transmission NISSAN TIIDA 2008 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 840 of 2771

CVT-1

TRANSMISSION/TRANSAXLE

D

E

F

G

H

I

J

K

L

M

SECTION CVT

A

B

CVT

N

O

P

CONTENTS

CVT

SERVICE INFORMATION ............................5

INDEX FOR DTC .................................................5

Alphabetical Index .....................................................5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

7

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine ....................................................

7

Service After Replacing TCM and Transaxle As-

sembly .......................................................................

8

Removal and Installation Procedure for CVT Unit

Connector ..................................................................

9

Precaution ...............................................................10

Service Notice or Precaution ...................................11

PREPARATION ..................................................12

Special Service Tool ...............................................12

Commercial Service Tool ........................................12

CVT FLUID .........................................................13

Checking CVT Fluid ................................................13

Changing CVT Fluid ................................................14

CVT Fluid Cooler Cleaning .....................................14

CVT SYSTEM .....................................................18

Cross-Sectional View - RE0F08A ...........................18

Control System ........................................................19

Hydraulic Control System ........................................20

TCM Function ..........................................................20

CAN Communication ...............................................21

Input/Output Signal of TCM .....................................22

Line Pressure and Secondary Pressure Control .....22

Shift Control ............................................................23

Lock-up and Select Control .....................................24

Control Valve ...........................................................25

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....26

Introduction ..............................................................26

OBD-II Function for CVT System ............................26

One or Two Trip Detection Logic of OBD-II .............26

OBD-II Diagnostic Trouble Code (DTC) ..................26

Malfunction Indicator Lamp (MIL) ............................27

TROUBLE DIAGNOSIS ....................................29

DTC Inspection Priority Chart ..................................29

Fail-Safe ..................................................................29

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

30

CVT Electrical Parts Location ..................................35

Circuit Diagram ........................................................36

Inspections before Trouble Diagnosis .....................36

Road Test ................................................................40

Check before Engine Is Started ...............................41

Check at Idle ............................................................41

Cruise Test ..............................................................43

Vehicle Speed When Shifting Gears .......................45

TCM Terminal and Reference Value .......................45

CONSULT-III Function (TRANSMISSION) ..............47

Diagnosis Procedure without CONSULT-III ............55

DTC U1000 CAN COMMUNICATION LINE .....56

Description ...............................................................56

On Board Diagnosis Logic .......................................56

Possible Cause ........................................................56

DTC Confirmation Procedure ..................................56

Wiring Diagram - CVT - CAN ...................................57

Diagnosis Procedure ...............................................58

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) ................................................

59

Description ...............................................................59

On Board Diagnosis Logic .......................................59

Possible Cause ........................................................59

DTC Confirmation Procedure ..................................59

Diagnosis Procedure ...............................................59

DTC P0615 START SIGNAL CIRCUIT .............60

Page 842 of 2771

CVT-3

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P N CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

100

On Board Diagnosis Logic ....................................100

Possible Cause .....................................................100

DTC Confirmation Procedure ................................100

Diagnosis Procedure .............................................100

DTC P0776 PRESSURE CONTROL SOLE-

NOID B PERFORMANCE (SEC PRESSURE

SOLENOID VALVE) .........................................

102

Description ............................................................102

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

102

On Board Diagnosis Logic ....................................102

Possible Cause .....................................................102

DTC Confirmation Procedure ................................102

Diagnosis Procedure .............................................102

DTC P0778 PRESSURE CONTROL SOLE-

NOID B ELECTRICAL (SEC PRESSURE SO-

LENOID VALVE) ..............................................

104

Description ............................................................104

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

104

On Board Diagnosis Logic ....................................104

Possible Cause .....................................................104

DTC Confirmation Procedure ................................104

Wiring Diagram - CVT - SECPSV .........................105

Diagnosis Procedure .............................................106

Component Inspection ..........................................107

DTC P0840 TRANSMISSION FLUID PRES-

SURE SENSOR A CIRCUIT (SEC PRES-

SURE SENSOR) ...............................................

109

Description ............................................................109

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ................................109

Wiring Diagram - CVT - SECPS ............................110

Diagnosis Procedure .............................................111

DTC P0841 PRESSURE SENSOR FUNC-

TION .................................................................

113

Description ............................................................113

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

113

On Board Diagnosis Logic ....................................113

Possible Cause .....................................................113

DTC Confirmation Procedure ................................113

Diagnosis Procedure .............................................113

DTC P0845 TRANSMISSION FLUID PRES-

SURE SENSOR B CIRCUIT (PRI PRESSURE

SENSOR) ..........................................................

115

Description ............................................................115

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

115

On Board Diagnosis Logic .....................................115

Possible Cause ......................................................115

DTC Confirmation Procedure ................................115

Wiring Diagram - CVT - PRIPS .............................116

Diagnosis Procedure .............................................117

DTC P0868 SECONDARY PRESSURE

DOWN .............................................................

119

Description .............................................................119

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

119

On Board Diagnosis Logic .....................................119

Possible Cause ......................................................119

DTC Confirmation Procedure ................................119

Diagnosis Procedure .............................................119

DTC P1701 TRANSMISSION CONTROL

MODULE (POWER SUPPLY) .........................

