NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1711 of 2771

EM-34

< SERVICE INFORMATION >

FUEL INJECTOR AND FUEL TUBE

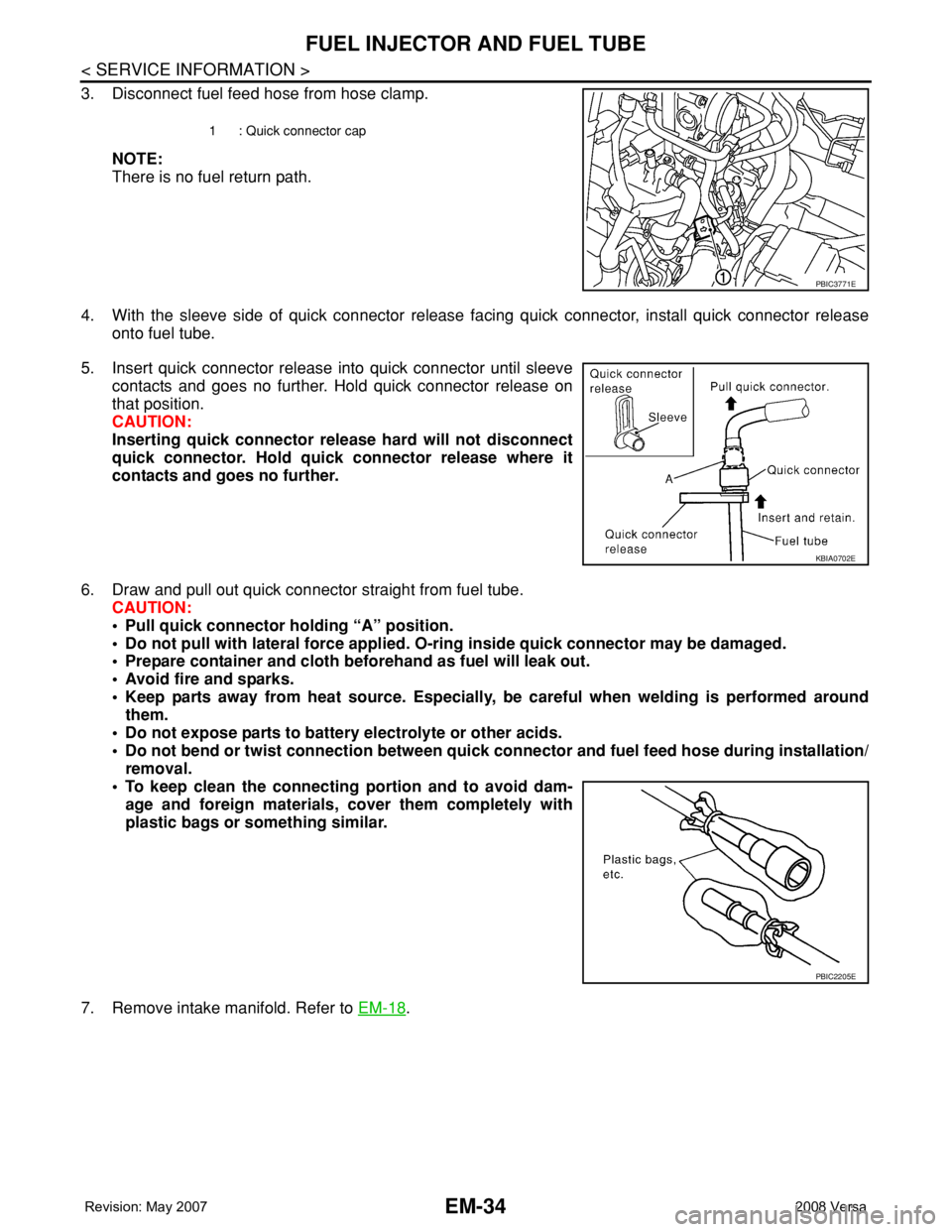

3. Disconnect fuel feed hose from hose clamp.

NOTE:

There is no fuel return path.

4. With the sleeve side of quick connector release facing quick connector, install quick connector release

onto fuel tube.

5. Insert quick connector release into quick connector until sleeve

contacts and goes no further. Hold quick connector release on

that position.

CAUTION:

Inserting quick connector release hard will not disconnect

quick connector. Hold quick connector release where it

contacts and goes no further.

6. Draw and pull out quick connector straight from fuel tube.

CAUTION:

• Pull quick connector holding “A” position.

• Do not pull with lateral force applied. O-ring inside quick connector may be damaged.

• Prepare container and cloth beforehand as fuel will leak out.

• Avoid fire and sparks.

• Keep parts away from heat source. Especially, be careful when welding is performed around

them.

• Do not expose parts to battery electrolyte or other acids.

• Do not bend or twist connection between quick connector and fuel feed hose during installation/

removal.

• To keep clean the connecting portion and to avoid dam-

age and foreign materials, cover them completely with

plastic bags or something similar.

7. Remove intake manifold. Refer to EM-18

.

