Fill Plug NISSAN TIIDA 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 2278 of 2771

MA-18

< SERVICE INFORMATION >

ENGINE MAINTENANCE

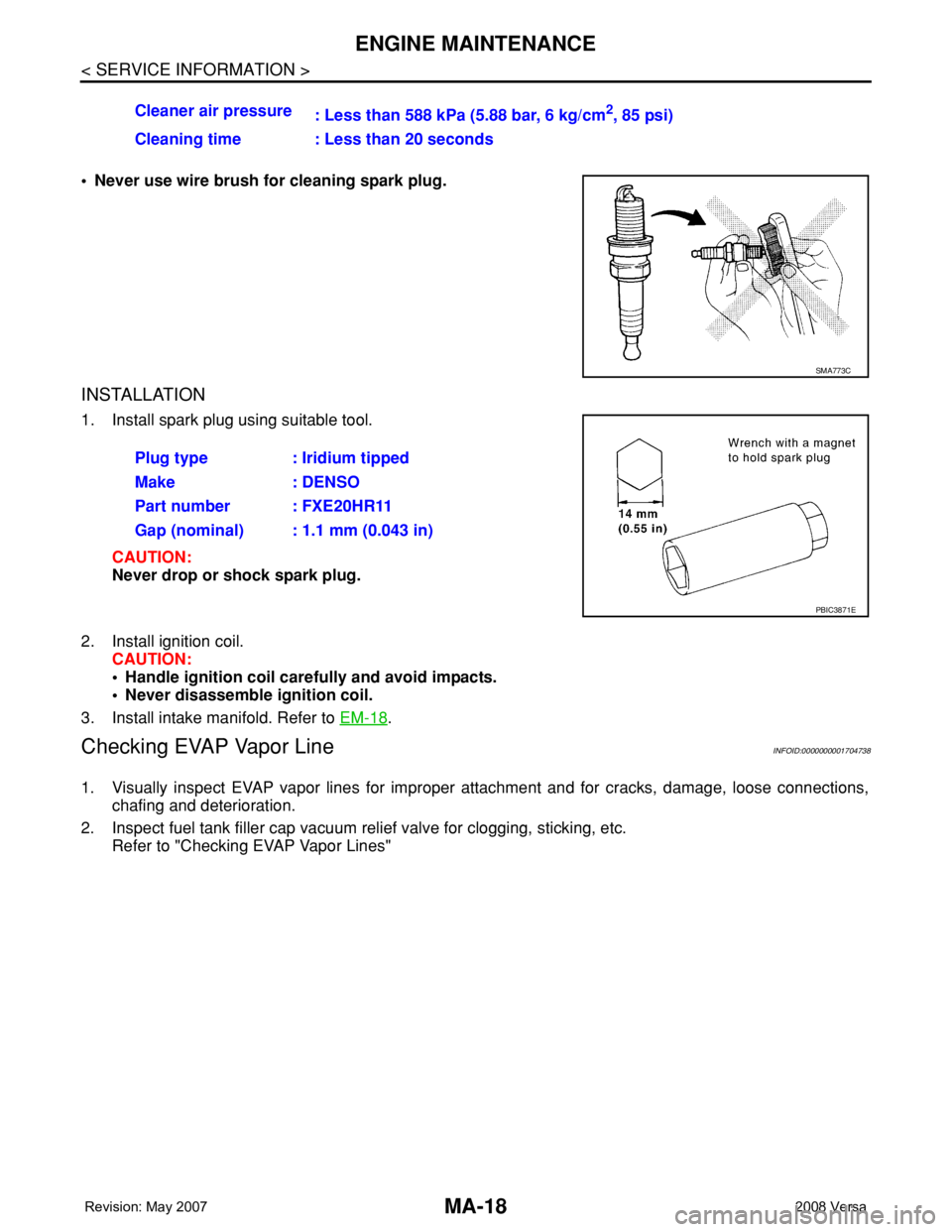

• Never use wire brush for cleaning spark plug.

INSTALLATION

1. Install spark plug using suitable tool.

CAUTION:

Never drop or shock spark plug.

2. Install ignition coil.

CAUTION:

• Handle ignition coil carefully and avoid impacts.

• Never disassemble ignition coil.

3. Install intake manifold. Refer to EM-18

.

Checking EVAP Vapor LineINFOID:0000000001704738

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to "Checking EVAP Vapor Lines"Cleaner air pressure

: Less than 588 kPa (5.88 bar, 6 kg/cm

2, 85 psi)

Cleaning time : Less than 20 seconds

SMA773C

Plug type : Iridium tipped

Make : DENSO

Part number : FXE20HR11

Gap (nominal) : 1.1 mm (0.043 in)

PBIC3871E

Page 2281 of 2771

CHASSIS AND BODY MAINTENANCE

MA-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to MA-19, "

Checking CVT Fluid" .

