relay NISSAN TIIDA 2008 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1197 of 2771

TROUBLE DIAGNOSIS

EC-123

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

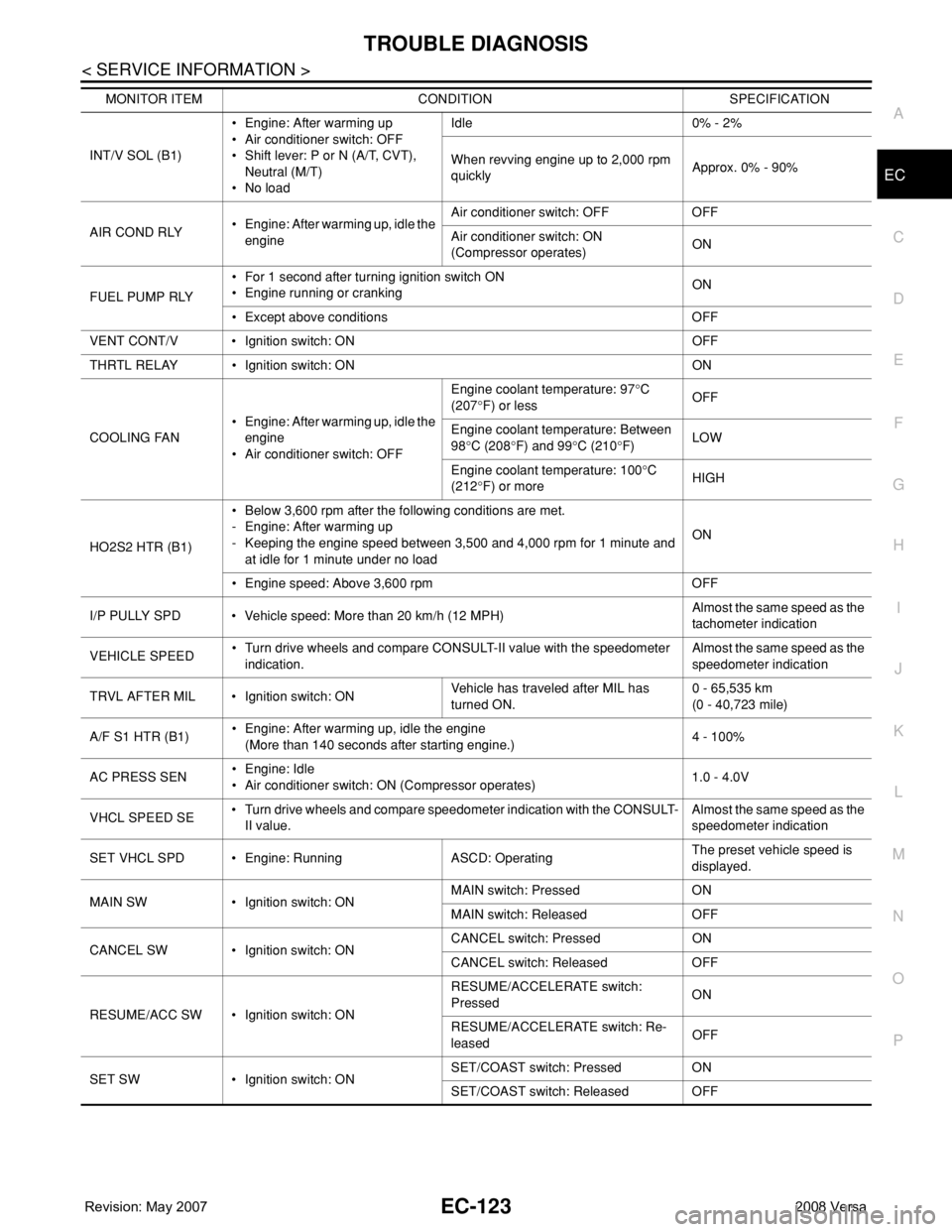

INT/V SOL (B1)• Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

•No loadIdle 0% - 2%

When revving engine up to 2,000 rpm

quicklyApprox. 0% - 90%

AIR COND RLY• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF

VENT CONT/V • Ignition switch: ON OFF

THRTL RELAY • Ignition switch: ON ON

COOLING FAN• Engine: After warming up, idle the

engine

• Air conditioner switch: OFFEngine coolant temperature: 97°C

(207°F) or lessOFF

Engine coolant temperature: Between

98°C (208°F) and 99°C (210°F)LOW

Engine coolant temperature: 100°C

(212°F) or moreHIGH

HO2S2 HTR (B1)• Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no loadON

• Engine speed: Above 3,600 rpm OFF

I/P PULLY SPD • Vehicle speed: More than 20 km/h (12 MPH)Almost the same speed as the

tachometer indication

VEHICLE SPEED• Turn drive wheels and compare CONSULT-II value with the speedometer

indication.Almost the same speed as the

speedometer indication

TRVL AFTER MIL • Ignition switch: ONVehicle has traveled after MIL has

turned ON.0 - 65,535 km

(0 - 40,723 mile)

A/F S1 HTR (B1)• Engine: After warming up, idle the engine

(More than 140 seconds after starting engine.)4 - 100%

AC PRESS SEN• Engine: Idle

• Air conditioner switch: ON (Compressor operates)1.0 - 4.0V

VHCL SPEED SE• Turn drive wheels and compare speedometer indication with the CONSULT-

II value.Almost the same speed as the

speedometer indication

SET VHCL SPD • Engine: Running ASCD: OperatingThe preset vehicle speed is

displayed.

MAIN SW • Ignition switch: ONMAIN switch: Pressed ON

MAIN switch: Released OFF

CANCEL SW • Ignition switch: ONCANCEL switch: Pressed ON

CANCEL switch: Released OFF

RESUME/ACC SW • Ignition switch: ONRESUME/ACCELERATE switch:

PressedON

RESUME/ACCELERATE switch: Re-

leased

OFF

SET SW • Ignition switch: ONSET/COAST switch: Pressed ON

SET/COAST switch: Released OFF MONITOR ITEM CONDITION SPECIFICATION

Page 1212 of 2771

EC-138

< SERVICE INFORMATION >

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis Procedure

INFOID:0000000001702606

1.INSPECTION START

Start engine.

