Lighting System NISSAN TIIDA 2008 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 2162 of 2771

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

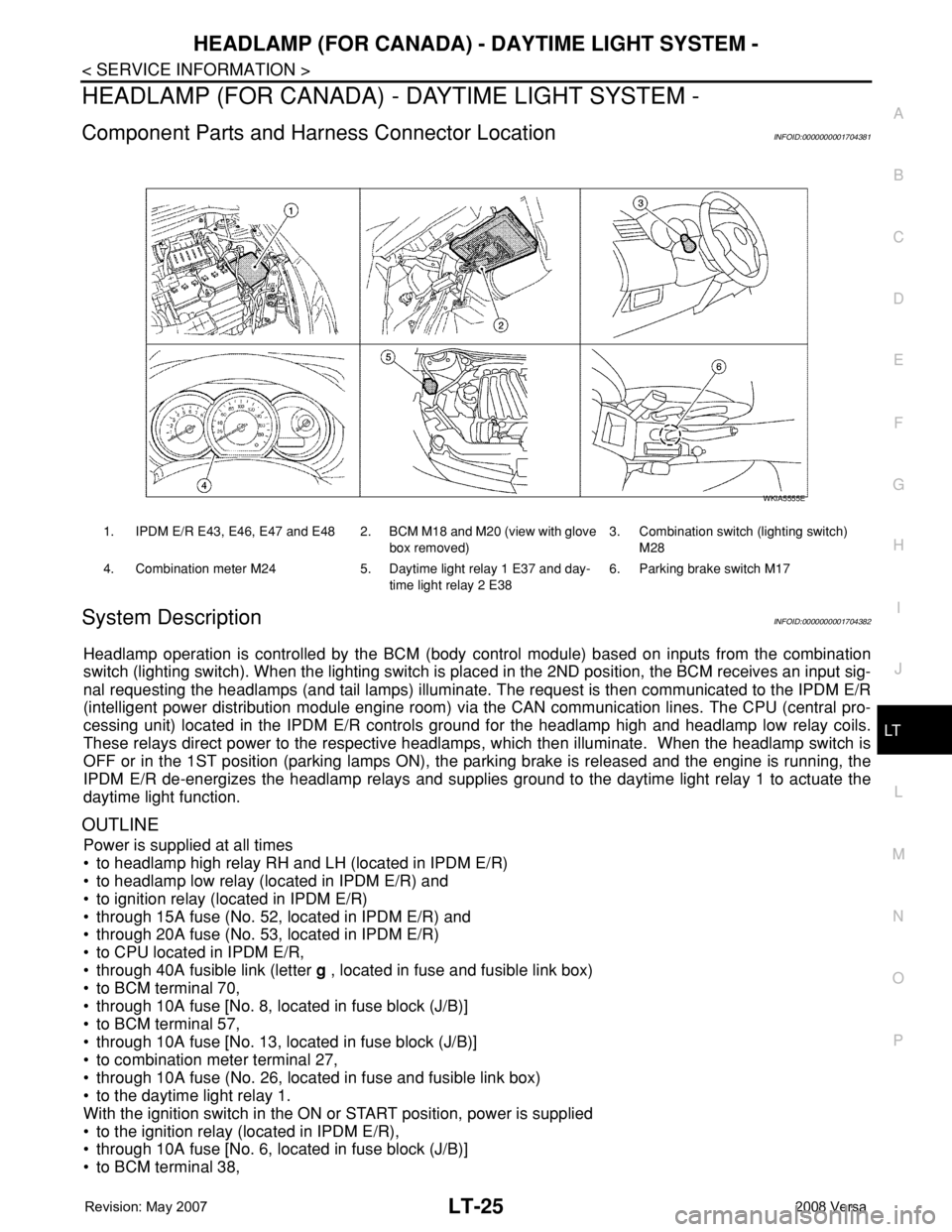

Component Parts and Harness Connector LocationINFOID:0000000001704381

System DescriptionINFOID:0000000001704382

Headlamp operation is controlled by the BCM (body control module) based on inputs from the combination

switch (lighting switch). When the lighting switch is placed in the 2ND position, the BCM receives an input sig-

nal requesting the headlamps (and tail lamps) illuminate. The request is then communicated to the IPDM E/R

(intelligent power distribution module engine room) via the CAN communication lines. The CPU (central pro-

cessing unit) located in the IPDM E/R controls ground for the headlamp high and headlamp low relay coils.

These relays direct power to the respective headlamps, which then illuminate. When the headlamp switch is

OFF or in the 1ST position (parking lamps ON), the parking brake is released and the engine is running, the

IPDM E/R de-energizes the headlamp relays and supplies ground to the daytime light relay 1 to actuate the

daytime light function.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R)

• to headlamp low relay (located in IPDM E/R) and

• to ignition relay (located in IPDM E/R)

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27,

• through 10A fuse (No. 26, located in fuse and fusible link box)

• to the daytime light relay 1.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

1. IPDM E/R E43, E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting switch)

M28

4. Combination meter M24 5. Daytime light relay 1 E37 and day-

time light relay 2 E386. Parking brake switch M17

WKIA5555E

Page 2163 of 2771

![NISSAN TIIDA 2008 Service Owners Guide LT-26

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in NISSAN TIIDA 2008 Service Owners Guide LT-26

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in](/img/5/57399/w960_57399-2162.png)

LT-26

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24,

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in 2ND position, the BCM receives an input signal requesting the headlamps to illumi-

nate. This input signal is communicated to the IPDM E/R via the CAN communication lines. The CPU located

in the IPDM E/R controls the headlamp low relay coil, which when energized, directs power

• through 15A fuse (No. 41, located in IPDM E/R)

• through IPDM E/R terminal 54

• to daytime light relay 2 terminals 1 and 5 (energizing the relay),

• through daytime light relay 2 terminal 3

• to front combination lamp RH terminal 3, and

• through 15A fuse (No. 40, located in IPDM E/R)

• through IPDM E/R terminal 52

• to front combination lamp LH terminal 3.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24,

• to headlamp RH terminal 2 via

• daytime light relay 1 terminals 3 and 4

• through grounds E15 and E24.

