NISSAN TIIDA 2008 Service Workshop Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 51 of 2771

TROUBLE DIAGNOSIS

AT-39

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000001703177

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 3

.

Fail-SafeINFOID:0000000001703178

The TCM has an electronic Fail-safe mode. This allows the vehicle to be driven even if a major electrical input/

output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

Always follow the “AT-40, "

How to Perform Trouble Diagnosis for Quick and Accurate Repair" ”.

The SELF-DIAGNOSIS results will be as follows:

• The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

• During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

FAIL-SAFE FUNCTION

The following fail-safe functions allow vehicles to be driven even when sensor, switch or solenoid malfunction

occurs.

Vehicle Speed Sensor·A/T (Revolution Sensor)

Vehicle speed sensor·MTR signal is input from combination meter.

Accelerator Pedal Position Signal and Throttle Position Signal

TCM controls the throttle opening angle to a predetermined fixed position to enable driving if a malfunctioning

signal is input to TCM.

PNP Switch

When the multiple PNP switch signals are input to TCM, the priority of selector lever position becomes “D”,

“N”, “R”, “2” and “1” in order by internal TCM determination.

The use of 4th gear is inhibited until normal operation resumes. Because the hydraulic circuit of the control

valve is switched by manual valve according to the selector lever position, however, actual operating condition

of vehicle becomes as follows.

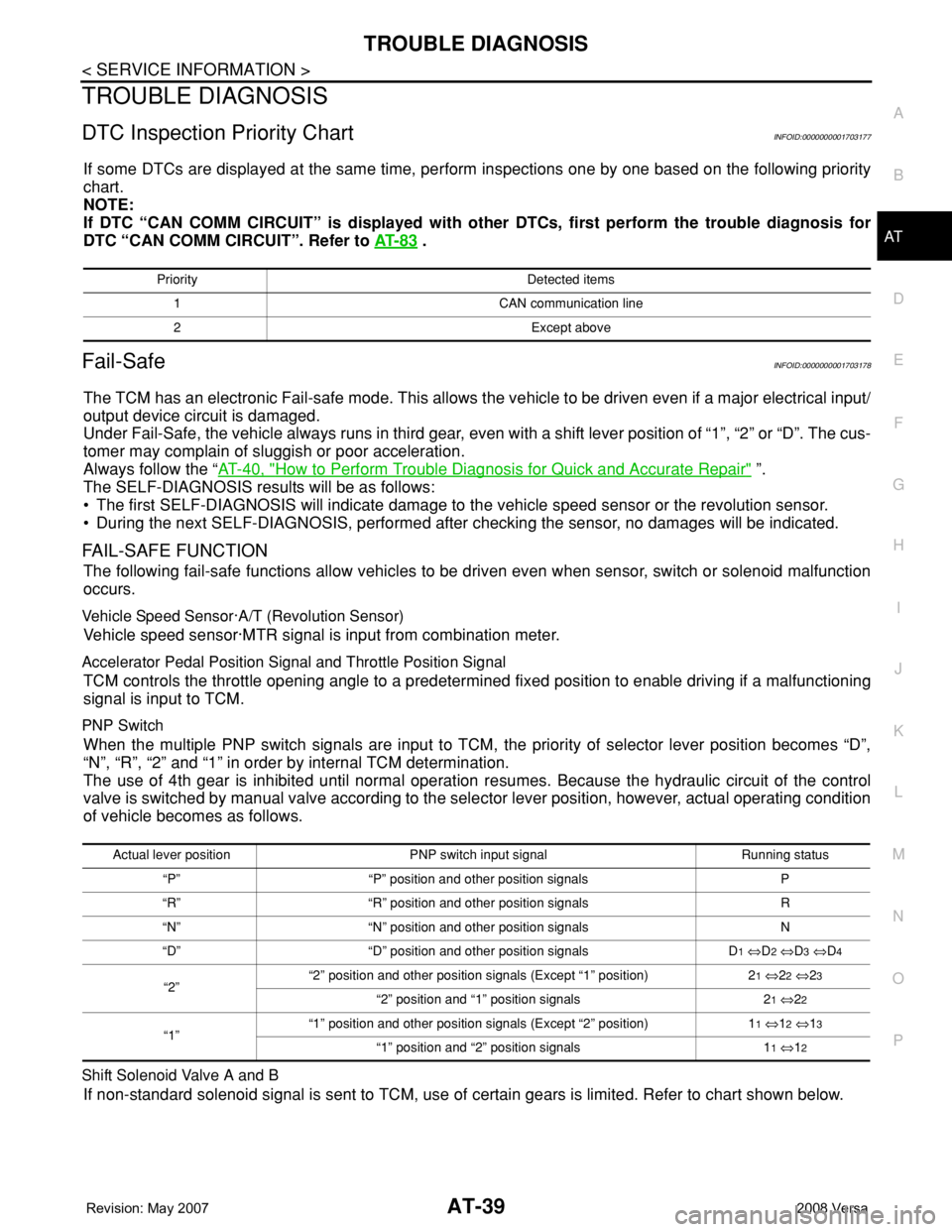

Shift Solenoid Valve A and B

If non-standard solenoid signal is sent to TCM, use of certain gears is limited. Refer to chart shown below.