Is engine running?

Ye s o r N o

Ye s > > G O T O 8 .

No >> GO TO 2.

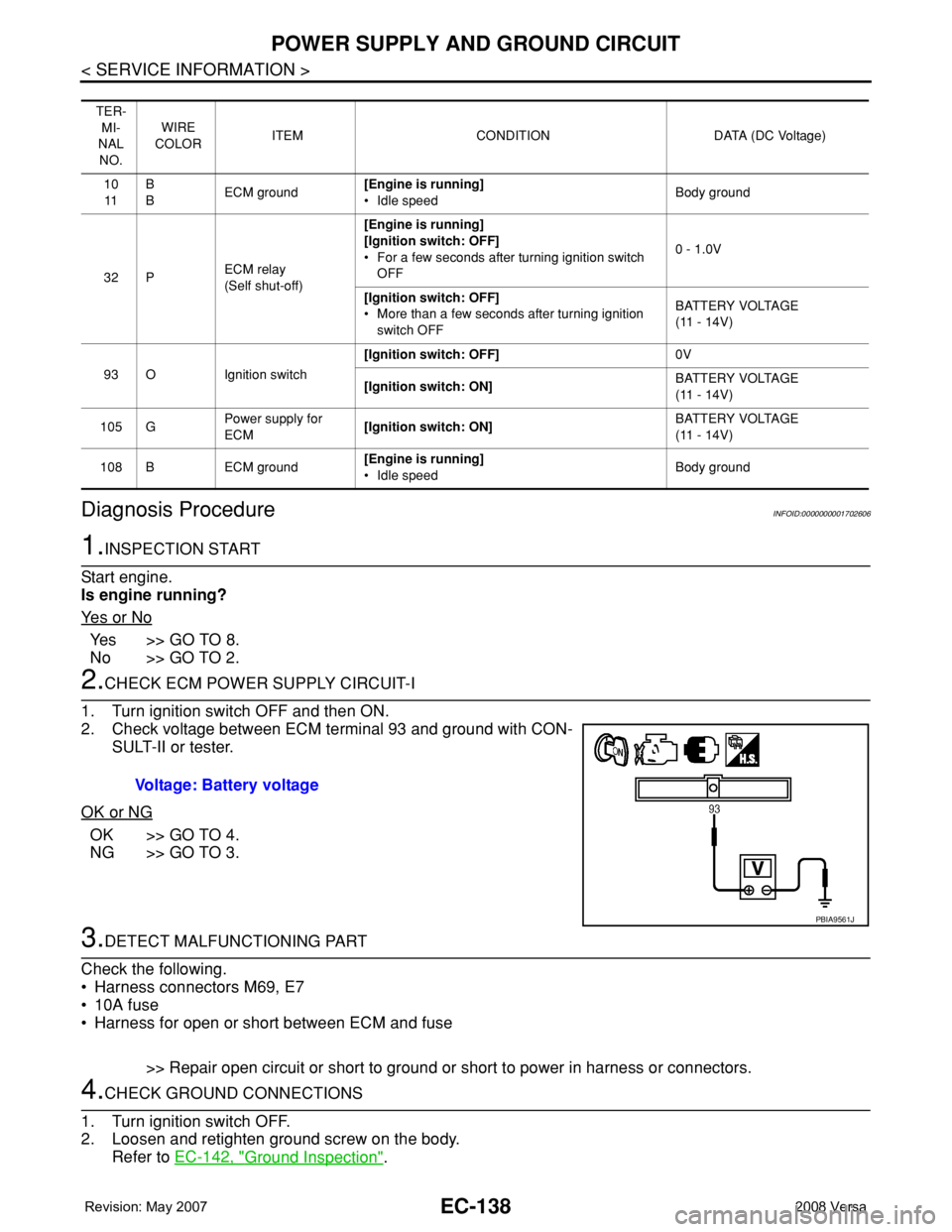

2.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF and then ON.

2. Check voltage between ECM terminal 93 and ground with CON-

SULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M69, E7

• 10A fuse

• Harness for open or short between ECM and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

10

11B

BECM ground[Engine is running]

