ENGINE OIL FLUID NISSAN TIIDA 2008 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 877 of 2771

CVT-38

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

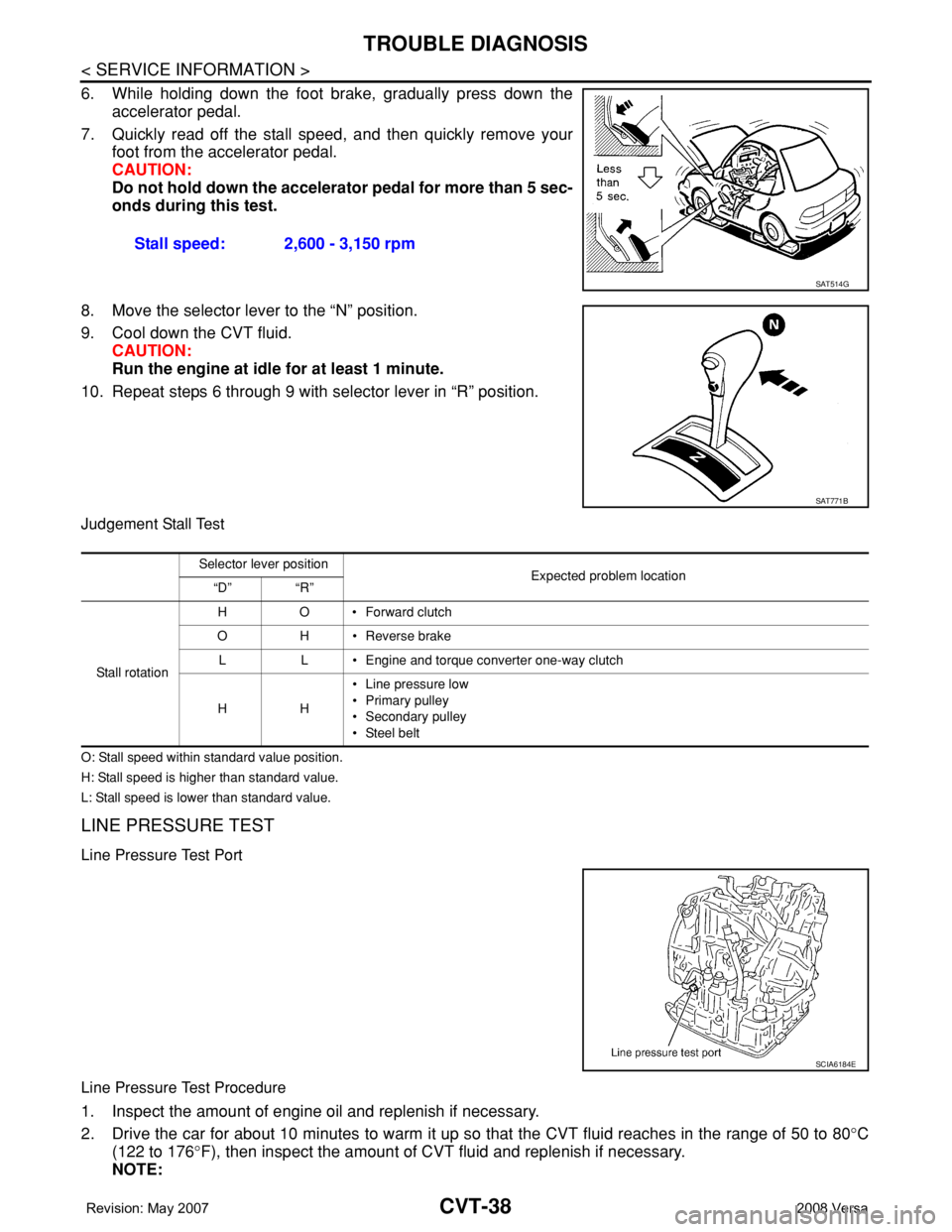

6. While holding down the foot brake, gradually press down the

accelerator pedal.

7. Quickly read off the stall speed, and then quickly remove your

foot from the accelerator pedal.

CAUTION:

Do not hold down the accelerator pedal for more than 5 sec-

onds during this test.