121

Description .............................................................121

On Board Diagnosis Logic .....................................121

Possible Cause ......................................................121

DTC Confirmation Procedure ................................121

Wiring Diagram - CVT - POWER ...........................122

Diagnosis Procedure .............................................123

DTC P1705 THROTTLE POSITION SENSOR .125

Description .............................................................125

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

125

On Board Diagnosis Logic .....................................125

Possible Cause ......................................................125

DTC Confirmation Procedure ................................125

Diagnosis Procedure .............................................125

DTC P1722 ESTM VEHICLE SPEED SIGNAL .127

Description .............................................................127

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

127

On Board Diagnosis Logic .....................................127

Possible Cause ......................................................127

DTC Confirmation Procedure ................................127

Diagnosis Procedure .............................................127

DTC P1723 CVT SPEED SENSOR FUNC-

TION ................................................................

129

Description .............................................................129

On Board Diagnosis Logic .....................................129

Possible Cause ......................................................129

DTC Confirmation Procedure ................................129

Diagnosis Procedure .............................................129

DTC P1726 ELECTRIC THROTTLE CON-

TROL SYSTEM ...............................................

131

Description .............................................................131

On Board Diagnosis Logic .....................................131

Possible Cause ......................................................131

DTC Confirmation Procedure ................................131

Diagnosis Procedure .............................................131

Page 843 of 2771

CVT-4

DTC P1740 LOCK-UP SELECT SOLENOID

VALVE CIRCUIT ..............................................

132

Description .............................................................132

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

132

On Board Diagnosis Logic .....................................132

Possible Cause ......................................................132

DTC Confirmation Procedure ................................132

Wiring Diagram - CVT - L/USSV ............................133

Diagnosis Procedure .............................................134

Component Inspection ...........................................135

DTC P1745 LINE PRESSURE CONTROL ......136

Description .............................................................136

On Board Diagnosis Logic .....................................136

Possible Cause ......................................................136

DTC Confirmation Procedure ................................136

Diagnosis Procedure .............................................136

DTC P1777 STEP MOTOR - CIRCUIT ............137

Description .............................................................137

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

137

On Board Diagnosis Logic .....................................137

Possible Cause ......................................................137

DTC Confirmation Procedure ................................137

Wiring Diagram - CVT - STM .................................138

Diagnosis Procedure .............................................139

Component Inspection ...........................................140

DTC P1778 STEP MOTOR - FUNCTION ........141

Description .............................................................141

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

141

On Board Diagnosis Logic .....................................141

Possible Cause ......................................................141

DTC Confirmation Procedure ................................141

Diagnosis Procedure .............................................142

OVERDRIVE CONTROL SWITCH ..................143

Description .............................................................143

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

143

Wiring Diagram - CVT - ODSW .............................144

Diagnosis Procedure .............................................144

Component Inspection ...........................................146

SHIFT POSITION INDICATOR CIRCUIT ........148

Description .............................................................148

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

148

Diagnosis Procedure .............................................148

TROUBLE DIAGNOSIS FOR SYMPTOMS .....149

Wiring Diagram - CVT - NONDTC .........................149

O/D OFF Indicator Lamp Does Not Come On ......151

Engine Cannot Be Started in "P" and "N" Position .153

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

153

In "N" Position, Vehicle Moves ..............................154

Large Shock "N" → "R" Position ...........................154

Vehicle Does Not Creep Backward in "R" Position .155

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition ......................................................................

156

Vehicle Speed Does Not Change in "L" Position ..157

Vehicle Speed Does Not Change in overdrive-off

mode .....................................................................

