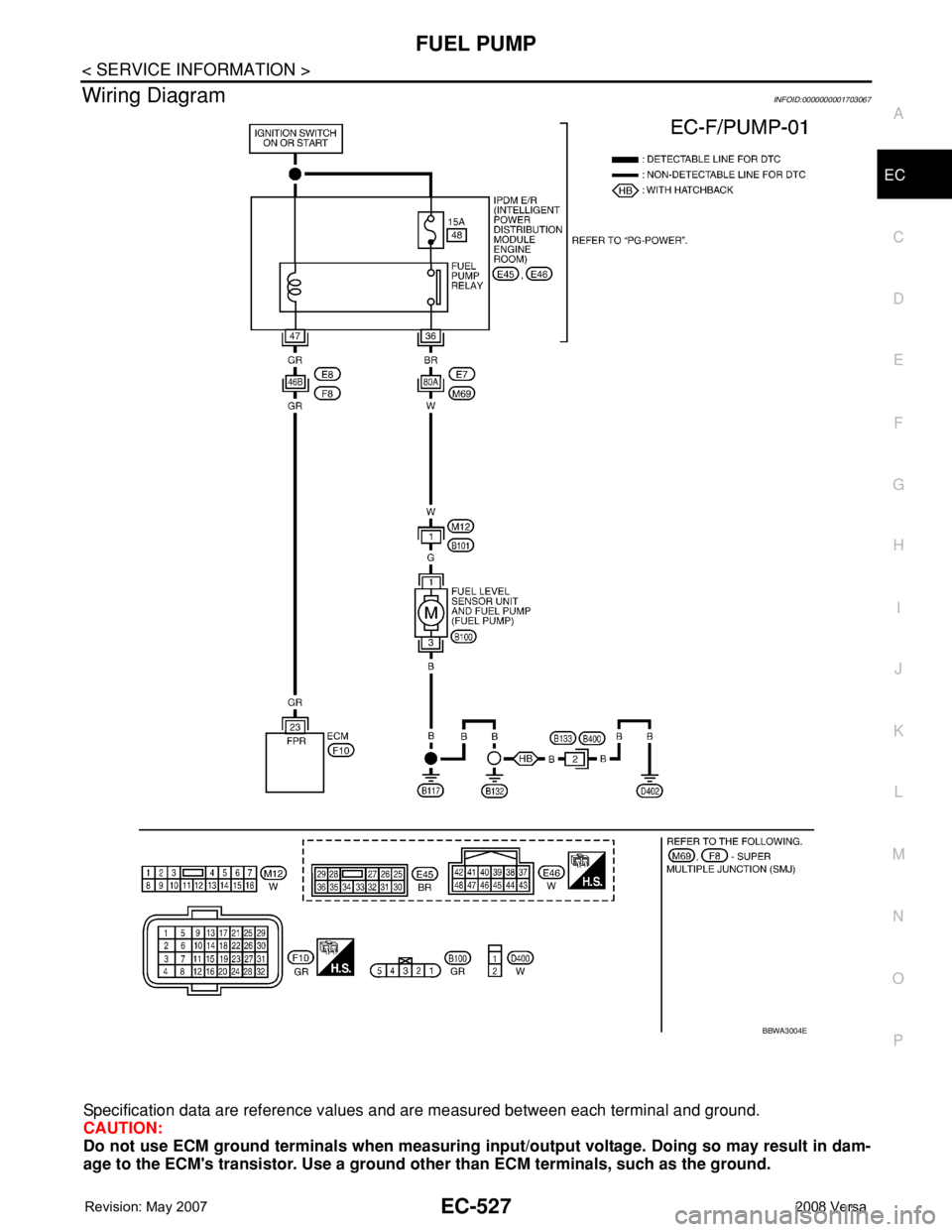

Wiring DiagramINFOID:0000000001703067

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBWA3004E

Page 1602 of 2771

EC-528

< SERVICE INFORMATION >

FUEL PUMP

Diagnosis Procedure

INFOID:0000000001703068

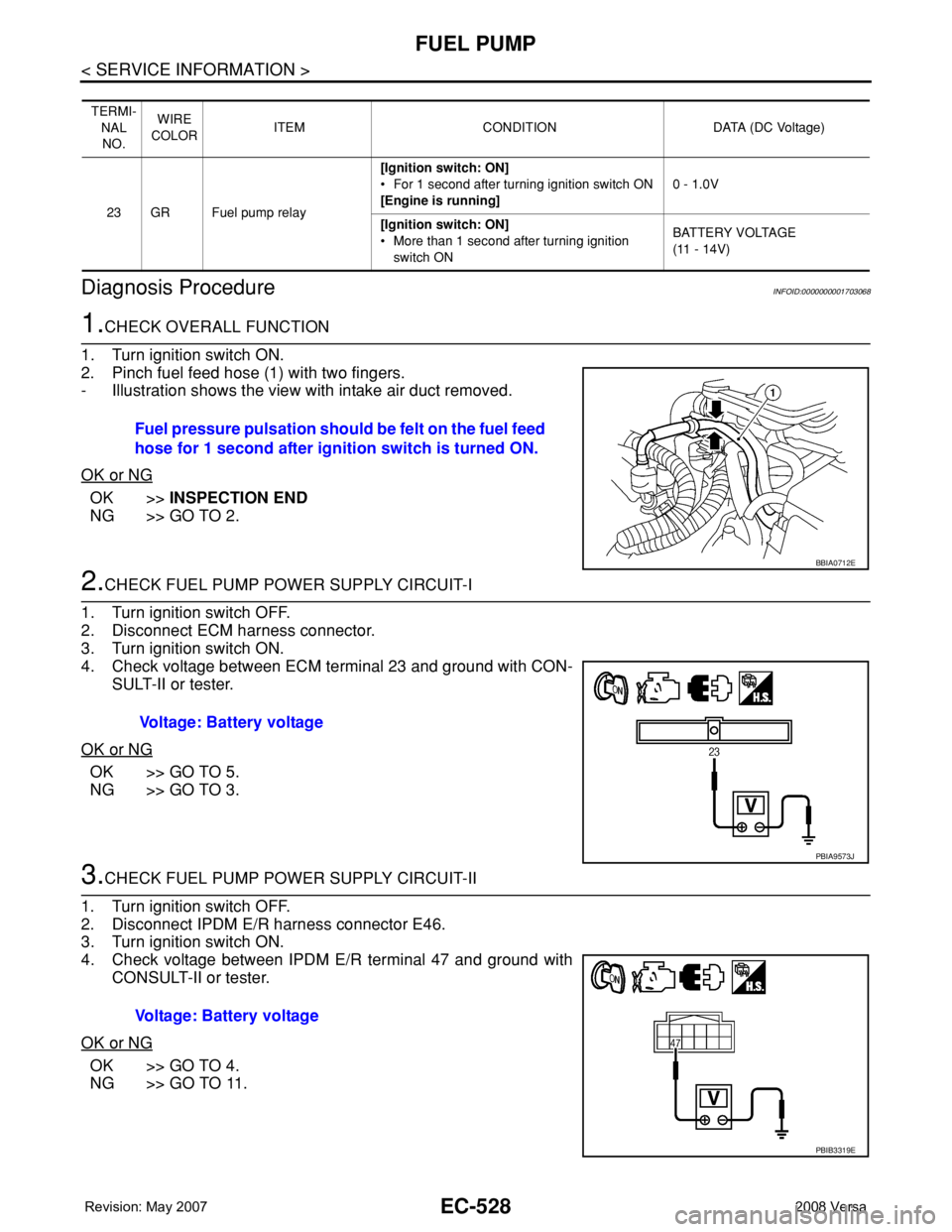

1.CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose (1) with two fingers.

- Illustration shows the view with intake air duct removed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

4. Check voltage between ECM terminal 23 and ground with CON-

SULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E46.

3. Turn ignition switch ON.

4. Check voltage between IPDM E/R terminal 47 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 11.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

23 GR Fuel pump relay[Ignition switch: ON]

• For 1 second after turning ignition switch ON

[Engine is running]0 - 1.0V

[Ignition switch: ON]

• More than 1 second after turning ignition

switch ONBATTERY VOLTAGE

(11 - 14V)

Fuel pressure pulsation should be felt on the fuel feed

hose for 1 second after ignition switch is turned ON.

