relay NISSAN TIIDA 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 509 of 2771

INTELLIGENT KEY SYSTEM

BL-75

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

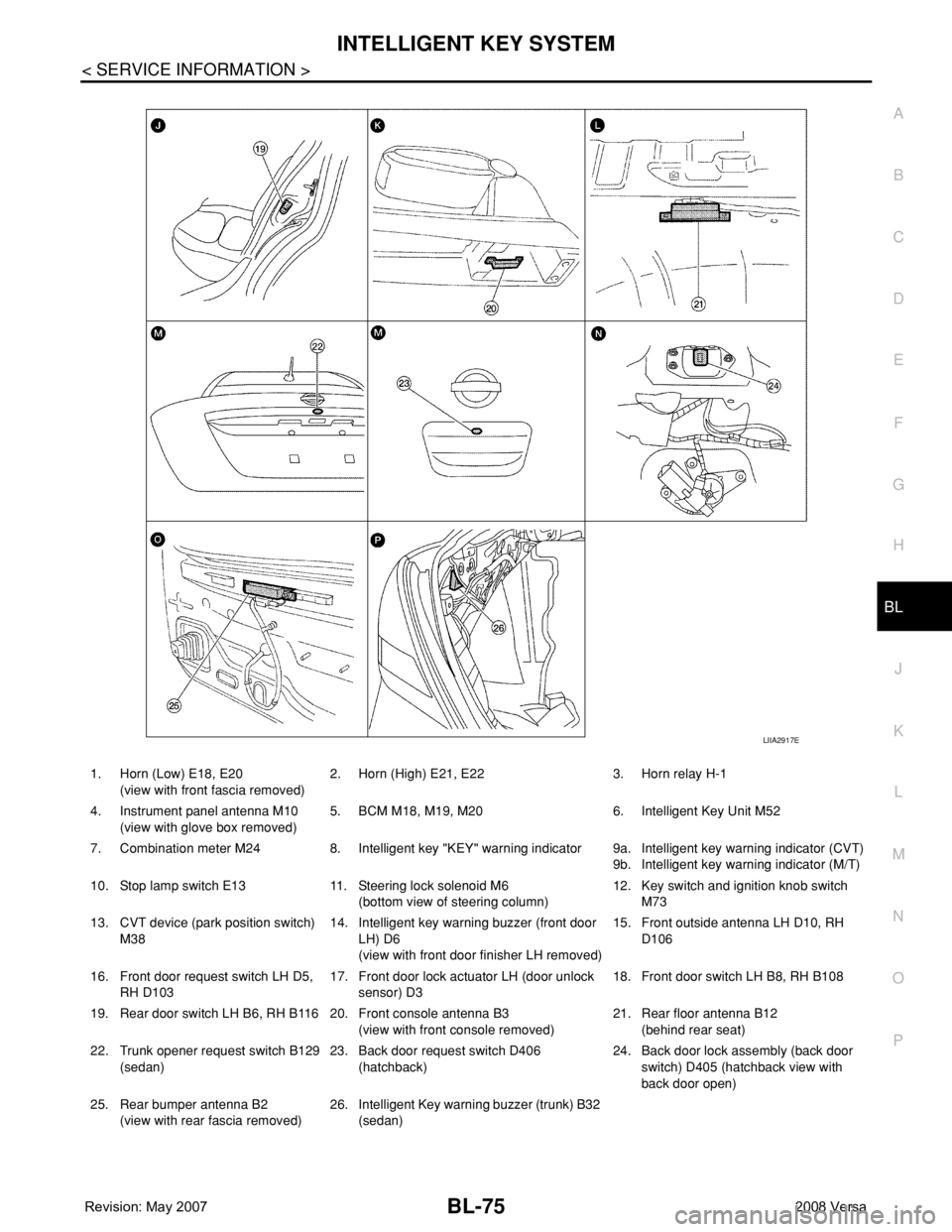

1. Horn (Low) E18, E20

(view with front fascia removed)2. Horn (High) E21, E22 3. Horn relay H-1

4. Instrument panel antenna M10

(view with glove box removed)5. BCM M18, M19, M20 6. Intelligent Key Unit M52

7. Combination meter M24 8. Intelligent key "KEY" warning indicator 9a.

9b.Intelligent key warning indicator (CVT)

Intelligent key warning indicator (M/T)

10. Stop lamp switch E13 11. Steering lock solenoid M6

(bottom view of steering column)12. Key switch and ignition knob switch

M73

13. CVT device (park position switch)

M3814. Intelligent key warning buzzer (front door

LH) D6

(view with front door finisher LH removed)15. Front outside antenna LH D10, RH

D106

16. Front door request switch LH D5,

RH D10317. Front door lock actuator LH (door unlock

sensor) D318. Front door switch LH B8, RH B108

19. Rear door switch LH B6, RH B116 20. Front console antenna B3

(view with front console removed)21. Rear floor antenna B12

(behind rear seat)

22. Trunk opener request switch B129

(sedan)23. Back door request switch D406

(hatchback)24. Back door lock assembly (back door

switch) D405 (hatchback view with

back door open)