CAUTION:

Delete CVT fluid deterioration date with CONSULT-II after changing CVT fluid. Refer to CVT-47,

"CONSULT-III Function (TRANSMISSION)" .

Checking Clutch Fluid Level and LeaksINFOID:0000000001704743

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch SystemINFOID:0000000001704744

Check fluid lines and operating cylinder for improper attachment, cracks, damage, loose connections, chafing

and deterioration.

Checking M/T OilINFOID:0000000001704745

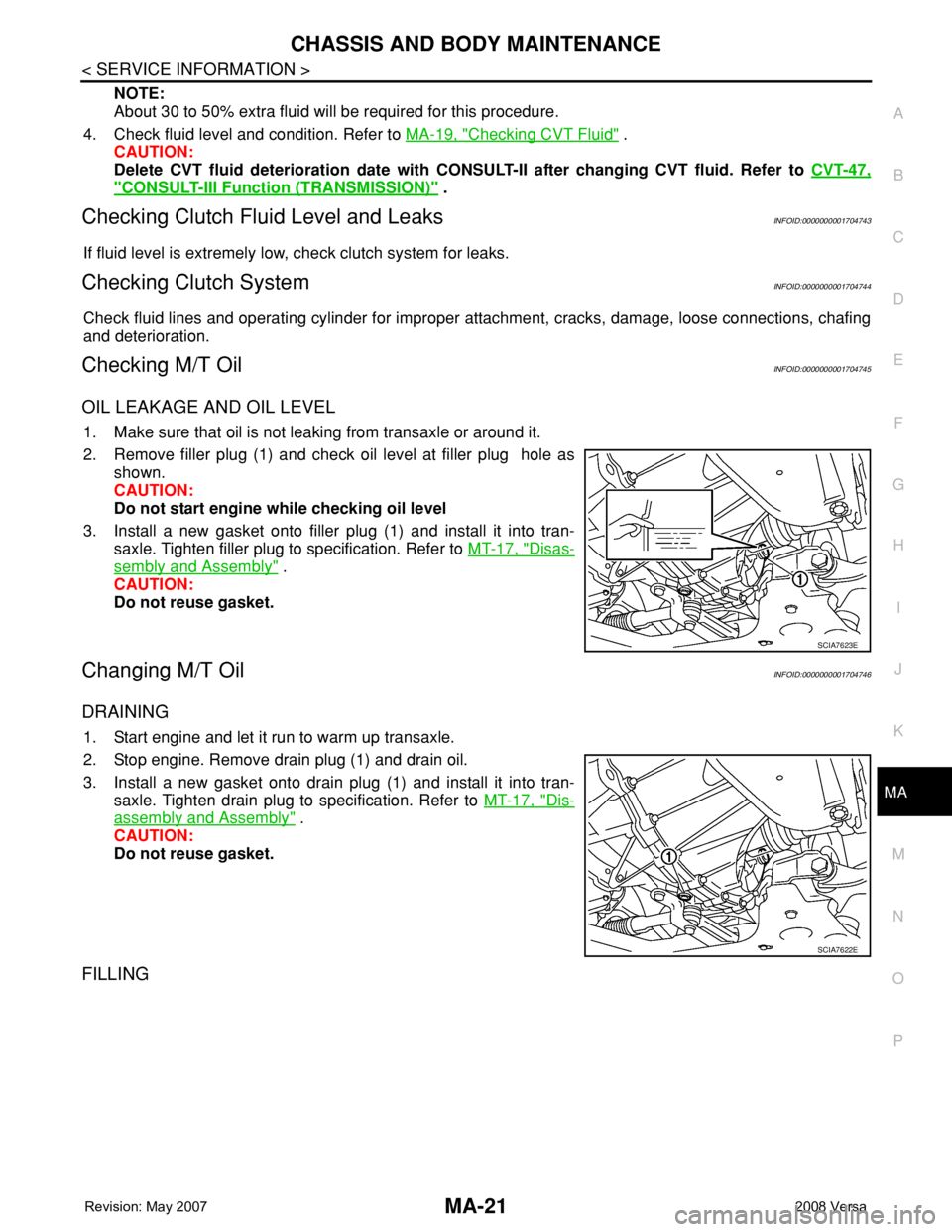

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as

shown.

CAUTION:

Do not start engine while checking oil level

3. Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-17, "

Disas-

sembly and Assembly" .

CAUTION:

Do not reuse gasket.

Changing M/T OilINFOID:0000000001704746

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into tran-

saxle. Tighten drain plug to specification. Refer to MT-17, "

Dis-

assembly and Assembly" .