BBIA0712E

Voltage: Battery voltage

PBIA9573J

Voltage: Battery voltage

PBIB3319E

Page 1603 of 2771

FUEL PUMP

EC-529

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

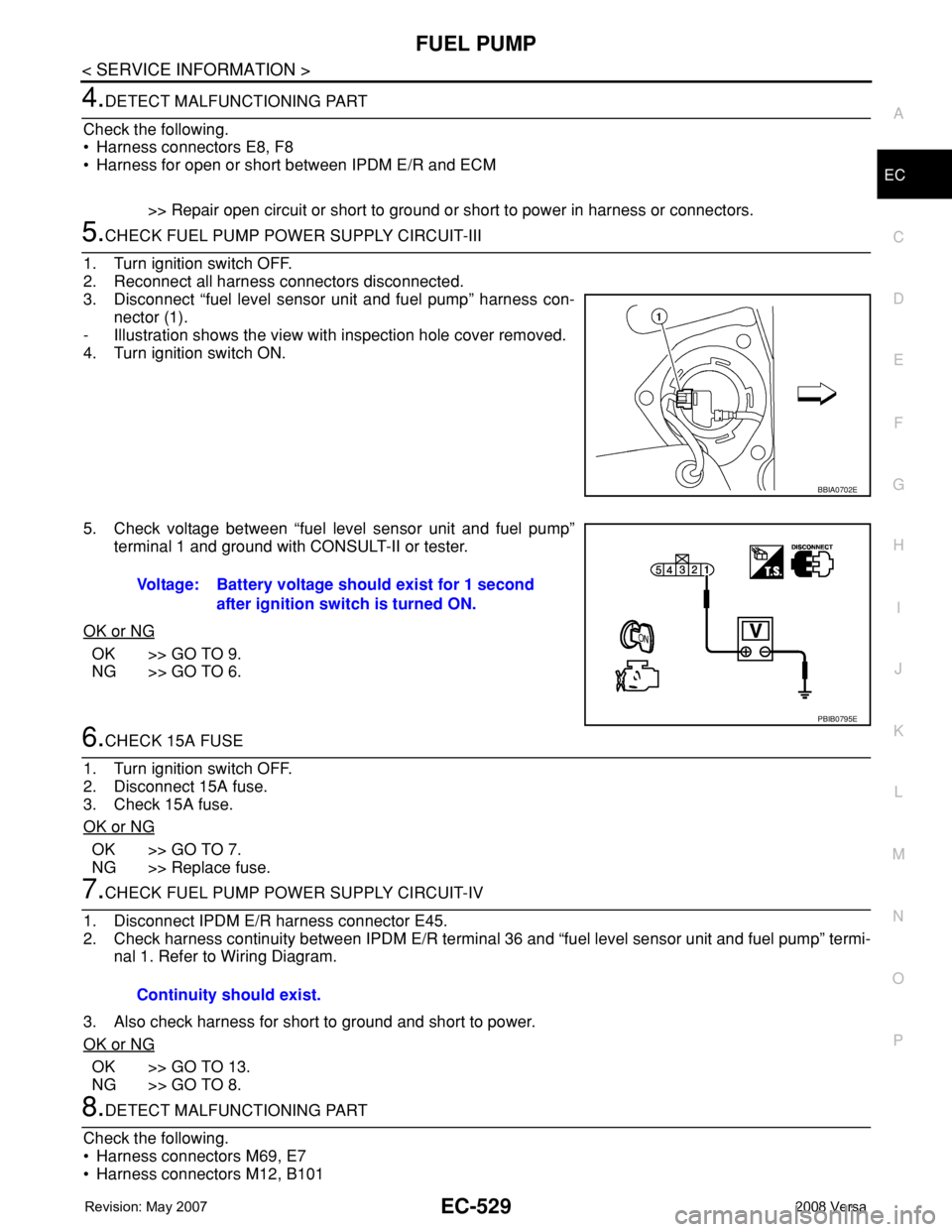

5.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Disconnect “fuel level sensor unit and fuel pump” harness con-

nector (1).

- Illustration shows the view with inspection hole cover removed.

4. Turn ignition switch ON.

5. Check voltage between “fuel level sensor unit and fuel pump”

terminal 1 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 6.

6.CHECK 15A FUSE

1. Turn ignition switch OFF.

2. Disconnect 15A fuse.

3. Check 15A fuse.

OK or NG

OK >> GO TO 7.

NG >> Replace fuse.

7.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-IV

1. Disconnect IPDM E/R harness connector E45.

2. Check harness continuity between IPDM E/R terminal 36 and “fuel level sensor unit and fuel pump” termi-

nal 1. Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M69, E7

• Harness connectors M12, B101

BBIA0702E

Voltage: Battery voltage should exist for 1 second

after ignition switch is turned ON.

PBIB0795E

Continuity should exist.

Page 1604 of 2771

EC-530

< SERVICE INFORMATION >

FUEL PUMP

• Harness for open or short between IPDM E/R and “fuel level sensor unit and fuel pump”

>> Repair open circuit or short to ground or short to power in harness or connectors.