Priority Detected items

1 CAN communication line

2 Except above

Actual lever position PNP switch input signal Running status

“P” “P” position and other position signals P

“R” “R” position and other position signals R

“N” “N” position and other position signals N

“D” “D” position and other position signals D

1 ⇔D2 ⇔D3 ⇔D4

“2”“2” position and other position signals (Except “1” position) 21 ⇔22 ⇔23

“2” position and “1” position signals 21 ⇔22

“1”“1” position and other position signals (Except “2” position) 11 ⇔12 ⇔13

“1” position and “2” position signals 11 ⇔12

Page 52 of 2771

AT-40

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

●: Solenoid ON

×: Solenoid OFF

–: Non-standard condition

Line Pressure Solenoid Valve

If non-standard solenoid signal is sent to TCM, line pressure solenoid valve is turned OFF to achieve maxi-

mum oil pressure.

Torque Converter Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, torque converter clutch solenoid valve is turned OFF to release

lock-up.

Overrun Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, overrun clutch solenoid valve is turned OFF to engage overrun

clutch. This will result in more effective engine brake during deceleration.

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000001703179

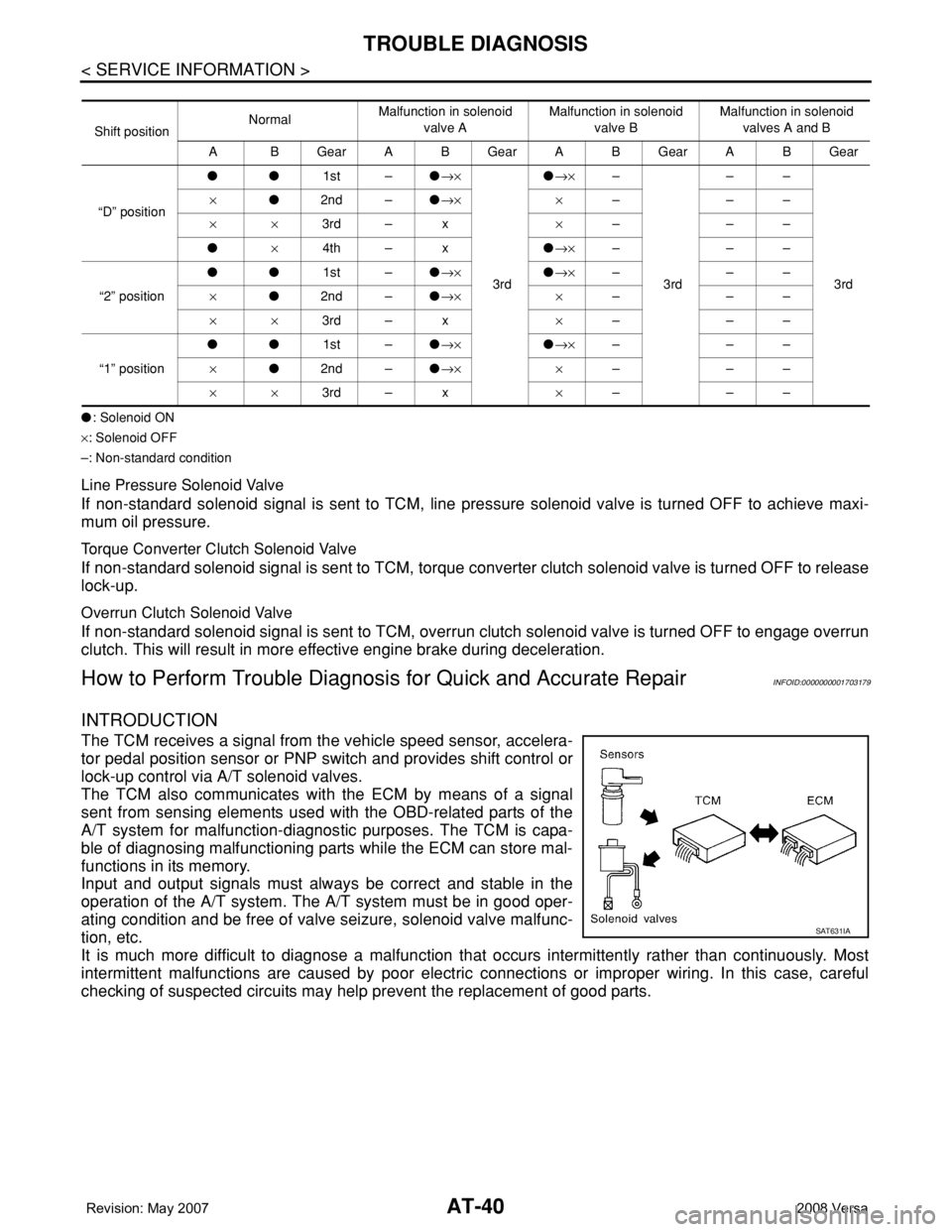

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelera-

tor pedal position sensor or PNP switch and provides shift control or

lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose a malfunction that occurs intermittently rather than continuously. Most

intermittent malfunctions are caused by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of good parts.