CAUTION:

Do not reuse gasket.

FILLING

SCIA7623E

SCIA7622E

Page 2282 of 2771

MA-22

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug

(1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-17, "

Disassembly and Assembly" .

CAUTION:

Do not reuse gasket.

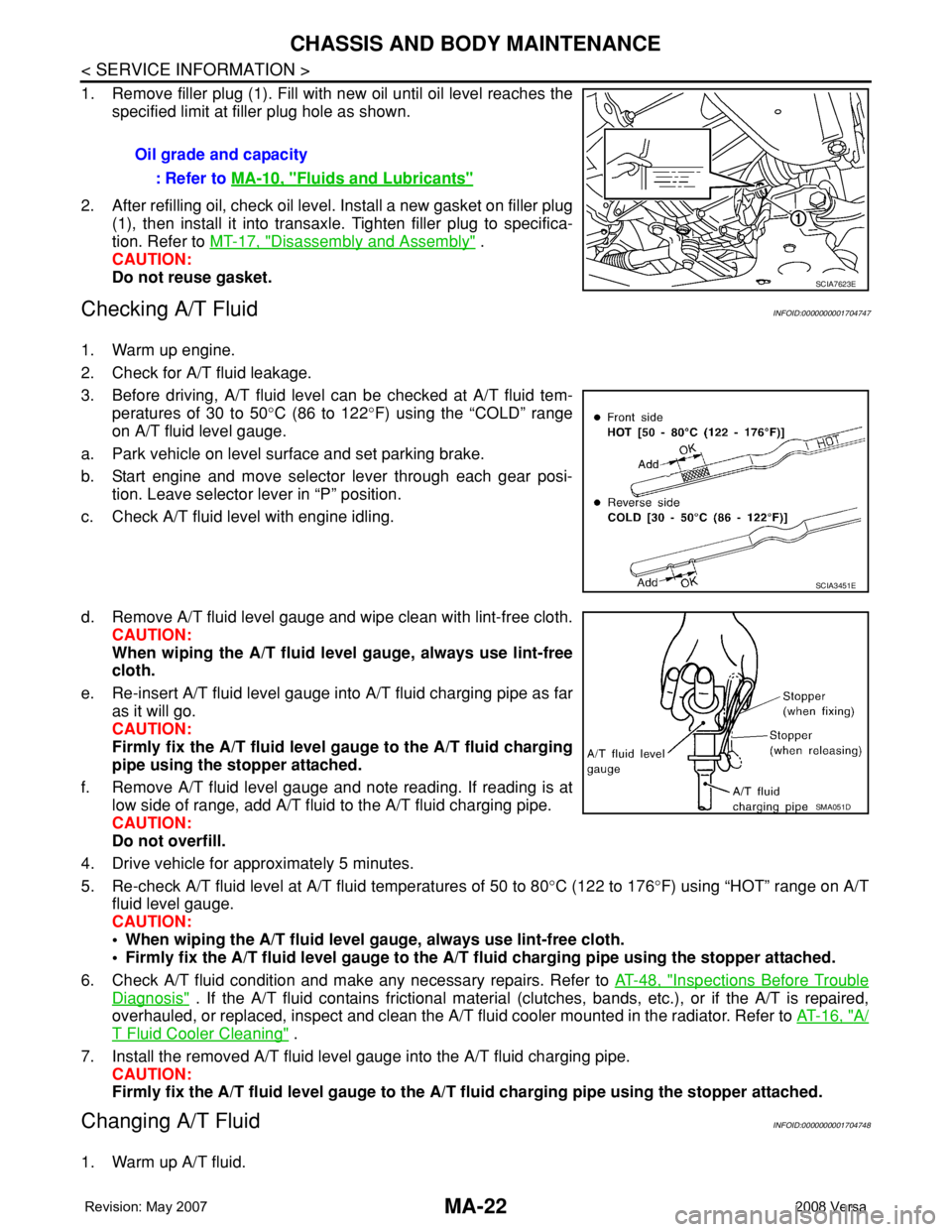

Checking A/T FluidINFOID:0000000001704747

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Before driving, A/T fluid level can be checked at A/T fluid tem-

peratures of 30 to 50°C (86 to 122°F) using the “COLD” range

on A/T fluid level gauge.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth.

CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far

as it will go.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at

low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on A/T

fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-48, "

Inspections Before Trouble

Diagnosis" . If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired,

overhauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-16, "

A/

T Fluid Cooler Cleaning" .

