NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1691 of 2771

EM-14

< SERVICE INFORMATION >

DRIVE BELTS

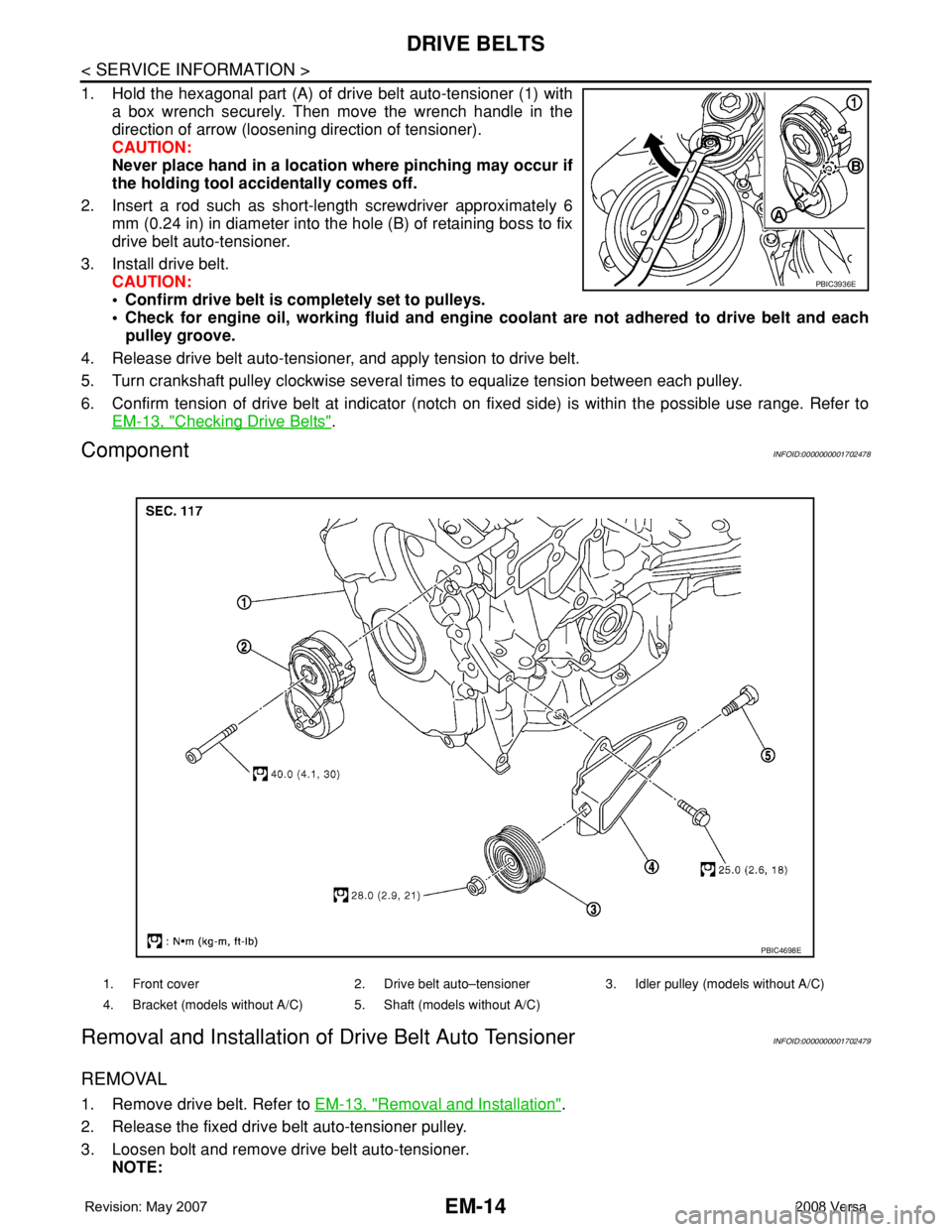

1. Hold the hexagonal part (A) of drive belt auto-tensioner (1) with

a box wrench securely. Then move the wrench handle in the

direction of arrow (loosening direction of tensioner).

CAUTION:

Never place hand in a location where pinching may occur if

the holding tool accidentally comes off.

2. Insert a rod such as short-length screwdriver approximately 6

mm (0.24 in) in diameter into the hole (B) of retaining boss to fix

drive belt auto-tensioner.

3. Install drive belt.

CAUTION:

• Confirm drive belt is completely set to pulleys.

• Check for engine oil, working fluid and engine coolant are not adhered to drive belt and each

pulley groove.

4. Release drive belt auto-tensioner, and apply tension to drive belt.

5. Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

6. Confirm tension of drive belt at indicator (notch on fixed side) is within the possible use range. Refer to

EM-13, "

Checking Drive Belts".