8. Move the selector lever to the “N” position.

9. Cool down the CVT fluid.

CAUTION:

Run the engine at idle for at least 1 minute.

10. Repeat steps 6 through 9 with selector lever in “R” position.

Judgement Stall Test

O: Stall speed within standard value position.

H: Stall speed is higher than standard value.

L: Stall speed is lower than standard value.

LINE PRESSURE TEST

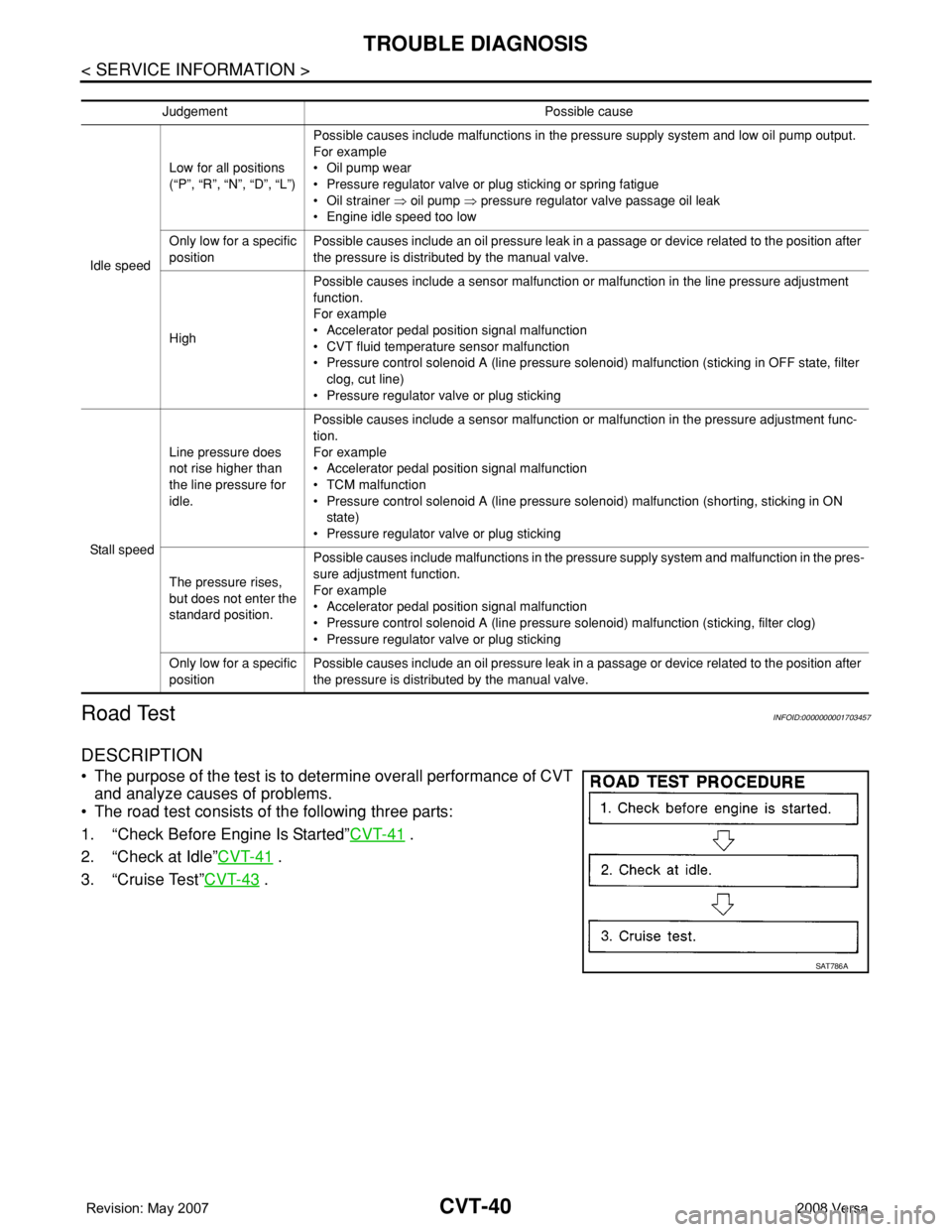

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the CVT fluid reaches in the range of 50 to 80°C

(122 to 176°F), then inspect the amount of CVT fluid and replenish if necessary.