1 : Quick connector cap

PBIC3771E

KBIA0702E

PBIC2205E

Page 1712 of 2771

FUEL INJECTOR AND FUEL TUBE

EM-35

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

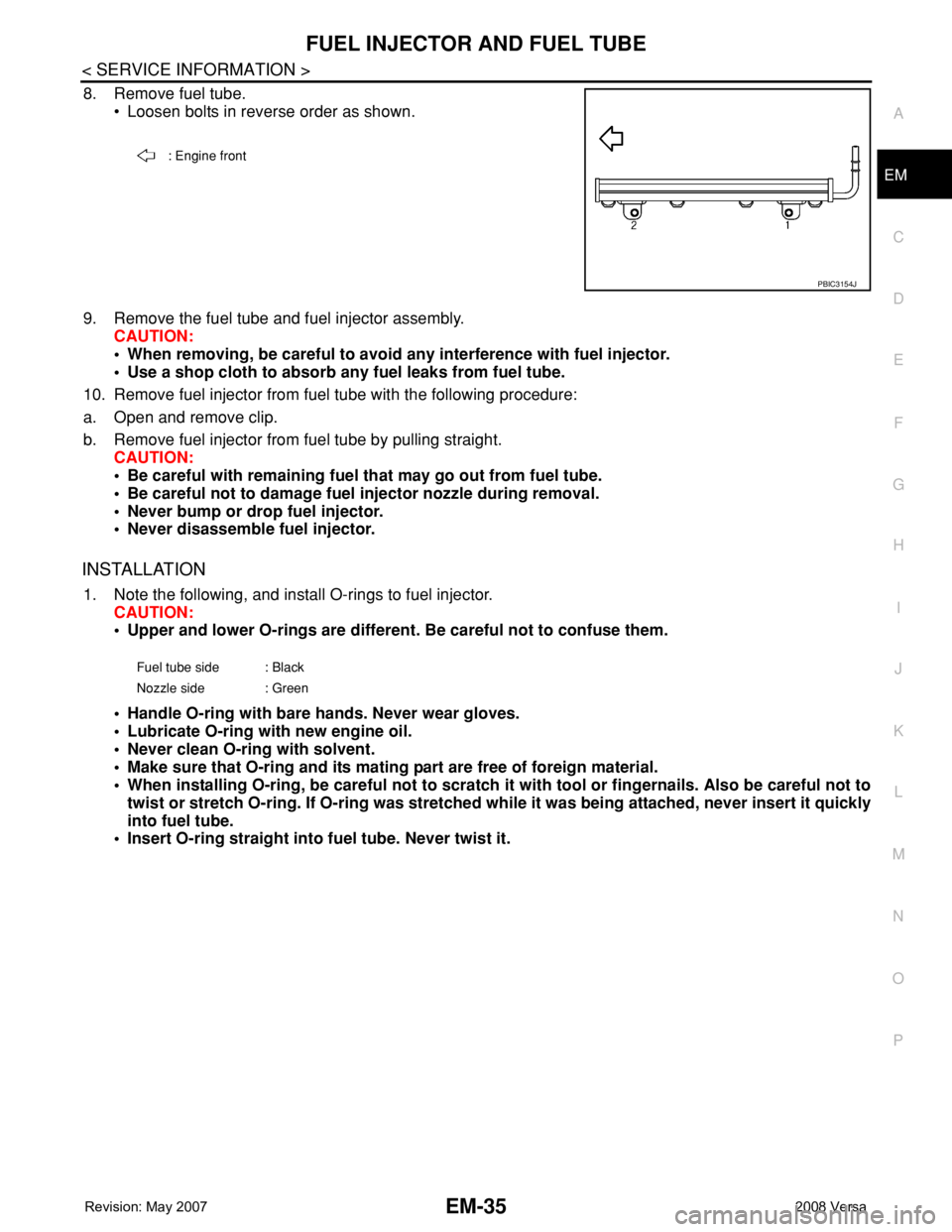

8. Remove fuel tube.

• Loosen bolts in reverse order as shown.

9. Remove the fuel tube and fuel injector assembly.

CAUTION:

• When removing, be careful to avoid any interference with fuel injector.

• Use a shop cloth to absorb any fuel leaks from fuel tube.

10. Remove fuel injector from fuel tube with the following procedure:

a. Open and remove clip.

b. Remove fuel injector from fuel tube by pulling straight.

CAUTION:

• Be careful with remaining fuel that may go out from fuel tube.

• Be careful not to damage fuel injector nozzle during removal.

• Never bump or drop fuel injector.

• Never disassemble fuel injector.

INSTALLATION

1. Note the following, and install O-rings to fuel injector.

CAUTION:

• Upper and lower O-rings are different. Be careful not to confuse them.

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Never clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretched while it was being attached, never insert it quickly

into fuel tube.

• Insert O-ring straight into fuel tube. Never twist it.