25. Rear bumper antenna B2

(view with rear fascia removed)26. Intelligent Key warning buzzer (trunk) B32

(sedan)

LIIA2917E

Page 575 of 2771

INTELLIGENT KEY SYSTEM

BL-141

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

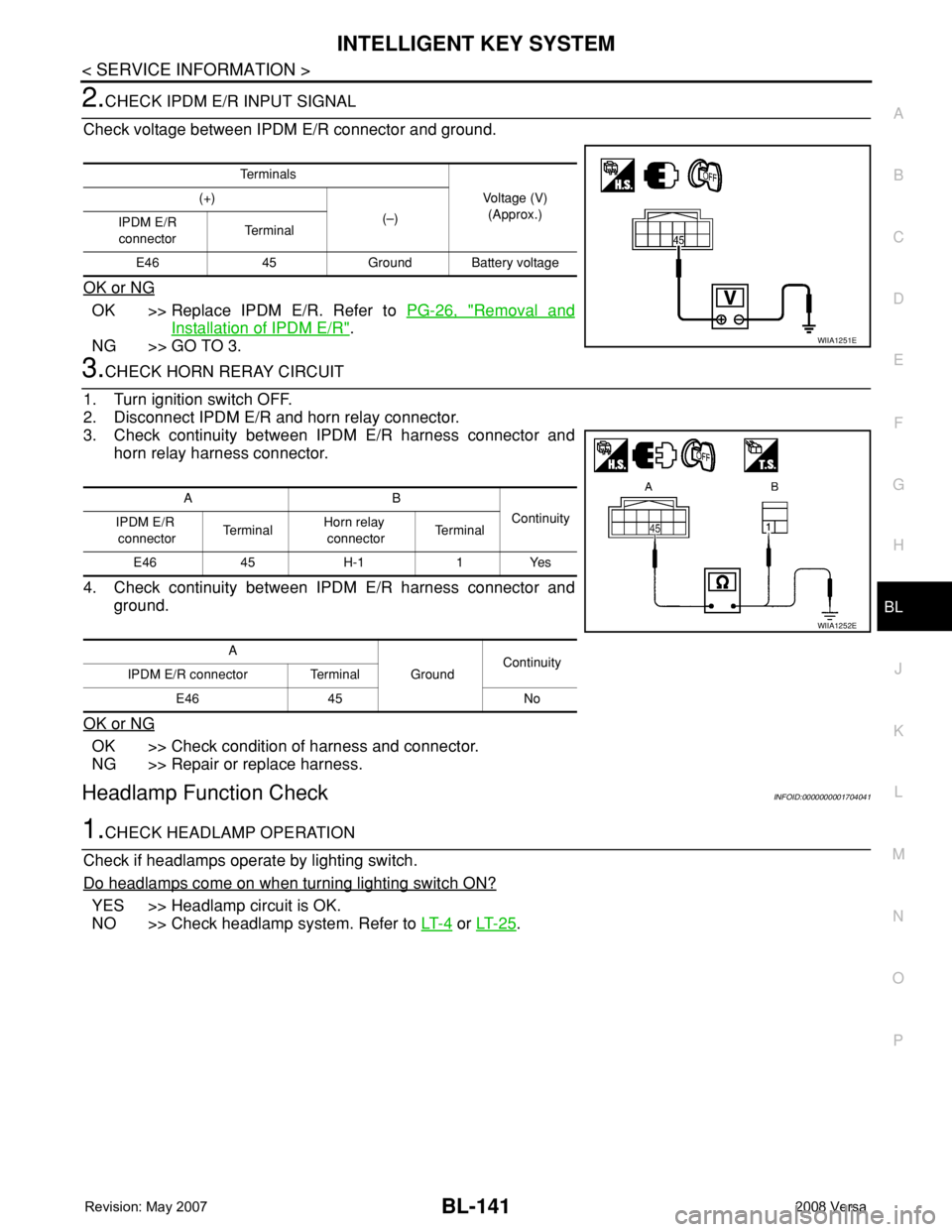

2.CHECK IPDM E/R INPUT SIGNAL

Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> GO TO 3.

3.CHECK HORN RERAY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R and horn relay connector.

3. Check continuity between IPDM E/R harness connector and

horn relay harness connector.

4. Check continuity between IPDM E/R harness connector and

ground.

OK or NG

OK >> Check condition of harness and connector.

NG >> Repair or replace harness.

Headlamp Function CheckINFOID:0000000001704041

1.CHECK HEADLAMP OPERATION

Check if headlamps operate by lighting switch.

Do headlamps come on when turning lighting switch ON?

YES >> Headlamp circuit is OK.

NO >> Check headlamp system. Refer to LT- 4

or LT- 2 5.