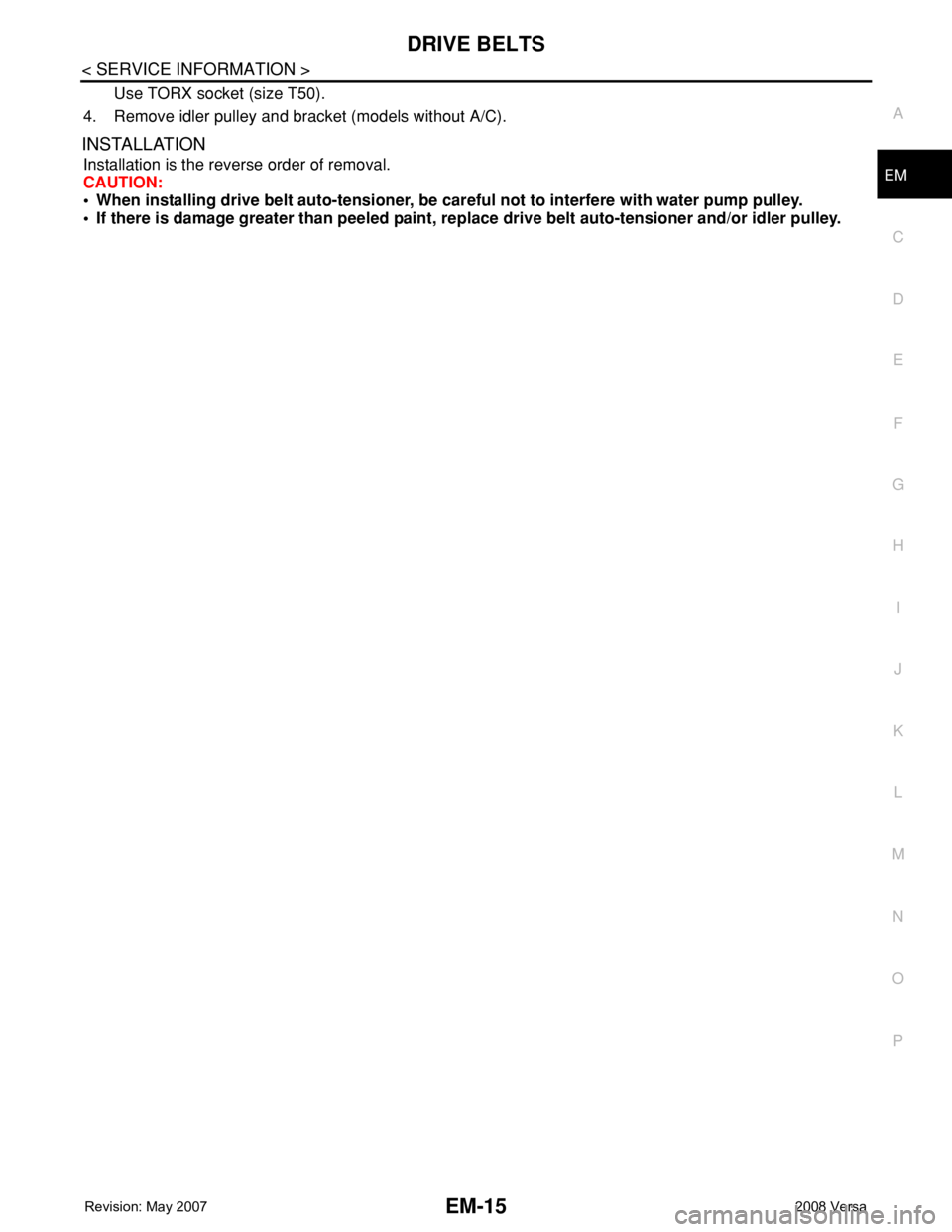

ComponentINFOID:0000000001702478

Removal and Installation of Drive Belt Auto TensionerINFOID:0000000001702479

REMOVAL

1. Remove drive belt. Refer to EM-13, "Removal and Installation".

2. Release the fixed drive belt auto-tensioner pulley.

3. Loosen bolt and remove drive belt auto-tensioner.

NOTE:

PBIC3936E

1. Front cover 2. Drive belt auto–tensioner 3. Idler pulley (models without A/C)

4. Bracket (models without A/C) 5. Shaft (models without A/C)

PBIC4698E

Page 1692 of 2771

DRIVE BELTS

EM-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Use TORX socket (size T50).

4. Remove idler pulley and bracket (models without A/C).

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

• When installing drive belt auto-tensioner, be careful not to interfere with water pump pulley.

• If there is damage greater than peeled paint, replace drive belt auto-tensioner and/or idler pulley.

