can NISSAN TIIDA 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 7 of 2771

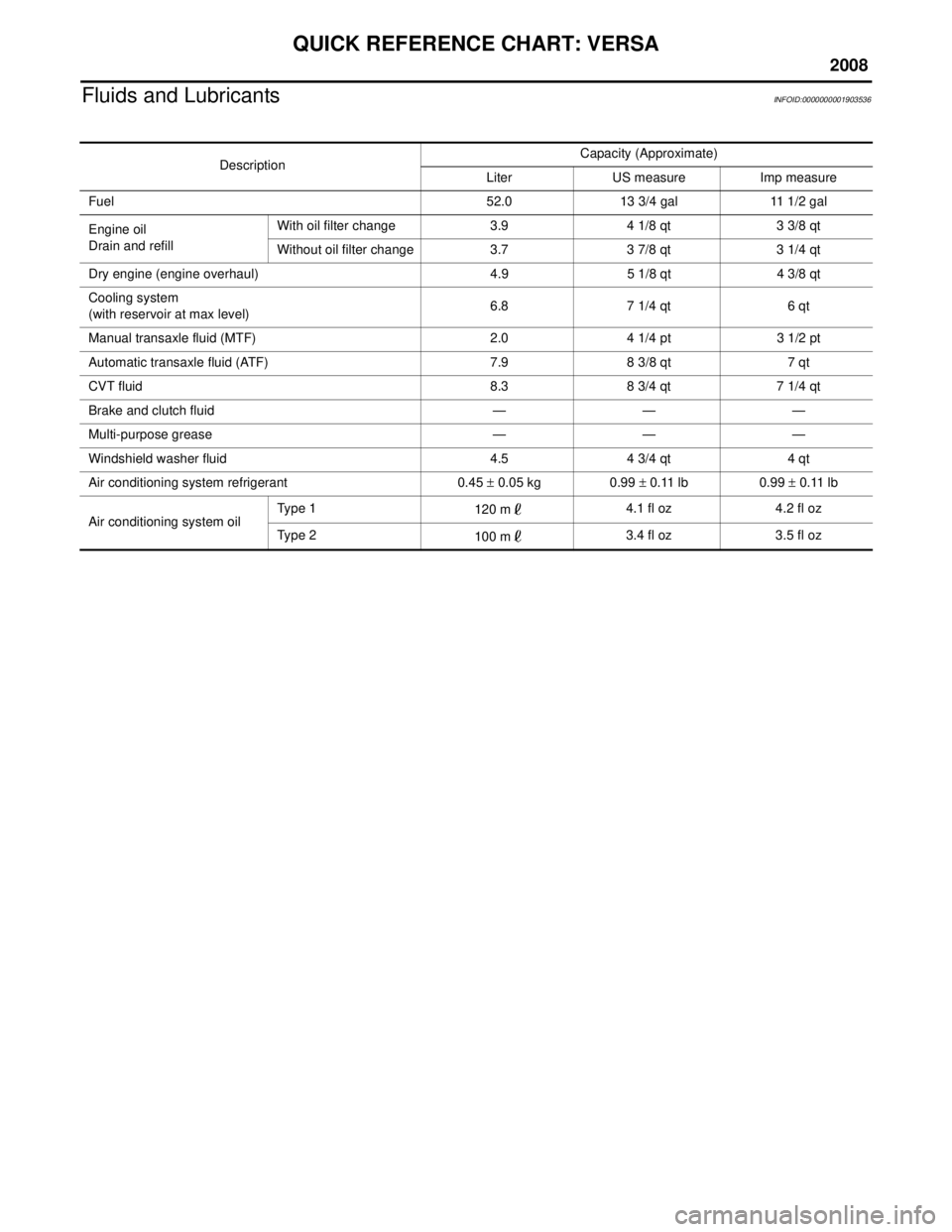

QUICK REFERENCE CHART: VERSA

2008

Fluids and LubricantsINFOID:0000000001903536

DescriptionCapacity (Approximate)