Te r m i n a l s

Voltage (V)

(Approx.) (+)

(–)

IPDM E/R

connectorTe r m i n a l

E46 45 Ground Battery voltage

WIIA1251E

AB

Continuity

IPDM E/R

connectorTe r m i n a lHorn relay

connectorTe r m i n a l

E46 45 H-1 1 Yes

A

GroundContinuity

IPDM E/R connector Terminal

E46 45 No

WIIA1252E

Page 621 of 2771

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-187

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

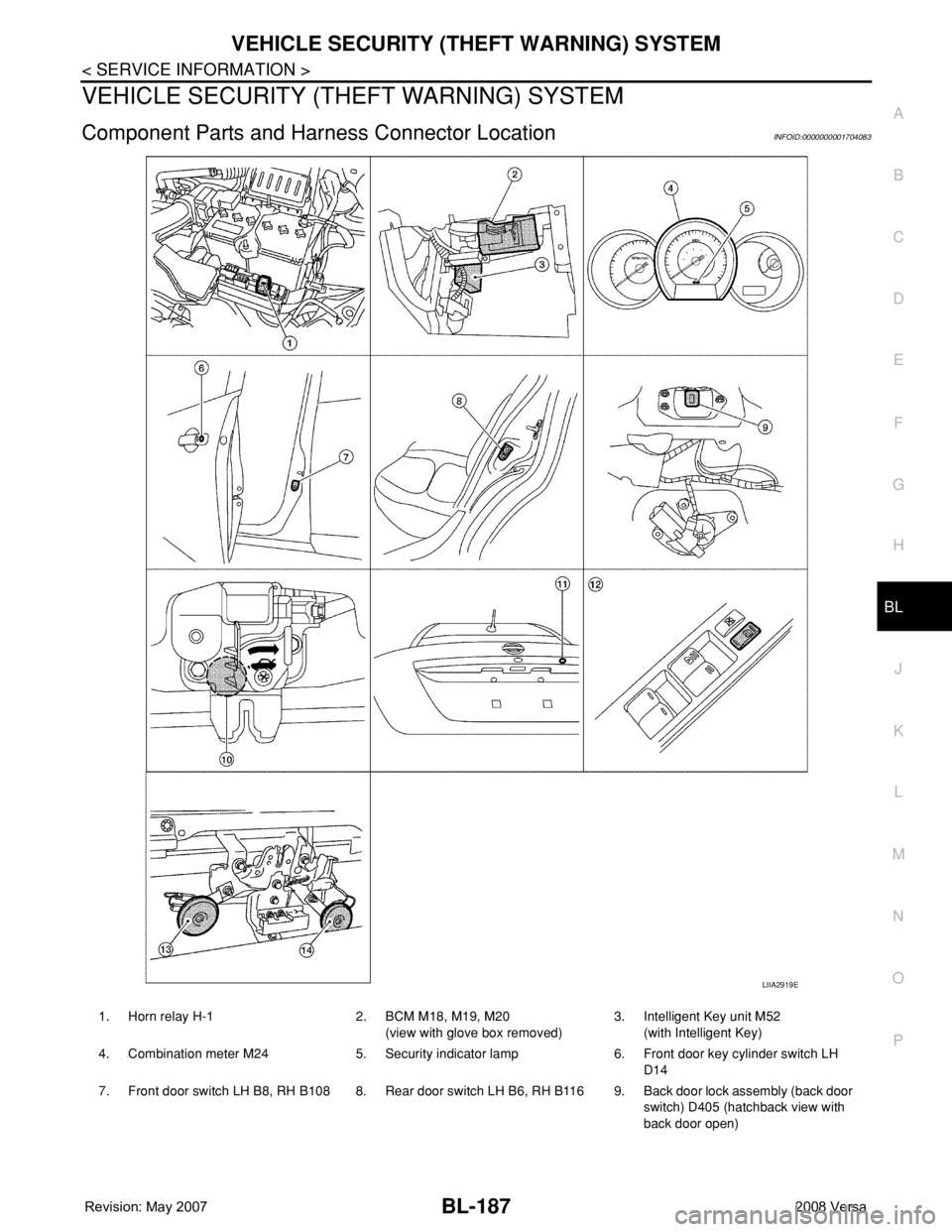

VEHICLE SECURITY (THEFT WARNING) SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001704083

LIIA2919E

1. Horn relay H-1 2. BCM M18, M19, M20

(view with glove box removed)3. Intelligent Key unit M52

(with Intelligent Key)

4. Combination meter M24 5. Security indicator lamp 6. Front door key cylinder switch LH

D14

7. Front door switch LH B8, RH B108 8. Rear door switch LH B6, RH B116 9. Back door lock assembly (back door

switch) D405 (hatchback view with

back door open)