Page 1693 of 2771

EM-16

< SERVICE INFORMATION >

AIR CLEANER AND AIR DUCT

AIR CLEANER AND AIR DUCT

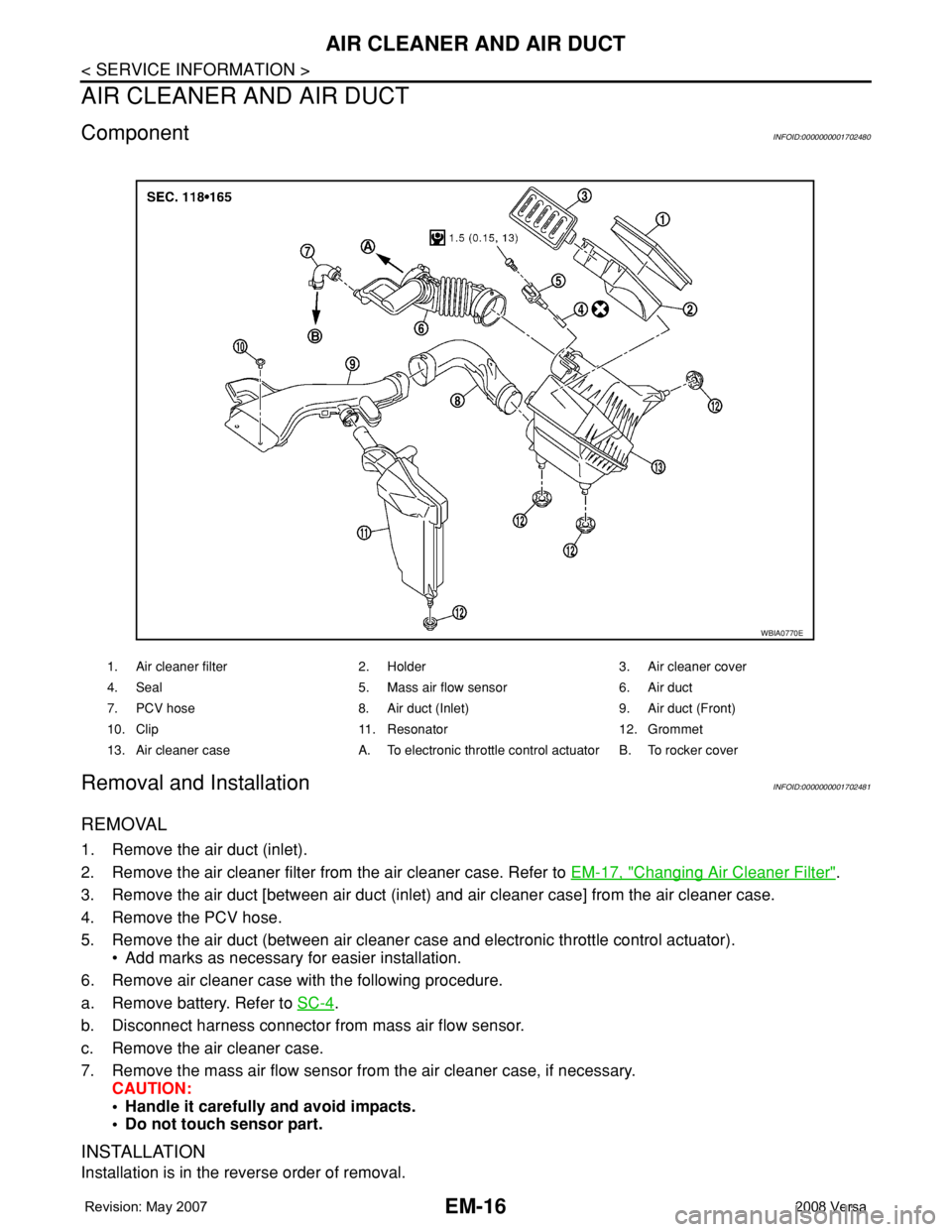

ComponentINFOID:0000000001702480

Removal and InstallationINFOID:0000000001702481

REMOVAL

1. Remove the air duct (inlet).

2. Remove the air cleaner filter from the air cleaner case. Refer to EM-17, "

Changing Air Cleaner Filter".

3. Remove the air duct [between air duct (inlet) and air cleaner case] from the air cleaner case.

4. Remove the PCV hose.

5. Remove the air duct (between air cleaner case and electronic throttle control actuator).

• Add marks as necessary for easier installation.

6. Remove air cleaner case with the following procedure.

a. Remove battery. Refer to SC-4

.

b. Disconnect harness connector from mass air flow sensor.

c. Remove the air cleaner case.

7. Remove the mass air flow sensor from the air cleaner case, if necessary.

CAUTION:

• Handle it carefully and avoid impacts.

• Do not touch sensor part.

INSTALLATION

Installation is in the reverse order of removal.

1. Air cleaner filter 2. Holder 3. Air cleaner cover

4. Seal 5. Mass air flow sensor 6. Air duct

7. PCV hose 8. Air duct (Inlet) 9. Air duct (Front)

10. Clip 11. Resonator 12. Grommet

13. Air cleaner case A. To electronic throttle control actuator B. To rocker cover

WBIA0770E

Page 1694 of 2771

AIR CLEANER AND AIR DUCT

EM-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

• Align marks.

• Attach each joint securely.

• Screw clamps firmly.