• Idle speedBody ground

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition switch

OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

93 O Ignition switch[Ignition switch: OFF]0V

[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

105 GPower supply for

ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

108 B ECM ground[Engine is running]

• Idle speedBody ground

Voltage: Battery voltage

PBIA9561J

Page 1238 of 2771

EC-164

< SERVICE INFORMATION >

DTC P0075 IVT CONTROL SOLENOID VALVE

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702645

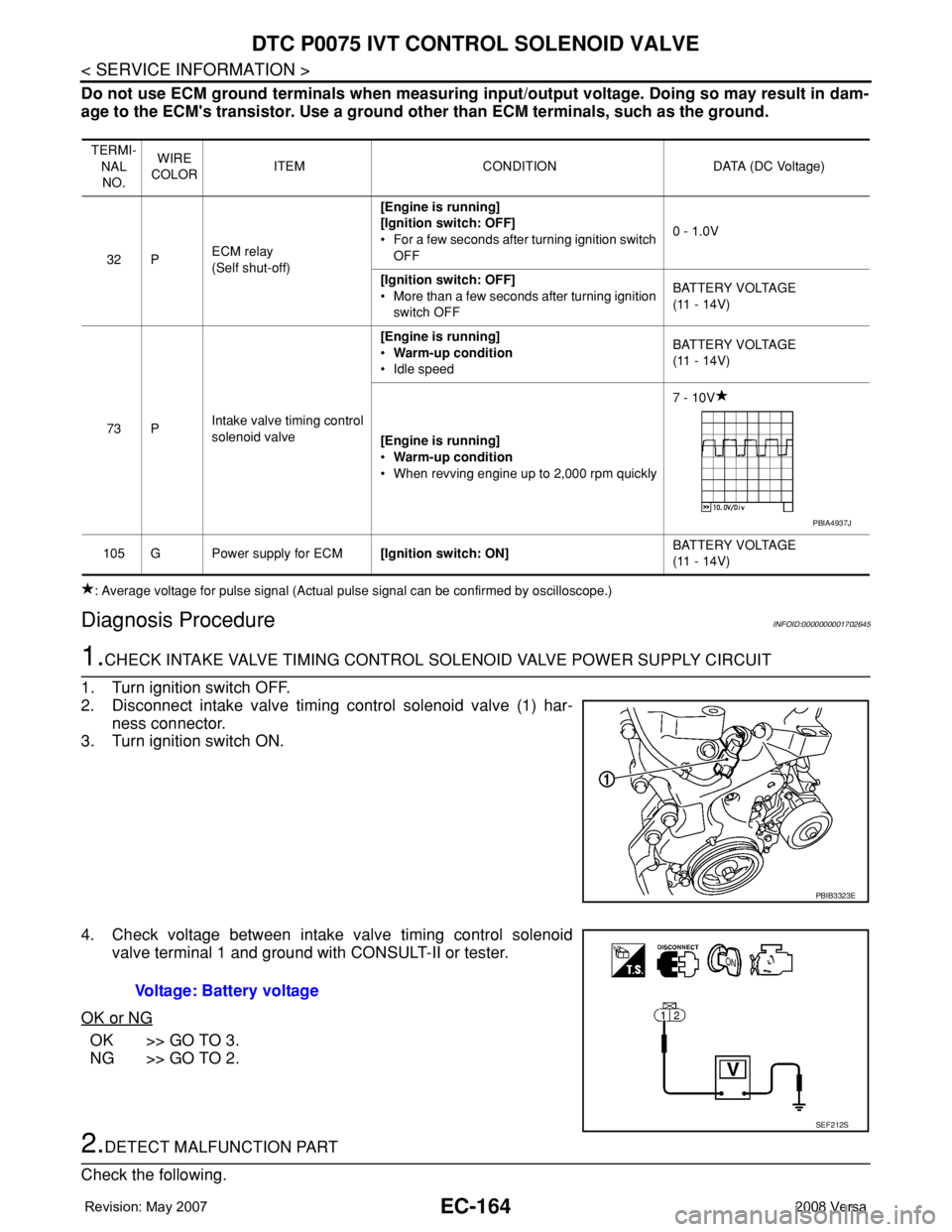

1.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect intake valve timing control solenoid valve (1) har-

ness connector.

3. Turn ignition switch ON.

4. Check voltage between intake valve timing control solenoid

valve terminal 1 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTION PART

Check the following.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition switch

OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

73 PIntake valve timing control

solenoid valve[Engine is running]

•Warm-up condition

• Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

•Warm-up condition

• When revving engine up to 2,000 rpm quickly7 - 10V

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIA4937J

PBIB3323E

Voltage: Battery voltage

SEF212S

Page 1245 of 2771

DTC P0101 MAF SENSOR

EC-171

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

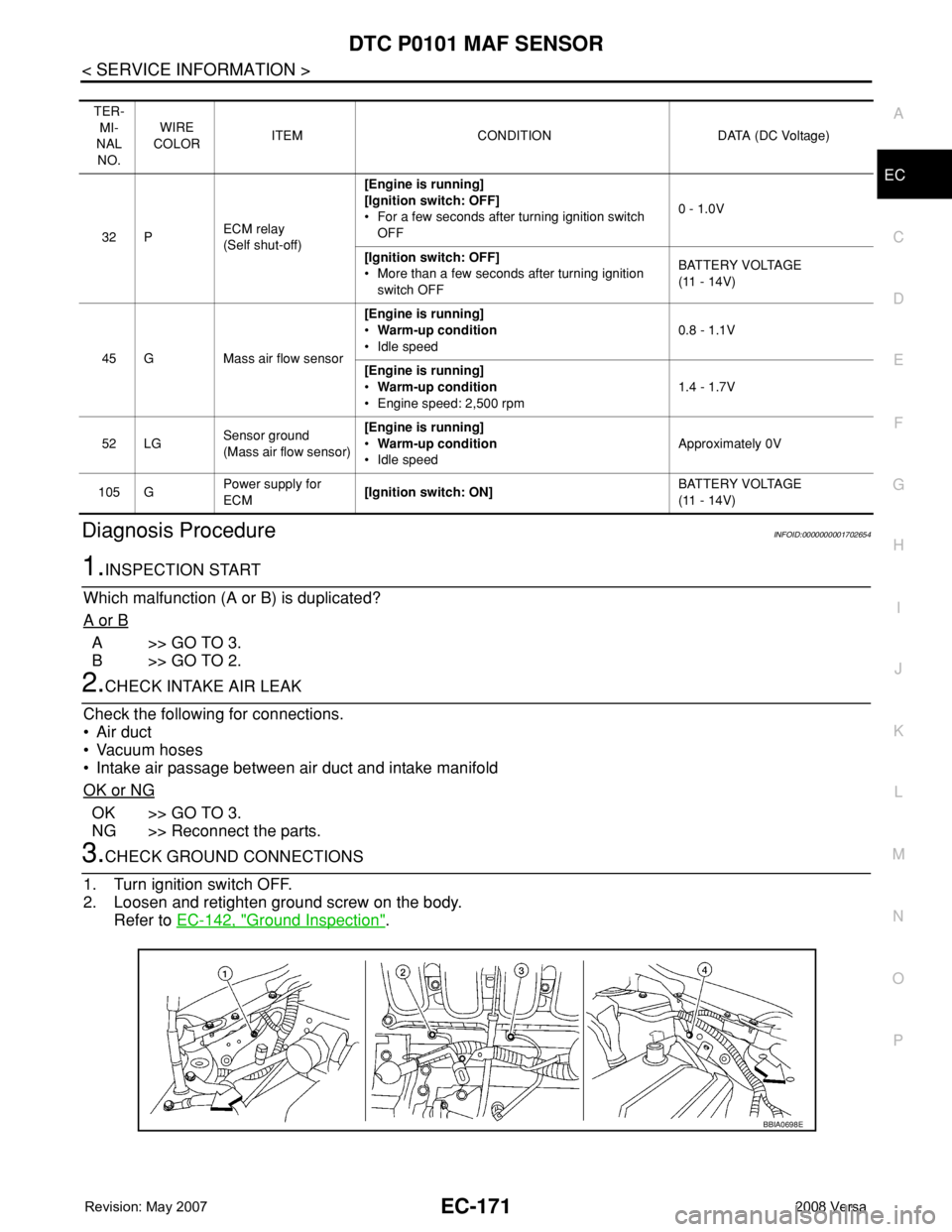

Diagnosis ProcedureINFOID:0000000001702654

1.INSPECTION START

Which malfunction (A or B) is duplicated?