Shift positionNormalMalfunction in solenoid

valve AMalfunction in solenoid

valve BMalfunction in solenoid

valves A and B

A B Gear A B Gear A B Gear A B Gear

“D” position●●1st –●→×

3rd ●→×–

3rd ––

3rd ×●2nd –●→× ×–––

××3rd – x×–––

●×4th – x●→×–––

“2” position●●1st –●→×●→×–––

×●2nd –●→× ×–––

××3rd – x×–––

“1” position●●1st –●→×●→×–––

×●2nd –●→× ×–––

××3rd – x×–––

SAT631IA

Page 53 of 2771

TROUBLE DIAGNOSIS

AT-41

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

A visual check only, may not find the cause of the malfunctions. A

road test with CONSULT-III or a circuit tester connected should be

performed. Follow the "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such malfunctions, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A “DIAGNOSTIC WORKSHEET”

like the example ("DIAGNOSTIC WORKSHEET" ) should be used.

Start your diagnosis by looking for “conventional” malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

Also check related Service bulletins for information.

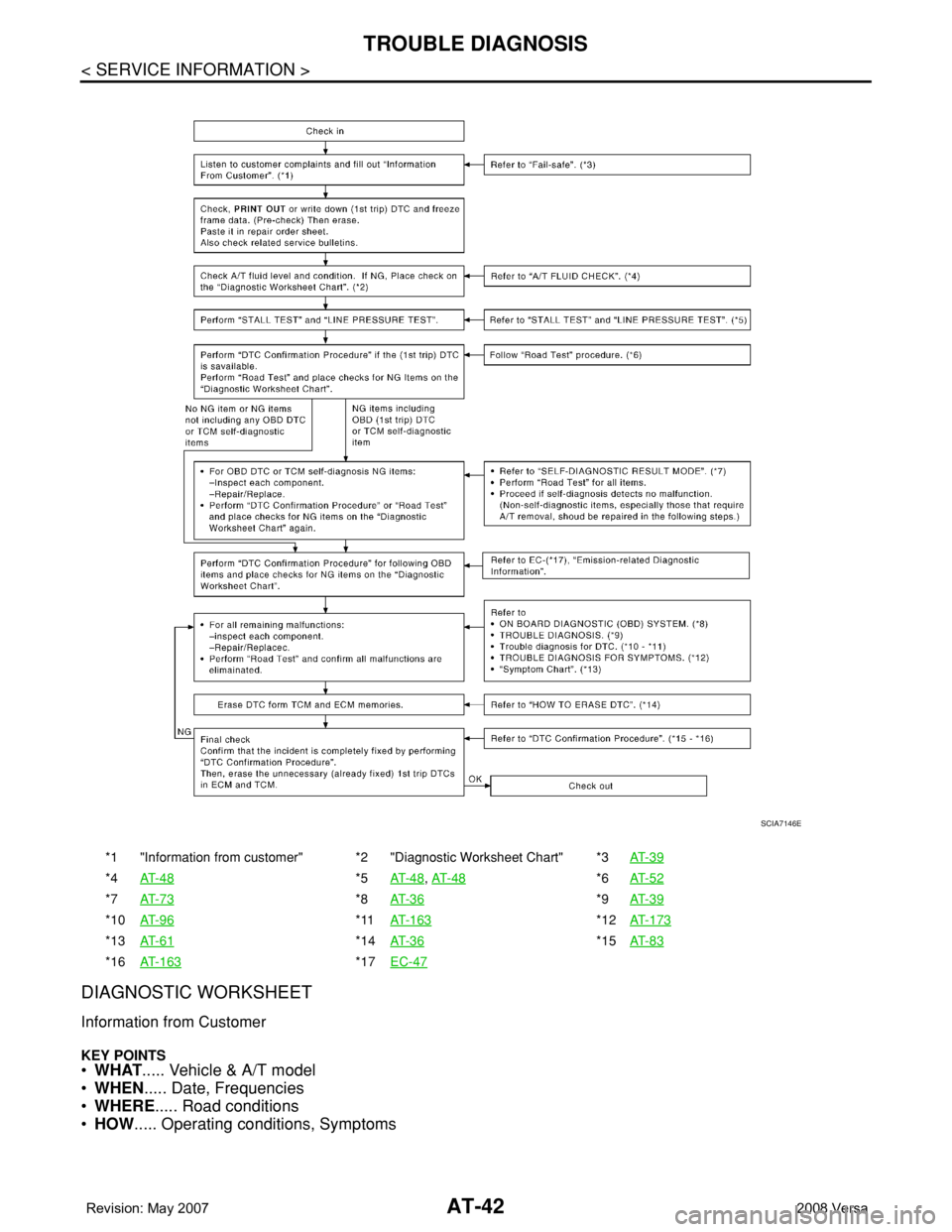

WORK FLOW

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate. In

general, each customer feels differently about a malfunction. It is important to fully understand the symptoms

or conditions for a customer complaint.

Make good use of the two sheets provided, "Information from customer" and "Diagnostic Worksheet Chart" ,

to perform the best troubleshooting possible.