: Engine front

PBIC3154J

Fuel tube side : Black

Nozzle side : Green

Page 1713 of 2771

EM-36

< SERVICE INFORMATION >

FUEL INJECTOR AND FUEL TUBE

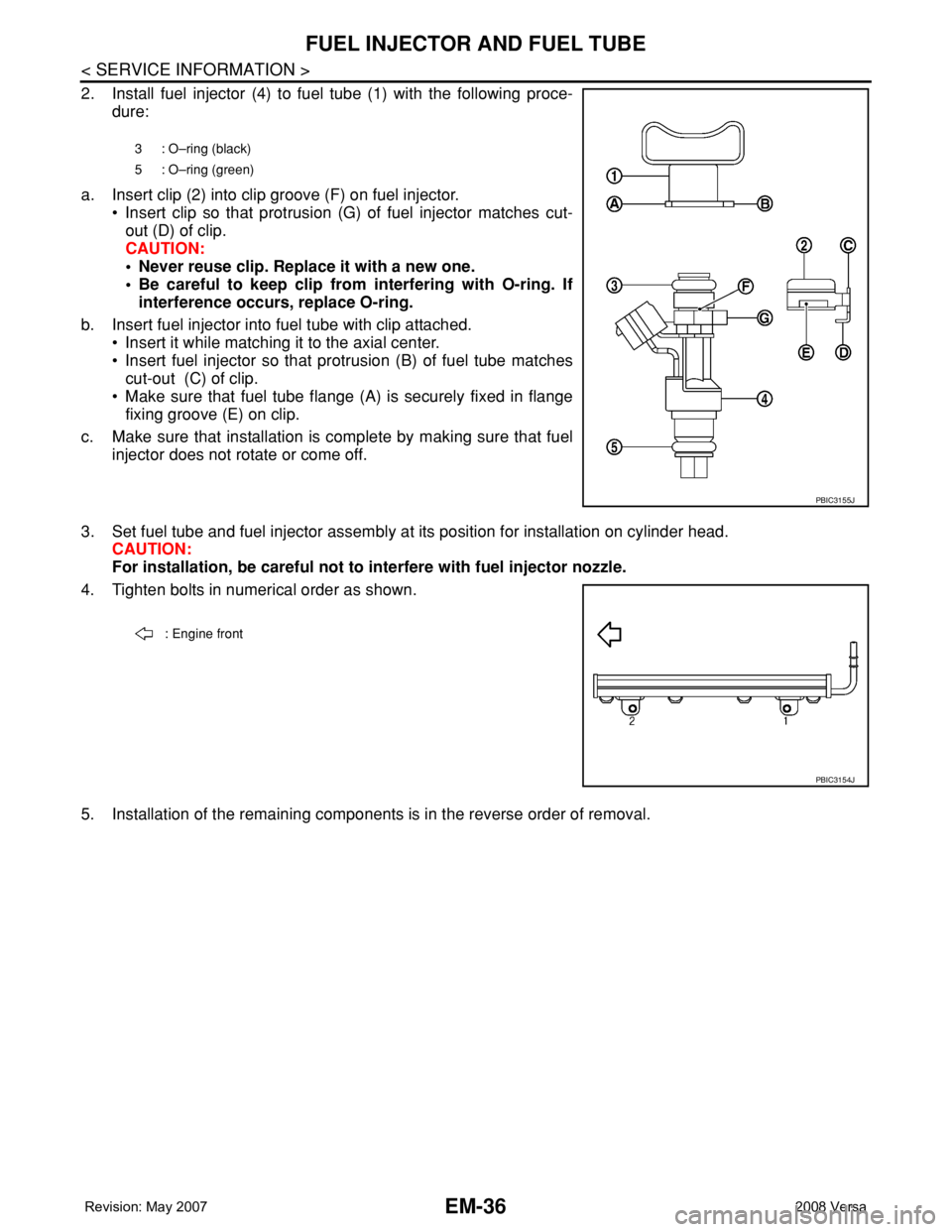

2. Install fuel injector (4) to fuel tube (1) with the following proce-

dure:

a. Insert clip (2) into clip groove (F) on fuel injector.

• Insert clip so that protrusion (G) of fuel injector matches cut-

out (D) of clip.

CAUTION:

• Never reuse clip. Replace it with a new one.

• Be careful to keep clip from interfering with O-ring. If

interference occurs, replace O-ring.

b. Insert fuel injector into fuel tube with clip attached.

• Insert it while matching it to the axial center.

• Insert fuel injector so that protrusion (B) of fuel tube matches

cut-out (C) of clip.

• Make sure that fuel tube flange (A) is securely fixed in flange

fixing groove (E) on clip.

c. Make sure that installation is complete by making sure that fuel

injector does not rotate or come off.

3. Set fuel tube and fuel injector assembly at its position for installation on cylinder head.

CAUTION:

For installation, be careful not to interfere with fuel injector nozzle.

4. Tighten bolts in numerical order as shown.

5. Installation of the remaining components is in the reverse order of removal.

3 : O–ring (black)

5 : O–ring (green)

PBIC3155J

: Engine front

PBIC3154J

Page 1714 of 2771

TIMING CHAIN

EM-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

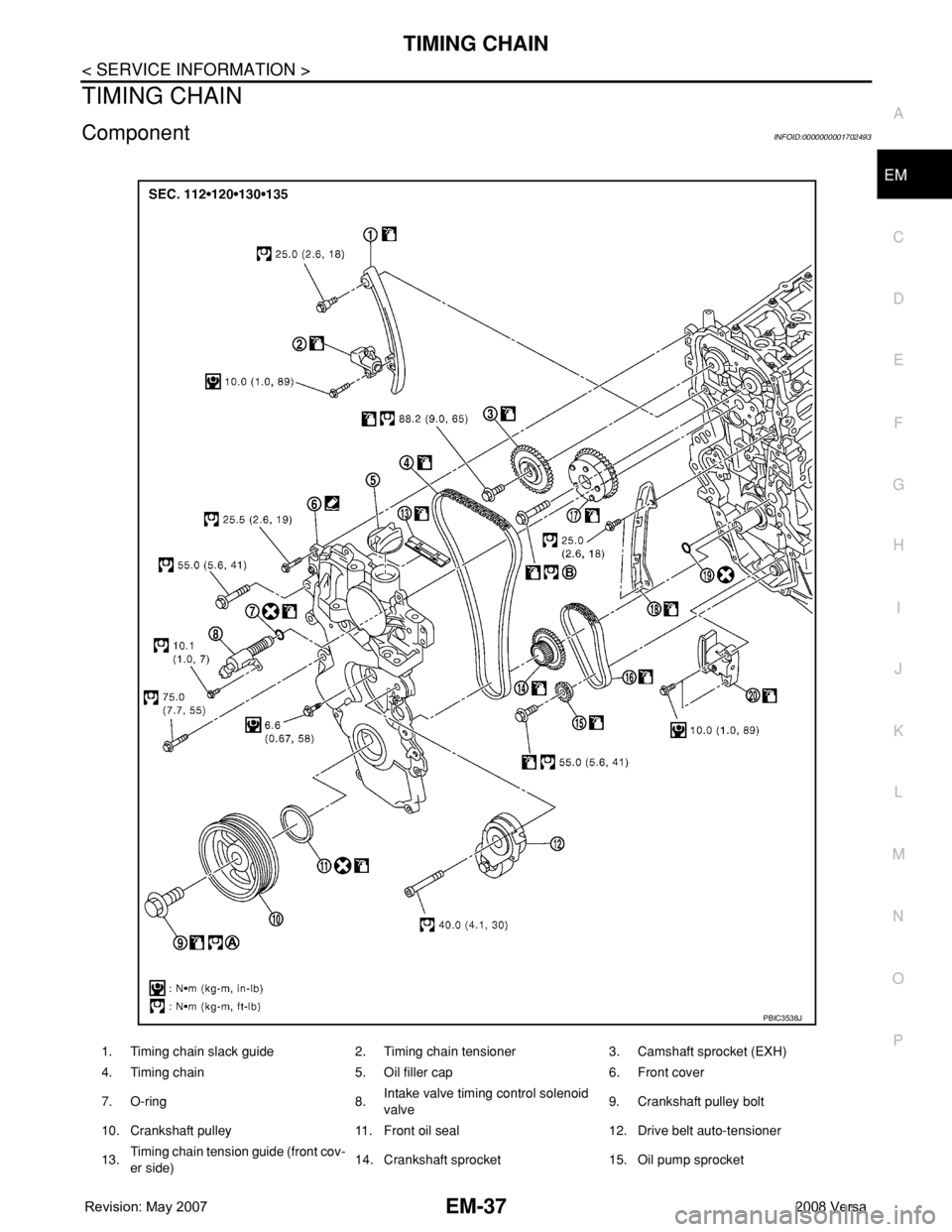

TIMING CHAIN

ComponentINFOID:0000000001702493

1. Timing chain slack guide 2. Timing chain tensioner 3. Camshaft sprocket (EXH)

4. Timing chain 5. Oil filler cap 6. Front cover

7. O-ring 8.Intake valve timing control solenoid

valve9. Crankshaft pulley bolt

10. Crankshaft pulley 11. Front oil seal 12. Drive belt auto-tensioner

13.Timing chain tension guide (front cov-

er side)14. Crankshaft sprocket 15. Oil pump sprocket

PBIC3538J

Page 1715 of 2771

EM-38

< SERVICE INFORMATION >

TIMING CHAIN

Removal and Installation

INFOID:0000000001844926

CAUTION:

The rotating direction indicated in the text indicates all directions seen from the engine front.