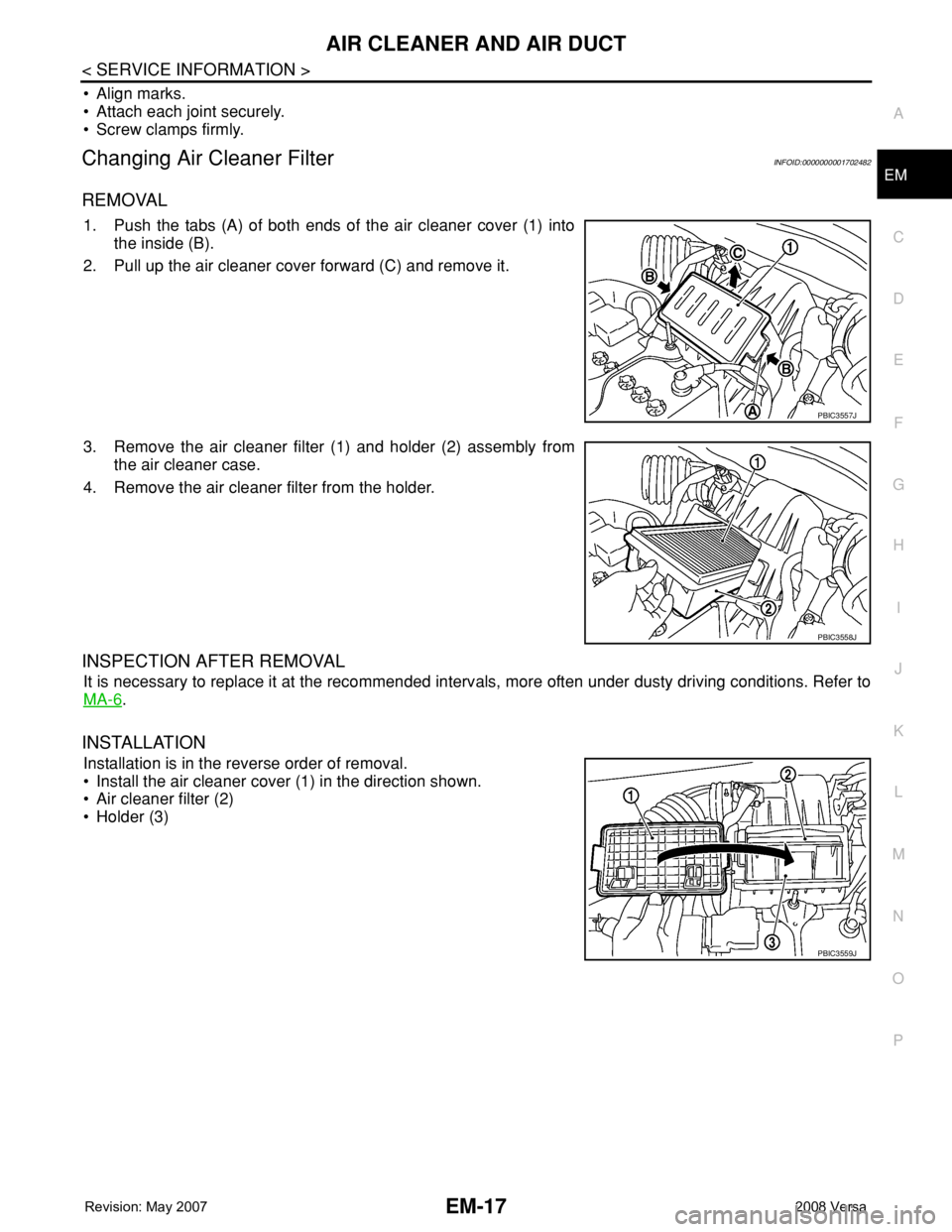

Changing Air Cleaner FilterINFOID:0000000001702482

REMOVAL

1. Push the tabs (A) of both ends of the air cleaner cover (1) into

the inside (B).

2. Pull up the air cleaner cover forward (C) and remove it.

3. Remove the air cleaner filter (1) and holder (2) assembly from

the air cleaner case.

4. Remove the air cleaner filter from the holder.

INSPECTION AFTER REMOVAL

It is necessary to replace it at the recommended intervals, more often under dusty driving conditions. Refer to

MA-6

.

INSTALLATION

Installation is in the reverse order of removal.

• Install the air cleaner cover (1) in the direction shown.

• Air cleaner filter (2)

• Holder (3)

PBIC3557J

PBIC3558J

PBIC3559J

Page 1695 of 2771

EM-18

< SERVICE INFORMATION >

INTAKE MANIFOLD

INTAKE MANIFOLD

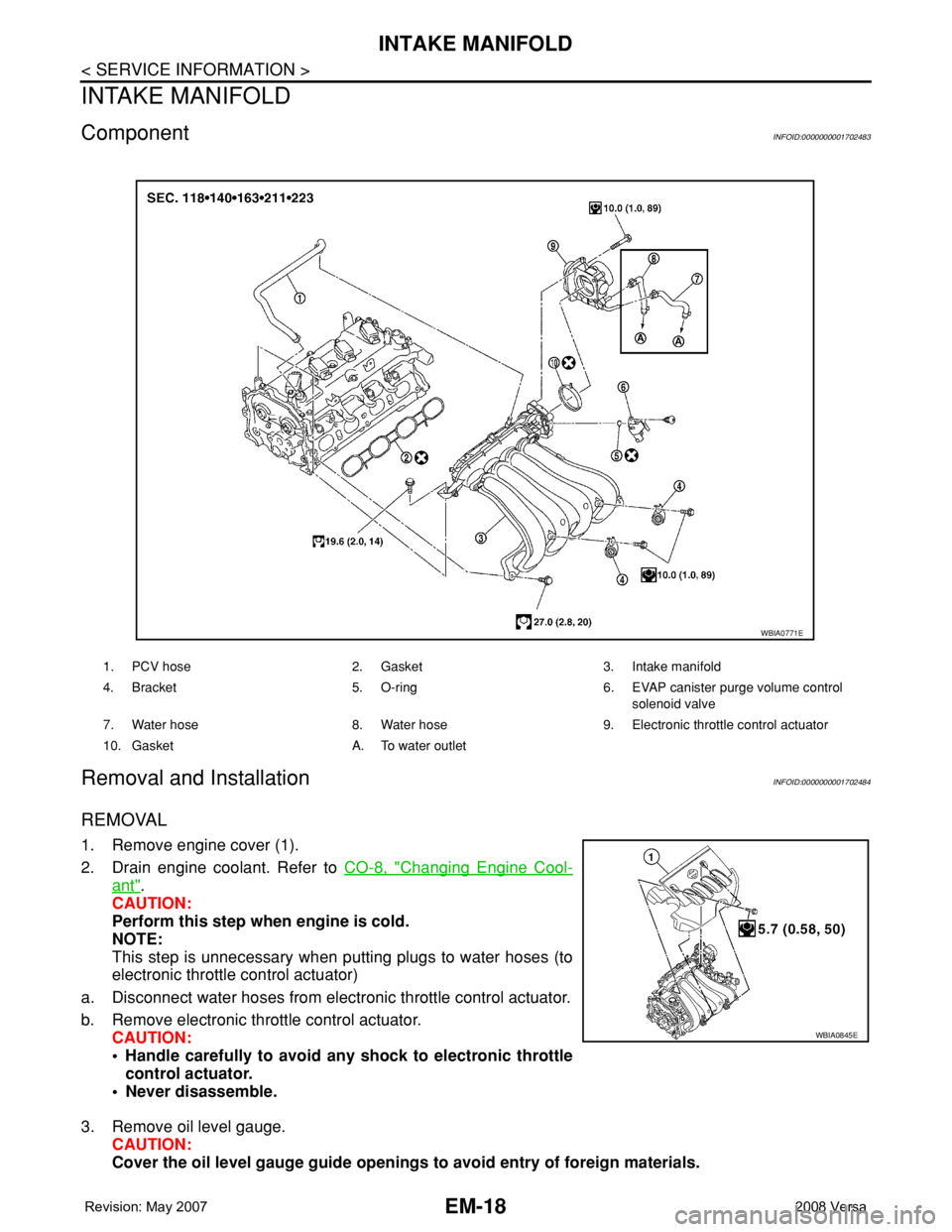

ComponentINFOID:0000000001702483

Removal and InstallationINFOID:0000000001702484

REMOVAL

1. Remove engine cover (1).

2. Drain engine coolant. Refer to CO-8, "

Changing Engine Cool-

ant".

