ENGINE OIL FLUID NISSAN TIIDA 2008 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 2282 of 2771

MA-22

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug

(1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-17, "

Disassembly and Assembly" .

CAUTION:

Do not reuse gasket.

Checking A/T FluidINFOID:0000000001704747

1. Warm up engine.

2. Check for A/T fluid leakage.

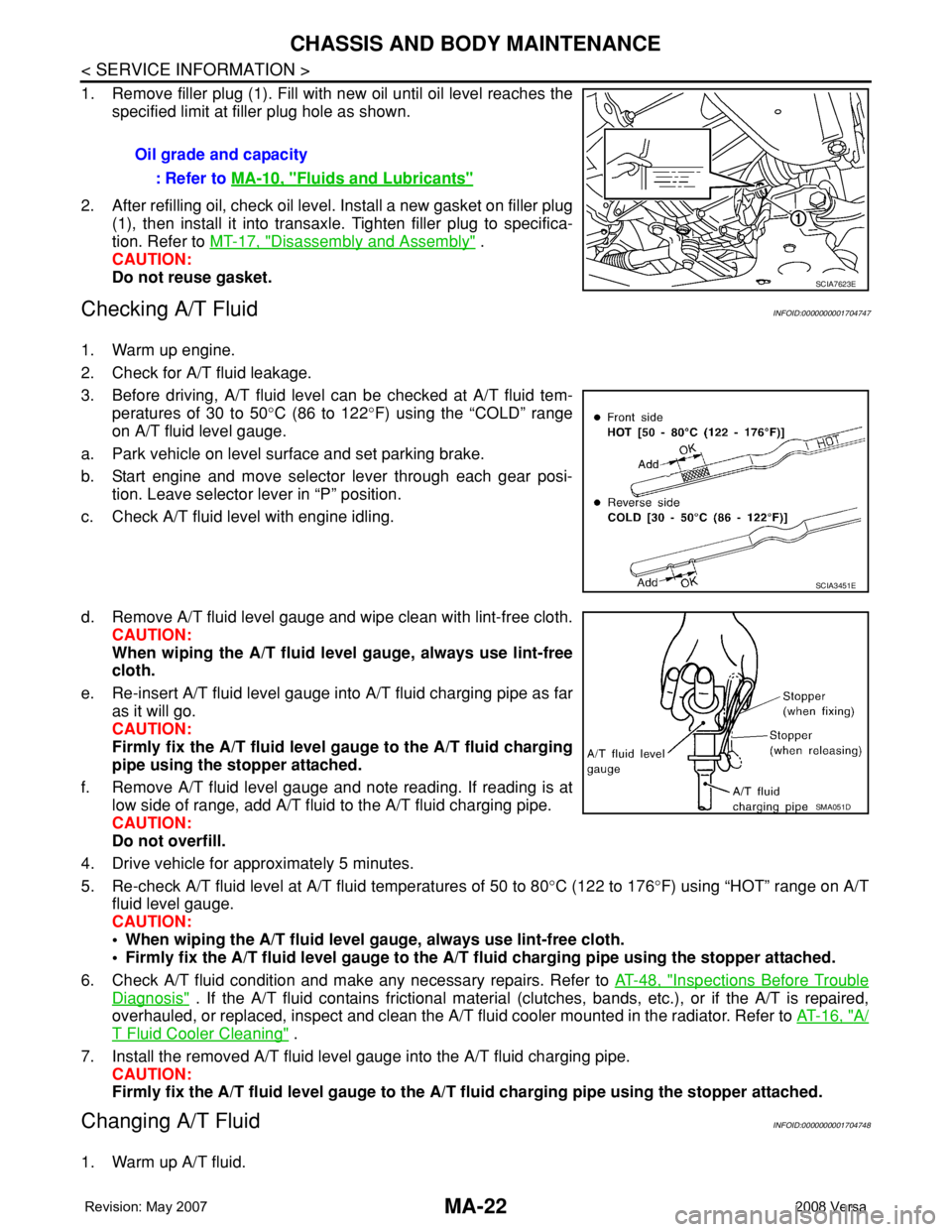

3. Before driving, A/T fluid level can be checked at A/T fluid tem-

peratures of 30 to 50°C (86 to 122°F) using the “COLD” range

on A/T fluid level gauge.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth.

CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

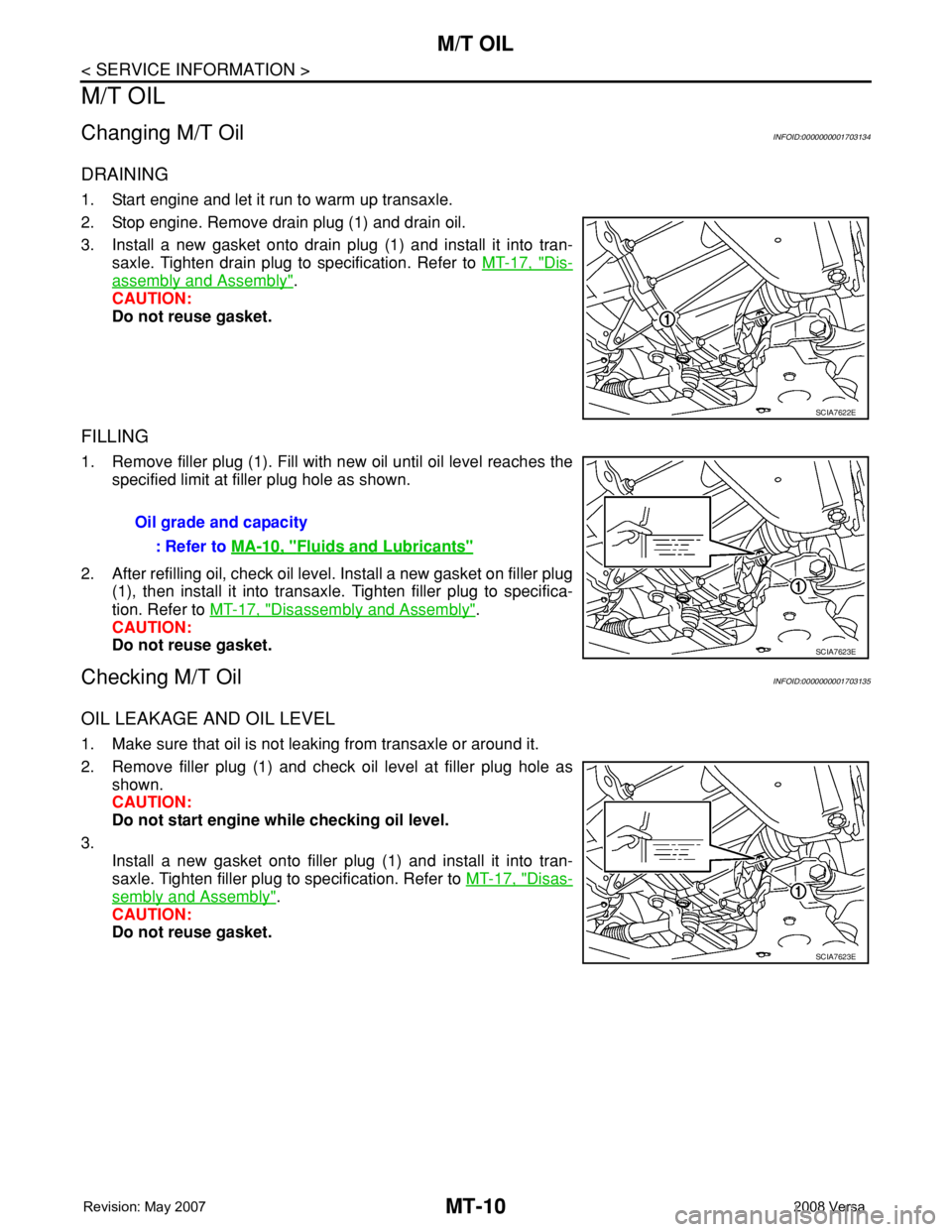

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far

as it will go.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at

low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:

Do not overfill.

4. Drive vehicle for approximately 5 minutes.

5. Re-check A/T fluid level at A/T fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on A/T

fluid level gauge.

CAUTION:

• When wiping the A/T fluid level gauge, always use lint-free cloth.

• Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

6. Check A/T fluid condition and make any necessary repairs. Refer to AT-48, "

Inspections Before Trouble

Diagnosis" . If the A/T fluid contains frictional material (clutches, bands, etc.), or if the A/T is repaired,

overhauled, or replaced, inspect and clean the A/T fluid cooler mounted in the radiator. Refer to AT-16, "

A/

T Fluid Cooler Cleaning" .

7. Install the removed A/T fluid level gauge into the A/T fluid charging pipe.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging pipe using the stopper attached.

Changing A/T FluidINFOID:0000000001704748

1. Warm up A/T fluid.Oil grade and capacity

: Refer to MA-10, "

Fluids and Lubricants"

SCIA7623E

SCIA3451E

SMA051D

Page 2298 of 2771

MT-10

< SERVICE INFORMATION >

M/T OIL

M/T OIL

Changing M/T OilINFOID:0000000001703134

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into tran-

saxle. Tighten drain plug to specification. Refer to MT-17, "

Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug

(1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-17, "

Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

Checking M/T OilINFOID:0000000001703135

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as

shown.