Liter US measure Imp measure

Fuel 52.0 13 3/4 gal 11 1/2 gal

Engine oil

Drain and refill With oil filter change 3.9 4 1/8 qt 3 3/8 qt

Without oil filter change 3.7 3 7/8 qt 3 1/4 qt

Dry engine (engine overhaul) 4.9 5 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) 6.8 7 1/4 qt 6 qt

Manual transaxle fluid (MTF) 2.0 4 1/4 pt 3 1/2 pt

Automatic transaxle fluid (ATF) 7.9 8 3/8 qt 7 qt

CVT fluid 8.3 8 3/4 qt 7 1/4 qt

Brake and clutch fluid — — —

Multi-purpose grease — — —

Windshield washer fluid 4.5 4 3/4 qt 4 qt

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb

Air conditioning system oil Typ e 1

120 m4.1 fl oz 4.2 fl oz

Typ e 2 100 m3.4 fl oz 3.5 fl oz

Page 9 of 2771

ACC-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703109

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 13 of 2771

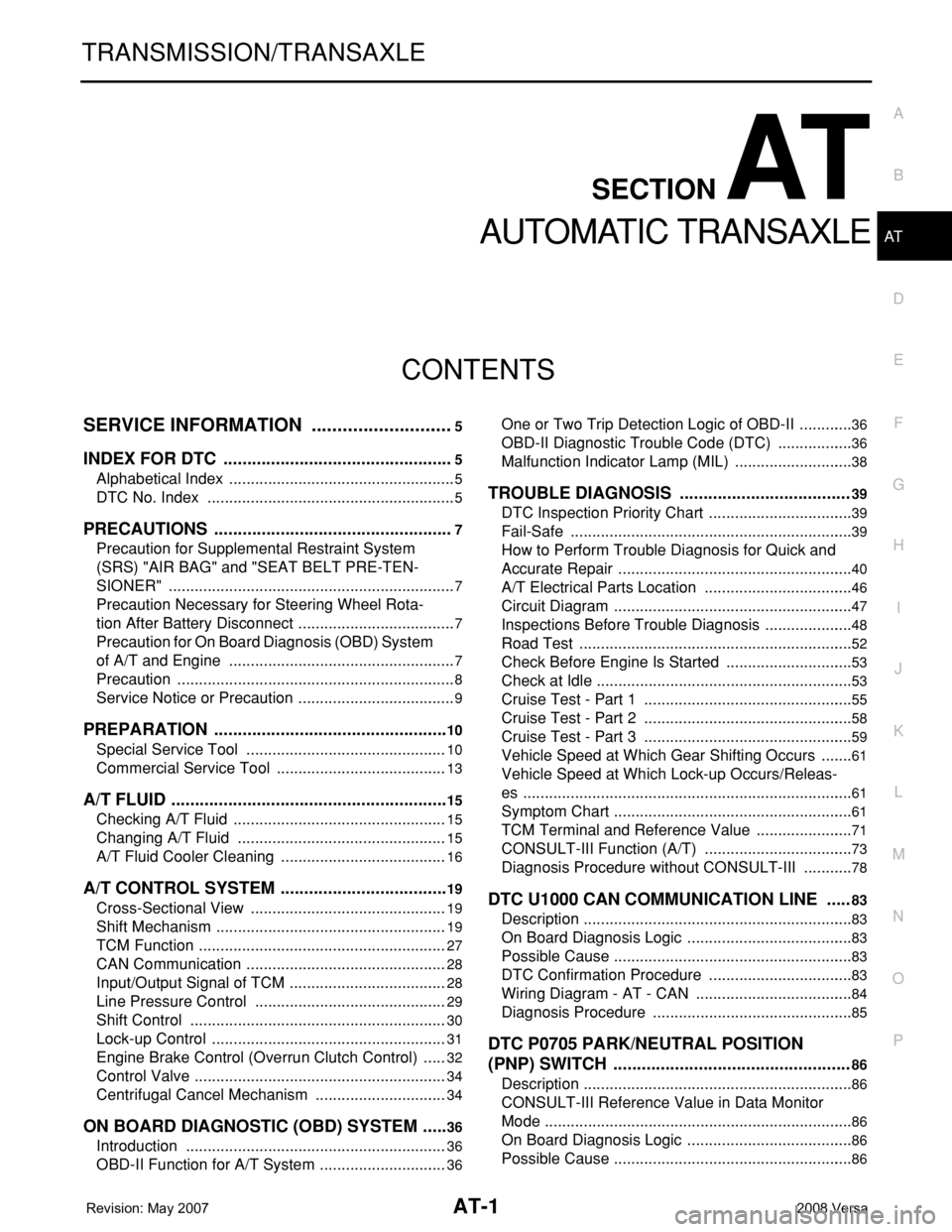

AT-1

TRANSMISSION/TRANSAXLE

D

E

F

G

H

I

J

K

L

M

SECTION AT

A

B

AT

N

O

P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION ............................5

INDEX FOR DTC .................................................5

Alphabetical Index .....................................................5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

7

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................10

Special Service Tool ...............................................10

Commercial Service Tool ........................................13

A/T FLUID ...........................................................15

Checking A/T Fluid ..................................................15

Changing A/T Fluid .................................................15

A/T Fluid Cooler Cleaning .......................................16

A/T CONTROL SYSTEM ....................................19

Cross-Sectional View ..............................................19

Shift Mechanism ......................................................19

TCM Function ..........................................................27

CAN Communication ...............................................28

Input/Output Signal of TCM .....................................28

Line Pressure Control .............................................29

Shift Control ............................................................30

Lock-up Control .......................................................31

Engine Brake Control (Overrun Clutch Control) ......32

Control Valve ...........................................................34