With power and ground supplied, low beam headlamps illuminate.

High Beam/Flash-to-Pass Operation

With the lighting switch in 2ND position and high beam switch in the HIGH position, the BCM receives input

signal requesting the headlamp high beams to illuminate. The flash-to-pass feature can be used any time and

also sends a signal to the BCM. This input signal is communicated to the IPDM E/R and the combination

meter via the CAN communication lines. The CPU located in the IPDM E/R controls the headlamp high relay

coil, which when energized, directs power

• through 10A fuse (No. 34, located in IPDM E/R)

• through IPDM E/R terminal 56

• to front combination lamp RH terminal 1, and

• through 10A fuse (No. 35, located in IPDM E/R)

• through IPDM E/R terminal 55

• to front combination lamp LH terminal 1.

Ground is supplied

• to front combination lamp LH terminal 2

• through grounds E15 and E24, and

• to front combination lamp RH terminal 2 via

• daytime light relay 1 terminals 3 and 4

• through grounds E15 and E24.

With power and ground supplied, the high beam headlamps illuminate.

The BCM sends a signal to the combination meter requesting the high beam indicator lamp to turn ON.

Daytime Light System Operation

With the lighting switch in the OFF or 1ST position (parking lamps ON), the BCM receives inputs requesting

the headlights off. If the parking brake is released and the engine is running, the BCM then sends a signal, via

the CAN communication lines, requesting the IPDM E/R to activate the daytime light system. The CPU located

in the IPDM E/R controls the daytime light relay 1 coil, which when energized, directs power

• from daytime light relay 1 terminal 3

• to front combination lamp RH terminal 2,

• through front combination lamp RH high beam terminal 1

Page 2173 of 2771

LT-36

< SERVICE INFORMATION >

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

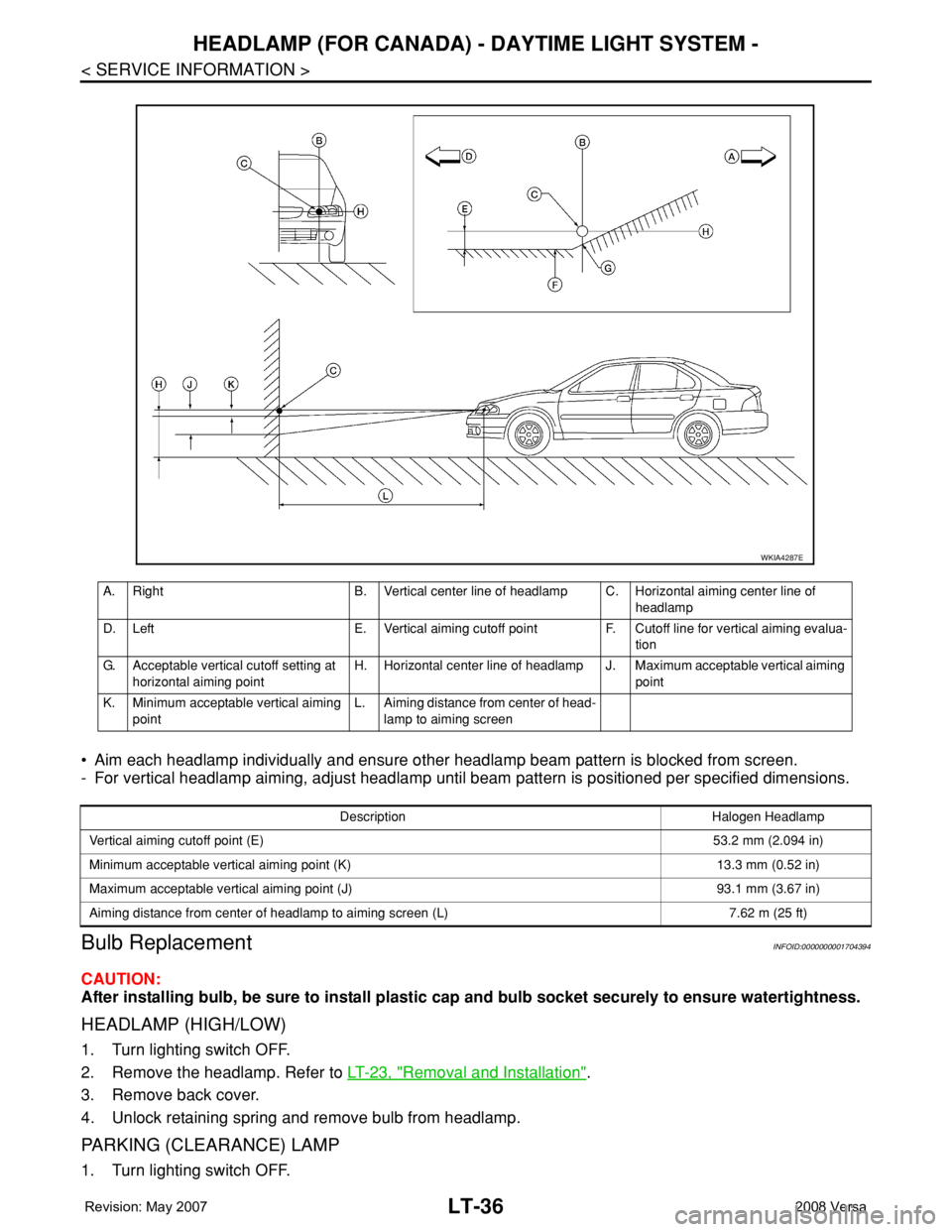

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- For vertical headlamp aiming, adjust headlamp until beam pattern is positioned per specified dimensions.

Bulb ReplacementINFOID:0000000001704394

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to ensure watertightness.

HEADLAMP (HIGH/LOW)

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-23, "

Removal and Installation".