A or B

A >> GO TO 3.

B >> GO TO 2.

2.CHECK INTAKE AIR LEAK

Check the following for connections.

• Air duct

• Vacuum hoses

• Intake air passage between air duct and intake manifold

OK or NG

OK >> GO TO 3.

NG >> Reconnect the parts.

3.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition switch

OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

45 G Mass air flow sensor[Engine is running]

•Warm-up condition

• Idle speed0.8 - 1.1V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm1.4 - 1.7V

52 LGSensor ground

(Mass air flow sensor)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

105 GPower supply for

ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0698E

Page 1252 of 2771

EC-178

< SERVICE INFORMATION >

DTC P0102, P0103 MAF SENSOR

Diagnosis Procedure

INFOID:0000000001702662

1.INSPECTION START

Which malfunction (P0102 or P0103) is duplicated?

P0102 or P0103

P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.CHECK INTAKE SYSTEM

Check the following for connection.

• Air duct

• Vacuum hoses

• Intake air passage between air duct and intake manifold

OK or NG

OK >> GO TO 3.

NG >> Reconnect the parts.

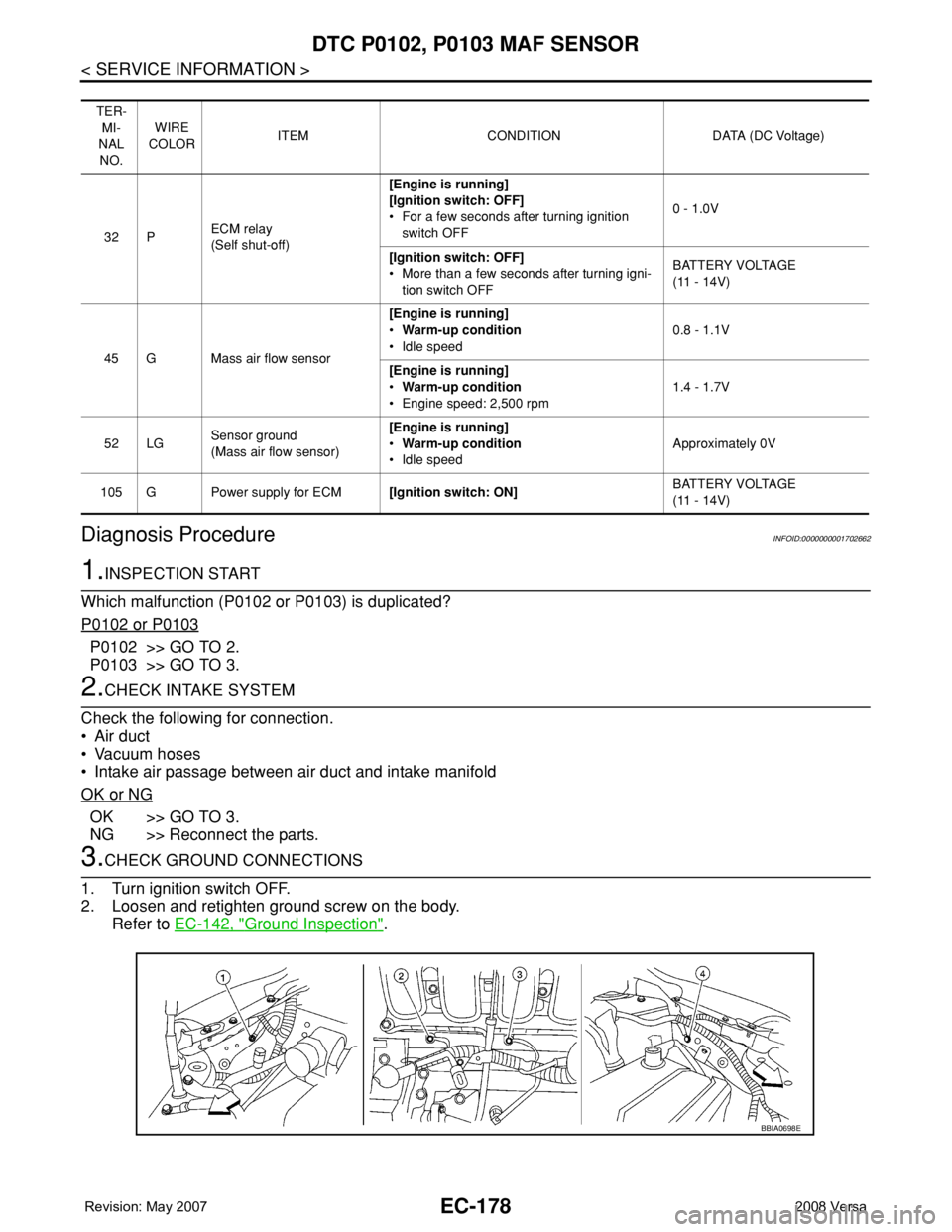

3.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

45 G Mass air flow sensor[Engine is running]

•Warm-up condition

• Idle speed0.8 - 1.1V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm1.4 - 1.7V