Centrifugal Cancel Mechanism ...............................34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......36

Introduction .............................................................36

OBD-II Function for A/T System ..............................36

One or Two Trip Detection Logic of OBD-II .............36

OBD-II Diagnostic Trouble Code (DTC) ..................36

Malfunction Indicator Lamp (MIL) ............................38

TROUBLE DIAGNOSIS ....................................39

DTC Inspection Priority Chart ..................................39

Fail-Safe ..................................................................39

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

40

A/T Electrical Parts Location ...................................46

Circuit Diagram ........................................................47

Inspections Before Trouble Diagnosis .....................48

Road Test ................................................................52

Check Before Engine Is Started ..............................53

Check at Idle ............................................................53

Cruise Test - Part 1 .................................................55

Cruise Test - Part 2 .................................................58

Cruise Test - Part 3 .................................................59

Vehicle Speed at Which Gear Shifting Occurs ........61

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

61

Symptom Chart ........................................................61

TCM Terminal and Reference Value .......................71

CONSULT-III Function (A/T) ...................................73

Diagnosis Procedure without CONSULT-III ............78

DTC U1000 CAN COMMUNICATION LINE .....83

Description ...............................................................83

On Board Diagnosis Logic .......................................83

Possible Cause ........................................................83

DTC Confirmation Procedure ..................................83

Wiring Diagram - AT - CAN .....................................84

Diagnosis Procedure ...............................................85

DTC P0705 PARK/NEUTRAL POSITION

(PNP) SWITCH ..................................................

86

Description ...............................................................86

CONSULT-III Reference Value in Data Monitor

Mode ........................................................................