158

Vehicle Speed Does Not Change in "D" Position .159

Vehicle Does Not Decelerate by Engine Brake ....159

TRANSMISSION CONTROL MODULE ...........161

Removal and Installation .......................................161

CVT SHIFT LOCK SYSTEM .............................162

Description ............................................................162

Shift Lock System Electrical Parts Location ..........162

Wiring Diagram - CVT - SHIFT .............................163

Diagnosis Procedure .............................................163

SHIFT CONTROL SYSTEM .............................167

Removal and Installation .......................................167

Control Device Disassembly and Assembly .........170

Selector Lever Knob Removal and Installation .....170

Adjustment of CVT Position ..................................171

Checking of CVT Position .....................................171

KEY INTERLOCK CABLE ...............................173

Removal and Installation .......................................173

AIR BREATHER HOSE ....................................176

Removal and Installation .......................................176

DIFFERENTIAL SIDE OIL SEAL .....................177

Removal and Installation .......................................177

TRANSAXLE ASSEMBLY ...............................178

Removal and Installation .......................................178

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

181

General Specification ............................................181

Vehicle Speed When Shifting Gears .....................181

Stall Speed ............................................................181

Line Pressure ........................................................181

Solenoid Valves ....................................................182

CVT Fluid Temperature Sensor ............................182

Primary Speed Sensor ..........................................182

Secondary Speed Sensor .....................................182

Removal and Installation .......................................182

Page 844 of 2771

INDEX FOR DTC

CVT-5

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

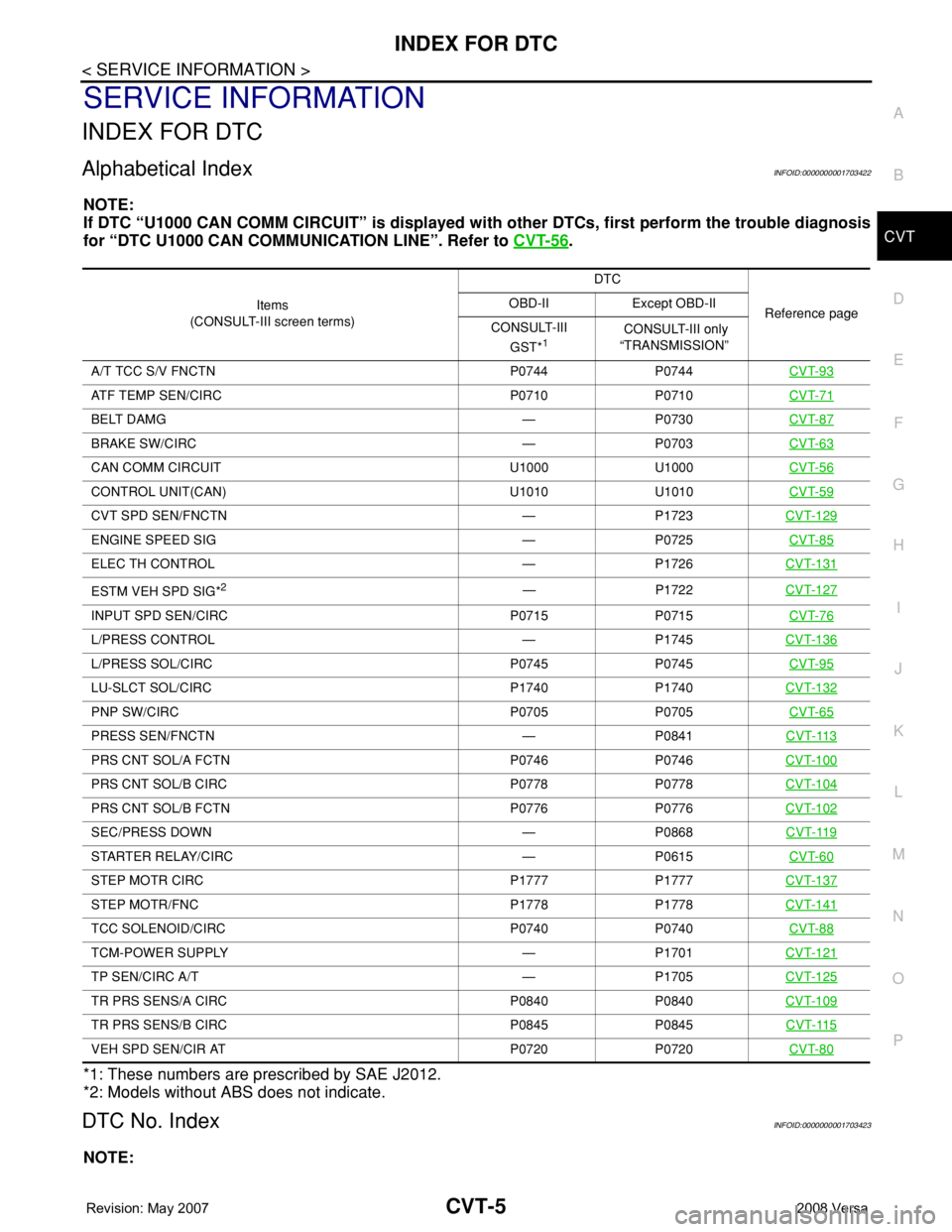

SERVICE INFORMATION

INDEX FOR DTC

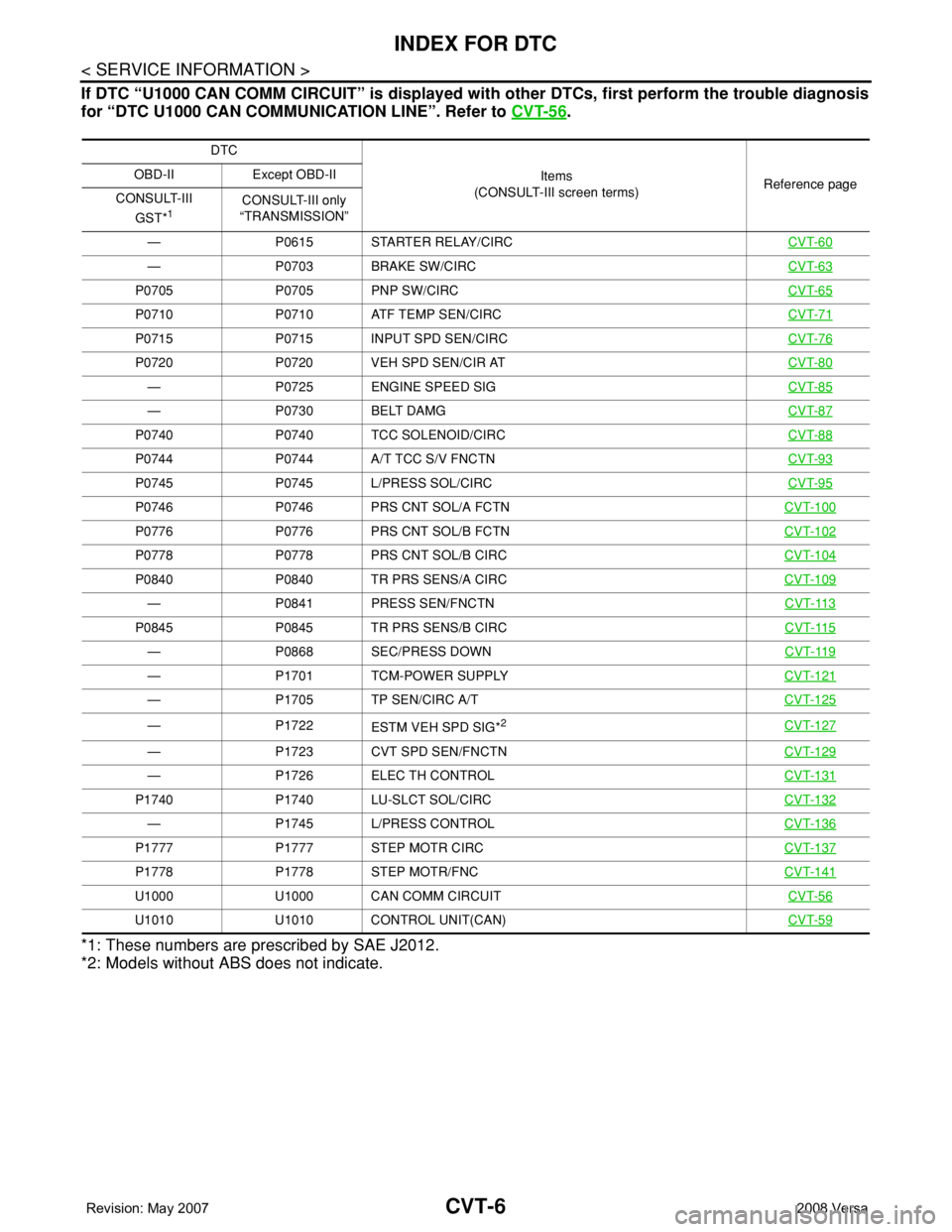

Alphabetical IndexINFOID:0000000001703422

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-56

.

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. IndexINFOID:0000000001703423

NOTE:

Items

(CONSULT-III screen terms) DTC

Reference page OBD-II Except OBD-II

CONSULT-III

GST*

1 CONSULT-III only

“TRANSMISSION”