NOTE:Stall speed: 2,600 - 3,150 rpm

SAT514G

SAT771B

Selector lever position

Expected problem location

“D” “R”

Stall rotation HO•Forward clutch

O H • Reverse brake

L L • Engine and torque converter one-way clutch

HH• Line pressure low

• Primary pulley

• Secondary pulley

• Steel belt

SCIA6184E

Page 878 of 2771

TROUBLE DIAGNOSIS

CVT-39

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

The CVT fluid temperature rises in the range of 50 - 80°C (122 - 176°F) during 10 minutes of driving.

3. After warming up CVT, remove the oil pressure detection plug and install the oil pressure gauge [special

service tool: - (OTC3492)].

CAUTION:

When using the oil pressure gauge, be sure to use the O-ring attached to the oil pressure detec-

tion plug.

4. Securely engage the parking brake so that the tires do not turn.

5. Start the engine, and then measure the line pressure at both idle

and the stall speed.

CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer

to "STALL TEST" .

6. After the measurements are complete, install the oil pressure

detection plug and tighten to the specified torque below.

CAUTION:

• Do not reuse O-ring.

• Apply CVT fluid to O-ring.

Line Pressure

*: Reference values

Judgement of Line Pressure Test

SAT513G

: 7.5 N·m (0.77 kg-m, 66 in-lb)SAT493G

Engine speed Line pressure kPa (kg/cm

2 , psi)

“R”, “D” and “L” positions

At idle 650 (6.63, 94.3)