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

Changing A/T FluidINFOID:0000000001704748

1. Warm up A/T fluid.Oil grade and capacity

: Refer to MA-10, "

Fluids and Lubricants"

SCIA7623E

SCIA3451E

SMA051D

Page 2283 of 2771

CHASSIS AND BODY MAINTENANCE

MA-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

2. Stop engine.

3. Drain A/T fluid by removing the drain plug. Reinstall the drain plug to the specified torque.

CAUTION:

Do not reuse drain plug gasket.

4. Refill the transaxle with new specified A/T fluid through the A/T fluid charging pipe. Always refill the tran-

saxle with the same volume of A/T fluid that was drained out.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to MA-22, "

Checking A/T Fluid" .

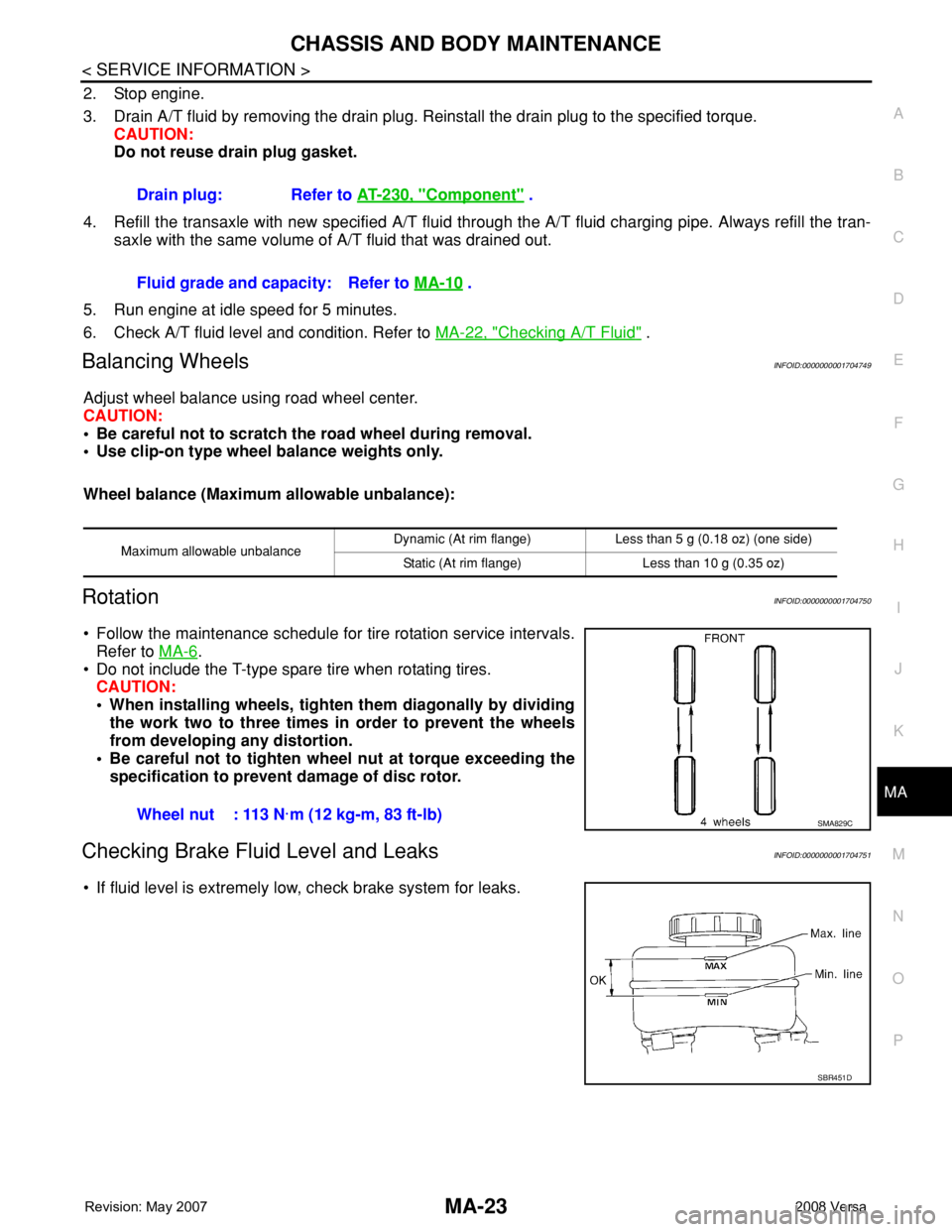

Balancing WheelsINFOID:0000000001704749

Adjust wheel balance using road wheel center.

CAUTION:

• Be careful not to scratch the road wheel during removal.

• Use clip-on type wheel balance weights only.

Wheel balance (Maximum allowable unbalance):

RotationINFOID:0000000001704750

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-6

.

• Do not include the T-type spare tire when rotating tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

specification to prevent damage of disc rotor.