CAUTION:

Do not start engine while checking oil level.

3.

Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-17, "

Disas-

sembly and Assembly".

CAUTION:

Do not reuse gasket.

SCIA7622E

Oil grade and capacity

: Refer to MA-10, "

Fluids and Lubricants"

SCIA7623E

SCIA7623E

Page 2304 of 2771

MT-16

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000001703141

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder).

Inserted CSC returns to the original position when removing transaxle assembly. Dust on clutch disc

sliding parts may damage CSC seal, and may cause clutch fluid leakage.

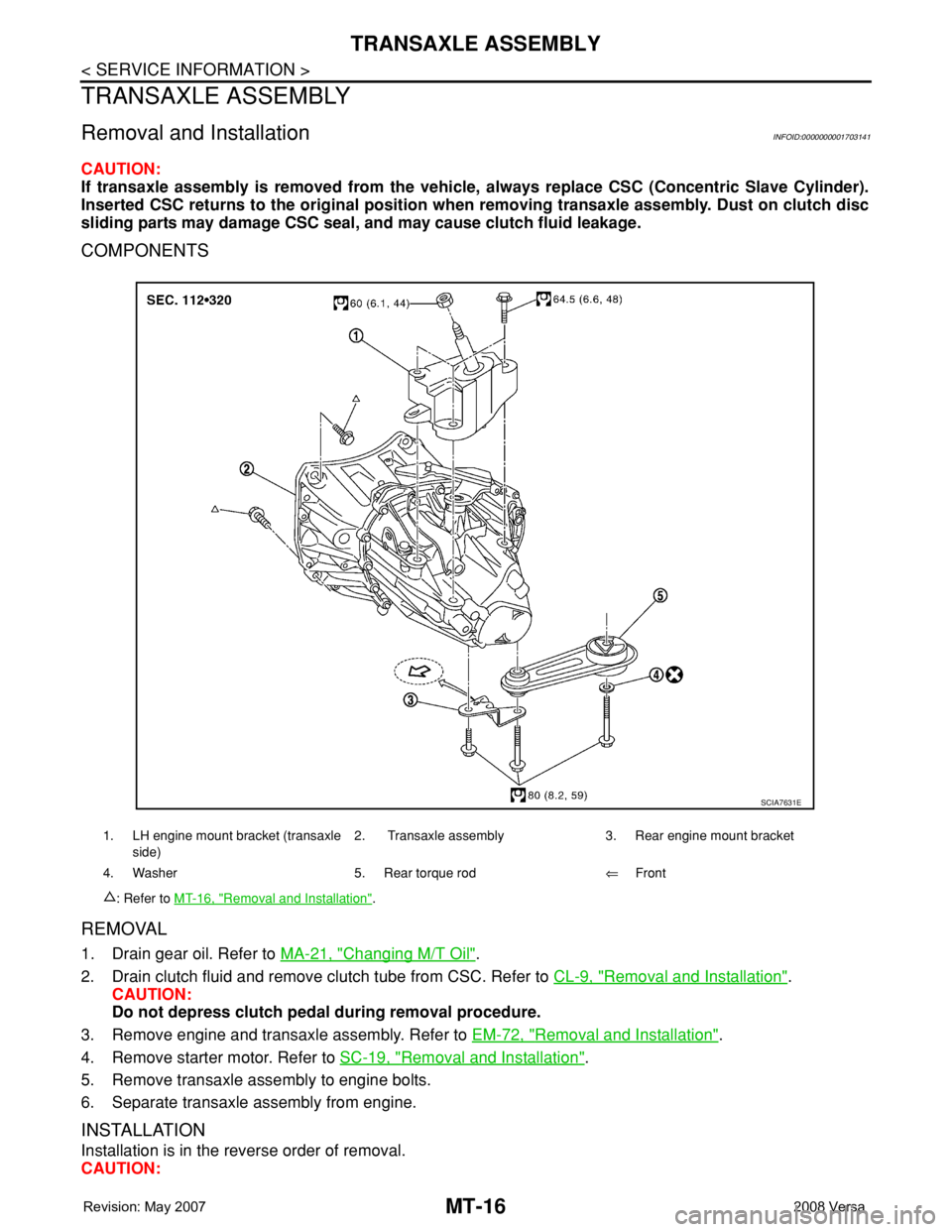

COMPONENTS

REMOVAL

1. Drain gear oil. Refer to MA-21, "Changing M/T Oil".

2. Drain clutch fluid and remove clutch tube from CSC. Refer to CL-9, "

Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

3. Remove engine and transaxle assembly. Refer to EM-72, "

Removal and Installation".

4. Remove starter motor. Refer to SC-19, "

Removal and Installation".