At stall 4,250 (43.35, 616.3)*

Page 879 of 2771

CVT-40

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

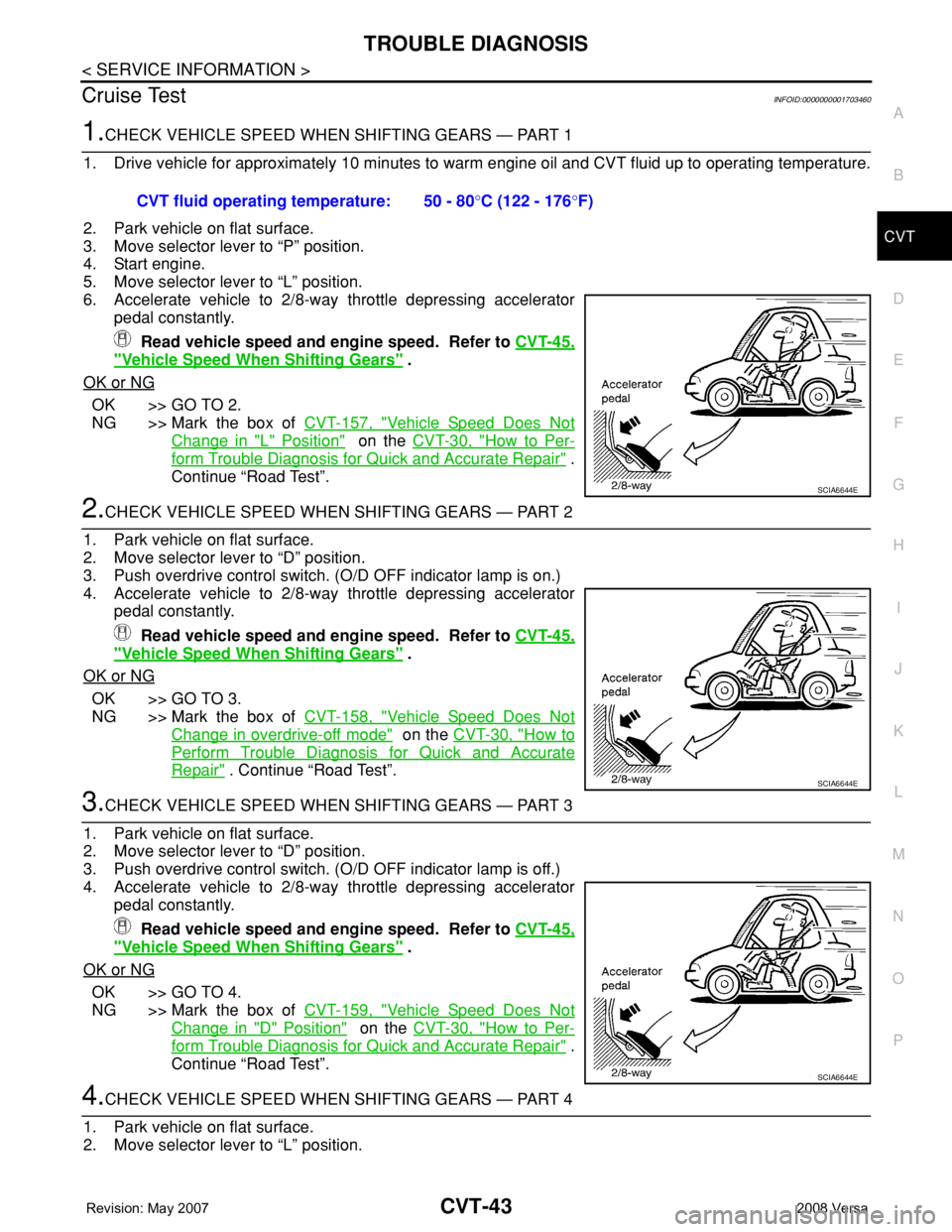

Road Test

INFOID:0000000001703457

DESCRIPTION

• The purpose of the test is to determine overall performance of CVT

and analyze causes of problems.

• The road test consists of the following three parts:

1. “Check Before Engine Is Started”CVT-41

.

2. “Check at Idle”CVT-41

.

3. “Cruise Test”CVT-43

.

Judgement Possible cause

Idle speedLow for all positions

(“P”, “R”, “N”, “D”, “L”)Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

•Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

•Oil strainer ⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a specific

positionPossible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

HighPossible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example

• Accelerator pedal position signal malfunction

• CVT fluid temperature sensor malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (sticking in OFF state, filter

clog, cut line)

• Pressure regulator valve or plug sticking

Sta ll sp ee dLine pressure does

not rise higher than

the line pressure for

idle.Possible causes include a sensor malfunction or malfunction in the pressure adjustment func-

tion.

For example

• Accelerator pedal position signal malfunction

•TCM malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (shorting, sticking in ON

state)

• Pressure regulator valve or plug sticking

The pressure rises,

but does not enter the

standard position.Possible causes include malfunctions in the pressure supply system and malfunction in the pres-

sure adjustment function.

For example

• Accelerator pedal position signal malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (sticking, filter clog)

• Pressure regulator valve or plug sticking

Only low for a specific

positionPossible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

SAT786A

Page 882 of 2771

TROUBLE DIAGNOSIS

CVT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

Cruise TestINFOID:0000000001703460

1.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 1

1. Drive vehicle for approximately 10 minutes to warm engine oil and CVT fluid up to operating temperature.

2. Park vehicle on flat surface.

3. Move selector lever to “P” position.

4. Start engine.

5. Move selector lever to “L” position.

6. Accelerate vehicle to 2/8-way throttle depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT-45,

"Vehicle Speed When Shifting Gears" .

OK or NG

OK >> GO TO 2.

NG >> Mark the box of CVT-157, "

Vehicle Speed Does Not

Change in "L" Position" on the CVT-30, "How to Per-

form Trouble Diagnosis for Quick and Accurate Repair" .

Continue “Road Test”.

2.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 2

1. Park vehicle on flat surface.

2. Move selector lever to “D” position.

3. Push overdrive control switch. (O/D OFF indicator lamp is on.)

4. Accelerate vehicle to 2/8-way throttle depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT-45,

"Vehicle Speed When Shifting Gears" .

OK or NG

OK >> GO TO 3.

NG >> Mark the box of CVT-158, "

Vehicle Speed Does Not

Change in overdrive-off mode" on the CVT-30, "How to

Perform Trouble Diagnosis for Quick and Accurate

Repair" . Continue “Road Test”.

3.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 3

1. Park vehicle on flat surface.

2. Move selector lever to “D” position.

3. Push overdrive control switch. (O/D OFF indicator lamp is off.)

4. Accelerate vehicle to 2/8-way throttle depressing accelerator

pedal constantly.