52 LGSensor ground

(Mass air flow sensor)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0698E

Page 1402 of 2771

EC-328

< SERVICE INFORMATION >

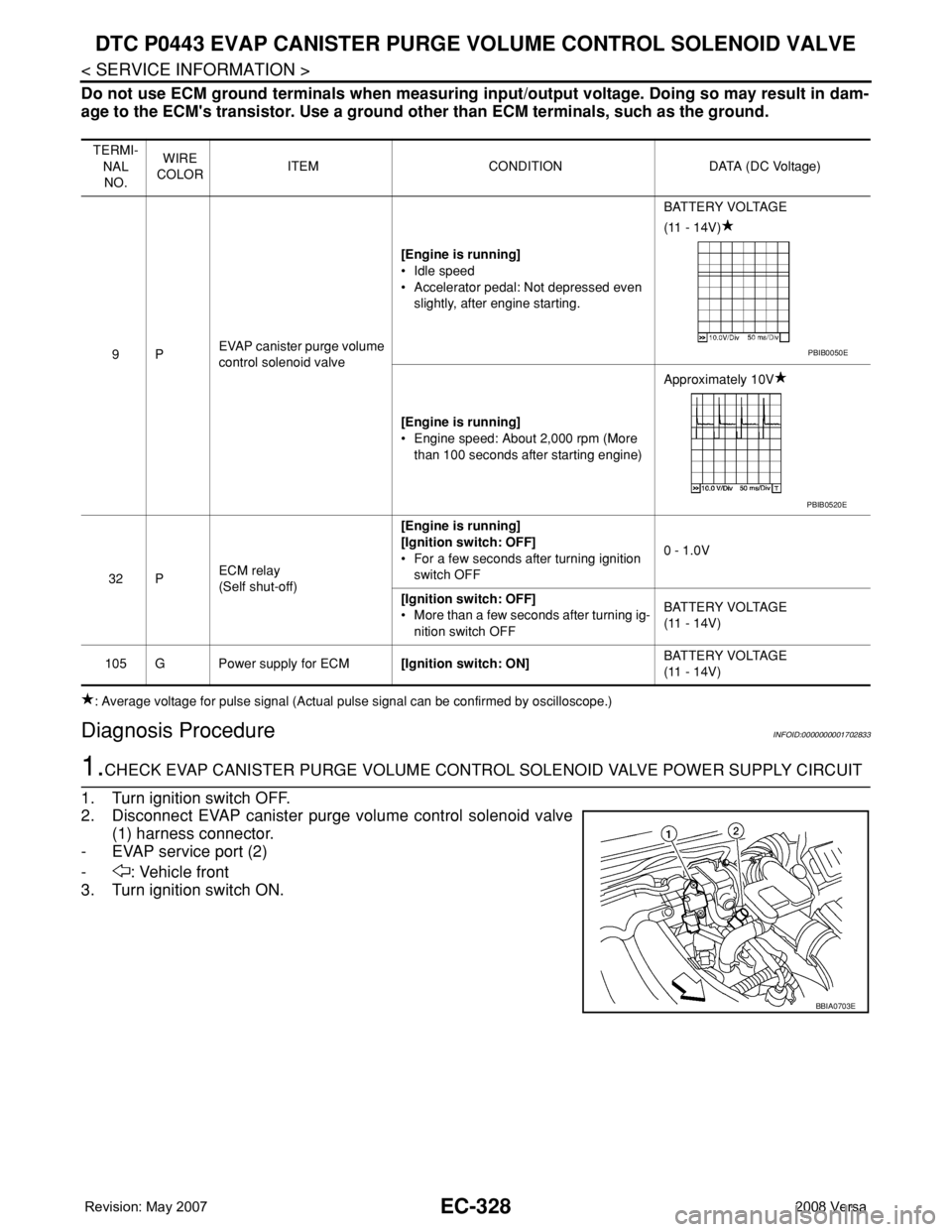

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702833

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve

(1) harness connector.

- EVAP service port (2)

- : Vehicle front

3. Turn ignition switch ON.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

9PEVAP canister purge volume

control solenoid valve[Engine is running]

• Idle speed

• Accelerator pedal: Not depressed even

slightly, after engine starting.BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