3. Remove back cover.

4. Unlock retaining spring and remove bulb from headlamp.

PARKING (CLEARANCE) LAMP

1. Turn lighting switch OFF.

A. Right B. Vertical center line of headlamp C. Horizontal aiming center line of

headlamp

D. Left E. Vertical aiming cutoff point F. Cutoff line for vertical aiming evalua-

tion

G. Acceptable vertical cutoff setting at

horizontal aiming pointH. Horizontal center line of headlamp J. Maximum acceptable vertical aiming

point

K. Minimum acceptable vertical aiming

pointL. Aiming distance from center of head-

lamp to aiming screen

WKIA4287E

Description Halogen Headlamp

Vertical aiming cutoff point (E)53.2 mm (2.094 in)

Minimum acceptable vertical aiming point (K) 13.3 mm (0.52 in)

Maximum acceptable vertical aiming point (J) 93.1 mm (3.67 in)

Aiming distance from center of headlamp to aiming screen (L) 7.62 m (25 ft)

Page 2174 of 2771

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

2. Remove the headlamp. Refer to LT-23, "Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-23, "

Removal and Installation".

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

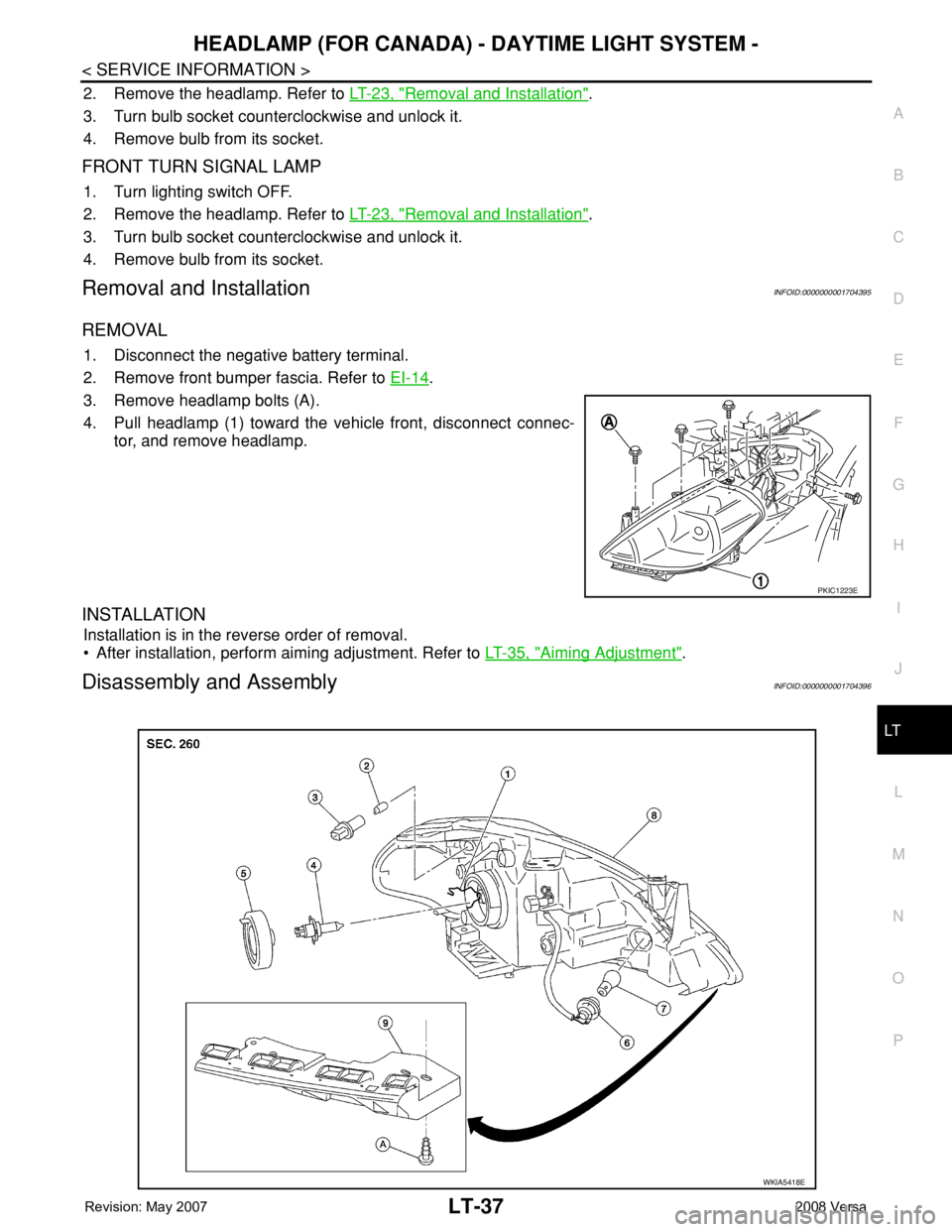

Removal and InstallationINFOID:0000000001704395

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove front bumper fascia. Refer to EI-14

.

3. Remove headlamp bolts (A).

4. Pull headlamp (1) toward the vehicle front, disconnect connec-

tor, and remove headlamp.

INSTALLATION

Installation is in the reverse order of removal.

• After installation, perform aiming adjustment. Refer to LT-35, "

Aiming Adjustment".