Read vehicle speed and engine speed. Refer to CVT-45,

"Vehicle Speed When Shifting Gears" .

OK or NG

OK >> GO TO 4.

NG >> Mark the box of CVT-159, "

Vehicle Speed Does Not

Change in "D" Position" on the CVT-30, "How to Per-

form Trouble Diagnosis for Quick and Accurate Repair" .

Continue “Road Test”.

4.CHECK VEHICLE SPEED WHEN SHIFTING GEARS — PART 4

1. Park vehicle on flat surface.

2. Move selector lever to “L” position. CVT fluid operating temperature: 50 - 80°C (122 - 176°F)

SCIA6644E

SCIA6644E

SCIA6644E

Page 891 of 2771

CVT-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*1: Refer to CVT-27, "Malfunction Indicator Lamp (MIL)" .

*2: Models without ABS does not indicate.

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

CVT SPD SEN/

FNCTNA rotation sensor error is detected because the gear does not

change in accordance with the position of the stepping motor

CAUTION:

One of the “P0720 VEH SPD SEN/CIR AT”, the “P0715 IN-

PUT SPD SEN/CIRC” or the “P0725 ENGINE SPEED SIG“

is displayed with the DTC at the same timeP1723 —CVT-129

ELEC TH CON-

TROLThe electronically controlled throttle for ECM is malfunction-

ingP1726 —CVT-131

LU-SLCT SOL/

CIRC• Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with

monitor valueP1740 P1740CVT-132

L/PRESS CON-

TROLTCM detects the unexpected line pressure P1745 —CVT-136

STEP MOTR CIRCEach coil of the step motor is not energized properly due to

an open or a shortP1777 P1777CVT-137

STEP MOTR/FNCThere is a great difference between the number of steps for

the stepping motor and for the actual gear ratioP1778 P1778CVT-141

NO DTC IS DE-

TECTED: FUR-

THER TESTING

MAY BE RE-

QUIREDNo NG item has been detected X X — Items (CONSULT-

III screen terms)Malfunction is detected when...TCM self-di-

agnosisOBD-III (DTC)

Reference

page “TRANSMIS-

SION” with

CONSULT-IIIMIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III

or GST

Monitored item (Unit)Monitor item selection

Remarks ECU IN-

PUT SIG-

NALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

VSP SENSOR (km/h) X — Output speed sensor (secondary speed sensor).

ESTM VSP SIG (km/h) X — Models without ABS does not indicate.

PRI SPEED SEN (rpm) X —

ENG SPEED SIG (rpm) X —

SEC HYDR SEN (V) X —

PRI HYDR SEN (V) X —

ATF TEMP SEN (V) X — CVT fluid temperature sensor

VIGN SEN (V) X —

VEHICLE SPEED (km/h) — X Vehicle speed recognized by the TCM.

PRI SPEED (rpm) — X Primary pulley speed.

SEC SPEED (rpm) — — Secondary pulley speed.

Page 892 of 2771

TROUBLE DIAGNOSIS

CVT-53

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

ENG SPEED (rpm) — X

SLIP REV (rpm) — XDifference between engine speed and primary

pulley speed

GEAR RATIO — X

G SPEED (G) — —

ACC PEDAL OPEN (0.0/8) X XDegree of opening for accelerator recognized by

the TCM

For fail-safe operation, the specific value used for

control is displayed.

TRQ RTO — —

SEC PRESS (MPa) — X

PRI PRESS (MPa) — X

ATFTEMP COUNT — XMeans CVT fluid temperature. Actual oil temper-

ature (°C) cannot be checked unless a numeric

value is converted. Refer to CVT-8

.