REMOVAL

1. Remove front RH wheel. Refer to WT-6, "Rotation".

2. Remove front fender protector (RH). Refer to EI-23, "

Removal and Installation".

3. Drain engine oil. Refer to LU-7, "

Changing Engine Oil".

NOTE:

Perform this step when engine is cold.

4. Remove the following parts.

• Rocker cover: Refer to EM-30, "

Component".

• Drive belt: Refer to EM-13, "

Removal and Installation".

• Water pump pulley: Refer to CO-16, "

Component".

• Ground cable (between engine bracket (RH) and radiator core support)

5. Support the bottom surface of engine using a transmission jack, and then remove the engine bracket and

insulator (RH). Refer to EM-72, "

Component".

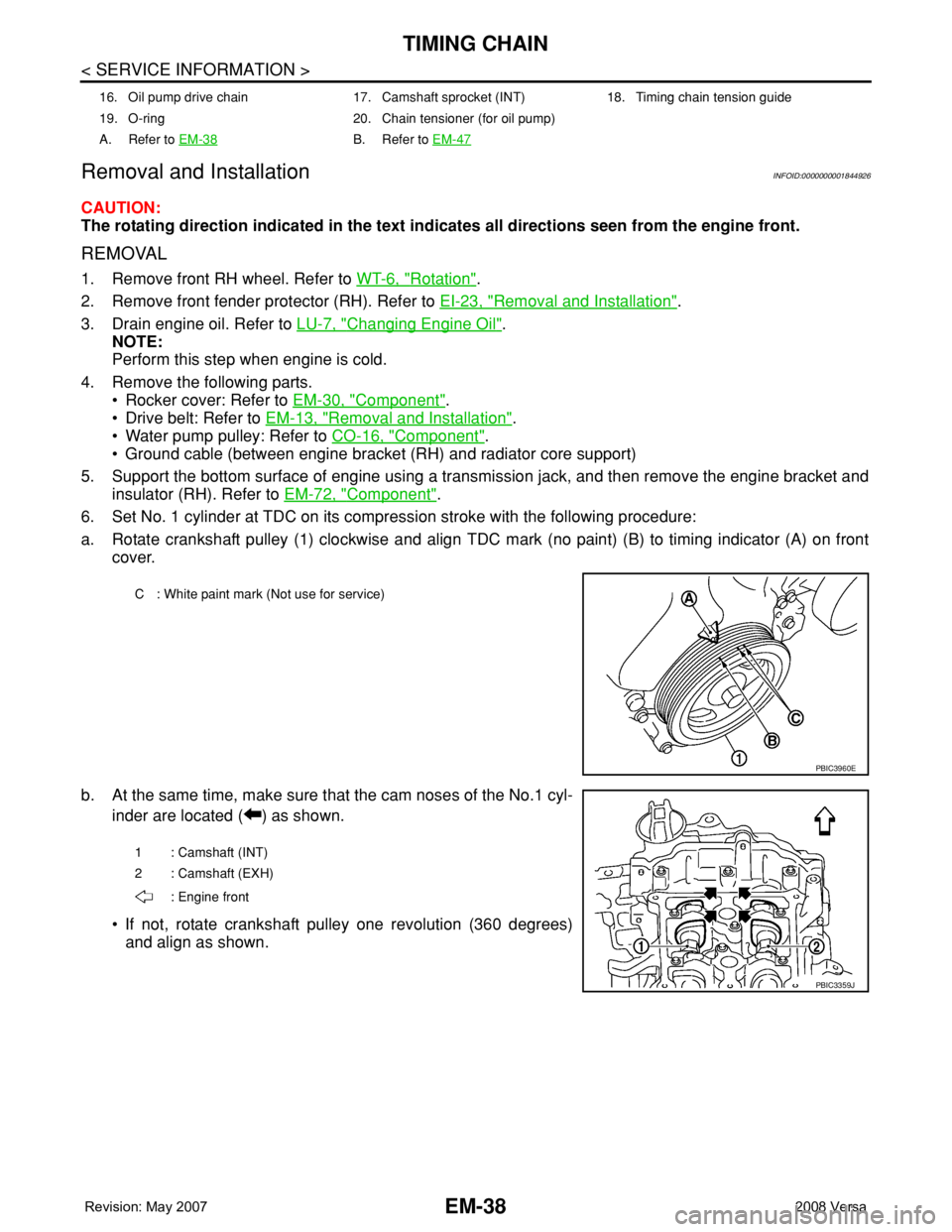

6. Set No. 1 cylinder at TDC on its compression stroke with the following procedure:

a. Rotate crankshaft pulley (1) clockwise and align TDC mark (no paint) (B) to timing indicator (A) on front

cover.

b. At the same time, make sure that the cam noses of the No.1 cyl-

inder are located ( ) as shown.

• If not, rotate crankshaft pulley one revolution (360 degrees)

and align as shown.