Page 623 of 2771

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-189

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

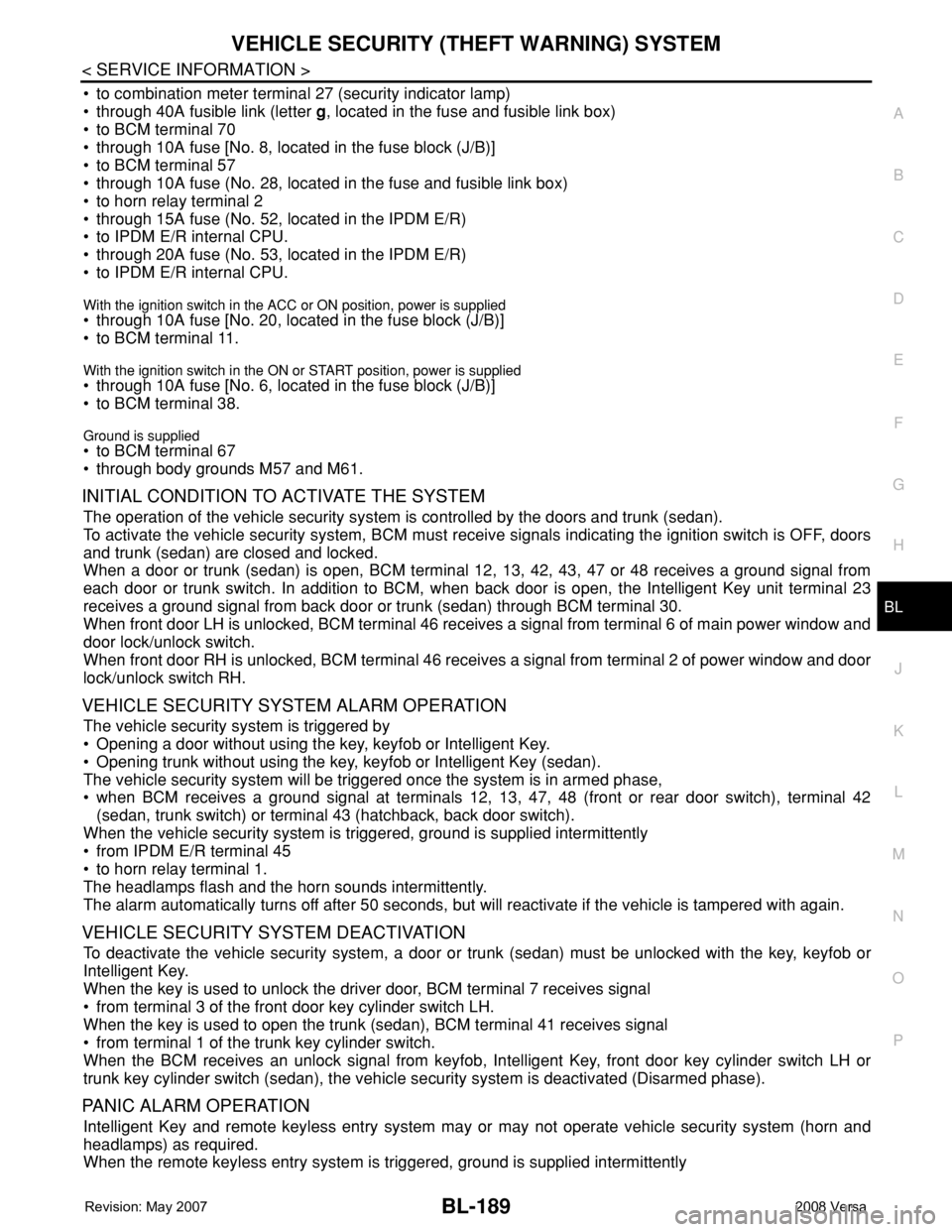

• to combination meter terminal 27 (security indicator lamp)

• through 40A fusible link (letter g, located in the fuse and fusible link box)

• to BCM terminal 70

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse (No. 28, located in the fuse and fusible link box)

• to horn relay terminal 2

• through 15A fuse (No. 52, located in the IPDM E/R)

• to IPDM E/R internal CPU.

• through 20A fuse (No. 53, located in the IPDM E/R)

• to IPDM E/R internal CPU.

With the ignition switch in the ACC or ON position, power is supplied• through 10A fuse [No. 20, located in the fuse block (J/B)]

• to BCM terminal 11.

With the ignition switch in the ON or START position, power is supplied• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied• to BCM terminal 67

• through body grounds M57 and M61.

INITIAL CONDITION TO ACTIVATE THE SYSTEM

The operation of the vehicle security system is controlled by the doors and trunk (sedan).

To activate the vehicle security system, BCM must receive signals indicating the ignition switch is OFF, doors

and trunk (sedan) are closed and locked.

When a door or trunk (sedan) is open, BCM terminal 12, 13, 42, 43, 47 or 48 receives a ground signal from

each door or trunk switch. In addition to BCM, when back door is open, the Intelligent Key unit terminal 23

receives a ground signal from back door or trunk (sedan) through BCM terminal 30.

When front door LH is unlocked, BCM terminal 46 receives a signal from terminal 6 of main power window and

door lock/unlock switch.

When front door RH is unlocked, BCM terminal 46 receives a signal from terminal 2 of power window and door

lock/unlock switch RH.

VEHICLE SECURITY SYSTEM ALARM OPERATION

The vehicle security system is triggered by

• Opening a door without using the key, keyfob or Intelligent Key.

• Opening trunk without using the key, keyfob or Intelligent Key (sedan).

The vehicle security system will be triggered once the system is in armed phase,

• when BCM receives a ground signal at terminals 12, 13, 47, 48 (front or rear door switch), terminal 42

(sedan, trunk switch) or terminal 43 (hatchback, back door switch).

When the vehicle security system is triggered, ground is supplied intermittently

• from IPDM E/R terminal 45

• to horn relay terminal 1.

The headlamps flash and the horn sounds intermittently.