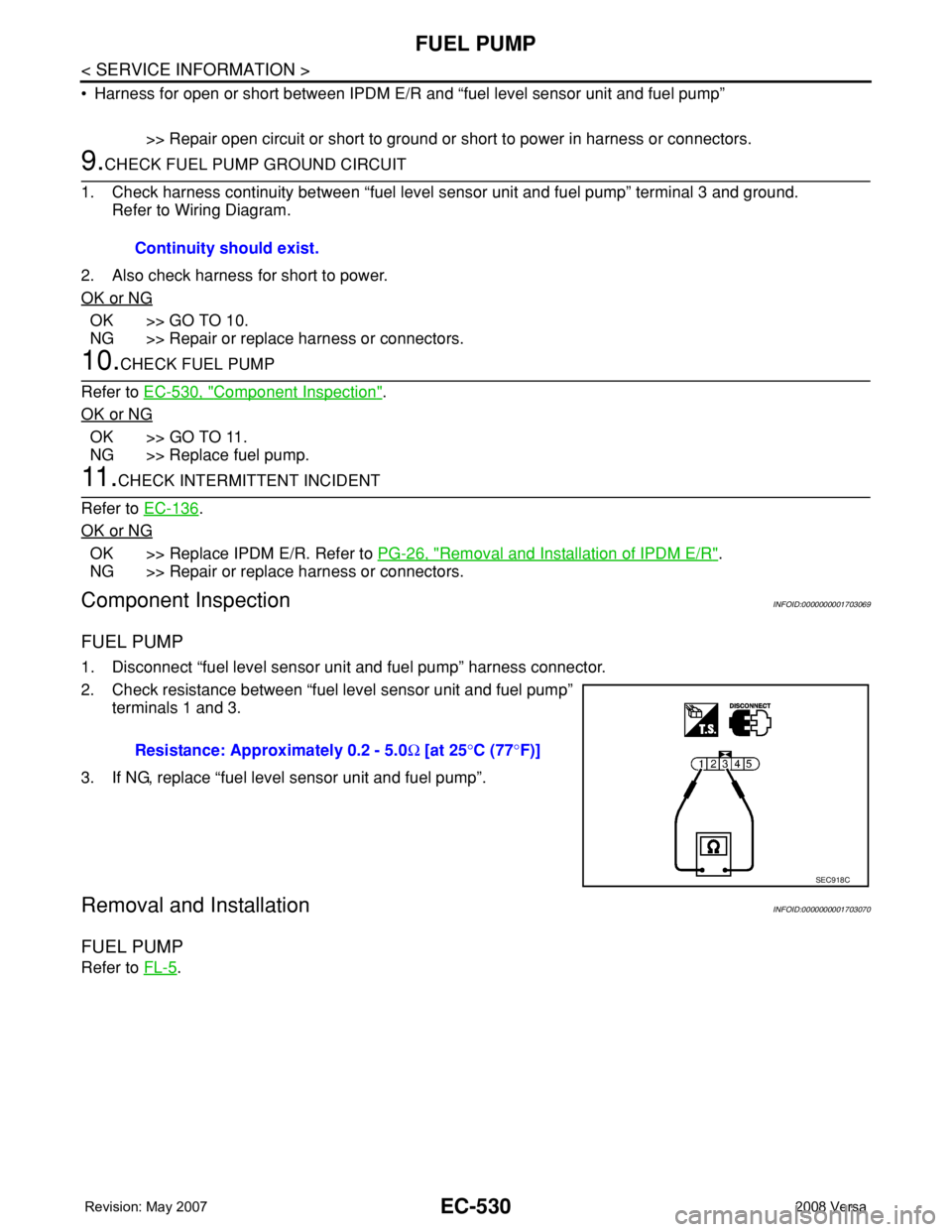

9.CHECK FUEL PUMP GROUND CIRCUIT

1. Check harness continuity between “fuel level sensor unit and fuel pump” terminal 3 and ground.

Refer to Wiring Diagram.

2. Also check harness for short to power.

OK or NG

OK >> GO TO 10.

NG >> Repair or replace harness or connectors.

10.CHECK FUEL PUMP

Refer to EC-530, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace fuel pump.

11 .CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and Installation of IPDM E/R".

NG >> Repair or replace harness or connectors.

Component InspectionINFOID:0000000001703069

FUEL PUMP

1. Disconnect “fuel level sensor unit and fuel pump” harness connector.

2. Check resistance between “fuel level sensor unit and fuel pump”

terminals 1 and 3.