CAUTION:

Perform this step when engine is cold.

NOTE:

This step is unnecessary when putting plugs to water hoses (to

electronic throttle control actuator)

a. Disconnect water hoses from electronic throttle control actuator.

b. Remove electronic throttle control actuator.

CAUTION:

• Handle carefully to avoid any shock to electronic throttle

control actuator.

• Never disassemble.

3. Remove oil level gauge.

CAUTION:

Cover the oil level gauge guide openings to avoid entry of foreign materials.

1. PCV hose 2. Gasket 3. Intake manifold

4. Bracket 5. O-ring 6. EVAP canister purge volume control

solenoid valve

7. Water hose 8. Water hose 9. Electronic throttle control actuator

10. Gasket A. To water outlet

WBIA0771E

WBIA0845E

Page 1696 of 2771

INTAKE MANIFOLD

EM-19

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

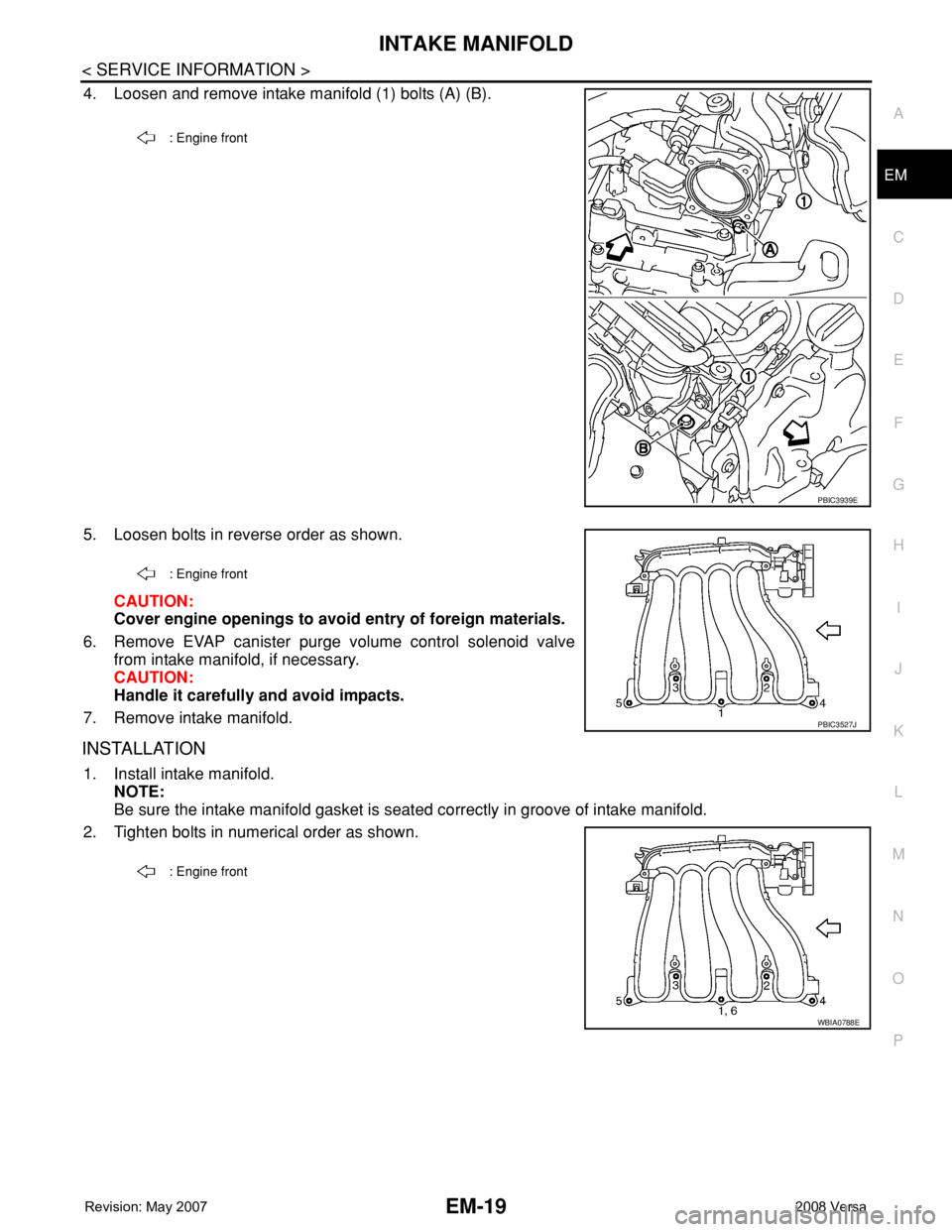

4. Loosen and remove intake manifold (1) bolts (A) (B).

5. Loosen bolts in reverse order as shown.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

6. Remove EVAP canister purge volume control solenoid valve

from intake manifold, if necessary.

CAUTION:

Handle it carefully and avoid impacts.

7. Remove intake manifold.

INSTALLATION

1. Install intake manifold.

NOTE:

Be sure the intake manifold gasket is seated correctly in groove of intake manifold.