Disassembly and AssemblyINFOID:0000000001704396

PKIC1223E

WKIA5418E

Page 2176 of 2771

FRONT FOG LAMP

LT-39

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

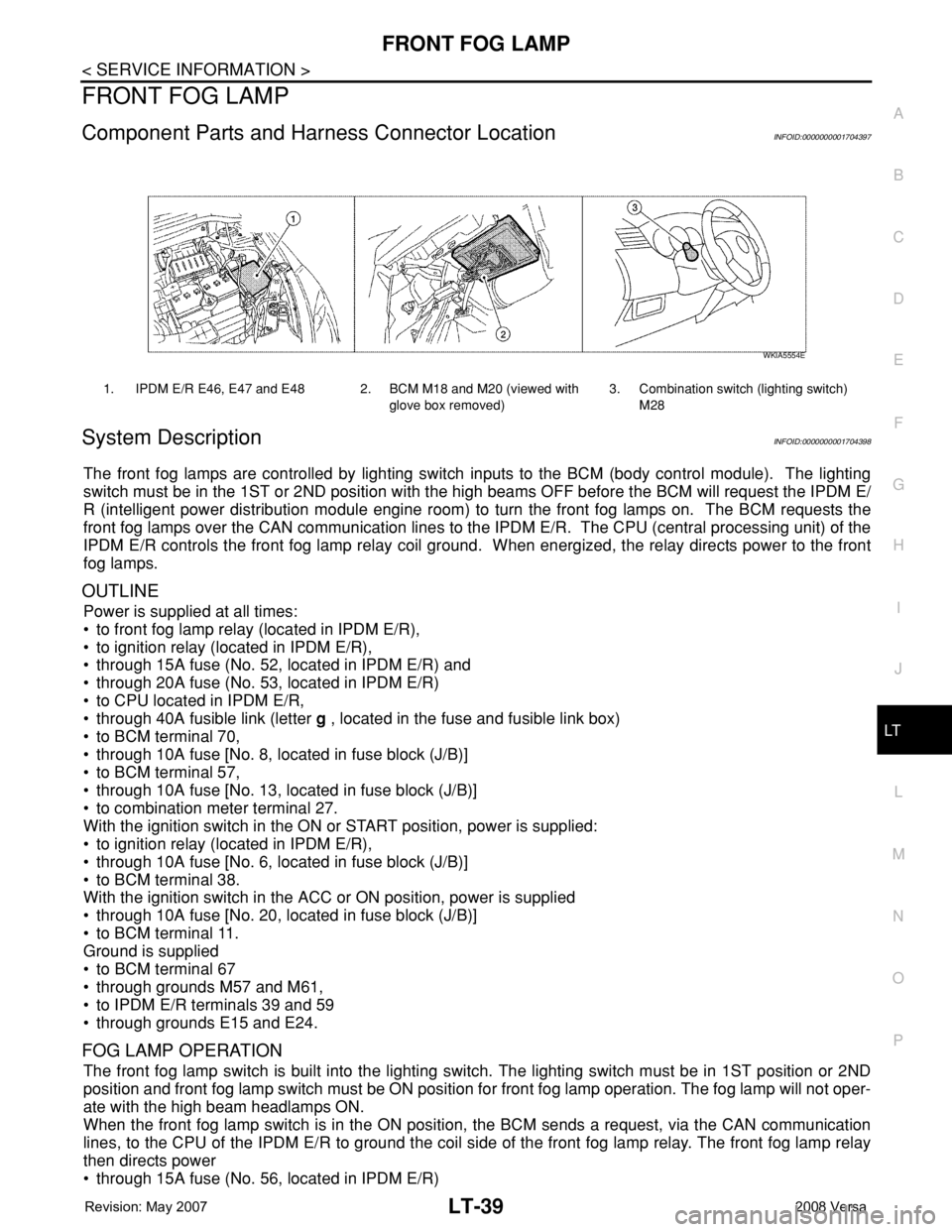

FRONT FOG LAMP

Component Parts and Harness Connector LocationINFOID:0000000001704397

System DescriptionINFOID:0000000001704398

The front fog lamps are controlled by lighting switch inputs to the BCM (body control module). The lighting

switch must be in the 1ST or 2ND position with the high beams OFF before the BCM will request the IPDM E/

R (intelligent power distribution module engine room) to turn the front fog lamps on. The BCM requests the

front fog lamps over the CAN communication lines to the IPDM E/R. The CPU (central processing unit) of the

IPDM E/R controls the front fog lamp relay coil ground. When energized, the relay directs power to the front

fog lamps.

OUTLINE

Power is supplied at all times:

• to front fog lamp relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied:

• to ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

FOG LAMP OPERATION

The front fog lamp switch is built into the lighting switch. The lighting switch must be in 1ST position or 2ND

position and front fog lamp switch must be ON position for front fog lamp operation. The fog lamp will not oper-

ate with the high beam headlamps ON.

When the front fog lamp switch is in the ON position, the BCM sends a request, via the CAN communication

lines, to the CPU of the IPDM E/R to ground the coil side of the front fog lamp relay. The front fog lamp relay

then directs power

• through 15A fuse (No. 56, located in IPDM E/R)

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (viewed with

glove box removed)3. Combination switch (lighting switch)