A/T TCC S/V FNCTN P0744 P0744 CVT-93

ATF TEMP SEN/CIRC P0710 P0710CVT-71

BELT DAMG — P0730CVT-87

BRAKE SW/CIRC — P0703CVT-63

CAN COMM CIRCUIT U1000 U1000CVT-56

CONTROL UNIT(CAN) U1010 U1010CVT-59

CVT SPD SEN/FNCTN — P1723CVT-129

ENGINE SPEED SIG — P0725CVT-85

ELEC TH CONTROL — P1726CVT-131

ESTM VEH SPD SIG*2— P1722CVT-127

INPUT SPD SEN/CIRC P0715 P0715CVT-76

L/PRESS CONTROL — P1745CVT-136

L/PRESS SOL/CIRC P0745 P0745CVT-95

LU-SLCT SOL/CIRC P1740 P1740CVT-132

PNP SW/CIRC P0705 P0705CVT-65

PRESS SEN/FNCTN — P0841CVT-113

PRS CNT SOL/A FCTN P0746 P0746CVT-100

PRS CNT SOL/B CIRC P0778 P0778CVT-104

PRS CNT SOL/B FCTN P0776 P0776CVT-102

SEC/PRESS DOWN — P0868CVT-119

STARTER RELAY/CIRC — P0615CVT-60

STEP MOTR CIRC P1777 P1777CVT-137

STEP MOTR/FNC P1778 P1778CVT-141

TCC SOLENOID/CIRC P0740 P0740CVT-88

TCM-POWER SUPPLY — P1701CVT-121

TP SEN/CIRC A/T — P1705CVT-125

TR PRS SENS/A CIRC P0840 P0840CVT-109

TR PRS SENS/B CIRC P0845 P0845CVT-115

VEH SPD SEN/CIR AT P0720 P0720CVT-80

Page 845 of 2771

CVT-6

< SERVICE INFORMATION >

INDEX FOR DTC

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-56

.

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms)Reference page OBD-II Except OBD-II

CONSULT-III

GST*

1CONSULT-III only

“TRANSMISSION”

— P0615 STARTER RELAY/CIRCCVT-60

— P0703 BRAKE SW/CIRCCVT-63

P0705 P0705 PNP SW/CIRCCVT-65

P0710 P0710 ATF TEMP SEN/CIRCCVT-71

P0715 P0715 INPUT SPD SEN/CIRCCVT-76

P0720 P0720 VEH SPD SEN/CIR ATCVT-80

— P0725 ENGINE SPEED SIGCVT-85

— P0730 BELT DAMGCVT-87

P0740 P0740 TCC SOLENOID/CIRCCVT-88

P0744 P0744 A/T TCC S/V FNCTNCVT-93

P0745 P0745 L/PRESS SOL/CIRCCVT-95

P0746 P0746 PRS CNT SOL/A FCTNCVT-100

P0776 P0776 PRS CNT SOL/B FCTNCVT-102

P0778 P0778 PRS CNT SOL/B CIRCCVT-104

P0840 P0840 TR PRS SENS/A CIRCCVT-109

— P0841 PRESS SEN/FNCTNCVT-113

P0845 P0845 TR PRS SENS/B CIRCCVT-115

— P0868 SEC/PRESS DOWNCVT-119

— P1701 TCM-POWER SUPPLYCVT-121

— P1705 TP SEN/CIRC A/TCVT-125

— P1722

ESTM VEH SPD SIG*2CVT-127

— P1723 CVT SPD SEN/FNCTNCVT-129

— P1726 ELEC TH CONTROLCVT-131

P1740 P1740 LU-SLCT SOL/CIRCCVT-132

— P1745 L/PRESS CONTROLCVT-136

P1777 P1777 STEP MOTR CIRCCVT-137

P1778 P1778 STEP MOTR/FNCCVT-141

U1000 U1000 CAN COMM CIRCUITCVT-56

U1010 U1010 CONTROL UNIT(CAN)CVT-59

Page 847 of 2771

CVT-8

< SERVICE INFORMATION >

PRECAUTIONS

• Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal

before any repair or inspection work. The open/short circuit of related switches, sensors, solenoid

valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EVAP system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