3. If NG, replace “fuel level sensor unit and fuel pump”.

Removal and InstallationINFOID:0000000001703070

FUEL PUMP

Refer to FL-5. Continuity should exist.

Resistance: Approximately 0.2 - 5.0Ω [at 25°C (77°F)]

SEC918C

Page 1605 of 2771

IGNITION SIGNAL

EC-531

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

IGNITION SIGNAL

Component DescriptionINFOID:0000000001703071

IGNITION COIL & POWER TRANSISTOR

The ignition signal from the ECM is sent to and amplified by the

power transistor. The power transistor turns ON and OFF the ignition

coil (1) primary circuit. This ON/OFF operation induces the proper

high voltage in the coil secondary circuit.

PBIB3328E

Page 1606 of 2771

EC-532

< SERVICE INFORMATION >

IGNITION SIGNAL

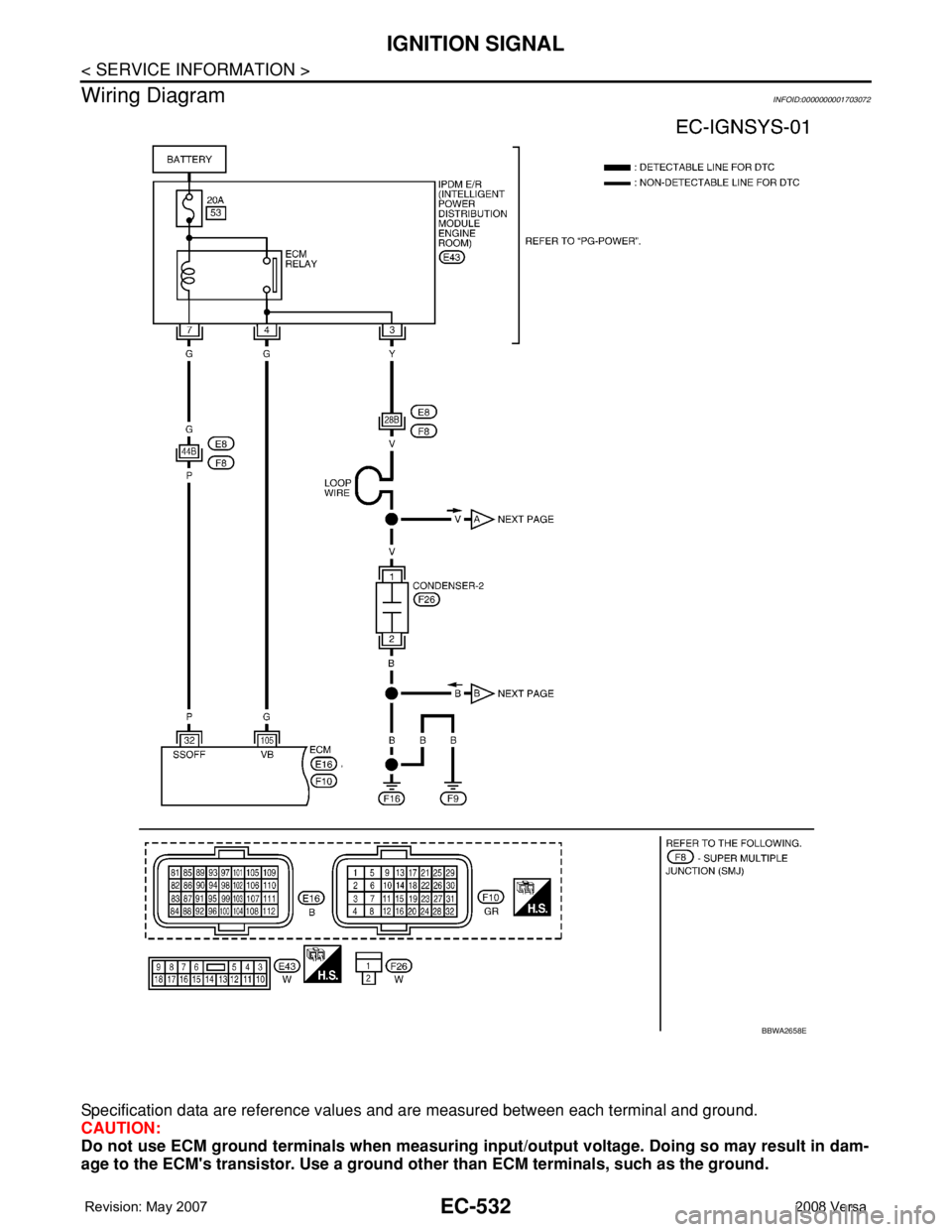

Wiring Diagram

INFOID:0000000001703072

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBWA2658E

Page 1607 of 2771

![NISSAN TIIDA 2008 Service Repair Manual IGNITION SIGNAL

EC-533

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition s NISSAN TIIDA 2008 Service Repair Manual IGNITION SIGNAL