Work Flow Chart

SAT632I

SEF234G

Page 54 of 2771

AT-42

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

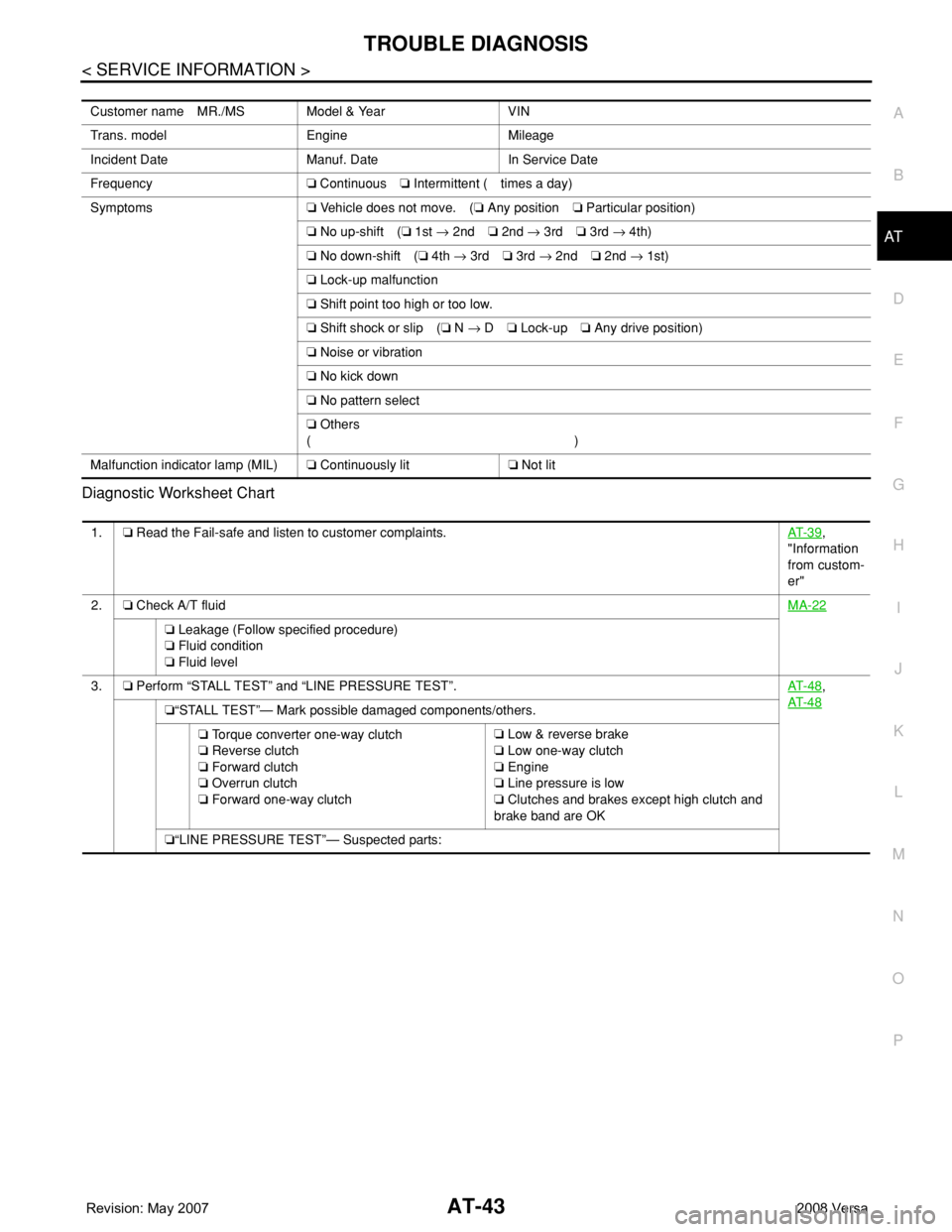

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

•WHAT..... Vehicle & A/T model

•WHEN..... Date, Frequencies

•WHERE..... Road conditions

•HOW..... Operating conditions, Symptoms

*1 "Information from customer" *2 "Diagnostic Worksheet Chart" *3AT- 3 9

*4AT- 4 8*5AT- 4 8, AT- 4 8*6AT- 5 2

*7AT- 7 3*8AT- 3 6*9AT- 3 9

*10AT- 9 6*11AT- 1 6 3*12AT- 1 7 3

*13AT- 6 1*14AT- 3 6*15AT- 8 3

*16AT- 1 6 3*17EC-47

SCIA7146E

Page 55 of 2771

TROUBLE DIAGNOSIS

AT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P Diagnostic Worksheet Chart

Customer name MR./MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

Frequency❏ Continuous❏ Intermittent ( times a day)

Symptoms❏ Vehicle does not move. (❏ Any position❏ Particular position)

❏ No up-shift (❏ 1st → 2nd❏ 2nd → 3rd❏ 3rd → 4th)

❏ No down-shift (❏ 4th → 3rd❏ 3rd → 2nd❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip (❏ N → D❏ Lock-up❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

Malfunction indicator lamp (MIL)❏ Continuously lit❏ Not lit

1.❏ Read the Fail-safe and listen to customer complaints.AT- 3 9,

"Information

from custom-

er"

2.❏ Check A/T fluidMA-22

❏ Leakage (Follow specified procedure)

❏ Fluid condition

❏ Fluid level

3.❏ Perform “STALL TEST” and “LINE PRESSURE TEST”.AT- 4 8

,

AT- 4 8

❏“STALL TEST”— Mark possible damaged components/others.