M28

WKIA5554E

Page 2180 of 2771

FRONT FOG LAMP

LT-43

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

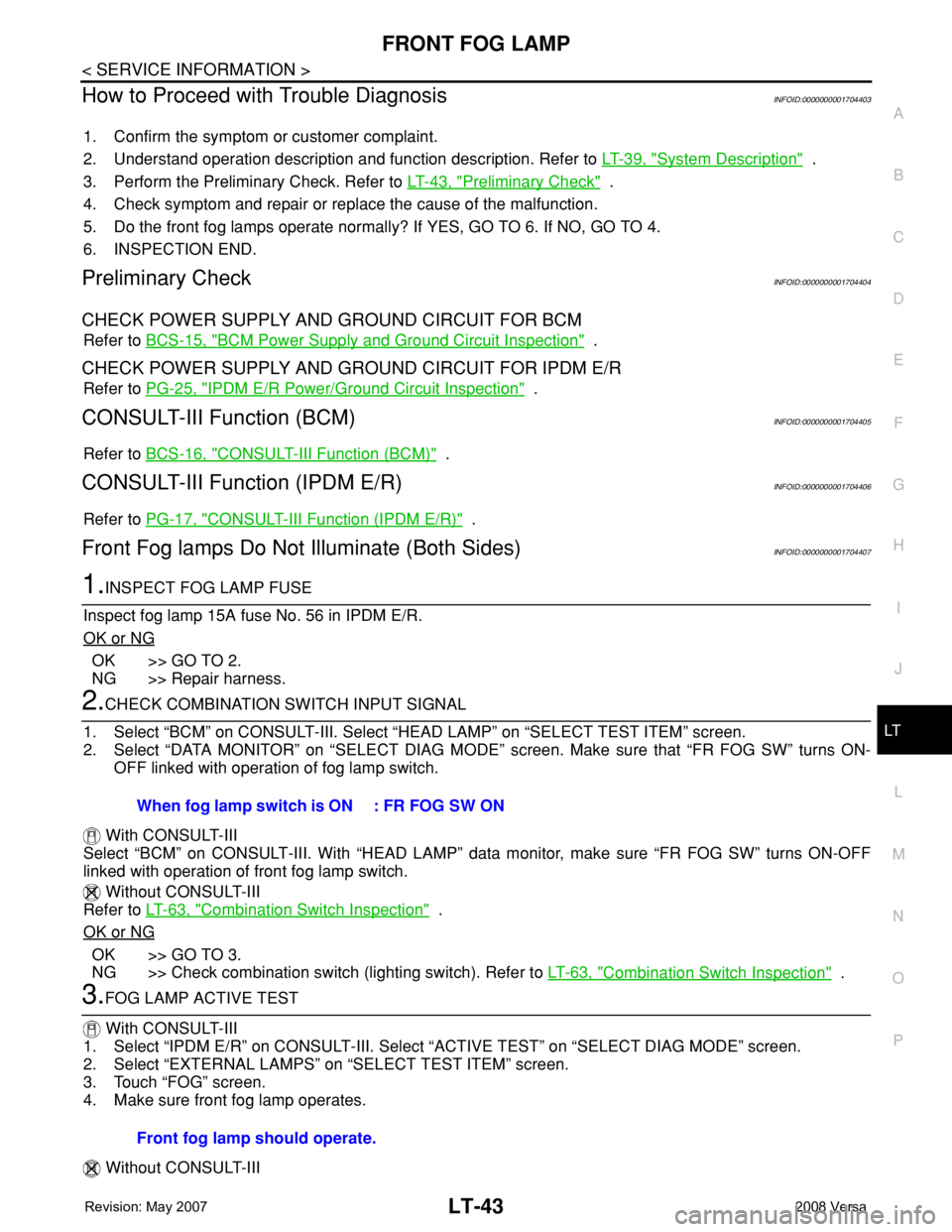

How to Proceed with Trouble DiagnosisINFOID:0000000001704403

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT-39, "

System Description" .

3. Perform the Preliminary Check. Refer to LT-43, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of the malfunction.

5. Do the front fog lamps operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END.

Preliminary CheckINFOID:0000000001704404

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-25, "IPDM E/R Power/Ground Circuit Inspection" .

CONSULT-III Function (BCM)INFOID:0000000001704405

Refer to BCS-16, "CONSULT-III Function (BCM)" .

CONSULT-III Function (IPDM E/R)INFOID:0000000001704406

Refer to PG-17, "CONSULT-III Function (IPDM E/R)" .

Front Fog lamps Do Not Illuminate (Both Sides)INFOID:0000000001704407

1.INSPECT FOG LAMP FUSE

Inspect fog lamp 15A fuse No. 56 in IPDM E/R.

OK or NG

OK >> GO TO 2.

NG >> Repair harness.

2.CHECK COMBINATION SWITCH INPUT SIGNAL

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen. Make sure that “FR FOG SW” turns ON-

OFF linked with operation of fog lamp switch.

With CONSULT-III

Select “BCM” on CONSULT-III. With “HEAD LAMP” data monitor, make sure “FR FOG SW” turns ON-OFF

linked with operation of front fog lamp switch.

Without CONSULT-III

Refer to LT-63, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 3.

NG >> Check combination switch (lighting switch). Refer to LT-63, "

Combination Switch Inspection" .

3.FOG LAMP ACTIVE TEST

With CONSULT-III

1. Select “IPDM E/R” on CONSULT-III. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “FOG” screen.

4. Make sure front fog lamp operates.

Without CONSULT-IIIWhen fog lamp switch is ON : FR FOG SW ON

Front fog lamp should operate.