• Engine speed: About 2,000 rpm (More

than 100 seconds after starting engine)Approximately 10V

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning ig-

nition switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB0050E

PBIB0520E

BBIA0703E

Page 1409 of 2771

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

EC-335

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

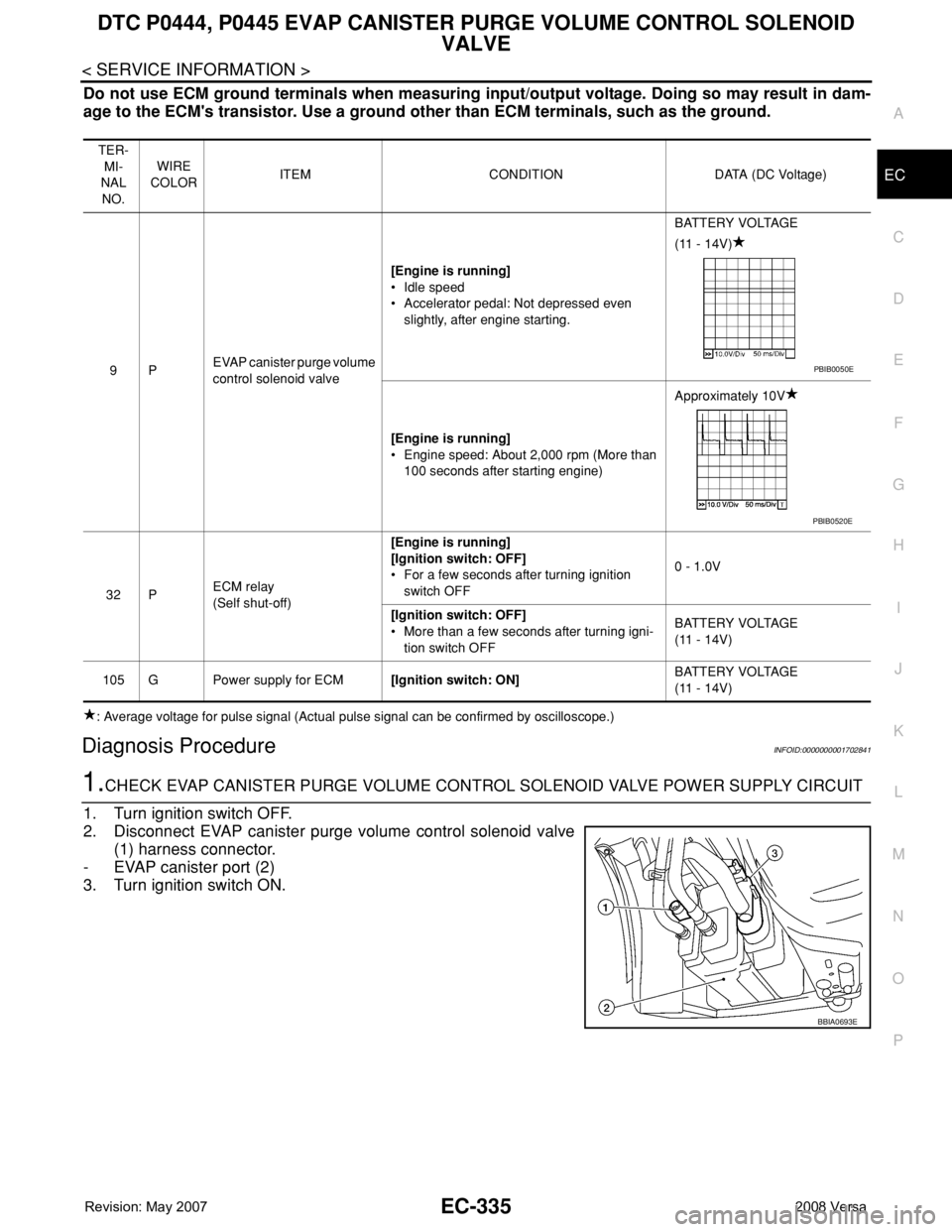

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702841

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve

(1) harness connector.

- EVAP canister port (2)

3. Turn ignition switch ON.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

9PEVAP canister purge volume

control solenoid valve[Engine is running]

• Idle speed

• Accelerator pedal: Not depressed even

slightly, after engine starting.BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

• Engine speed: About 2,000 rpm (More than

100 seconds after starting engine)Approximately 10V

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB0050E

PBIB0520E

BBIA0693E

Page 1415 of 2771

DTC P0447 EVAP CANISTER VENT CONTROL VALVE

EC-341

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

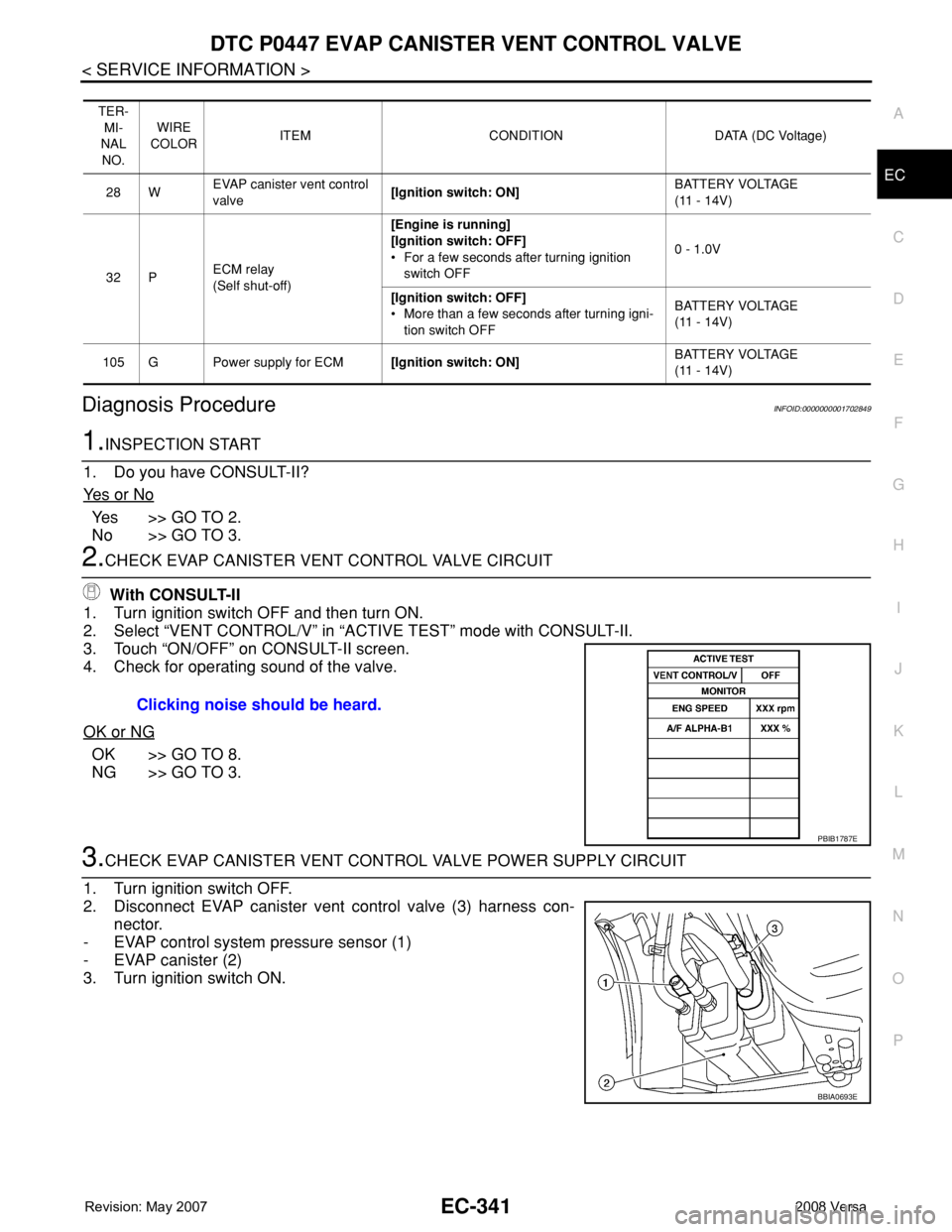

Diagnosis ProcedureINFOID:0000000001702849

1.INSPECTION START

1. Do you have CONSULT-II?

Ye s o r N o

Yes >> GO TO 2.