16. Oil pump drive chain 17. Camshaft sprocket (INT) 18. Timing chain tension guide

19. O-ring 20. Chain tensioner (for oil pump)

A. Refer to EM-38

B. Refer to EM-47

C : White paint mark (Not use for service)

PBIC3960E

1 : Camshaft (INT)

2 : Camshaft (EXH)

: Engine front

PBIC3359J

Page 1716 of 2771

TIMING CHAIN

EM-39

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

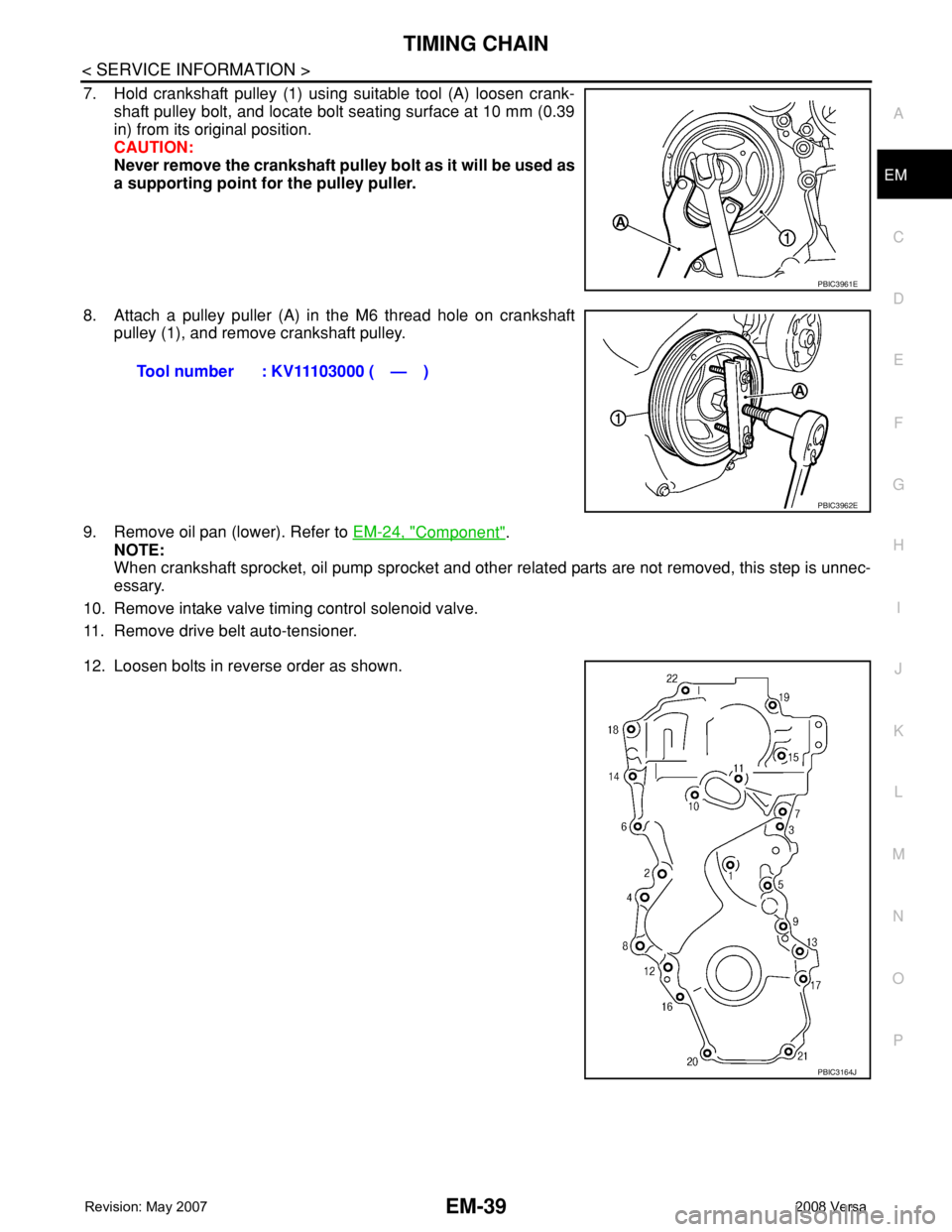

7. Hold crankshaft pulley (1) using suitable tool (A) loosen crank-

shaft pulley bolt, and locate bolt seating surface at 10 mm (0.39

in) from its original position.

CAUTION:

Never remove the crankshaft pulley bolt as it will be used as

a supporting point for the pulley puller.

8. Attach a pulley puller (A) in the M6 thread hole on crankshaft

pulley (1), and remove crankshaft pulley.

9. Remove oil pan (lower). Refer to EM-24, "

Component".

NOTE:

When crankshaft sprocket, oil pump sprocket and other related parts are not removed, this step is unnec-

essary.

10. Remove intake valve timing control solenoid valve.

11. Remove drive belt auto-tensioner.

12. Loosen bolts in reverse order as shown.

PBIC3961E

Tool number : KV11103000 ( — )