DSR REV (rpm) — —

DGEAR RATIO — —

DSTM STEP (step) — —

STM STEP (step) — X

LU PRS (MPa) — —

LINE PRS (MPa) — —

TGT SEC PRESS (MPa) — —

ISOLT1 (A) — XTorque converter clutch solenoid valve output

current

ISOLT2 (A) — XPressure control solenoid valve A (line pressure

solenoid valve) output current

ISOLT3 (A) — XPressure control solenoid valve B (secondary

pressure solenoid valve) output current

SOLMON1 (A) X XTorque converter clutch solenoid valve monitor

current

SOLMON2 (A) X XPressure control solenoid valve A (line pressure

solenoid valve) monitor current

SOLMON3 (A) X XPressure control solenoid valve B (secondary

pressure solenoid valve) monitor current

INH SW3M (ON/OFF) X — PNP switch 3 ON-OFF status monitor

INH SW4 (ON/OFF) X — PNP switch 4 ON-OFF status

INH SW3 (ON/OFF) X — PNP switch 3 ON-OFF status

INH SW2 (ON/OFF) X — PNP switch 2 ON-OFF status

INH SW1 (ON/OFF) X — PNP switch 1 ON-OFF status

BRAKE SW (ON/OFF) X XStop lamp switch (Signal input with CAN comuni-

cation) Monitored item (Unit)Monitor item selection

Remarks ECU IN-

PUT SIG-

NALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

Page 975 of 2771

CVT-136

< SERVICE INFORMATION >

DTC P1745 LINE PRESSURE CONTROL

DTC P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000001703635

The pressure control solenoid valve A (line pressure solenoid valve) regulates the oil pump discharge pres-

sure to suit the driving condition in response to a signal sent from the TCM.

On Board Diagnosis LogicINFOID:0000000001703636

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1745 L/PRESS CONTROL” with CONSULT-III is detected when TCM detects the

unexpected line pressure.

Possible CauseINFOID:0000000001703637

TCM

DTC Confirmation ProcedureINFOID:0000000001703638

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (cool down the fluid)

3. If DTC is detected, go to CVT-136, "

Diagnosis Procedure" .

Diagnosis ProcedureINFOID:0000000001703639

1.CHECK DTC

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “TRANSMISSION” with CONSULT-III.

3. Erase self-diagnostic results. Refer to CVT-26, "

OBD-II Diagnostic Trouble Code (DTC)".

4. Turn ignition switch OFF, and wait for 10 seconds or more.

5. Start engine.

6. Confirm self-diagnostic results again. Refer to CVT-47, "

CONSULT-III Function (TRANSMISSION)" .

Is the

“P1745 L/PRESS CONTROL” displayed?

YES >> Replace TCM. Refer to CVT-8, "Service After Replacing TCM and Transaxle Assembly" .