EC-533

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition s](/img/5/57399/w960_57399-1606.png)

IGNITION SIGNAL

EC-533

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

Page 1608 of 2771

EC-534

< SERVICE INFORMATION >

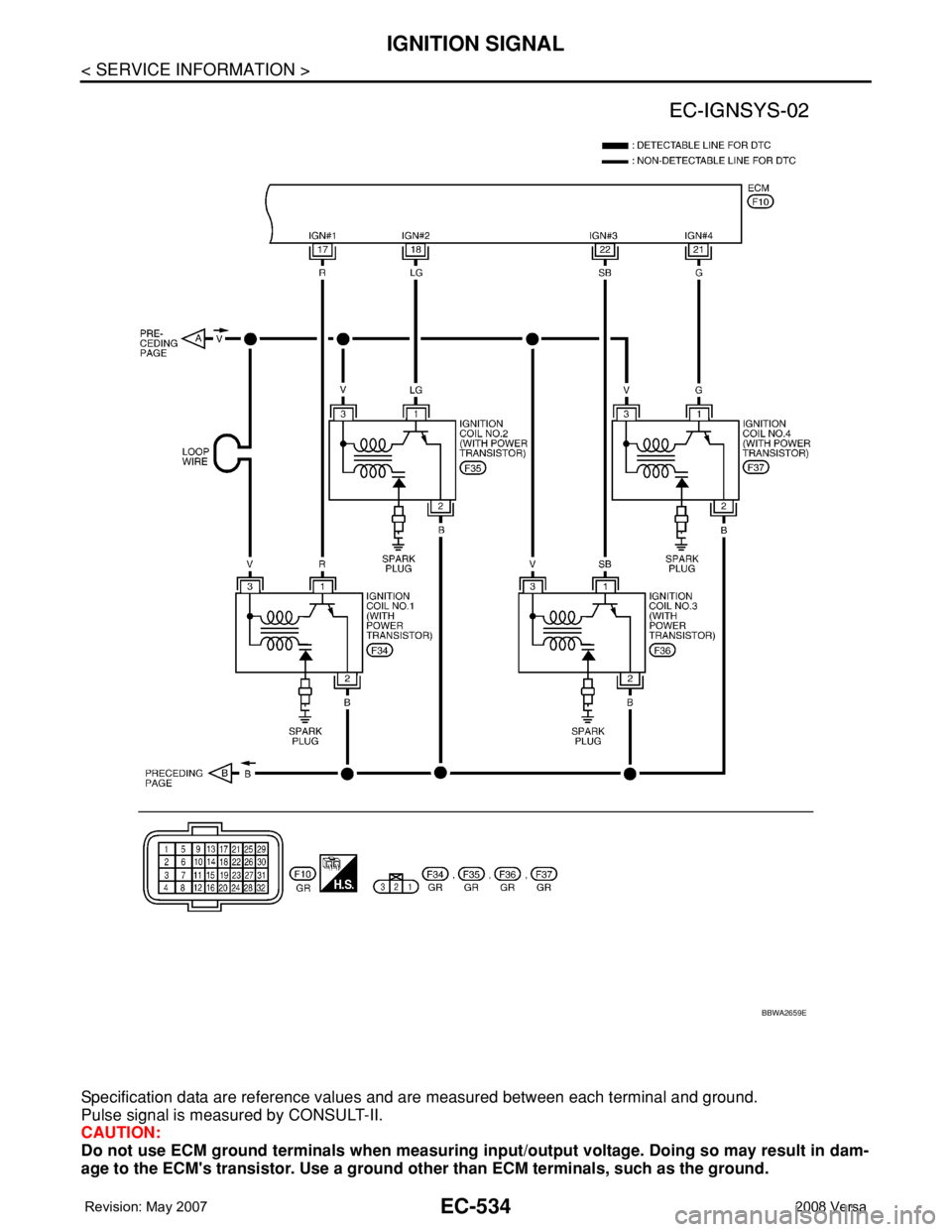

IGNITION SIGNAL

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

BBWA2659E

Page 1609 of 2771

IGNITION SIGNAL

EC-535

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

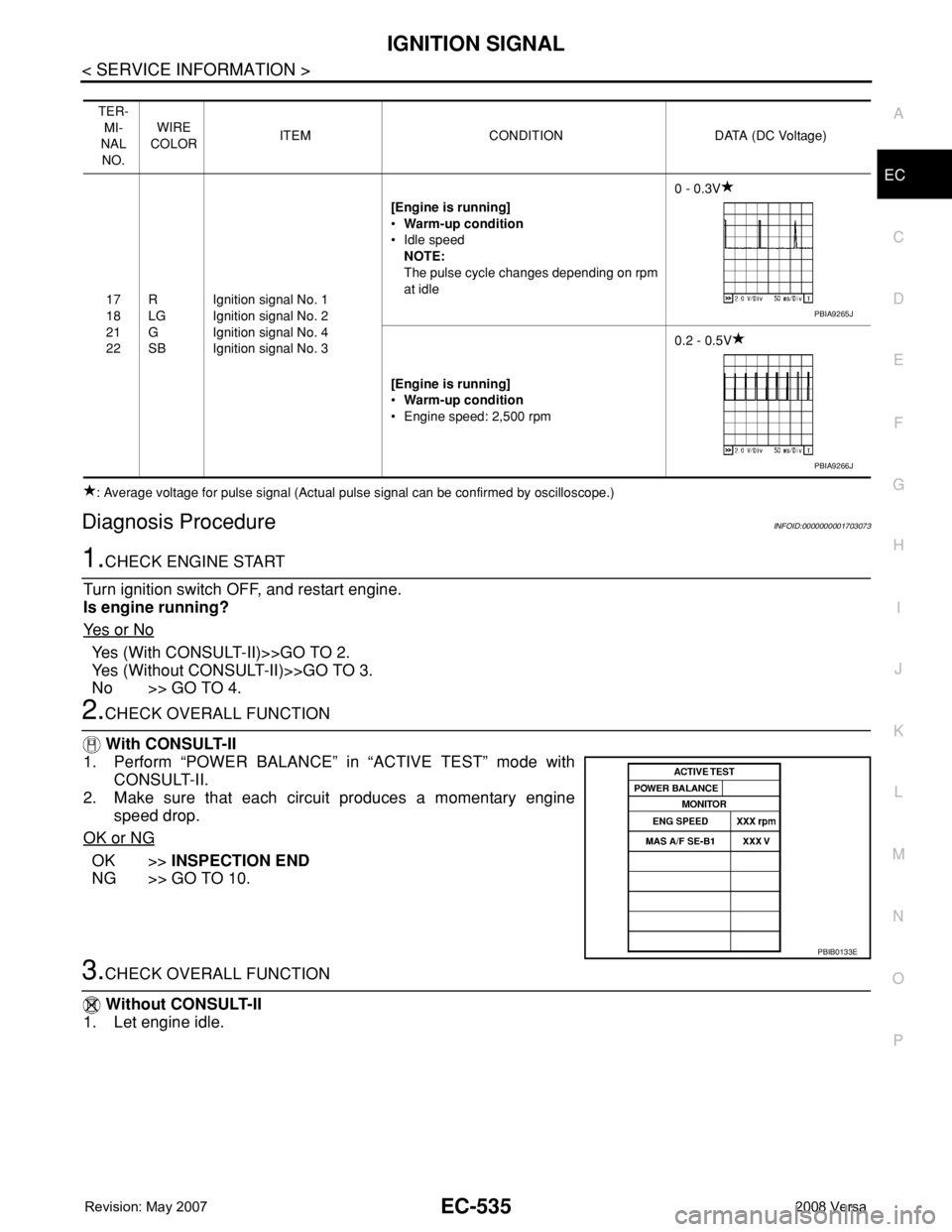

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001703073

1.CHECK ENGINE START

Turn ignition switch OFF, and restart engine.

Is engine running?

Ye s o r N o

Yes (With CONSULT-II)>>GO TO 2.

Yes (Without CONSULT-II)>>GO TO 3.

No >> GO TO 4.

2.CHECK OVERALL FUNCTION

With CONSULT-II

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

2. Make sure that each circuit produces a momentary engine

speed drop.

OK or NG

OK >>INSPECTION END

NG >> GO TO 10.