Page 2185 of 2771

LT-48

< SERVICE INFORMATION >

TURN SIGNAL AND HAZARD WARNING LAMPS

TURN SIGNAL AND HAZARD WARNING LAMPS

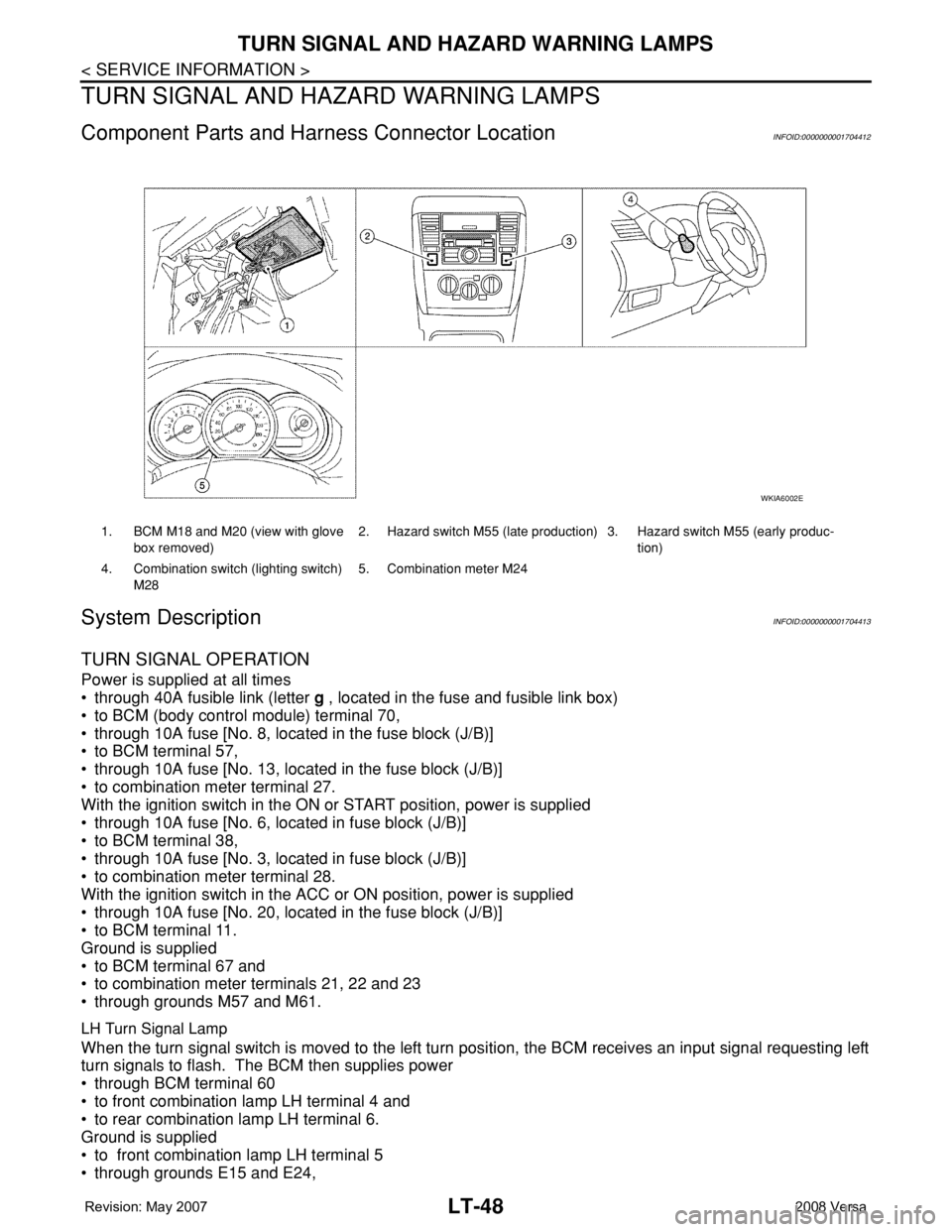

Component Parts and Harness Connector LocationINFOID:0000000001704412

System DescriptionINFOID:0000000001704413

TURN SIGNAL OPERATION

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM (body control module) terminal 70,

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in the fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

LH Turn Signal Lamp

When the turn signal switch is moved to the left turn position, the BCM receives an input signal requesting left

turn signals to flash. The BCM then supplies power

• through BCM terminal 60

• to front combination lamp LH terminal 4 and

• to rear combination lamp LH terminal 6.

Ground is supplied

• to front combination lamp LH terminal 5

• through grounds E15 and E24,

1. BCM M18 and M20 (view with glove

box removed)2. Hazard switch M55 (late production) 3. Hazard switch M55 (early produc-

tion)

4. Combination switch (lighting switch)

M285. Combination meter M24

WKIA6002E

Page 2200 of 2771

COMBINATION SWITCH

LT-63

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

Terminal and Reference Value for BCMINFOID:0000000001704434

Refer to BCS-11, "Terminal and Reference Value for BCM" .

CONSULT-III Function (BCM)INFOID:0000000001704435

Refer to LT- 11 , "CONSULT-III Function (BCM)" .