Checking Brake Fluid Level and LeaksINFOID:0000000001704751

• If fluid level is extremely low, check brake system for leaks.Drain plug: Refer to AT-230, "

Component" .

Fluid grade and capacity: Refer to MA-10

.

Maximum allowable unbalanceDynamic (At rim flange) Less than 5 g (0.18 oz) (one side)

Static (At rim flange) Less than 10 g (0.35 oz)

Wheel nut : 113 N·m (12 kg-m, 83 ft-lb)SMA829C

SBR451D

Page 2298 of 2771

MT-10

< SERVICE INFORMATION >

M/T OIL

M/T OIL

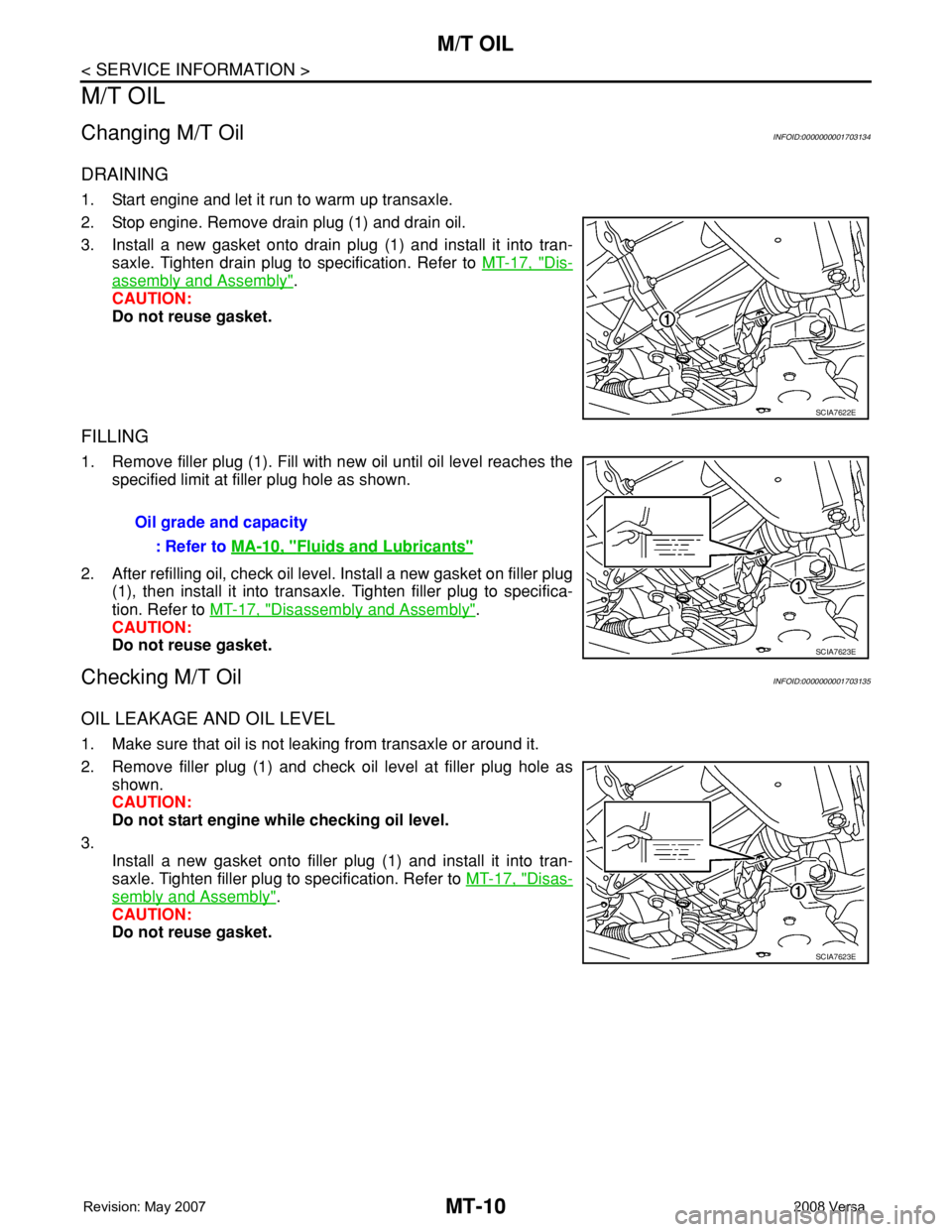

Changing M/T OilINFOID:0000000001703134

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into tran-

saxle. Tighten drain plug to specification. Refer to MT-17, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug

(1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-17, "

Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

Checking M/T OilINFOID:0000000001703135

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as

shown.

CAUTION:

Do not start engine while checking oil level.

3.

Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-17, "

Disas-

sembly and Assembly".