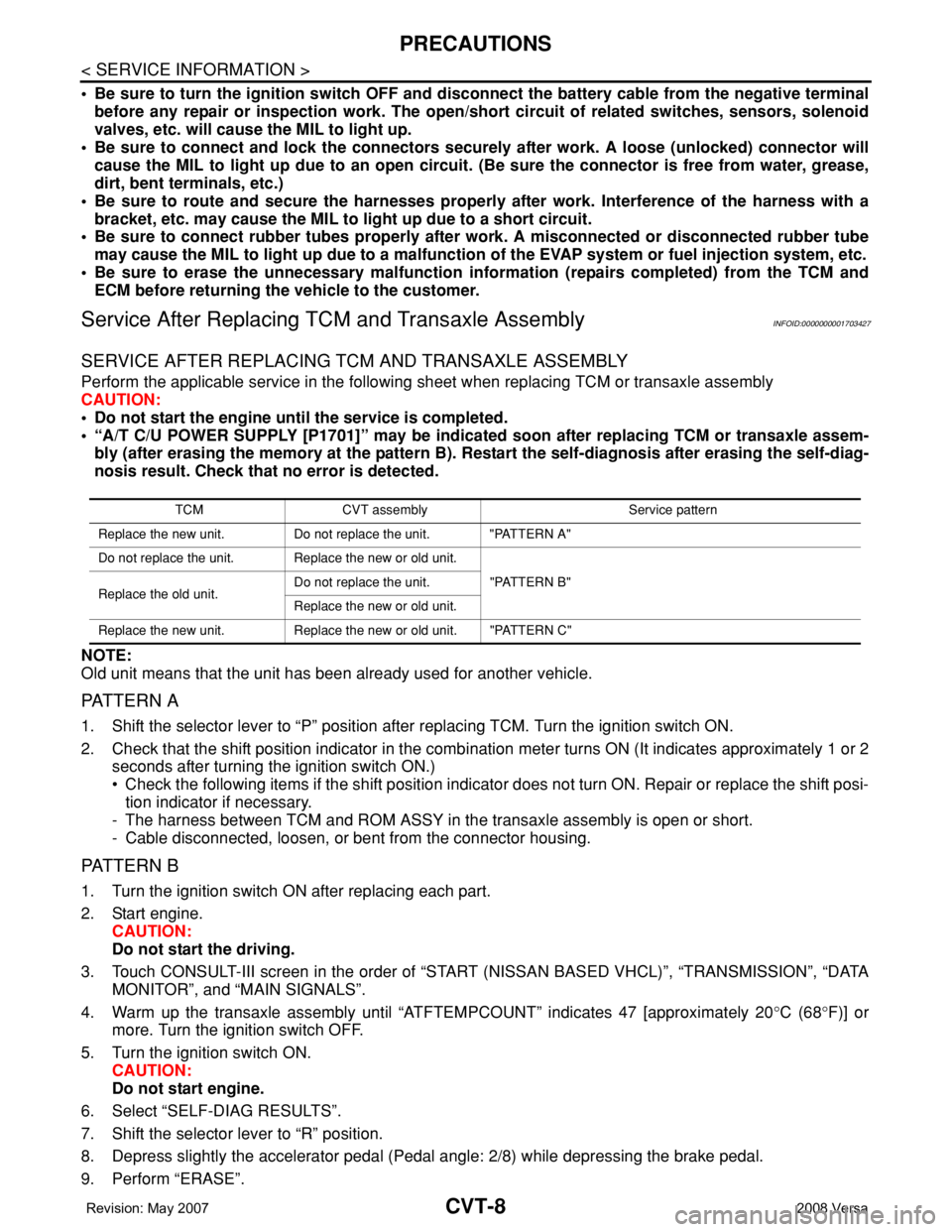

Service After Replacing TCM and Transaxle AssemblyINFOID:0000000001703427

SERVICE AFTER REPLACING TCM AND TRANSAXLE ASSEMBLY

Perform the applicable service in the following sheet when replacing TCM or transaxle assembly

CAUTION:

• Do not start the engine until the service is completed.

• “A/T C/U POWER SUPPLY [P1701]” may be indicated soon after replacing TCM or transaxle assem-

bly (after erasing the memory at the pattern B). Restart the self-diagnosis after erasing the self-diag-

nosis result. Check that no error is detected.

NOTE:

Old unit means that the unit has been already used for another vehicle.

PATTERN A

1. Shift the selector lever to “P” position after replacing TCM. Turn the ignition switch ON.

2. Check that the shift position indicator in the combination meter turns ON (It indicates approximately 1 or 2

seconds after turning the ignition switch ON.)

• Check the following items if the shift position indicator does not turn ON. Repair or replace the shift posi-

tion indicator if necessary.