2. Tighten bolts in numerical order as shown.

: Engine front

PBIC3939E

: Engine front

PBIC3527J

: Engine front

WBIA0788E

Page 1697 of 2771

EM-20

< SERVICE INFORMATION >

INTAKE MANIFOLD

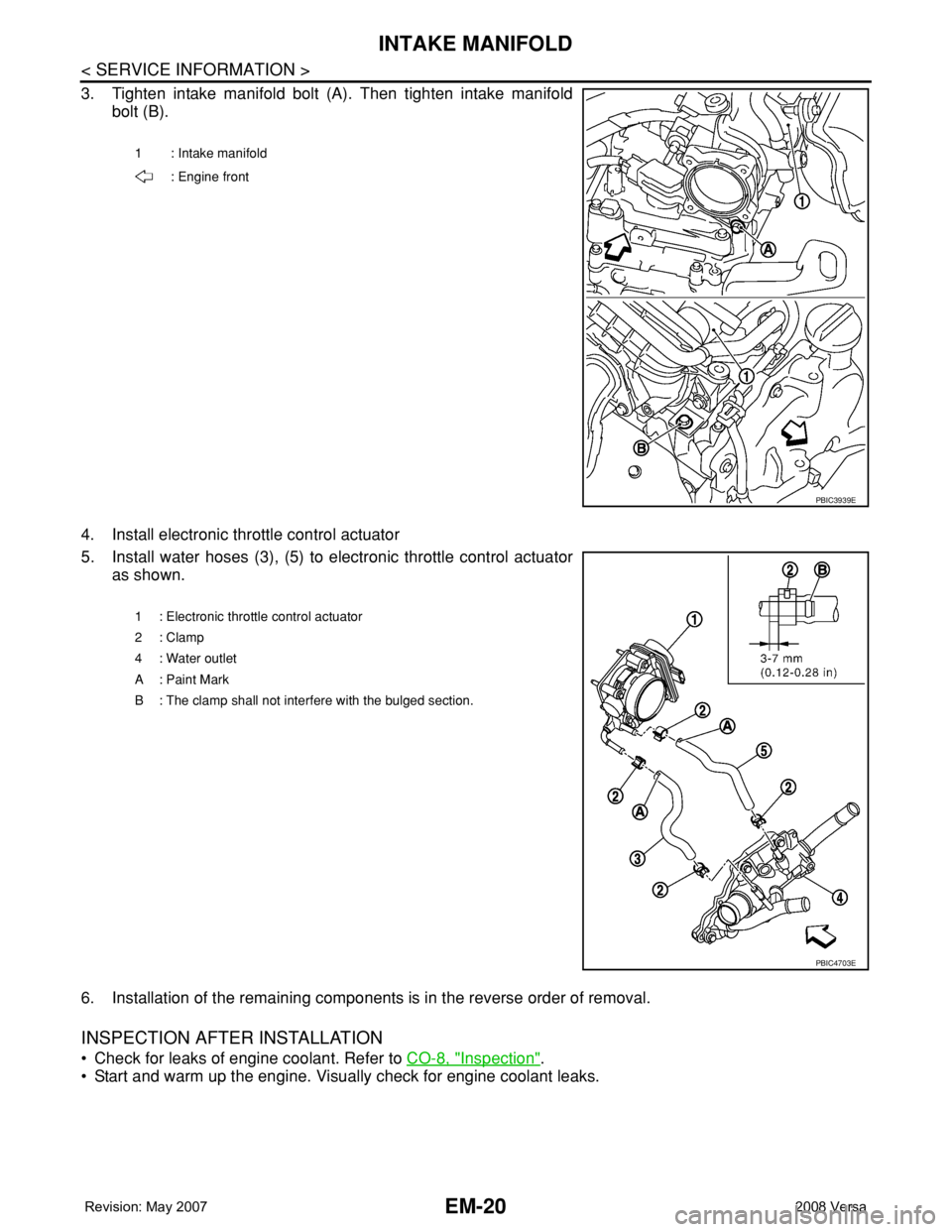

3. Tighten intake manifold bolt (A). Then tighten intake manifold

bolt (B).

4. Install electronic throttle control actuator

5. Install water hoses (3), (5) to electronic throttle control actuator

as shown.

6. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Check for leaks of engine coolant. Refer to CO-8, "Inspection".

• Start and warm up the engine. Visually check for engine coolant leaks.

1 : Intake manifold

: Engine front

PBIC3939E

1 : Electronic throttle control actuator

2: Clamp

4 : Water outlet

A: Paint Mark

B : The clamp shall not interfere with the bulged section.