No >> GO TO 3.

2.CHECK EVAP CANISTER VENT CONTROL VALVE CIRCUIT

With CONSULT-II

1. Turn ignition switch OFF and then turn ON.

2. Select “VENT CONTROL/V” in “ACTIVE TEST” mode with CONSULT-II.

3. Touch “ON/OFF” on CONSULT-II screen.

4. Check for operating sound of the valve.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3.CHECK EVAP CANISTER VENT CONTROL VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EVAP canister vent control valve (3) harness con-

nector.

- EVAP control system pressure sensor (1)

- EVAP canister (2)

3. Turn ignition switch ON.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

28 WEVAP canister vent control

valve[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

Clicking noise should be heard.

PBIB1787E

BBIA0693E

Page 1422 of 2771

EC-348

< SERVICE INFORMATION >

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

Diagnosis Procedure

INFOID:0000000001702856

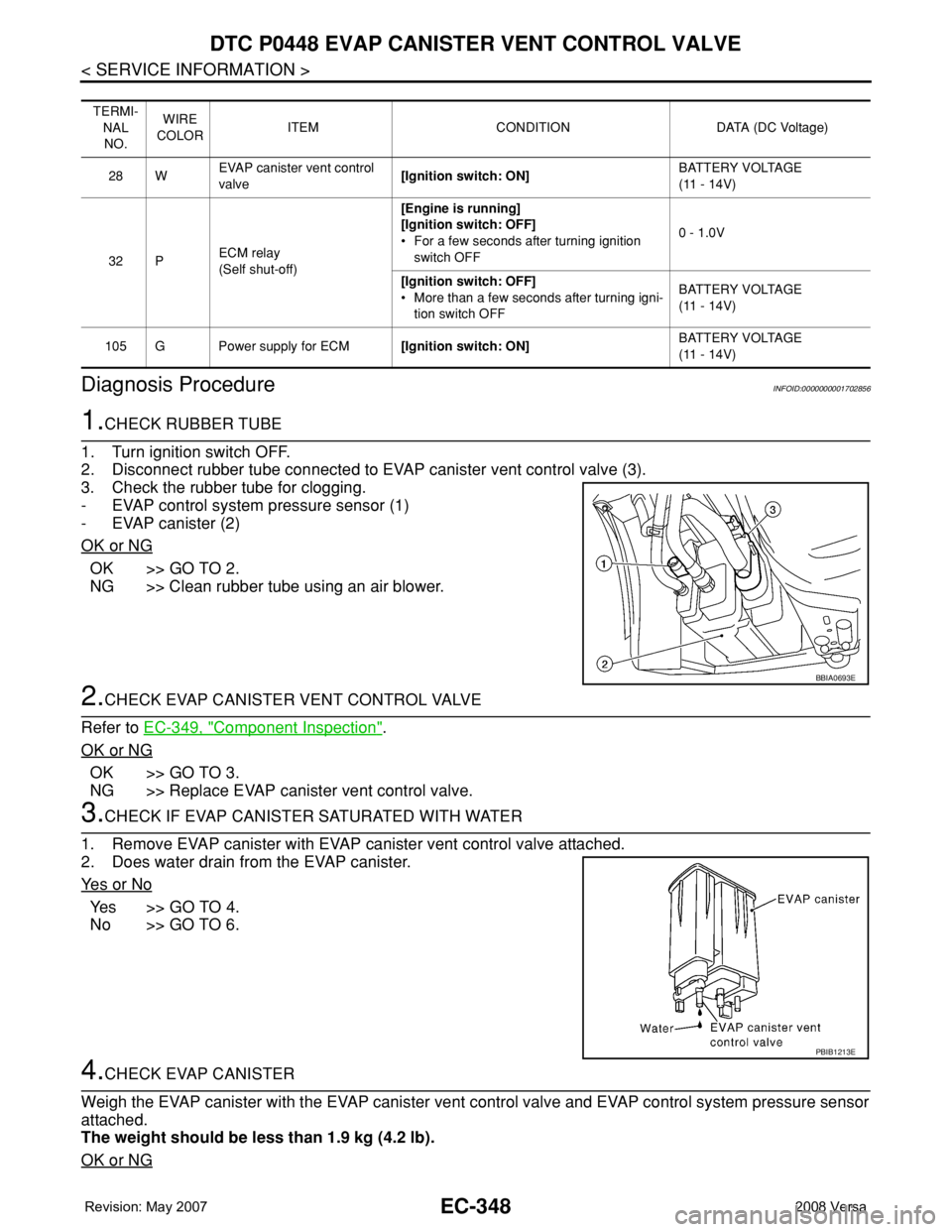

1.CHECK RUBBER TUBE

1. Turn ignition switch OFF.

2. Disconnect rubber tube connected to EVAP canister vent control valve (3).

3. Check the rubber tube for clogging.

- EVAP control system pressure sensor (1)

- EVAP canister (2)

OK or NG

OK >> GO TO 2.

NG >> Clean rubber tube using an air blower.

2.CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-349, "

Component Inspection".

OK or NG

OK >> GO TO 3.

NG >> Replace EVAP canister vent control valve.