- The harness between TCM and ROM ASSY in the transaxle assembly is open or short.

- Cable disconnected, loosen, or bent from the connector housing.

PATTERN B

1. Turn the ignition switch ON after replacing each part.

2. Start engine.

CAUTION:

Do not start the driving.

3. Touch CONSULT-III screen in the order of “START (NISSAN BASED VHCL)”, “TRANSMISSION”, “DATA

MONITOR”, and “MAIN SIGNALS”.

4. Warm up the transaxle assembly until “ATFTEMPCOUNT” indicates 47 [approximately 20°C (68°F)] or

more. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

CAUTION:

Do not start engine.

6. Select “SELF-DIAG RESULTS”.

7. Shift the selector lever to “R” position.

8. Depress slightly the accelerator pedal (Pedal angle: 2/8) while depressing the brake pedal.

9. Perform “ERASE”.

TCM CVT assemblyService pattern

Replace the new unit. Do not replace the unit. "PATTERN A"

Do not replace the unit. Replace the new or old unit.

"PATTERN B"

Replace the old unit.Do not replace the unit.

Replace the new or old unit.

Replace the new unit. Replace the new or old unit. "PATTERN C"

Page 850 of 2771

PRECAUTIONS

CVT-11

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

•Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. CVT-45, "

TCM Terminal and Reference Value".

•After performing each TROUBLE DIAGNOSIS, perform “DTC

Confirmation Procedure”.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

• Always use the specified brand of CVT fluid. Refer to MA-10, "

Flu-

ids and Lubricants".

• Use lint-free paper, not cloth rags, during work.

• After replacing the CVT fluid, dispose of the waste oil using the

methods prescribed by law, ordinance, etc.

Service Notice or PrecautionINFOID:0000000001703430

CVT FLUID COOLER SERVICE

If CVT fluid contains friction material (clutches, brakes, etc.), or if an CVT is replaced, inspect and clean the

CVT fluid cooler mounted in the radiator or replace the radiator. Flush cooler lines using cleaning solvent and

compressed air after repair. For CVT fluid cooler cleaning procedure, refer to CVT-14, "

CVT Fluid Cooler

Cleaning". For radiator replacement, refer to CO-11.

OBD-II SELF-DIAGNOSIS

• CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the malfunction indicator lamp (MIL). Refer to the table on CVT-47, "

CONSULT-III

Function (TRANSMISSION)" for the indicator used to display each self-diagnostic result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure on CVT-26, "

OBD-II Diagnostic Trouble Code (DTC)" to complete the

repair and avoid unnecessary blinking of the MIL.

For details of OBD-II, refer to EC-46

.

•Certain systems and components, especially those related to OBD, may use the new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-65

.