5. Remove transaxle assembly to engine bolts.

6. Separate transaxle assembly from engine.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

1. LH engine mount bracket (transaxle

side)2. Transaxle assembly 3. Rear engine mount bracket

4. Washer 5. Rear torque rod⇐Front

: Refer to MT-16, "

Removal and Installation".

SCIA7631E

Page 2423 of 2771

REFRIGERANT LINES

MTC-85

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

MTC

N

O

P

Checking System for Leaks Using the Fluorescent Leak DetectorINFOID:0000000001704334

1. Check A/C system for leaks using the UV lamp and safety goggles J-42220 in a low sunlight area (area

without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a bright

green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain opening indi-

cates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner J-43872 to prevent future misdiag-

nosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and oils, may falsely trigger the leak detector. Make sure the surfaces to be checked are

clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionINFOID:0000000001704335

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool J-41459.

3. Connect the injector tool to the A/C low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

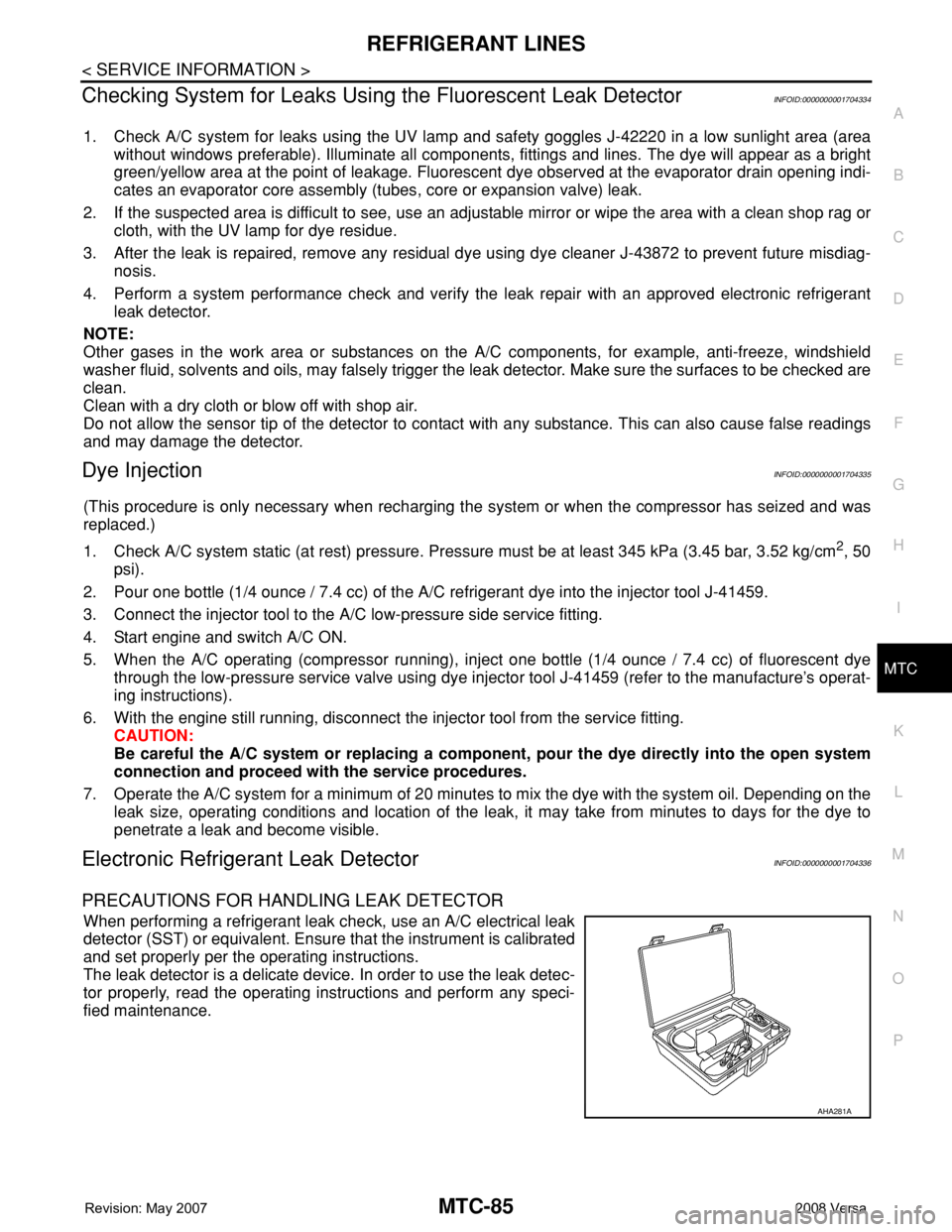

Electronic Refrigerant Leak DetectorINFOID:0000000001704336

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

AHA281A