PBIC3962E

PBIC3164J

Page 1717 of 2771

EM-40

< SERVICE INFORMATION >

TIMING CHAIN

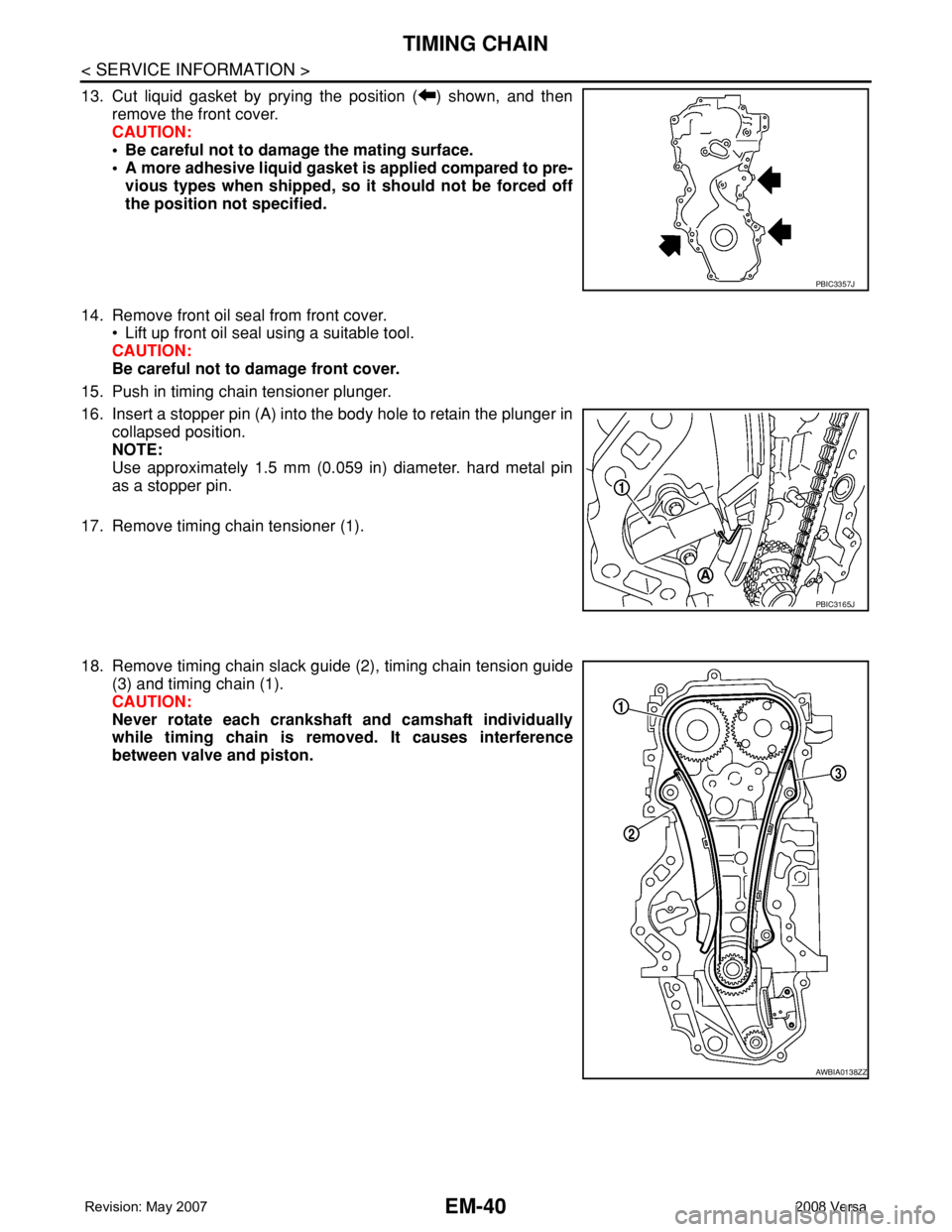

13. Cut liquid gasket by prying the position ( ) shown, and then

remove the front cover.

CAUTION:

• Be careful not to damage the mating surface.

• A more adhesive liquid gasket is applied compared to pre-

vious types when shipped, so it should not be forced off

the position not specified.

14. Remove front oil seal from front cover.

• Lift up front oil seal using a suitable tool.

CAUTION:

Be careful not to damage front cover.

15. Push in timing chain tensioner plunger.

16. Insert a stopper pin (A) into the body hole to retain the plunger in

collapsed position.

NOTE:

Use approximately 1.5 mm (0.059 in) diameter. hard metal pin

as a stopper pin.

17. Remove timing chain tensioner (1).

18. Remove timing chain slack guide (2), timing chain tension guide

(3) and timing chain (1).

CAUTION:

Never rotate each crankshaft and camshaft individually

while timing chain is removed. It causes interference

between valve and piston.

PBIC3357J

PBIC3165J

AWBIA0138ZZ

Page 1718 of 2771

TIMING CHAIN

EM-41

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

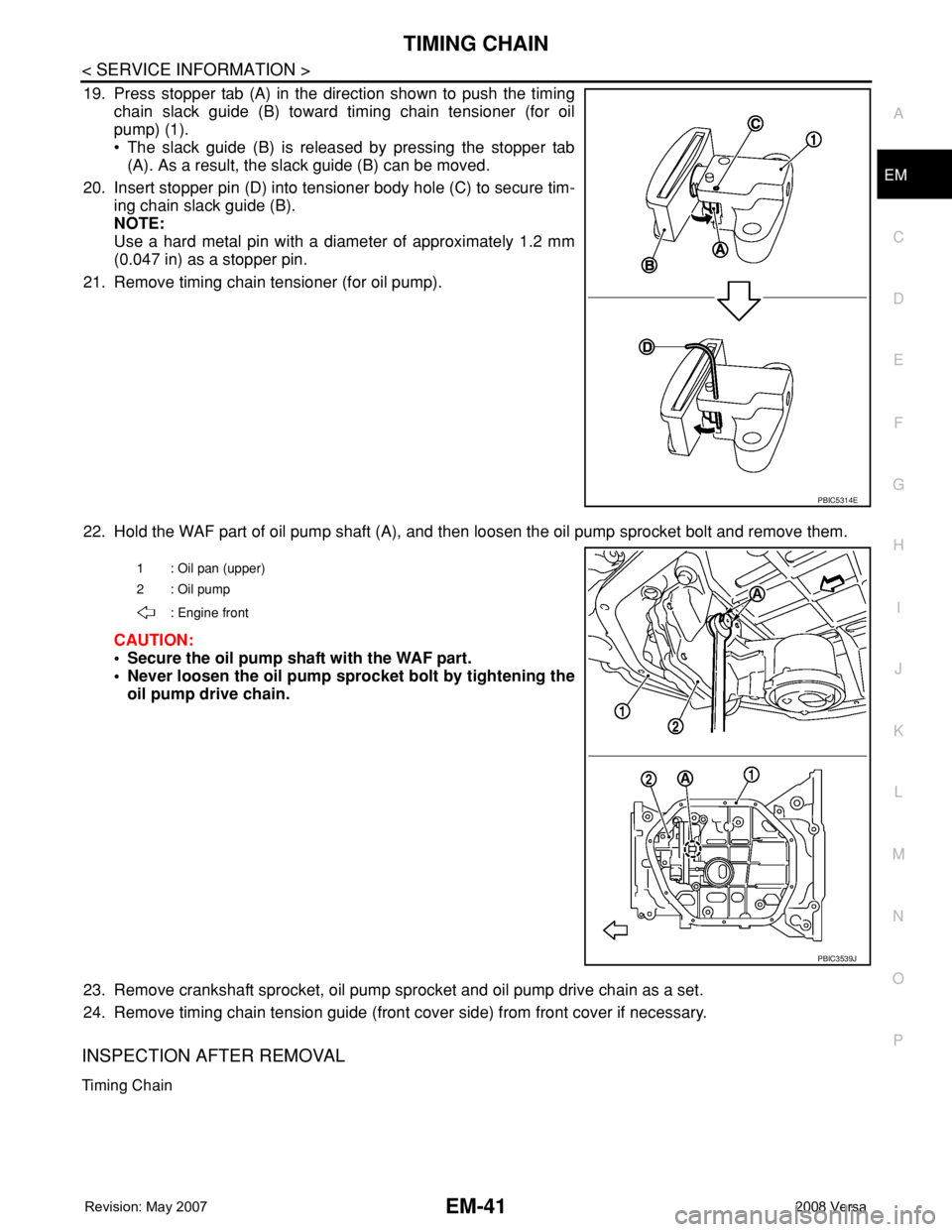

19. Press stopper tab (A) in the direction shown to push the timing

chain slack guide (B) toward timing chain tensioner (for oil

pump) (1).