86

On Board Diagnosis Logic .......................................86

Possible Cause ........................................................86

Page 15 of 2771

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

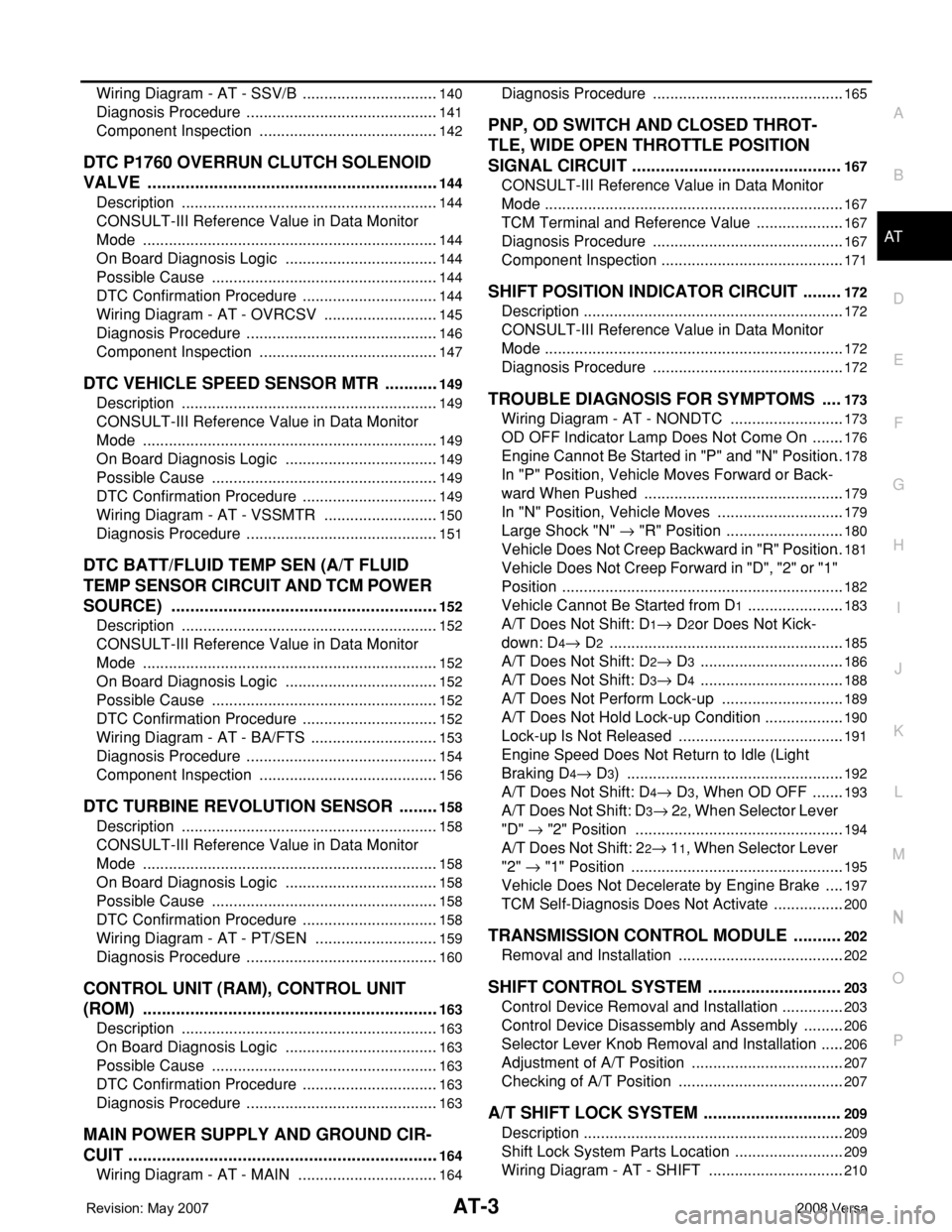

P N Wiring Diagram - AT - SSV/B ................................

140

Diagnosis Procedure .............................................141

Component Inspection ..........................................142

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE ..............................................................