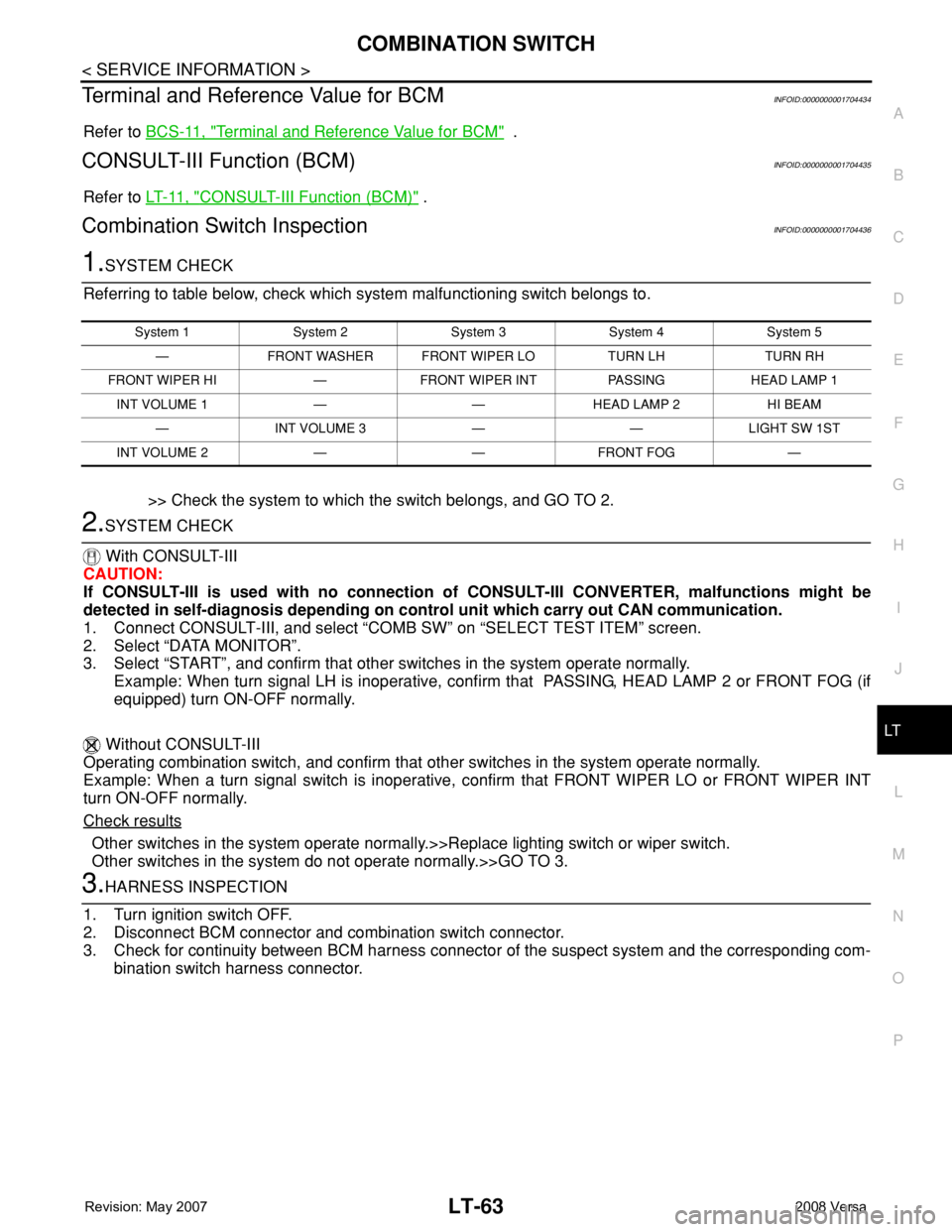

Combination Switch InspectionINFOID:0000000001704436

1.SYSTEM CHECK

Referring to table below, check which system malfunctioning switch belongs to.

>> Check the system to which the switch belongs, and GO TO 2.

2.SYSTEM CHECK

With CONSULT-III

CAUTION:

If CONSULT-III is used with no connection of CONSULT-III CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect CONSULT-III, and select “COMB SW” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in the system operate normally.

Example: When turn signal LH is inoperative, confirm that PASSING, HEAD LAMP 2 or FRONT FOG (if

equipped) turn ON-OFF normally.

Without CONSULT-III

Operating combination switch, and confirm that other switches in the system operate normally.

Example: When a turn signal switch is inoperative, confirm that FRONT WIPER LO or FRONT WIPER INT

turn ON-OFF normally.

Check results

Other switches in the system operate normally.>>Replace lighting switch or wiper switch.

Other switches in the system do not operate normally.>>GO TO 3.

3.HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM connector and combination switch connector.

3. Check for continuity between BCM harness connector of the suspect system and the corresponding com-

bination switch harness connector.

System 1 System 2 System 3 System 4 System 5

— FRONT WASHER FRONT WIPER LO TURN LH TURN RH

FRONT WIPER HI — FRONT WIPER INT PASSING HEAD LAMP 1

INT VOLUME 1 — — HEAD LAMP 2 HI BEAM

— INT VOLUME 3 — — LIGHT SW 1ST

INT VOLUME 2 — — FRONT FOG —

Page 2201 of 2771

LT-64

< SERVICE INFORMATION >

COMBINATION SWITCH

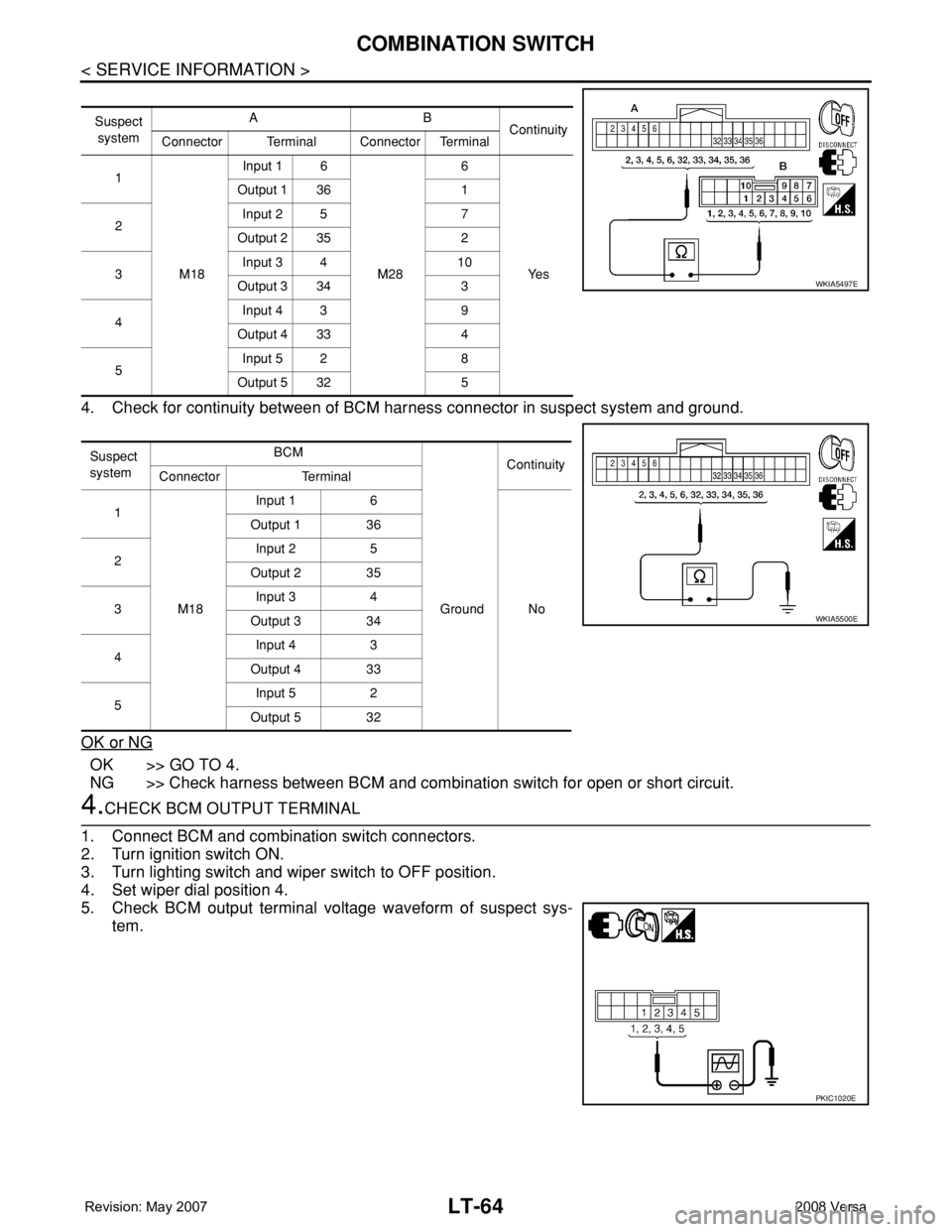

4. Check for continuity between of BCM harness connector in suspect system and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combination switch for open or short circuit.