CAUTION:

Do not reuse gasket.

SCIA7622E

Oil grade and capacity

: Refer to MA-10, "

Fluids and Lubricants"

SCIA7623E

SCIA7623E

Page 2306 of 2771

MT-18

< SERVICE INFORMATION >

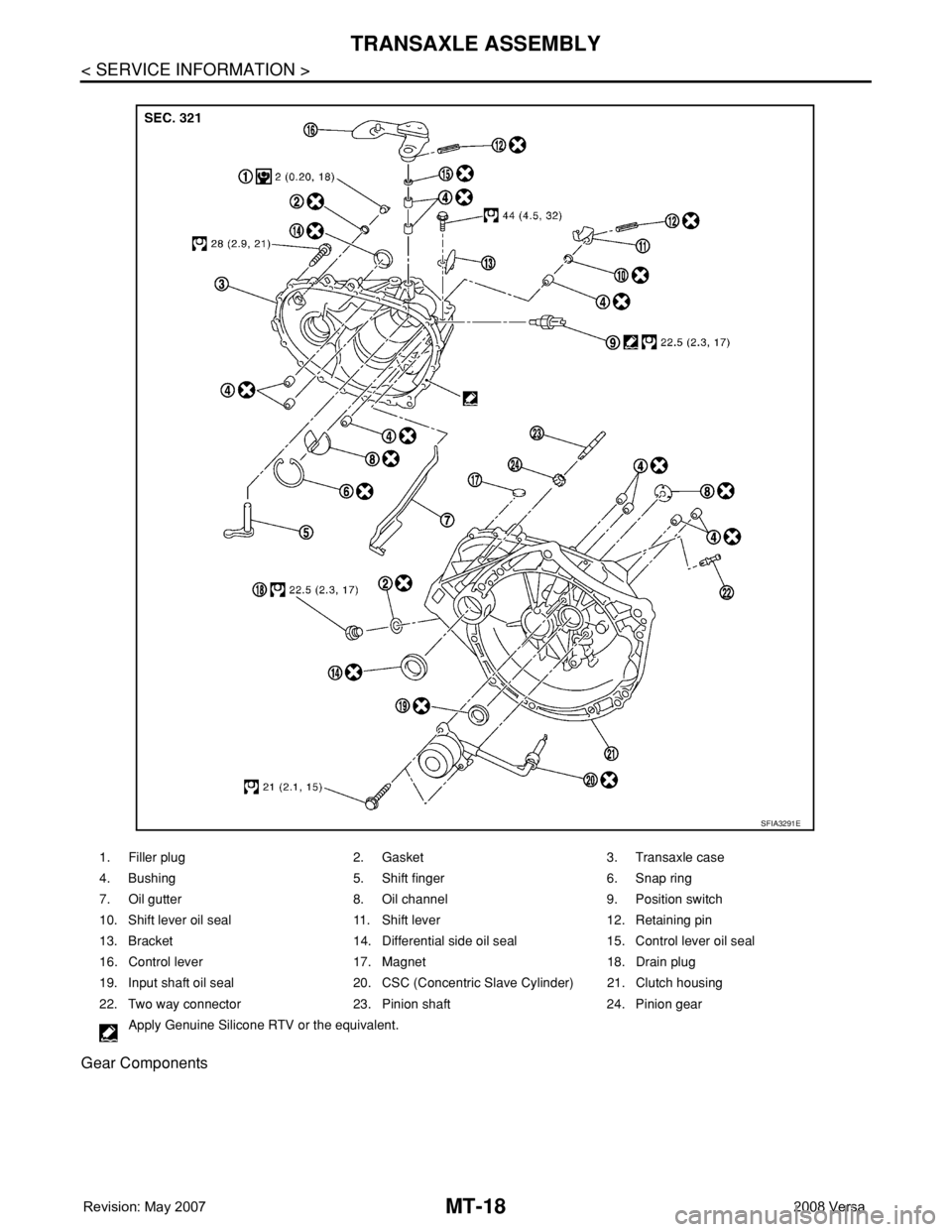

TRANSAXLE ASSEMBLY

Gear Components

1. Filler plug 2. Gasket 3. Transaxle case

4. Bushing 5. Shift finger 6. Snap ring

7. Oil gutter 8. Oil channel 9. Position switch

10. Shift lever oil seal 11. Shift lever 12. Retaining pin

13. Bracket 14. Differential side oil seal 15. Control lever oil seal

16. Control lever 17. Magnet 18. Drain plug

19. Input shaft oil seal 20. CSC (Concentric Slave Cylinder) 21. Clutch housing

22. Two way connector 23. Pinion shaft 24. Pinion gear

Apply Genuine Silicone RTV or the equivalent.