144

Description ............................................................144

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

144

On Board Diagnosis Logic ....................................144

Possible Cause .....................................................144

DTC Confirmation Procedure ................................144

Wiring Diagram - AT - OVRCSV ...........................145

Diagnosis Procedure .............................................146

Component Inspection ..........................................147

DTC VEHICLE SPEED SENSOR MTR ............149

Description ............................................................149

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

149

On Board Diagnosis Logic ....................................149

Possible Cause .....................................................149

DTC Confirmation Procedure ................................149

Wiring Diagram - AT - VSSMTR ...........................150

Diagnosis Procedure .............................................151

DTC BATT/FLUID TEMP SEN (A/T FLUID

TEMP SENSOR CIRCUIT AND TCM POWER

SOURCE) .........................................................

152

Description ............................................................152

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

152

On Board Diagnosis Logic ....................................152

Possible Cause .....................................................152

DTC Confirmation Procedure ................................152

Wiring Diagram - AT - BA/FTS ..............................153

Diagnosis Procedure .............................................154

Component Inspection ..........................................156

DTC TURBINE REVOLUTION SENSOR .........158

Description ............................................................158

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

158

On Board Diagnosis Logic ....................................158

Possible Cause .....................................................158

DTC Confirmation Procedure ................................158

Wiring Diagram - AT - PT/SEN .............................159

Diagnosis Procedure .............................................160

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

163

Description ............................................................163

On Board Diagnosis Logic ....................................163

Possible Cause .....................................................163

DTC Confirmation Procedure ................................163

Diagnosis Procedure .............................................163

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

164

Wiring Diagram - AT - MAIN .................................164

Diagnosis Procedure .............................................165

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT ............................................

167

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

167

TCM Terminal and Reference Value .....................167

Diagnosis Procedure .............................................167

Component Inspection ...........................................171

SHIFT POSITION INDICATOR CIRCUIT ........172

Description .............................................................172

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

172

Diagnosis Procedure .............................................172

TROUBLE DIAGNOSIS FOR SYMPTOMS ....173

Wiring Diagram - AT - NONDTC ...........................173

OD OFF Indicator Lamp Does Not Come On ........176

Engine Cannot Be Started in "P" and "N" Position ..178

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

179

In "N" Position, Vehicle Moves ..............................179

Large Shock "N" → "R" Position ............................180

Vehicle Does Not Creep Backward in "R" Position ..181

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ..................................................................

182

Vehicle Cannot Be Started from D1 .......................183

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 .......................................................185

A/T Does Not Shift: D2→ D3 ..................................186

A/T Does Not Shift: D3→ D4 ..................................188

A/T Does Not Perform Lock-up .............................189

A/T Does Not Hold Lock-up Condition ...................190

Lock-up Is Not Released .......................................191

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................192

A/T Does Not Shift: D4→ D3, When OD OFF ........193

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

194

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

195

Vehicle Does Not Decelerate by Engine Brake .....197

TCM Self-Diagnosis Does Not Activate .................200

TRANSMISSION CONTROL MODULE ..........202

Removal and Installation .......................................202

SHIFT CONTROL SYSTEM ............................203

Control Device Removal and Installation ...............203

Control Device Disassembly and Assembly ..........206

Selector Lever Knob Removal and Installation ......206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................209

Description .............................................................209

Shift Lock System Parts Location ..........................209

Wiring Diagram - AT - SHIFT ................................210

Page 17 of 2771

INDEX FOR DTC

AT-5

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000001703149

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 3

.

*1: These numbers is prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.

DTC No. IndexINFOID:0000000001703150

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 3

.