The alarm automatically turns off after 50 seconds, but will reactivate if the vehicle is tampered with again.

VEHICLE SECURITY SYSTEM DEACTIVATION

To deactivate the vehicle security system, a door or trunk (sedan) must be unlocked with the key, keyfob or

Intelligent Key.

When the key is used to unlock the driver door, BCM terminal 7 receives signal

• from terminal 3 of the front door key cylinder switch LH.

When the key is used to open the trunk (sedan), BCM terminal 41 receives signal

• from terminal 1 of the trunk key cylinder switch.

When the BCM receives an unlock signal from keyfob, Intelligent Key, front door key cylinder switch LH or

trunk key cylinder switch (sedan), the vehicle security system is deactivated (Disarmed phase).

PANIC ALARM OPERATION

Intelligent Key and remote keyless entry system may or may not operate vehicle security system (horn and

headlamps) as required.

When the remote keyless entry system is triggered, ground is supplied intermittently

Page 624 of 2771

BL-190

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

• from IPDM E/R terminal 45

• to horn relay terminal 1.

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off after 25 seconds or when BCM receives any signal from keyfob or Intelligent

Key.

CAN Communication System DescriptionINFOID:0000000001704085

Refer to LAN-6.

Page 638 of 2771

BL-204

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

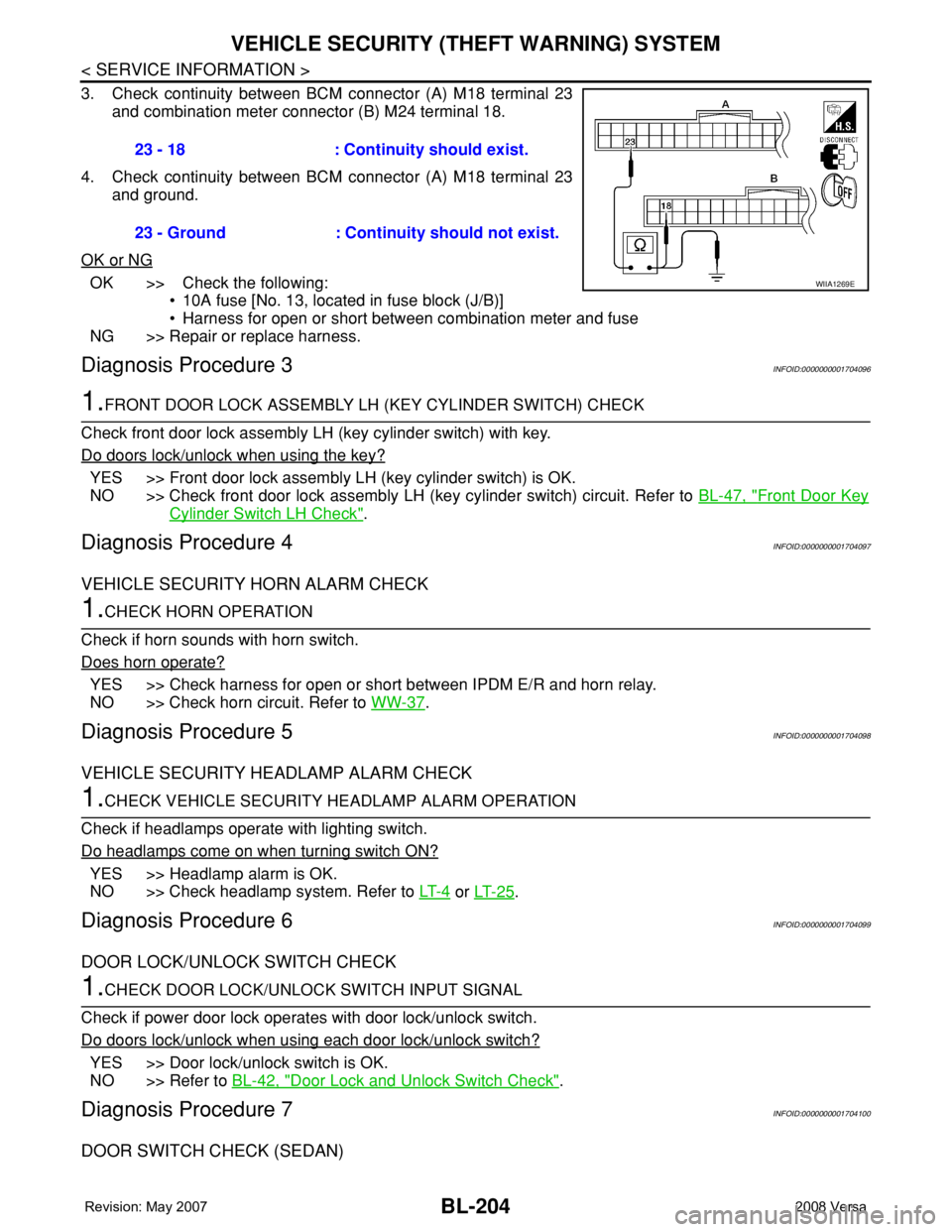

3. Check continuity between BCM connector (A) M18 terminal 23

and combination meter connector (B) M24 terminal 18.

4. Check continuity between BCM connector (A) M18 terminal 23

and ground.