MEF040DA

SEF217U

Page 853 of 2771

CVT-14

< SERVICE INFORMATION >

CVT FLUID

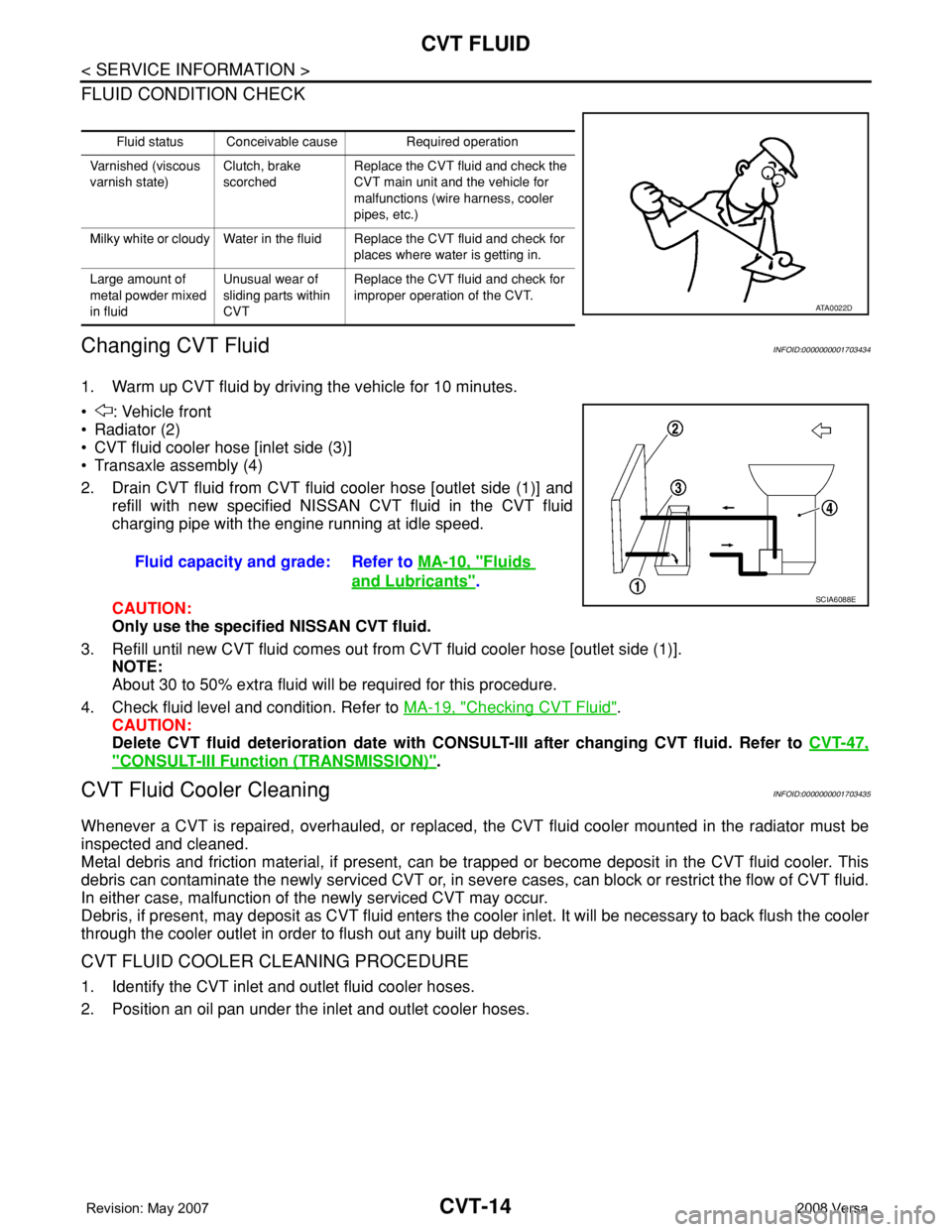

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000001703434

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and

refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specified NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)].

NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to MA-19, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-47,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000001703435

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state)Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for

places where water is getting in.

Large amount of

metal powder mixed

in fluidUnusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to MA-10, "Fluids

and Lubricants".SCIA6088E

Page 854 of 2771

CVT FLUID

CVT-15

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

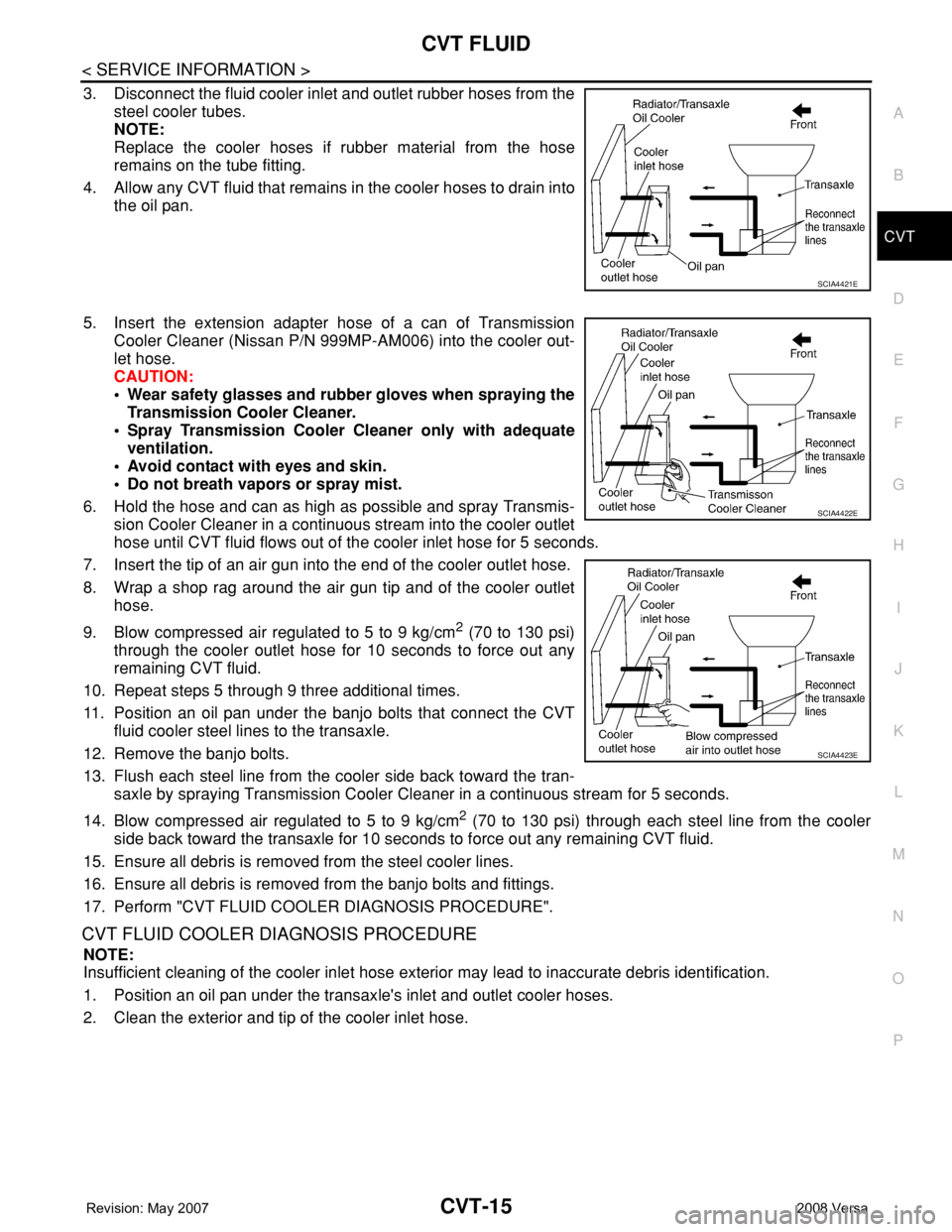

3. Disconnect the fluid cooler inlet and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any CVT fluid that remains in the cooler hoses to drain into

the oil pan.