SFIA3291E

Page 2311 of 2771

TRANSAXLE ASSEMBLY

MT-23

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

MT

N

O

P

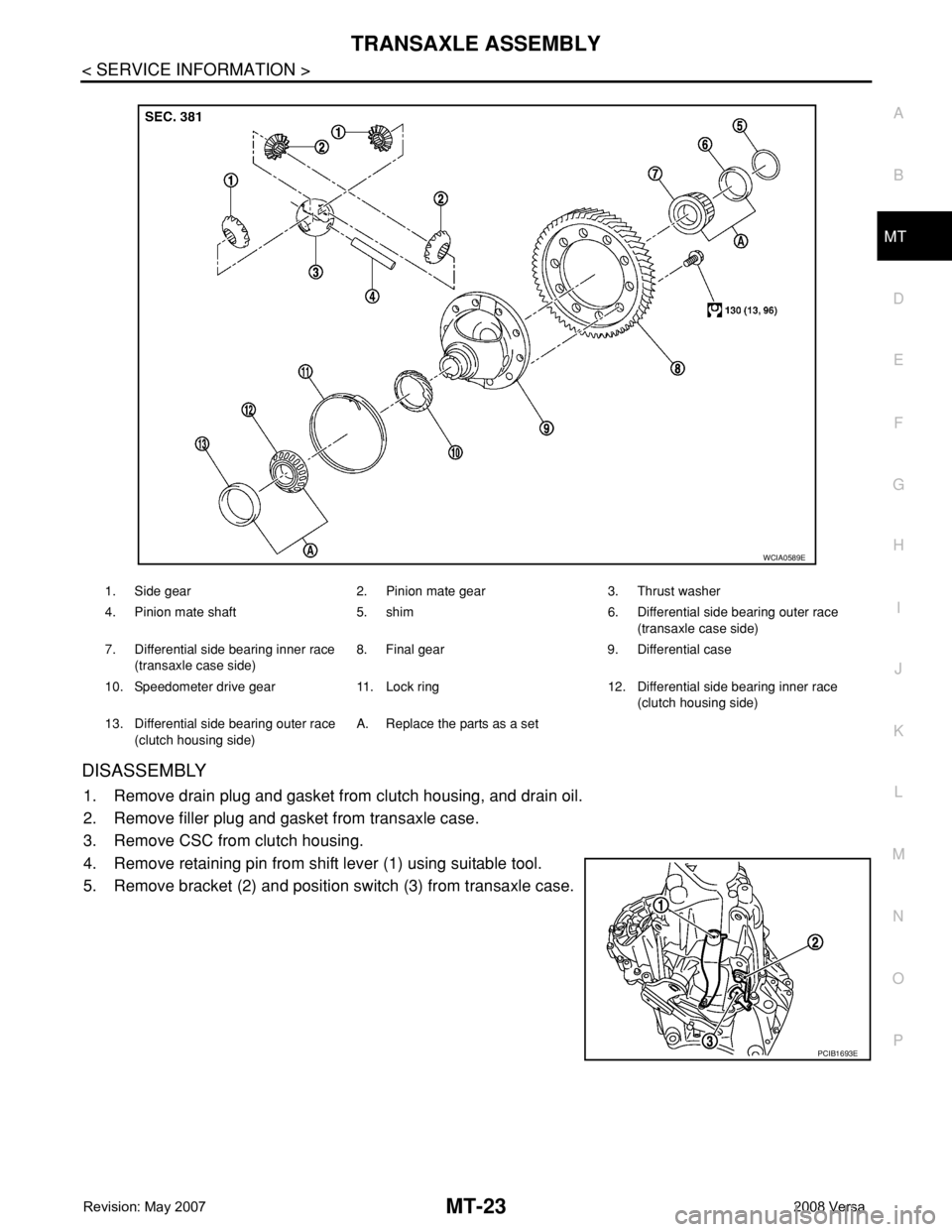

DISASSEMBLY

1. Remove drain plug and gasket from clutch housing, and drain oil.

2. Remove filler plug and gasket from transaxle case.

3. Remove CSC from clutch housing.

4. Remove retaining pin from shift lever (1) using suitable tool.

5. Remove bracket (2) and position switch (3) from transaxle case.

1. Side gear 2. Pinion mate gear 3. Thrust washer

4. Pinion mate shaft 5. shim 6. Differential side bearing outer race

(transaxle case side)

7. Differential side bearing inner race

(transaxle case side)8. Final gear 9. Differential case

10. Speedometer drive gear 11. Lock ring 12. Differential side bearing inner race

(clutch housing side)