OK or NG

OK >> Check the following:

• 10A fuse [No. 13, located in fuse block (J/B)]

• Harness for open or short between combination meter and fuse

NG >> Repair or replace harness.

Diagnosis Procedure 3INFOID:0000000001704096

1.FRONT DOOR LOCK ASSEMBLY LH (KEY CYLINDER SWITCH) CHECK

Check front door lock assembly LH (key cylinder switch) with key.

Do doors lock/unlock when using the key?

YES >> Front door lock assembly LH (key cylinder switch) is OK.

NO >> Check front door lock assembly LH (key cylinder switch) circuit. Refer to BL-47, "

Front Door Key

Cylinder Switch LH Check".

Diagnosis Procedure 4INFOID:0000000001704097

VEHICLE SECURITY HORN ALARM CHECK

1.CHECK HORN OPERATION

Check if horn sounds with horn switch.

Does horn operate?

YES >> Check harness for open or short between IPDM E/R and horn relay.

NO >> Check horn circuit. Refer to WW-37

.

Diagnosis Procedure 5INFOID:0000000001704098

VEHICLE SECURITY HEADLAMP ALARM CHECK

1.CHECK VEHICLE SECURITY HEADLAMP ALARM OPERATION

Check if headlamps operate with lighting switch.

Do headlamps come on when turning switch ON?

YES >> Headlamp alarm is OK.

NO >> Check headlamp system. Refer to LT- 4

or LT- 2 5.

Diagnosis Procedure 6INFOID:0000000001704099

DOOR LOCK/UNLOCK SWITCH CHECK

1.CHECK DOOR LOCK/UNLOCK SWITCH INPUT SIGNAL

Check if power door lock operates with door lock/unlock switch.

Do doors lock/unlock when using each door lock/unlock switch?

YES >> Door lock/unlock switch is OK.

NO >> Refer to BL-42, "

Door Lock and Unlock Switch Check".

Diagnosis Procedure 7INFOID:0000000001704100

DOOR SWITCH CHECK (SEDAN)

23 - 18 : Continuity should exist.

23 - Ground : Continuity should not exist.