NO >>INSPECTION END

Page 1018 of 2771

TRANSAXLE ASSEMBLY

CVT-179

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

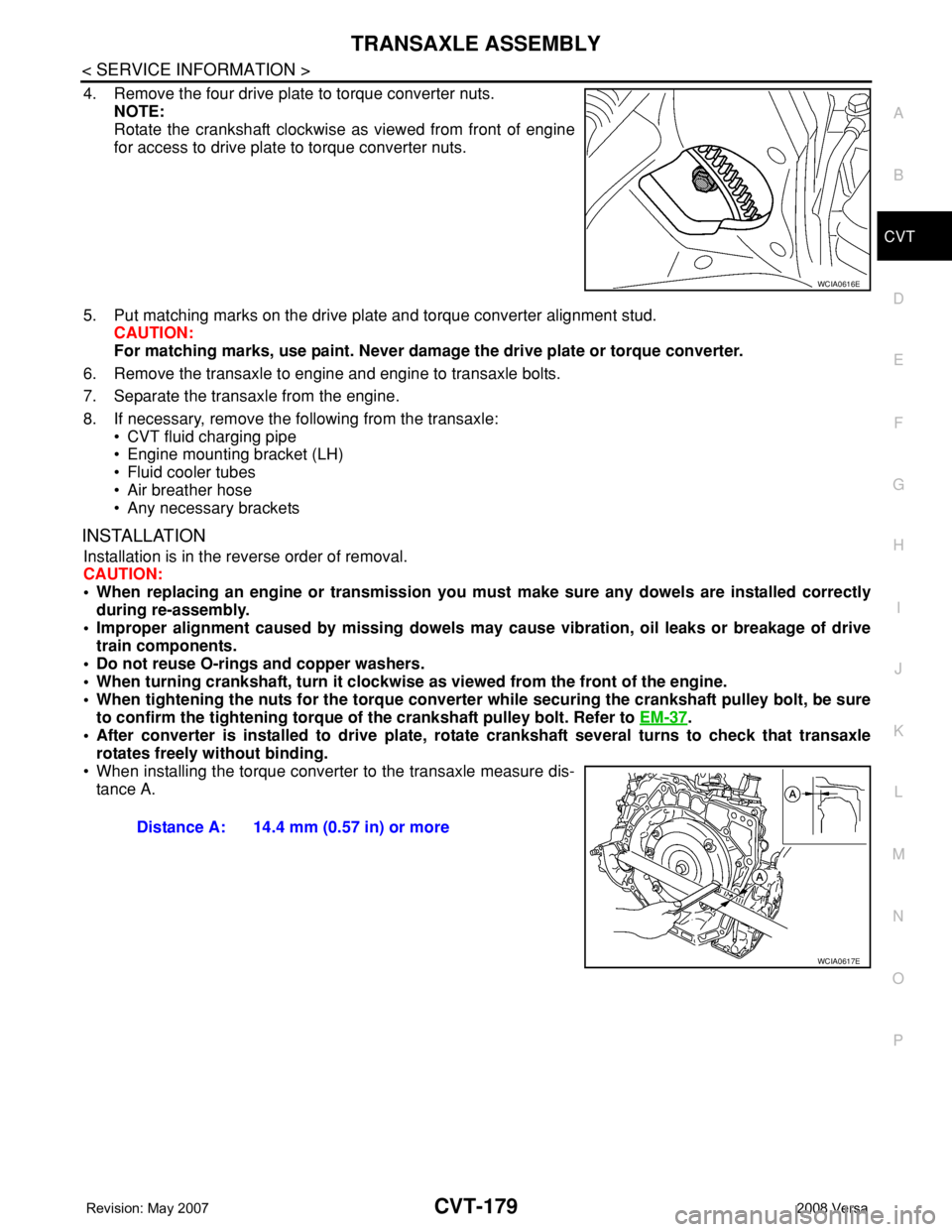

4. Remove the four drive plate to torque converter nuts.

NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter nuts.

5. Put matching marks on the drive plate and torque converter alignment stud.

CAUTION:

For matching marks, use paint. Never damage the drive plate or torque converter.

6. Remove the transaxle to engine and engine to transaxle bolts.

7. Separate the transaxle from the engine.

8. If necessary, remove the following from the transaxle:

• CVT fluid charging pipe

• Engine mounting bracket (LH)

• Fluid cooler tubes

• Air breather hose

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure any dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers.

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the nuts for the torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-37

.

• After converter is installed to drive plate, rotate crankshaft several turns to check that transaxle

rotates freely without binding.

• When installing the torque converter to the transaxle measure dis-

tance A.

WCIA0616E

Distance A: 14.4 mm (0.57 in) or more

WCIA0617E

Page 1683 of 2771

EM-6

< SERVICE INFORMATION >

PRECAUTIONS

• After 30 minutes or more have passed from the installation, fill

the engine with the specified oil and coolant. Refer to MA-10,

"Fluids and Lubricants".

CAUTION:

Follow all specific instructions in this manual.