Items

(CONSULT-III screen terms)DTC

Reference page

CONSULT-III or GST

*1

A/T 1ST GR FNCTN P0731AT-105

A/T 2ND GR FNCTN P0732AT-108

A/T 3RD GR FNCTN P0733AT- 111

A/T 4TH GR FNCTN P0734AT- 11 4

A/T TCC S/V FNCTN P0744AT-124

ATF TEMP SEN/CIRC P0710AT- 9 1

BATT/FLUID TEMP SEN —AT-152

CAN COMM CIRCUIT U1000AT- 8 3

CONTROL UNIT (RAM) —AT-163

CONTROL UNIT (ROM) —AT-163

ENGINE SPEED SIG P0725AT-101

LINE PRESSURE S/V P0745AT-129

OVERRUN CLUTCH S/V P1760AT-144

PNP SW/CIRC P0705AT- 8 6

SHIFT SOLENOID/V A*2P0750AT-134

SHIFT SOLENOID/V B*2P0755AT-139

T/C CLUTCH SOL/V P0740AT- 11 9

TURBINE SENSOR —AT-158

VHCL SPEED SEN-A/T*3P0720AT- 9 6

VHCL SPEED SEN-MTR —AT-149

DTC

Items

(CONSULT-III screen terms) Reference page

CONSULT-III or GST

*1

P0705 PNP SW/CIRCAT- 8 6

P0710 ATF TEMP SEN/CIRCAT- 9 1

P0720

VHCL SPEED SEN-A/T*3AT- 9 6

P0725 ENGINE SPEED SIGAT- 1 0 1

P0731 A/T 1ST GR FNCTNAT- 1 0 5

Page 18 of 2771

AT-6

< SERVICE INFORMATION >

INDEX FOR DTC

*1: These numbers is prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.P0732 A/T 2ND GR FNCTNAT- 1 0 8

P0733 A/T 3RD GR FNCTNAT- 111

P0734 A/T 4TH GR FNCTNAT- 11 4

P0740 T/C CLUTCH SOL/VAT- 11 9

P0744 A/T TCC S/V FNCTNAT- 1 2 4

P0745 LINE PRESSURE S/VAT- 1 2 9

P0750

SHIFT SOLENOID/V A*2AT- 1 3 4

P0755

SHIFT SOLENOID/V B*2AT- 1 3 9

P1760 OVERRUN CLUTCH S/VAT- 1 4 4

U1000 CAN COMM CIRCUITAT- 8 3

— BATT/FLUID TEMP SENAT- 1 5 2

— CONTROL UNIT (RAM)AT- 1 6 3

— CONTROL UNIT (ROM)AT- 1 6 3

— TURBINE SENSORAT- 1 5 8

— VHCL SPEED SEN-MTRAT- 1 4 9

DTC

Items

(CONSULT-III screen terms) Reference page

CONSULT-III or GST

*1

Page 19 of 2771

PRECAUTIONS

AT-7

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001703152

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000001703153

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 20 of 2771

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

• Be sure to turn the ignition switch OFF and disconnect battery negative cable from battery negative

terminal before any repair or inspection work. The open/short circuit of related switches, sensors,

solenoid valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000001703154

•Before connecting or disconnecting the TCM harness connec-

tor, turn ignition switch OFF and disconnect the battery cable

from the negative terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if igni-

tion switch is turned off.