❏ Torque converter one-way clutch

❏ Reverse clutch

❏ Forward clutch

❏ Overrun clutch

❏ Forward one-way clutch❏ Low & reverse brake

❏ Low one-way clutch

❏ Engine

❏ Line pressure is low

❏ Clutches and brakes except high clutch and

brake band are OK

❏“LINE PRESSURE TEST”— Suspected parts:

Page 56 of 2771

AT-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

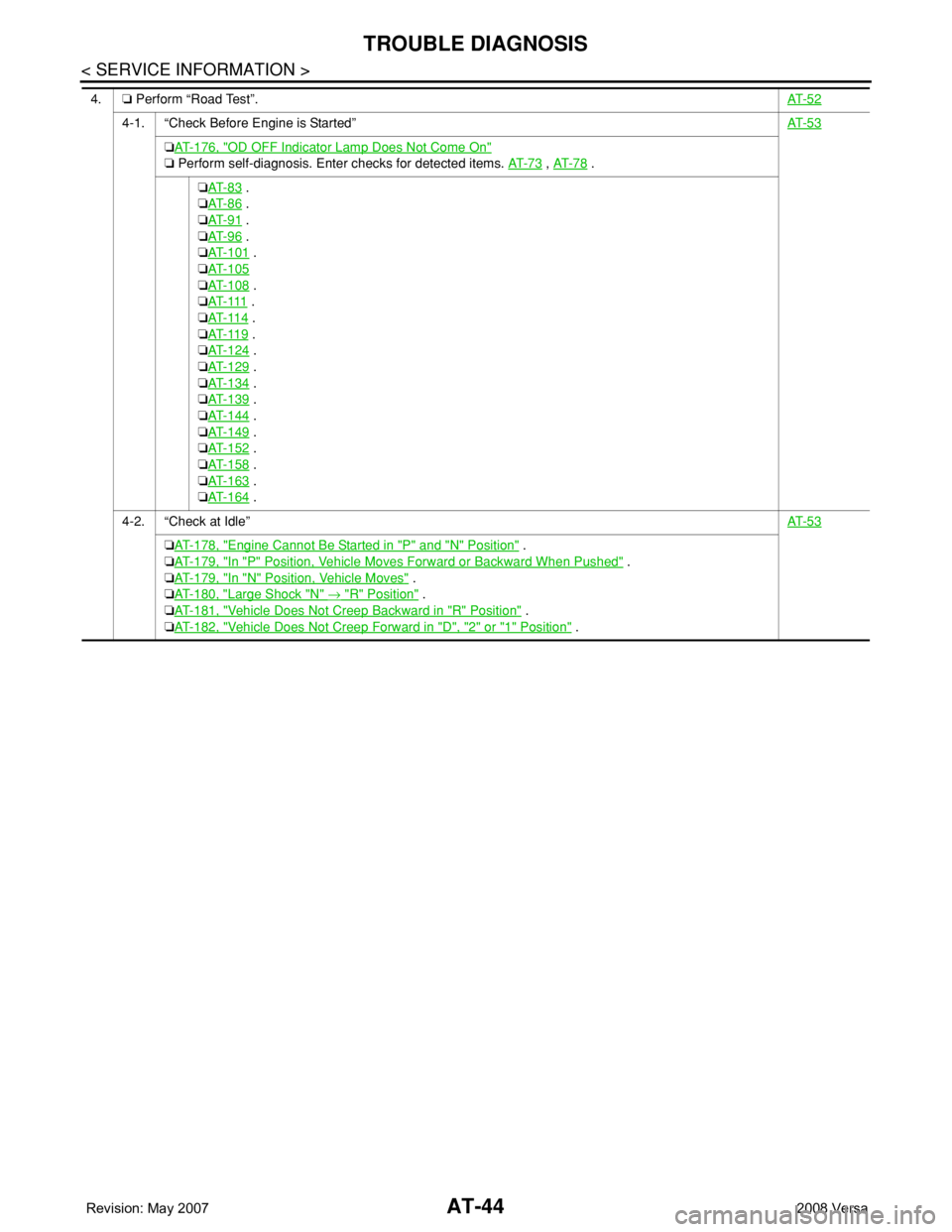

4.❏ Perform “Road Test”.AT- 5 2

4-1. “Check Before Engine is Started”AT- 5 3

❏AT- 1 7 6 , "OD OFF Indicator Lamp Does Not Come On"

❏ Perform self-diagnosis. Enter checks for detected items. AT- 7 3 , AT- 7 8 .

❏AT- 8 3

.

❏AT- 8 6

.

❏AT- 9 1

.

❏AT- 9 6

.

❏AT- 1 0 1

.

❏AT- 1 0 5

❏AT- 1 0 8 .

❏AT- 111

.

❏AT- 11 4

.

❏AT- 11 9

.

❏AT- 1 2 4

.

❏AT- 1 2 9

.

❏AT- 1 3 4

.

❏AT- 1 3 9

.

❏AT- 1 4 4

.

❏AT- 1 4 9

.

❏AT- 1 5 2

.

❏AT- 1 5 8

.

❏AT- 1 6 3

.

❏AT- 1 6 4

.

4-2. “Check at Idle”AT- 5 3

❏AT- 1 7 8 , "Engine Cannot Be Started in "P" and "N" Position" .

❏AT- 1 7 9 , "

In "P" Position, Vehicle Moves Forward or Backward When Pushed" .

❏AT- 1 7 9 , "

In "N" Position, Vehicle Moves" .