PBIC4703E

Page 1698 of 2771

EXHAUST MANIFOLD

EM-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

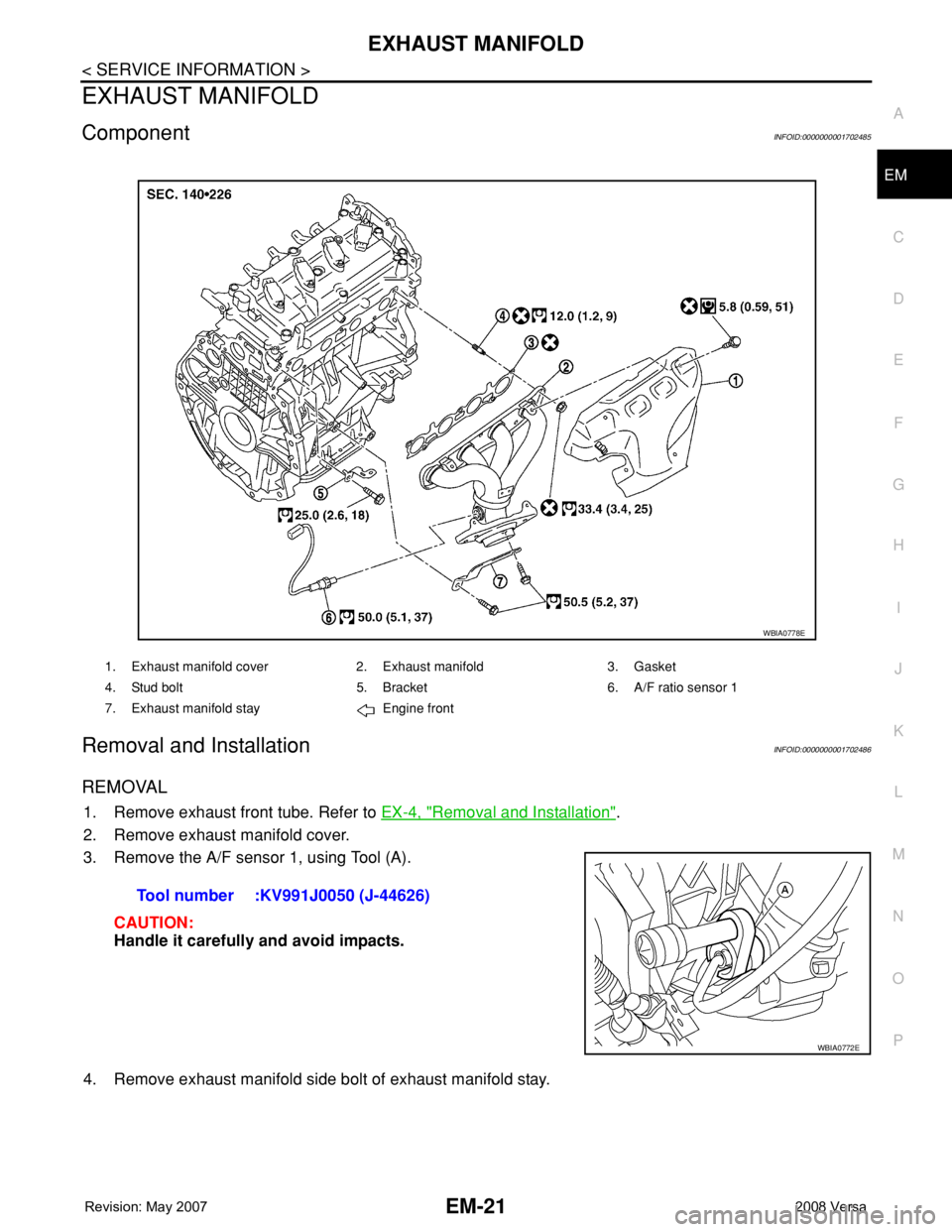

EXHAUST MANIFOLD

ComponentINFOID:0000000001702485

Removal and InstallationINFOID:0000000001702486

REMOVAL

1. Remove exhaust front tube. Refer to EX-4, "Removal and Installation".

2. Remove exhaust manifold cover.

3. Remove the A/F sensor 1, using Tool (A).

CAUTION:

Handle it carefully and avoid impacts.

4. Remove exhaust manifold side bolt of exhaust manifold stay.

1. Exhaust manifold cover 2. Exhaust manifold 3. Gasket

4. Stud bolt 5. Bracket 6. A/F ratio sensor 1

7. Exhaust manifold stay Engine front

WBIA0778E

Tool number :KV991J0050 (J-44626)

WBIA0772E

Page 1699 of 2771

EM-22

< SERVICE INFORMATION >

EXHAUST MANIFOLD

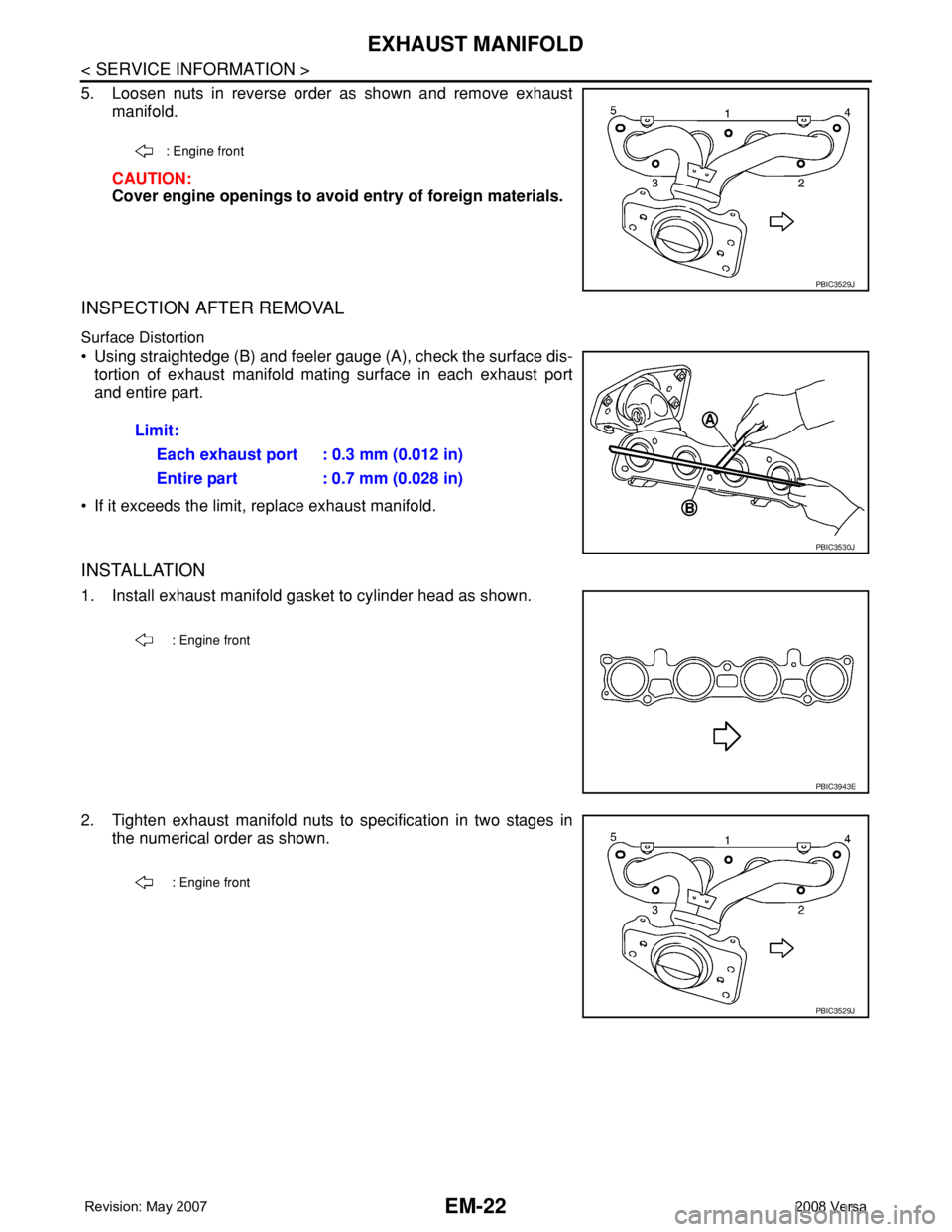

5. Loosen nuts in reverse order as shown and remove exhaust

manifold.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSPECTION AFTER REMOVAL

Surface Distortion

• Using straightedge (B) and feeler gauge (A), check the surface dis-

tortion of exhaust manifold mating surface in each exhaust port

and entire part.