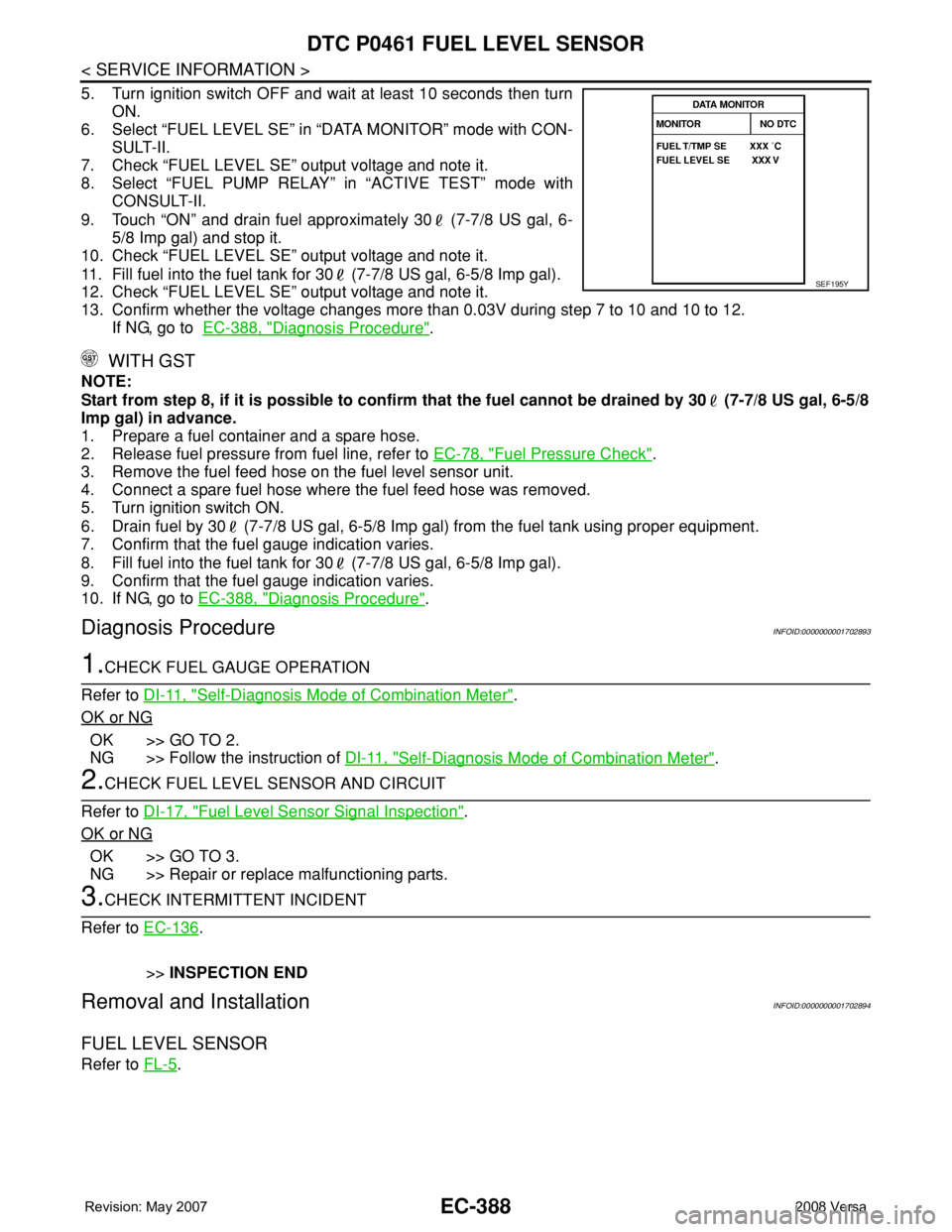

3.CHECK IF EVAP CANISTER SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve attached.

2. Does water drain from the EVAP canister.

Ye s o r N o

Ye s > > G O T O 4 .

No >> GO TO 6.

4.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

OK or NG

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

28 WEVAP canister vent control

valve[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0693E

PBIB1213E

Page 1462 of 2771

EC-388

< SERVICE INFORMATION >

DTC P0461 FUEL LEVEL SENSOR

5. Turn ignition switch OFF and wait at least 10 seconds then turn

ON.

6. Select “FUEL LEVEL SE” in “DATA MONITOR” mode with CON-

SULT-II.

7. Check “FUEL LEVEL SE” output voltage and note it.

8. Select “FUEL PUMP RELAY” in “ACTIVE TEST” mode with

CONSULT-II.

9. Touch “ON” and drain fuel approximately 30 (7-7/8 US gal, 6-

5/8 Imp gal) and stop it.

10. Check “FUEL LEVEL SE” output voltage and note it.

11. Fill fuel into the fuel tank for 30 (7-7/8 US gal, 6-5/8 Imp gal).

12. Check “FUEL LEVEL SE” output voltage and note it.

13. Confirm whether the voltage changes more than 0.03V during step 7 to 10 and 10 to 12.

If NG, go to EC-388, "

Diagnosis Procedure".

WITH GST

NOTE:

Start from step 8, if it is possible to confirm that the fuel cannot be drained by 30 (7-7/8 US gal, 6-5/8

Imp gal) in advance.

1. Prepare a fuel container and a spare hose.

2. Release fuel pressure from fuel line, refer to EC-78, "

Fuel Pressure Check".

3. Remove the fuel feed hose on the fuel level sensor unit.

4. Connect a spare fuel hose where the fuel feed hose was removed.

5. Turn ignition switch ON.

6. Drain fuel by 30 (7-7/8 US gal, 6-5/8 Imp gal) from the fuel tank using proper equipment.

7. Confirm that the fuel gauge indication varies.

8. Fill fuel into the fuel tank for 30 (7-7/8 US gal, 6-5/8 Imp gal).

9. Confirm that the fuel gauge indication varies.

10. If NG, go to EC-388, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001702893

1.CHECK FUEL GAUGE OPERATION

Refer to DI-11, "

Self-Diagnosis Mode of Combination Meter".

OK or NG

OK >> GO TO 2.

NG >> Follow the instruction of DI-11, "

Self-Diagnosis Mode of Combination Meter".

2.CHECK FUEL LEVEL SENSOR AND CIRCUIT

Refer to DI-17, "

Fuel Level Sensor Signal Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace malfunctioning parts.

3.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

Removal and InstallationINFOID:0000000001702894

FUEL LEVEL SENSOR

Refer to FL-5.

SEF195Y