❏AT- 1 8 0 , "

Large Shock "N" → "R" Position" .

❏AT- 1 8 1 , "

Vehicle Does Not Creep Backward in "R" Position" .

❏AT- 1 8 2 , "

Vehicle Does Not Creep Forward in "D", "2" or "1" Position" .

Page 57 of 2771

TROUBLE DIAGNOSIS

AT-45

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

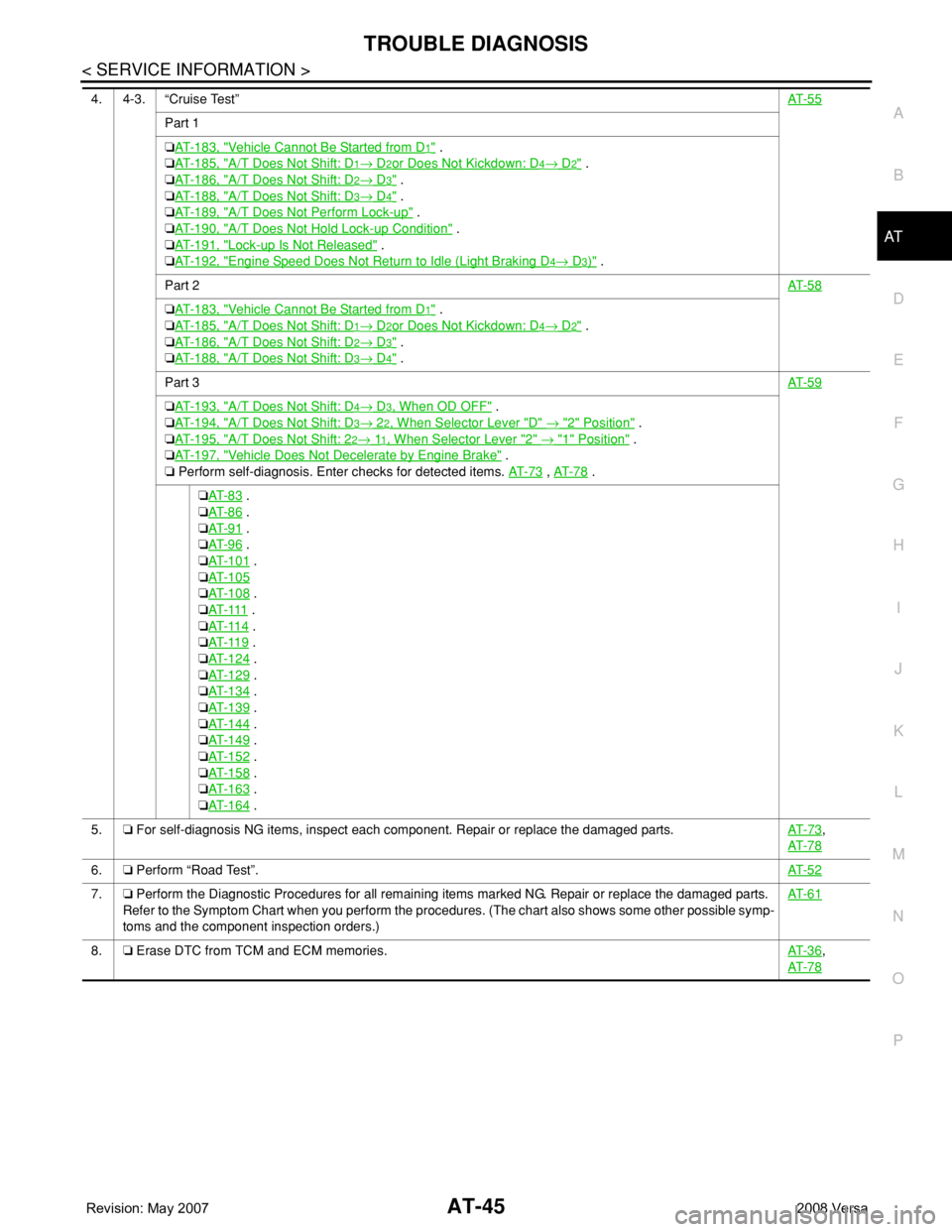

4. 4-3. “Cruise Test”AT- 5 5

Part 1

❏AT- 1 8 3 , "

Vehicle Cannot Be Started from D1" .

❏AT- 1 8 5 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

❏AT- 1 8 6 , "

A/T Does Not Shift: D2→ D3" .

❏AT- 1 8 8 , "

A/T Does Not Shift: D3→ D4" .

❏AT- 1 8 9 , "

A/T Does Not Perform Lock-up" .

❏AT- 1 9 0 , "

A/T Does Not Hold Lock-up Condition" .

❏AT- 1 9 1 , "

Lock-up Is Not Released" .

❏AT- 1 9 2 , "

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)" .

Part 2AT- 5 8

❏AT- 1 8 3 , "Vehicle Cannot Be Started from D1" .

❏AT- 1 8 5 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

❏AT- 1 8 6 , "

A/T Does Not Shift: D2→ D3" .

❏AT- 1 8 8 , "

A/T Does Not Shift: D3→ D4" .

Part 3AT- 5 9

❏AT- 1 9 3 , "A/T Does Not Shift: D4→ D3, When OD OFF" .