• If it exceeds the limit, replace exhaust manifold.

INSTALLATION

1. Install exhaust manifold gasket to cylinder head as shown.

2. Tighten exhaust manifold nuts to specification in two stages in

the numerical order as shown.

: Engine front

PBIC3529J

Limit:

Each exhaust port : 0.3 mm (0.012 in)

Entire part : 0.7 mm (0.028 in)

PBIC3530J

: Engine front

PBIC3943E

: Engine front

PBIC3529J

Page 1700 of 2771

EXHAUST MANIFOLD

EM-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

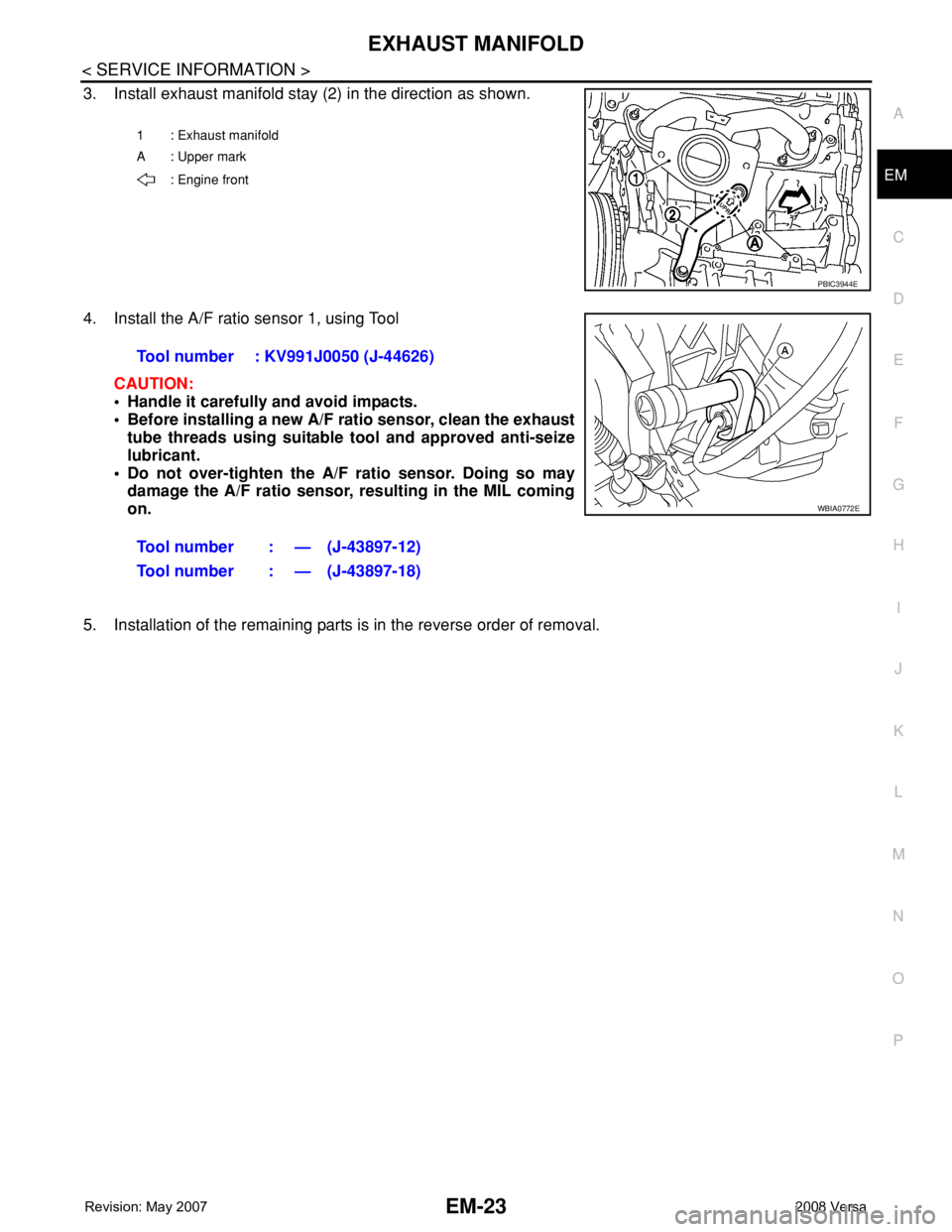

3. Install exhaust manifold stay (2) in the direction as shown.

4. Install the A/F ratio sensor 1, using Tool

CAUTION:

• Handle it carefully and avoid impacts.

• Before installing a new A/F ratio sensor, clean the exhaust

tube threads using suitable tool and approved anti-seize

lubricant.

• Do not over-tighten the A/F ratio sensor. Doing so may

damage the A/F ratio sensor, resulting in the MIL coming

on.

5. Installation of the remaining parts is in the reverse order of removal.

1 : Exhaust manifold

A : Upper mark

: Engine front

PBIC3944E

Tool number : KV991J0050 (J-44626)

Tool number : — (J-43897-12)

Tool number : — (J-43897-18)

WBIA0772E