3.CHECK OVERALL FUNCTION

Without CONSULT-II

1. Let engine idle.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

17

18

21

22R

LG

G

SBIgnition signal No. 1

Ignition signal No. 2

Ignition signal No. 4

Ignition signal No. 3[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle0 - 0.3V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm0.2 - 0.5V

PBIA9265J

PBIA9266J

PBIB0133E

Page 1610 of 2771

EC-536

< SERVICE INFORMATION >

IGNITION SIGNAL

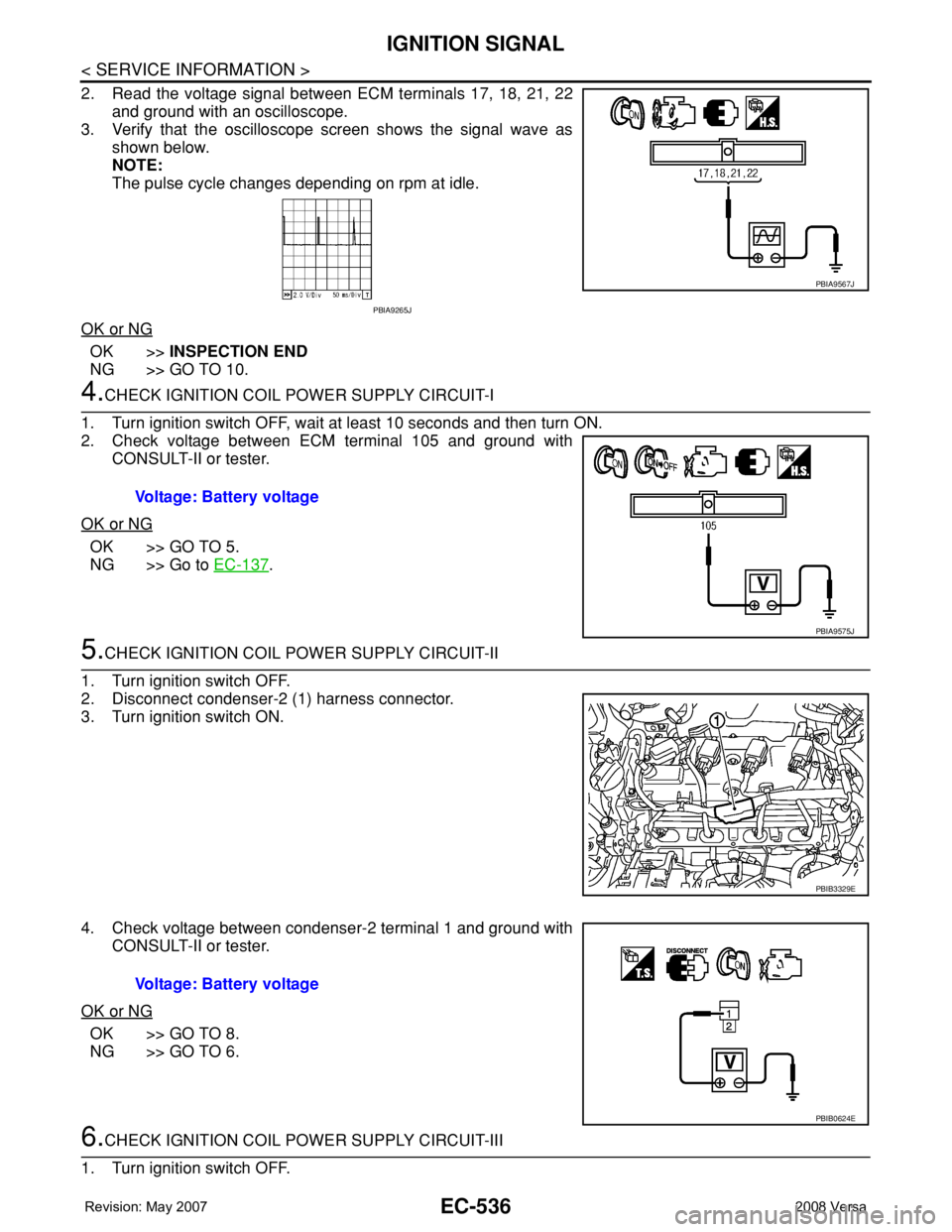

2. Read the voltage signal between ECM terminals 17, 18, 21, 22

and ground with an oscilloscope.

3. Verify that the oscilloscope screen shows the signal wave as

shown below.

NOTE:

The pulse cycle changes depending on rpm at idle.

OK or NG

OK >>INSPECTION END

NG >> GO TO 10.

4.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

2. Check voltage between ECM terminal 105 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> Go to EC-137

.

5.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser-2 (1) harness connector.

3. Turn ignition switch ON.

4. Check voltage between condenser-2 terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

6.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

PBIA9567J

PBIA9265J

Voltage: Battery voltage

PBIA9575J

PBIB3329E

Voltage: Battery voltage

PBIB0624E