WIIA1269E

Page 766 of 2771

BRC-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

N

O

P

CONTENTS

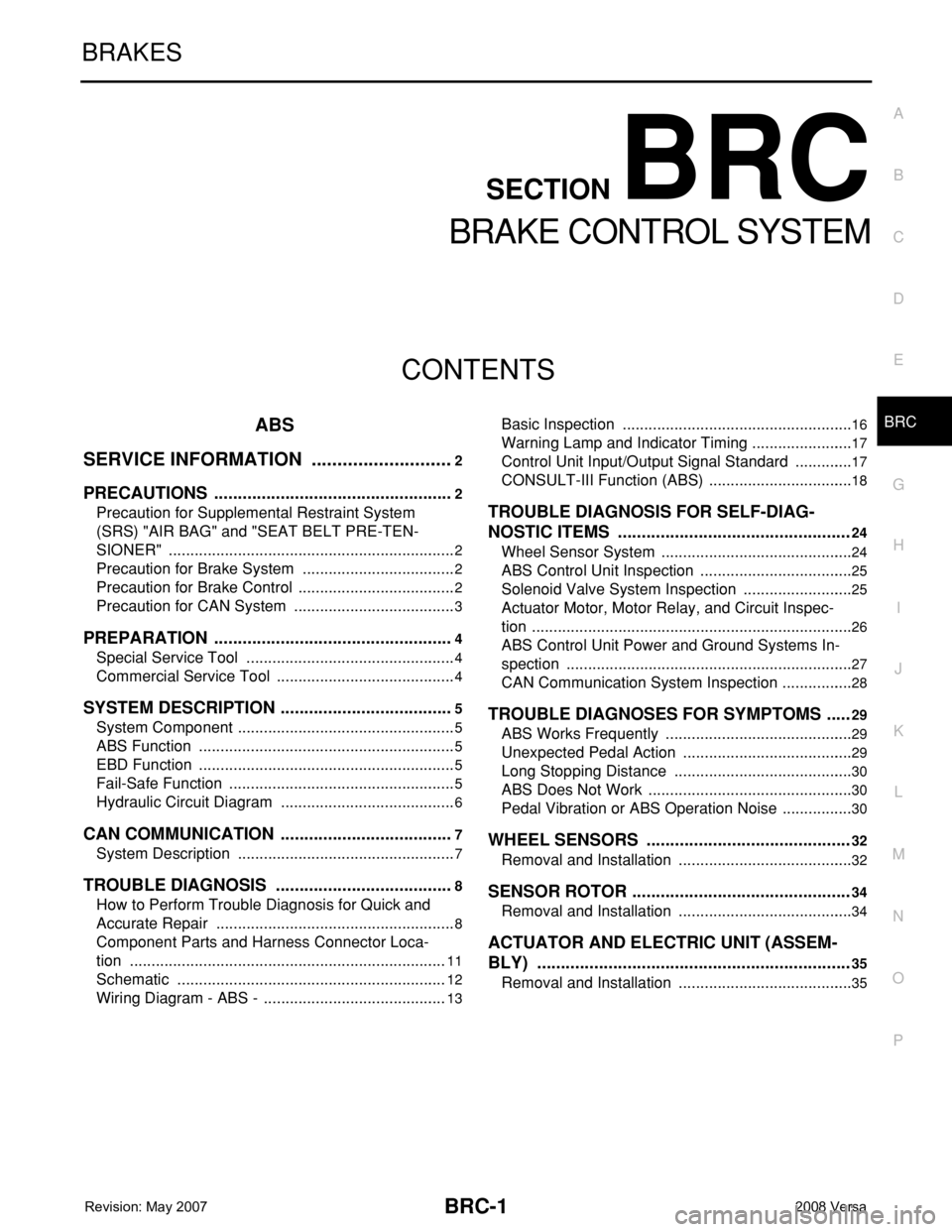

BRAKE CONTROL SYSTEM

ABS

SERVICE INFORMATION ............................

2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution for Brake System ....................................2

Precaution for Brake Control .....................................2

Precaution for CAN System ......................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SYSTEM DESCRIPTION .....................................5

System Component ...................................................5

ABS Function ............................................................5

EBD Function ............................................................5

Fail-Safe Function .....................................................5

Hydraulic Circuit Diagram .........................................6

CAN COMMUNICATION .....................................7

System Description ...................................................7

TROUBLE DIAGNOSIS ......................................8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........................................................

8

Component Parts and Harness Connector Loca-

tion ..........................................................................

11

Schematic ...............................................................12

Wiring Diagram - ABS - ...........................................13

Basic Inspection ......................................................16

Warning Lamp and Indicator Timing ........................17

Control Unit Input/Output Signal Standard ..............17

CONSULT-III Function (ABS) ..................................18

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

24

Wheel Sensor System .............................................24

ABS Control Unit Inspection ....................................25

Solenoid Valve System Inspection ..........................25

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ...........................................................................

26

ABS Control Unit Power and Ground Systems In-

spection ...................................................................

27

CAN Communication System Inspection .................28

TROUBLE DIAGNOSES FOR SYMPTOMS .....29

ABS Works Frequently ............................................29

Unexpected Pedal Action ........................................29

Long Stopping Distance ..........................................30

ABS Does Not Work ................................................30

Pedal Vibration or ABS Operation Noise .................30

WHEEL SENSORS ...........................................32

Removal and Installation .........................................32

SENSOR ROTOR ..............................................34

Removal and Installation .........................................34

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ..................................................................

35

Removal and Installation .........................................35

Page 783 of 2771

![NISSAN TIIDA 2008 Service User Guide BRC-18

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: For approximately 2 seconds after ignition switch is turned NISSAN TIIDA 2008 Service User Guide BRC-18

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: For approximately 2 seconds after ignition switch is turned](/img/5/57399/w960_57399-782.png)

BRC-18

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Note 1: Confirm tire pressure is normal.

Note 2: ON/OFF timing of ABS warning lamp

ON: For approximately 2 seconds after ignition switch is turned ON, or when a malfunction is detected.

OFF: Approximately 2 seconds after ignition switch is turned ON (when system is in normal operation).

CONSULT-III Function (ABS)INFOID:0000000001703838

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

Monitor item Display contentData monitor

Note: Error inspection

checklist

ConditionReference value in

normal operation

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSORWheel speedVehicle stopped 0 [km/h (MPH)]

BRC-24, "

Wheel Sensor

System"Vehicle running (Note 1)Almost in accor-

dance with speed-

ometer display

(within ±10%)

BATTERY VOLTBattery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit)Ignition switch ON 10 to 16VBRC-27, "

ABS Control

Unit Power and Ground

Systems Inspection"

STOP LAMP SWStop lamp switch oper-

ationBrake pedal depressed ON

—

Brake pedal not depressed OFF

ABS WARN LAMPABS warning lamp ON

condition (Note 2)ABS warning lamp ON ON

BRC-16, "

Basic Inspec-

tion"ABS warning lamp OFF OFF

MOTOR RELAYOperation status of mo-

tor and motor relayIgnition switch ON or running

(ABS not activated)OFF

BRC-26, "

Actuator Motor,

Motor Relay, and Circuit

Inspection"Ignition switch ON or engine

running (ABS activated)ON

ACTUATOR RLYActuator relay opera-

tion statusVehicle stopped (Ignition

switch ON)OFF

BRC-26, "

Actuator Motor,

Motor Relay, and Circuit

Inspection"Vehicle stopped (Engine run-

ning)ON

FR LH IN SOL

FR LH OUT SOL

FR RH IN SOL

FR RH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOLSolenoid valve opera-

tionActuator (solenoid) is active

(“ACTIVE TEST” with CON-

SULT-III) or actuator relay is in-

active (in fail-safe mode).ON

BRC-25, "

Solenoid Valve

System Inspection"When actuator (solenoid) is not

active and actuator relay is ac-

tive (ignition switch ON).OFF

ABS SIGNAL

EBD SIGNALSignal statusABS active

EBD activeON

ABS system

EBD system

ABS not active

EBD not activeOFF

ABS FAIL SIG

EBD FAIL SIGFail signal statusABS fail

EBD failON

ABS system

EBD system

ABS normal

EBD normalOFF

ABS diagnostic mode Description

SELF-DIAG RESULTS Displays ABS actuator and electric unit (control unit) self-diagnosis results.