❏AT- 1 9 4 , "

A/T Does Not Shift: D3→ 22, When Selector Lever "D" → "2" Position" .

❏AT- 1 9 5 , "

A/T Does Not Shift: 22→ 11, When Selector Lever "2" → "1" Position" .

❏AT- 1 9 7 , "

Vehicle Does Not Decelerate by Engine Brake" .

❏ Perform self-diagnosis. Enter checks for detected items. AT- 7 3

, AT- 7 8 .

❏AT- 8 3

.

❏AT- 8 6

.

❏AT- 9 1

.

❏AT- 9 6

.

❏AT- 1 0 1

.

❏AT- 1 0 5

❏AT- 1 0 8 .

❏AT- 111

.

❏AT- 11 4

.

❏AT- 11 9

.

❏AT- 1 2 4

.

❏AT- 1 2 9

.

❏AT- 1 3 4

.

❏AT- 1 3 9

.

❏AT- 1 4 4

.

❏AT- 1 4 9

.

❏AT- 1 5 2

.

❏AT- 1 5 8

.

❏AT- 1 6 3

.

❏AT- 1 6 4

.

5.❏ For self-diagnosis NG items, inspect each component. Repair or replace the damaged parts.AT- 7 3

,

AT- 7 8

6.❏ Perform “Road Test”.AT- 5 2

7.❏ Perform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible symp-

toms and the component inspection orders.)AT- 6 1

8.❏ Erase DTC from TCM and ECM memories.AT- 3 6,

AT- 7 8

Page 58 of 2771

AT-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

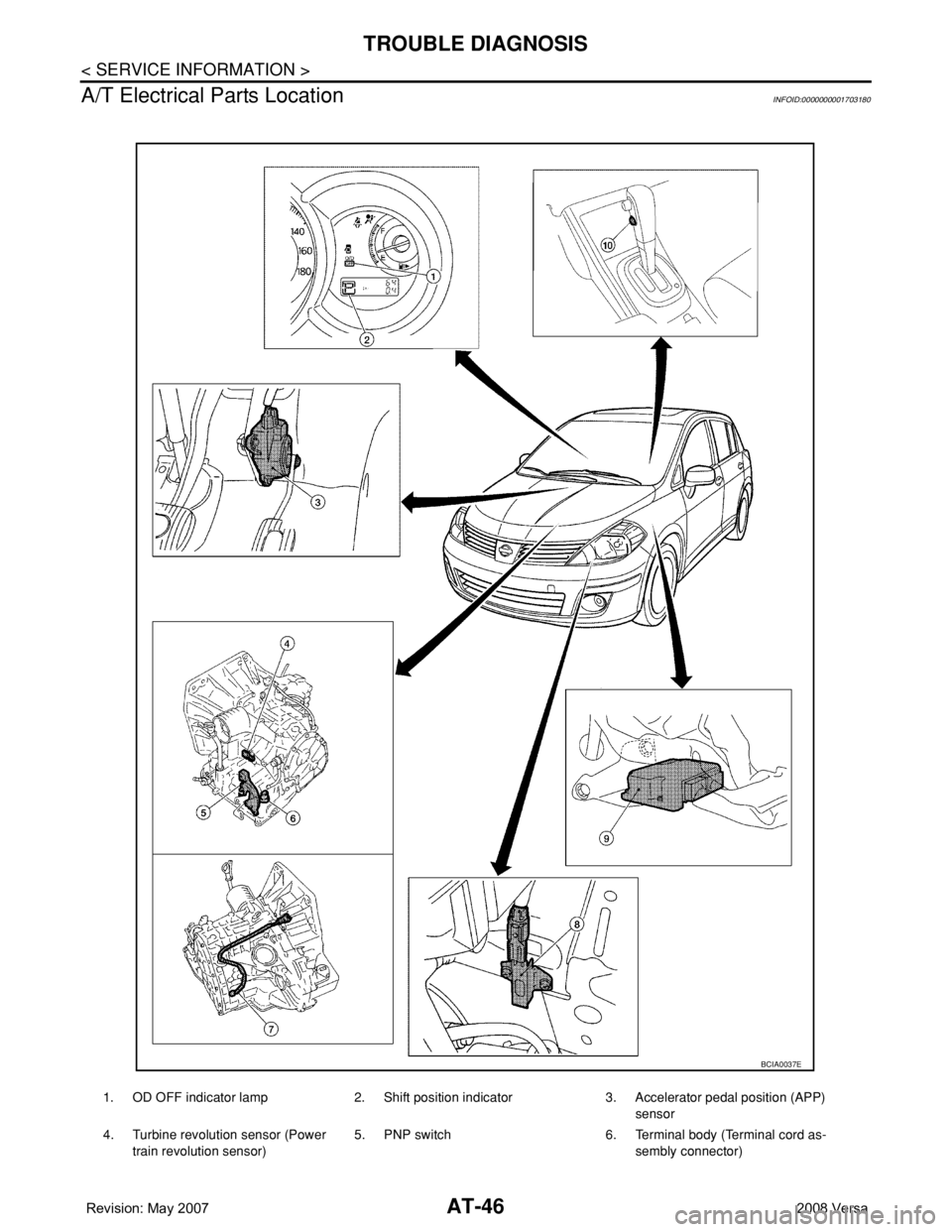

A/T Electrical Parts Location

INFOID:0000000001703180

1. OD OFF indicator lamp 2. Shift position indicator 3. Accelerator pedal position (APP)

sensor

4. Turbine revolution sensor (Power

train revolution sensor)5. PNP switch 6. Terminal body (Terminal cord as-

sembly connector)