• The slack guide (B) is released by pressing the stopper tab

(A). As a result, the slack guide (B) can be moved.

20. Insert stopper pin (D) into tensioner body hole (C) to secure tim-

ing chain slack guide (B).

NOTE:

Use a hard metal pin with a diameter of approximately 1.2 mm

(0.047 in) as a stopper pin.

21. Remove timing chain tensioner (for oil pump).

22. Hold the WAF part of oil pump shaft (A), and then loosen the oil pump sprocket bolt and remove them.

CAUTION:

• Secure the oil pump shaft with the WAF part.

• Never loosen the oil pump sprocket bolt by tightening the

oil pump drive chain.

23. Remove crankshaft sprocket, oil pump sprocket and oil pump drive chain as a set.

24. Remove timing chain tension guide (front cover side) from front cover if necessary.

INSPECTION AFTER REMOVAL

Timing Chain

PBIC5314E

1 : Oil pan (upper)

2: Oil pump

: Engine front

PBIC3539J

Page 1719 of 2771

EM-42

< SERVICE INFORMATION >

TIMING CHAIN

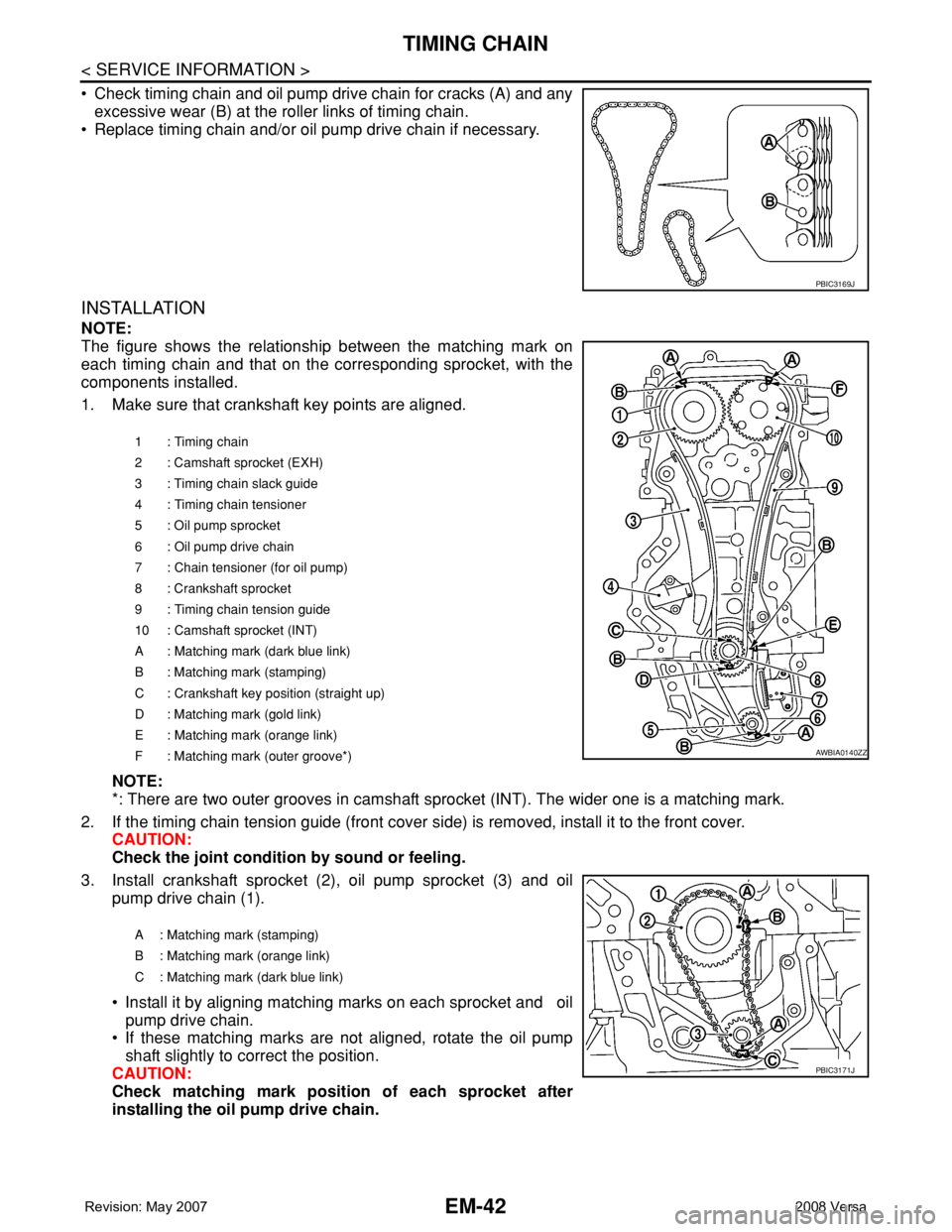

• Check timing chain and oil pump drive chain for cracks (A) and any

excessive wear (B) at the roller links of timing chain.

• Replace timing chain and/or oil pump drive chain if necessary.

INSTALLATION

NOTE:

The figure shows the relationship between the matching mark on

each timing chain and that on the corresponding sprocket, with the

components installed.

1. Make sure that crankshaft key points are aligned.

NOTE:

*: There are two outer grooves in camshaft sprocket (INT). The wider one is a matching mark.

2. If the timing chain tension guide (front cover side) is removed, install it to the front cover.

CAUTION:

Check the joint condition by sound or feeling.