SEM159F

Page 1691 of 2771

EM-14

< SERVICE INFORMATION >

DRIVE BELTS

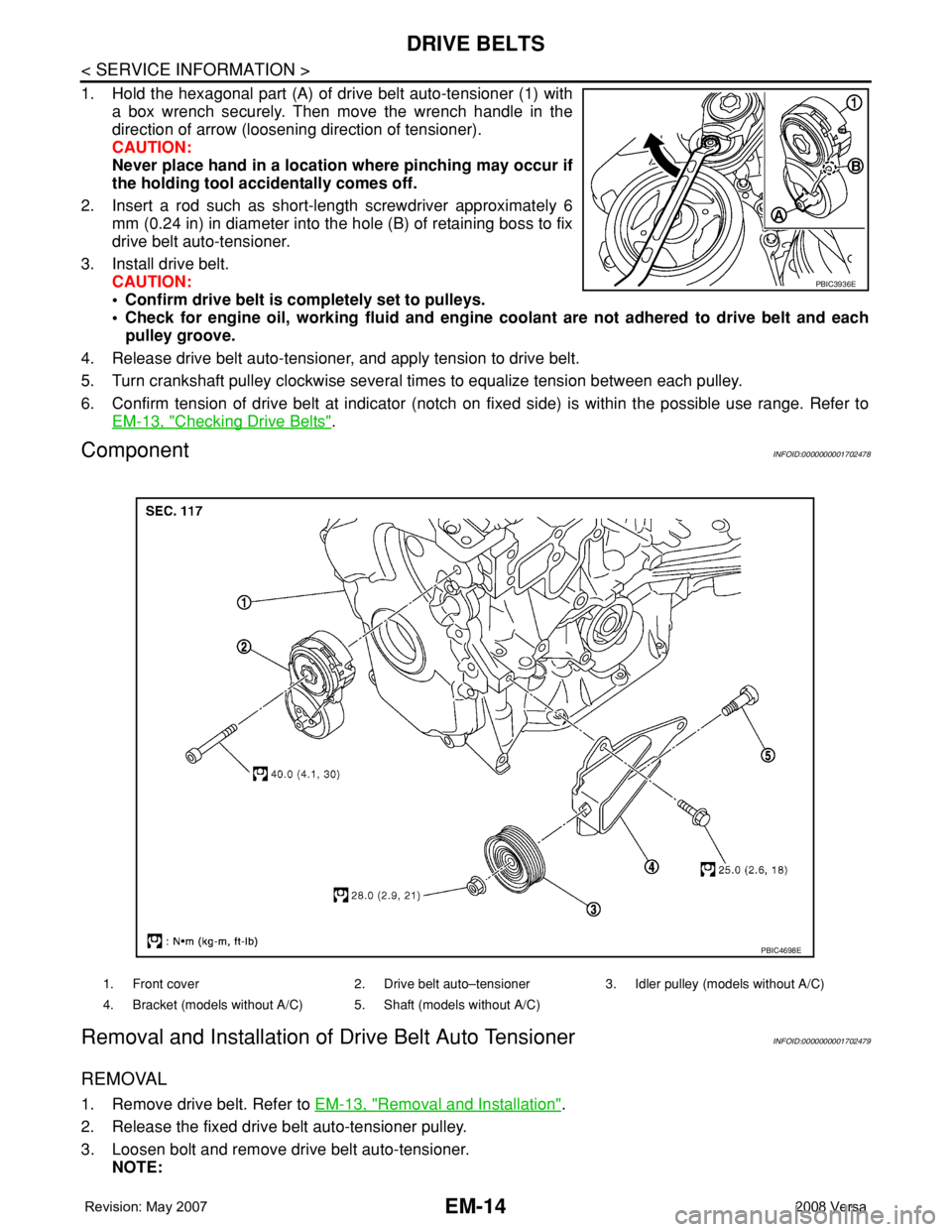

1. Hold the hexagonal part (A) of drive belt auto-tensioner (1) with

a box wrench securely. Then move the wrench handle in the

direction of arrow (loosening direction of tensioner).

CAUTION:

Never place hand in a location where pinching may occur if

the holding tool accidentally comes off.

2. Insert a rod such as short-length screwdriver approximately 6

mm (0.24 in) in diameter into the hole (B) of retaining boss to fix

drive belt auto-tensioner.

3. Install drive belt.

CAUTION:

• Confirm drive belt is completely set to pulleys.

• Check for engine oil, working fluid and engine coolant are not adhered to drive belt and each

pulley groove.

4. Release drive belt auto-tensioner, and apply tension to drive belt.

5. Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

6. Confirm tension of drive belt at indicator (notch on fixed side) is within the possible use range. Refer to

EM-13, "

Checking Drive Belts".

ComponentINFOID:0000000001702478

Removal and Installation of Drive Belt Auto TensionerINFOID:0000000001702479

REMOVAL

1. Remove drive belt. Refer to EM-13, "Removal and Installation".

2. Release the fixed drive belt auto-tensioner pulley.

3. Loosen bolt and remove drive belt auto-tensioner.

NOTE:

PBIC3936E

1. Front cover 2. Drive belt auto–tensioner 3. Idler pulley (models without A/C)

4. Bracket (models without A/C) 5. Shaft (models without A/C)

PBIC4698E