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis-

sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the air gun tip and of the cooler outlet

hose.

9. Blow compressed air regulated to 5 to 9 kg/cm

2 (70 to 130 psi)

through the cooler outlet hose for 10 seconds to force out any

remaining CVT fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the CVT

fluid cooler steel lines to the transaxle.

12. Remove the banjo bolts.

13. Flush each steel line from the cooler side back toward the tran-

saxle by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 5 to 9 kg/cm

2 (70 to 130 psi) through each steel line from the cooler

side back toward the transaxle for 10 seconds to force out any remaining CVT fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform "CVT FLUID COOLER DIAGNOSIS PROCEDURE".

CVT FLUID COOLER DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exterior may lead to inaccurate debris identification.

1. Position an oil pan under the transaxle's inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose.

SCIA4421E

SCIA4422E

SCIA4423E

Page 855 of 2771

CVT-16

< SERVICE INFORMATION >

CVT FLUID

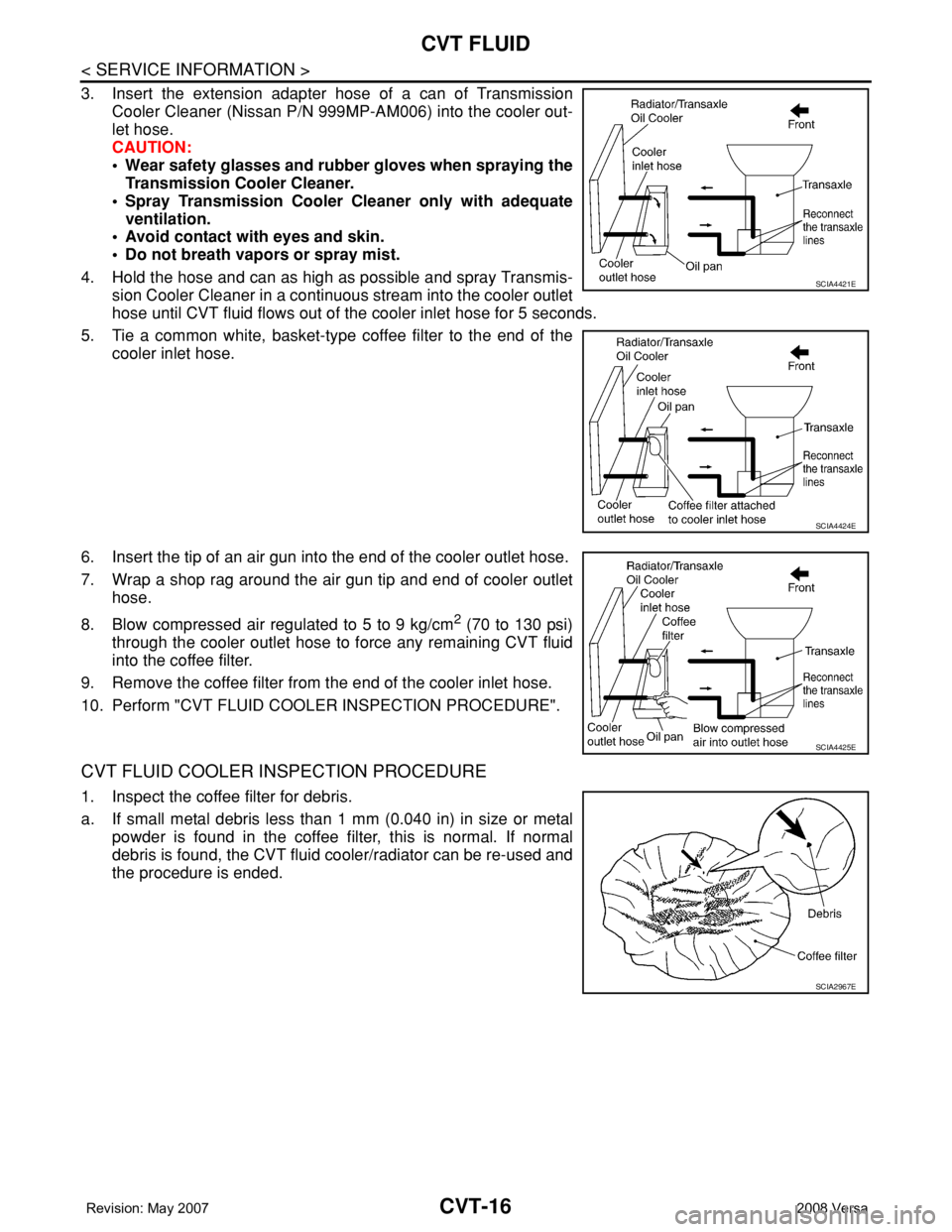

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis-

sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of the cooler inlet hose for 5 seconds.

5. Tie a common white, basket-type coffee filter to the end of the

cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet

hose.

8. Blow compressed air regulated to 5 to 9 kg/cm

2 (70 to 130 psi)

through the cooler outlet hose to force any remaining CVT fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform "CVT FLUID COOLER INSPECTION PROCEDURE".

CVT FLUID COOLER INSPECTION PROCEDURE

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1 mm (0.040 in) in size or metal

powder is found in the coffee filter, this is normal. If normal

debris is found, the CVT fluid cooler/radiator can be re-used and

the procedure is ended.

SCIA4421E

SCIA4424E

SCIA4425E

SCIA2967E