DATA MONITOR Displays ABS actuator and electric unit (control unit) input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 785 of 2771

![NISSAN TIIDA 2008 Service User Guide BRC-20

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101]Circuit of rear RH wheel sensor is open.

BRC-24, "

Whe NISSAN TIIDA 2008 Service User Guide BRC-20

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101]Circuit of rear RH wheel sensor is open.

BRC-24, "

Whe](/img/5/57399/w960_57399-784.png)

BRC-20

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1

[C1101]Circuit of rear RH wheel sensor is open.

BRC-24, "

Wheel Sensor

System" (Note 1) RR LH SENSOR-1

[C1102]Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1

[C1103]Circuit of front RH wheel sensor is open.

FR LH SENSOR-1

[C1104]Circuit of front LH wheel sensor is open.

RR RH SENSOR-2

[C1105]When the circuit in the rear RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2

[C1106]When the circuit in the rear LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2

[C1107]When the circuit in the front RH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2

[C1108]When the circuit in the front LH wheel sensor is short-circuited or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

ABS SENSOR

[ABNORMAL SIGNAL]

[ C 111 5 ]Wheel sensor input is abnormal.

BATTERY VOLTAGE

[ABNORMAL]

[C1109]ABS actuator and electric unit (control unit) power voltage is too

low.BRC-27, "

ABS Control

Unit Power and Ground

Systems Inspection"

CONTROLLER FAILURE

[ C 111 0 ]Internal malfunction of ABS actuator and electric unit (control unit)BRC-25, "ABS Control

Unit Inspection"

PUMP MOTOR

[ C 1111 ]During actuator motor operation with ON, when actuator motor

turns OFF or when control line for actuator motor relay is open.BRC-26, "Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

FR LH IN ABS SOL

[C1120]Circuit of front LH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-25, "

Solenoid Valve

System Inspection"

FR LH OUT ABS SOL

[C1121]Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122]Circuit of front RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123]Circuit of front RH OUT ABS solenoid is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124]Circuit of rear LH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126] Circuit of rear RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127] Circuit of rear RH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

Page 786 of 2771

![NISSAN TIIDA 2008 Service User Guide TROUBLE DIAGNOSIS

BRC-21

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Note 1: If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power NISSAN TIIDA 2008 Service User Guide TROUBLE DIAGNOSIS

BRC-21

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Note 1: If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power](/img/5/57399/w960_57399-785.png)

TROUBLE DIAGNOSIS

BRC-21

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Note 1: If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power supply voltage in addition

to wheel sensor circuit check.

Note 2: If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for CAN communication line

first.

DATA MONITOR

Operation Procedure

1. After turning OFF the ignition switch, connect CONSULT-III to the data link connector.

2. Touch “ABS”, “DATA MONITOR” in order on the CONSULT-III screen.

If “ABS” is not indicated, go to GI-36, "

CONSULT-III Data Link Connector (DLC) Circuit".

3. Return to the SELECT MONITOR ITEM screen, and touch “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”. Refer to the following information.

4. When “START” is touched, the data monitor screen is displayed.

Display Item List

MAIN RELAY

[ C 111 4 ]ABS actuator relay or circuit malfunction.BRC-26, "Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"

CAN COMM CIRCUIT

[U1000]• CAN communication line is open or shorted.

• ABS actuator and electric unit (control unit) internal malfunction

• Battery voltage for ECM is suddenly interrupted for approxi-

mately 0.5 second or more.BRC-28, "CAN Commu-

nication System Inspec-

tion" (Note 2) Self-diagnostic item Malfunction detecting condition Check system

Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

FR RH SENSOR

(km/h, MPH)×××Wheel speed calculated by front RH

wheel sensor signal is displayed.

FR LH SENSOR

(km/h, MPH)×××Wheel speed calculated by front LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, MPH)×××Wheel speed calculated by rear RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, MPH)×××Wheel speed calculated by rear LH

wheel sensor signal is displayed.

BATTERY VOLT

(V)×××Voltage supplied to ABS actuator

and electric unit (control unit) is dis-

played.

STOP LAMP SW

(ON/OFF)×××Stop lamp switch (ON/OFF) status is

displayed.

ABS WARN LAMP

(ON/OFF)–××ABS warning lamp (ON/OFF) status

is displayed.

FR LH IN SOL

(ON/OFF)–××Front LH IN ABS solenoid (ON/OFF)

status is displayed.

FR LH OUT SOL

(ON/OFF)–××Front LH OUT ABS solenoid (ON/

OFF) status is displayed.

FR RH IN SOL

(ON/OFF)–××Front RH IN ABS solenoid (ON/

OFF) status is displayed.

FR RH OUT SOL

(ON/OFF)–××Front RH OUT ABS solenoid (ON/

OFF) status is displayed.

RR LH IN SOL

(ON/OFF)–××Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF)–××Rear LH OUT ABS solenoid (ON/

OFF) status is displayed.