4.CHECK BCM OUTPUT TERMINAL

1. Connect BCM and combination switch connectors.

2. Turn ignition switch ON.

3. Turn lighting switch and wiper switch to OFF position.

4. Set wiper dial position 4.

5. Check BCM output terminal voltage waveform of suspect sys-

tem.

Suspect

systemAB

Continuity

Connector Terminal Connector Terminal

1

M18Input 1 6

M286

Ye s Output 1 36 1

2Input 2 5 7

Output 2 35 2

3Input 3 4 10

Output 3 34 3

4Input 4 3 9

Output 4 33 4

5Input 5 2 8

Output 5 32 5

Suspect

systemBCM

Continuity

Connector Terminal

1

M18Input 1 6

Ground No Output 1 36

2Input 2 5

Output 2 35

3Input 3 4

Output 3 34

4Input 4 3

Output 4 33

5Input 5 2

Output 5 32

WKIA5497E

WKIA5500E

PKIC1020E

Page 2202 of 2771

COMBINATION SWITCH

LT-65

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

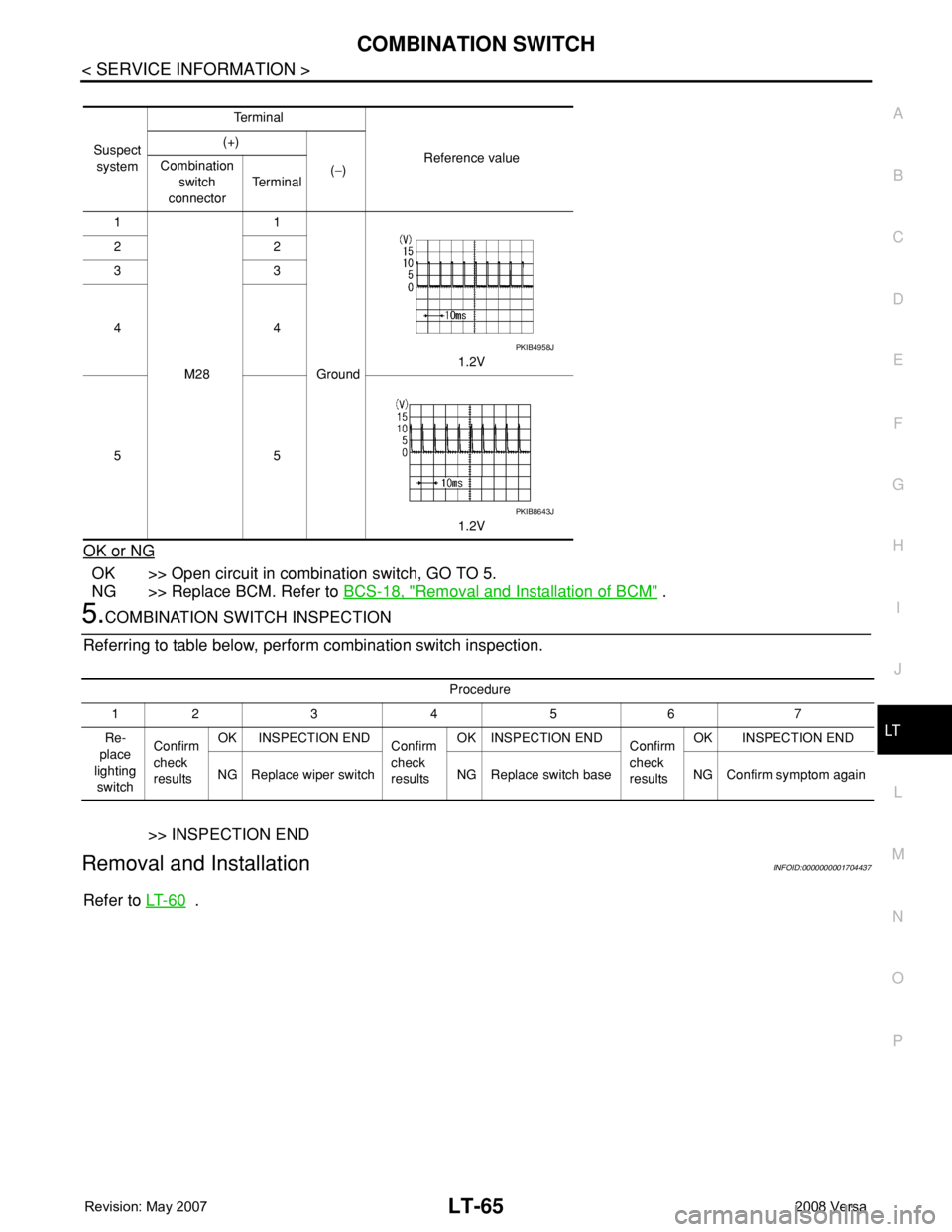

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM. Refer to BCS-18, "

Removal and Installation of BCM" .

5.COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

>> INSPECTION END

Removal and InstallationINFOID:0000000001704437

Refer to LT- 6 0 .

Suspect

systemTe r m i n a l

Reference value (+)

(−) Combination

switch

connectorTe r m i n a l

1

M281

Ground1.2V 22

33

44

55

1.2V

PKIB4958J

PKIB8643J

Procedure

12 3 4 5 6 7

Re-

place

lighting

switchConfirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

NG Replace wiper switch NG Replace switch base NG Confirm symptom again