3. Install crankshaft sprocket (2), oil pump sprocket (3) and oil

pump drive chain (1).

• Install it by aligning matching marks on each sprocket and oil

pump drive chain.

• If these matching marks are not aligned, rotate the oil pump

shaft slightly to correct the position.

CAUTION:

Check matching mark position of each sprocket after

installing the oil pump drive chain.

PBIC3169J

1 : Timing chain

2 : Camshaft sprocket (EXH)

3 : Timing chain slack guide

4 : Timing chain tensioner

5 : Oil pump sprocket

6 : Oil pump drive chain

7 : Chain tensioner (for oil pump)

8 : Crankshaft sprocket

9 : Timing chain tension guide

10 : Camshaft sprocket (INT)

A : Matching mark (dark blue link)

B : Matching mark (stamping)

C : Crankshaft key position (straight up)

D : Matching mark (gold link)

E : Matching mark (orange link)

F : Matching mark (outer groove*)

A : Matching mark (stamping)

B : Matching mark (orange link)

C : Matching mark (dark blue link)

AWBIA0140ZZ

PBIC3171J

Page 1720 of 2771

TIMING CHAIN

EM-43

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

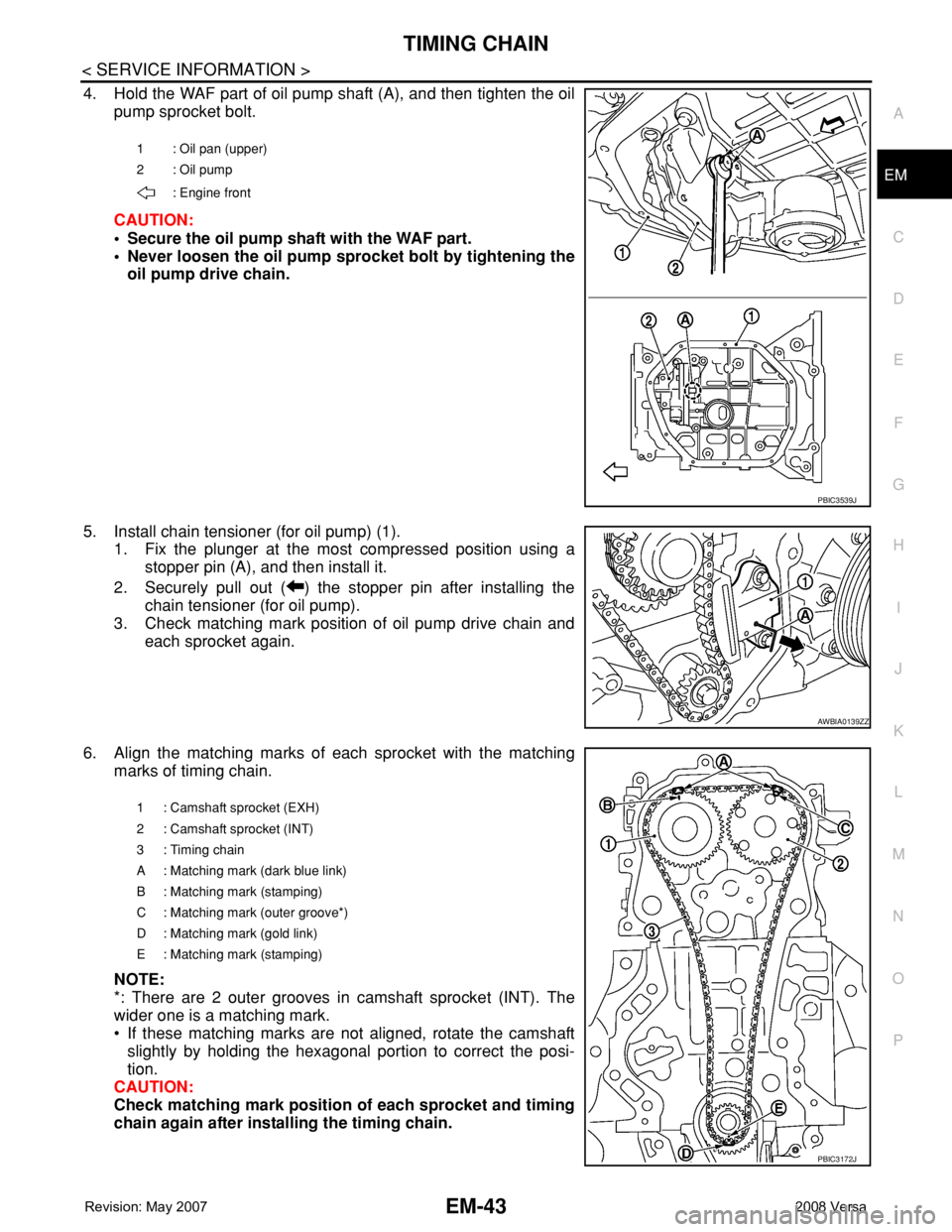

4. Hold the WAF part of oil pump shaft (A), and then tighten the oil

pump sprocket bolt.

CAUTION:

• Secure the oil pump shaft with the WAF part.

• Never loosen the oil pump sprocket bolt by tightening the

oil pump drive chain.

5. Install chain tensioner (for oil pump) (1).

1. Fix the plunger at the most compressed position using a

stopper pin (A), and then install it.

2. Securely pull out ( ) the stopper pin after installing the

chain tensioner (for oil pump).

3. Check matching mark position of oil pump drive chain and

each sprocket again.

6. Align the matching marks of each sprocket with the matching

marks of timing chain.

NOTE:

*: There are 2 outer grooves in camshaft sprocket (INT). The

wider one is a matching mark.

• If these matching marks are not aligned, rotate the camshaft

slightly by holding the hexagonal portion to correct the posi-

tion.

CAUTION:

Check matching mark position of each sprocket and timing

chain again after installing the timing chain.

1 : Oil pan (upper)

2 : Oil pump

: Engine front

PBIC3539J

AWBIA0139ZZ

1 : Camshaft sprocket (EXH)

2 : Camshaft sprocket (INT)

3: Timing chain

A : Matching mark (dark blue link)

B : Matching mark (stamping)

C : Matching mark (outer groove*)

D : Matching mark (gold link)

E : Matching mark (stamping)

PBIC3172J