BCIA0037E

Page 59 of 2771

TROUBLE DIAGNOSIS

AT-47

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

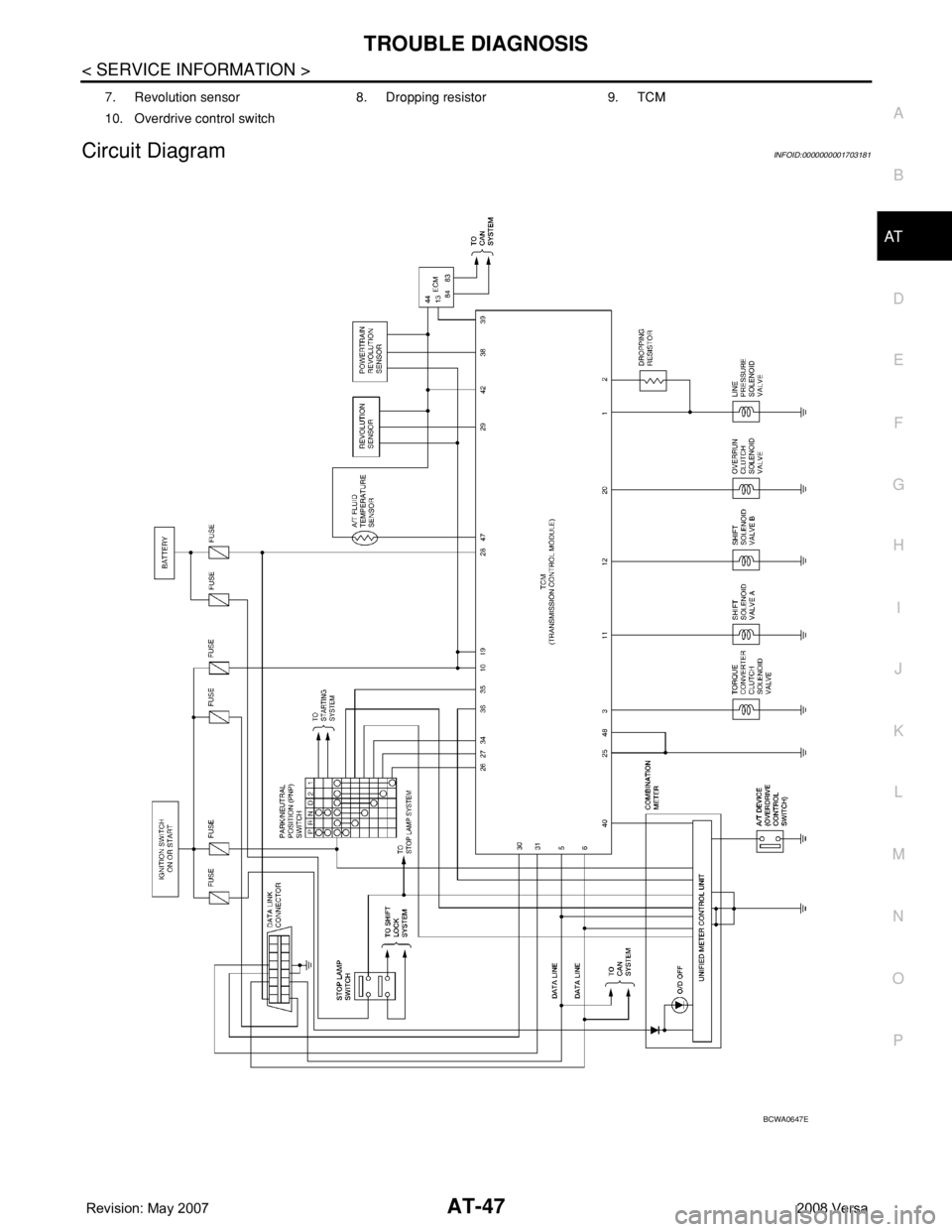

Circuit DiagramINFOID:0000000001703181

7. Revolution sensor 8. Dropping resistor 9. TCM

10. Overdrive control switch

BCWA0647E

Page 60 of 2771

AT-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Inspections Before Trouble Diagnosis

INFOID:0000000001703182

A/T FLUID CHECK

Fluid Leakage and Fluid Level Check

Check fluid leakage and check the fluid level. Refer to MA-22, "Checking A/T Fluid".

Fluid Condition Check

Check the A/T fluid condition.

STALL TEST

Stall Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF and

engine oil.

2. Drive vehicle for approximately 10 minutes or until ATF and

engine oil reach operating temperature.

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

•It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D”

position.

Fluid status Conceivable Cause Required Operation

Varnished (viscous

varnish state)Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or

cloudyWater in the ATFReplace the ATF and check for plac-

es where water is getting in.

Large amount of

metal powder mixed

inUnusual wear of

sliding parts within

A/TReplace the ATF and check for im-

proper operation of the A/T.

SAT638A

ATF operating temperature: 50 - 80°C (122 - 176°F)

SAT647B

SAT513G

SAT775B