13. Differential side bearing outer race

(clutch housing side)A. Replace the parts as a set

WCIA0589E

PCIB1693E

Page 2322 of 2771

MT-34

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

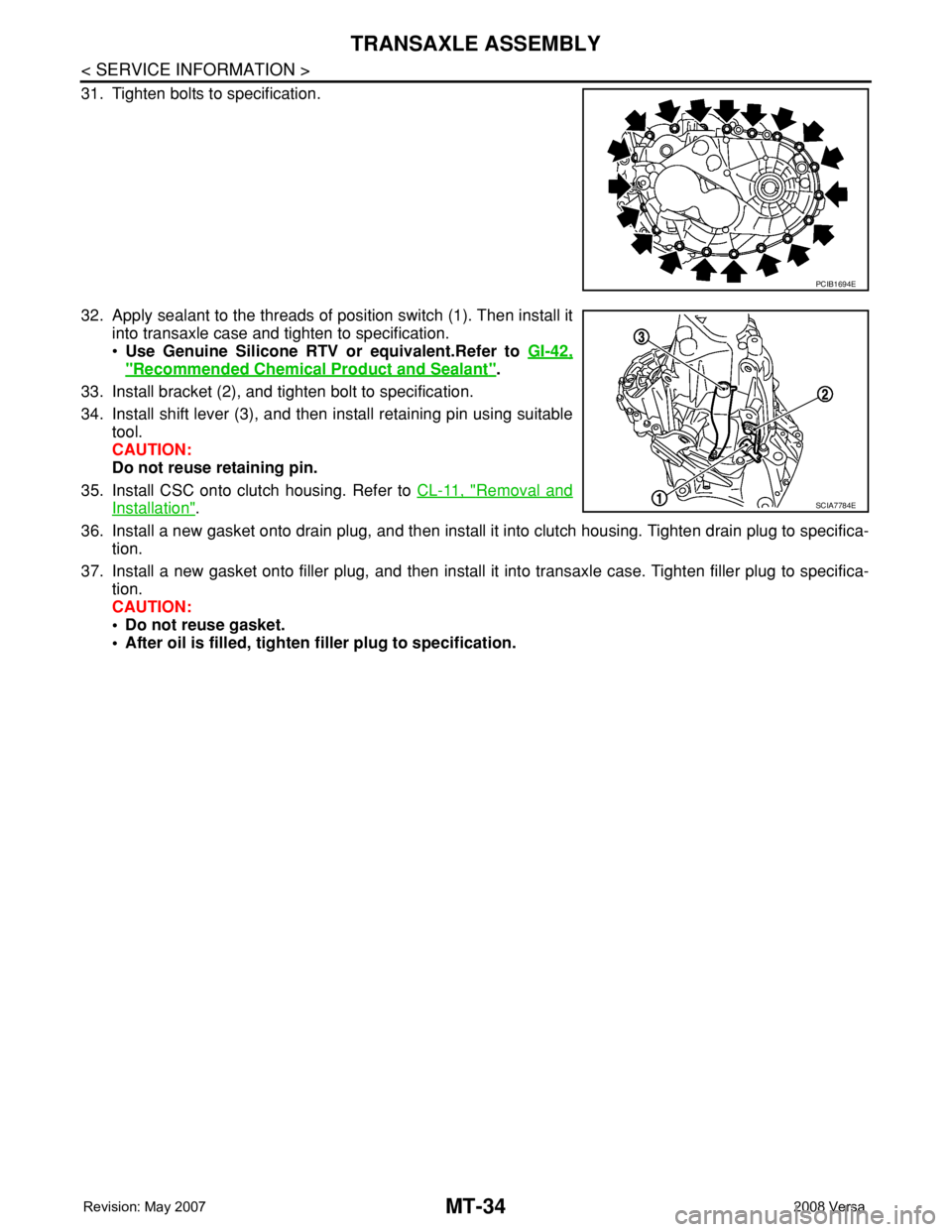

31. Tighten bolts to specification.

32. Apply sealant to the threads of position switch (1). Then install it

into transaxle case and tighten to specification.

•Use Genuine Silicone RTV or equivalent.Refer to GI-42,

"Recommended Chemical Product and Sealant".

33. Install bracket (2), and tighten bolt to specification.

34. Install shift lever (3), and then install retaining pin using suitable

tool.

CAUTION:

Do not reuse retaining pin.

35. Install CSC onto clutch housing. Refer to CL-11, "

Removal and

Installation".

36. Install a new gasket onto drain plug, and then install it into clutch housing. Tighten drain plug to specifica-

tion.

37. Install a new gasket onto filler plug, and then install it into transaxle case. Tighten filler plug to specifica-

tion.

CAUTION:

• Do not reuse gasket.

• After oil is filled, tighten filler plug to specification.

PCIB1694E

SCIA7784E