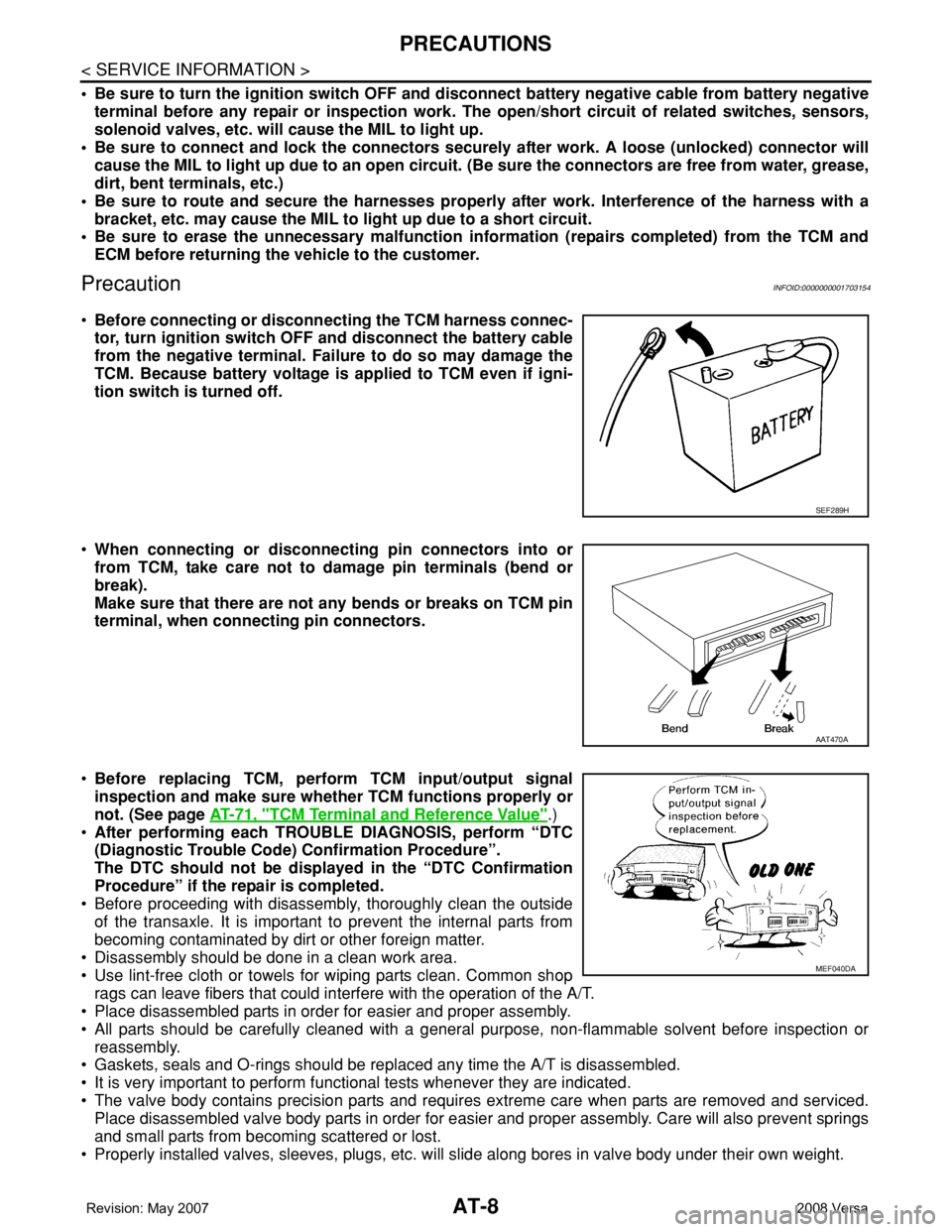

•When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM pin

terminal, when connecting pin connectors.

•Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. (See page AT-71, "

TCM Terminal and Reference Value".)

•After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

The DTC should not be displayed in the “DTC Confirmation

Procedure” if the repair is completed.

• Before proceeding with disassembly, thoroughly clean the outside

of the transaxle. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop

rags can leave fibers that could interfere with the operation of the A/T.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

• Gaskets, seals and O-rings should be replaced any time the A/T is disassembled.

• It is very important to perform functional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

SEF289H

AAT470A

MEF040DA

Page 21 of 2771

PRECAUTIONS

AT-9

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to

Refer to .

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

MA-22, "

Changing A/T Fluid", MA-22, "Checking A/T Fluid".

Service Notice or PrecautionINFOID:0000000001703155

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Service Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to Refer to CO-11

.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engine coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-78, "

Diagnosis Procedure without CONSULT-III" for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-36, "

OBD-II Diagnostic Trouble Code

(DTC)" to complete the repair and avoid unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD-II, refer to AT- 3 6

.

•Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector.

For description and how to disconnect, refer to PG-65

.

Page 23 of 2771

PREPARATION

AT-11

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

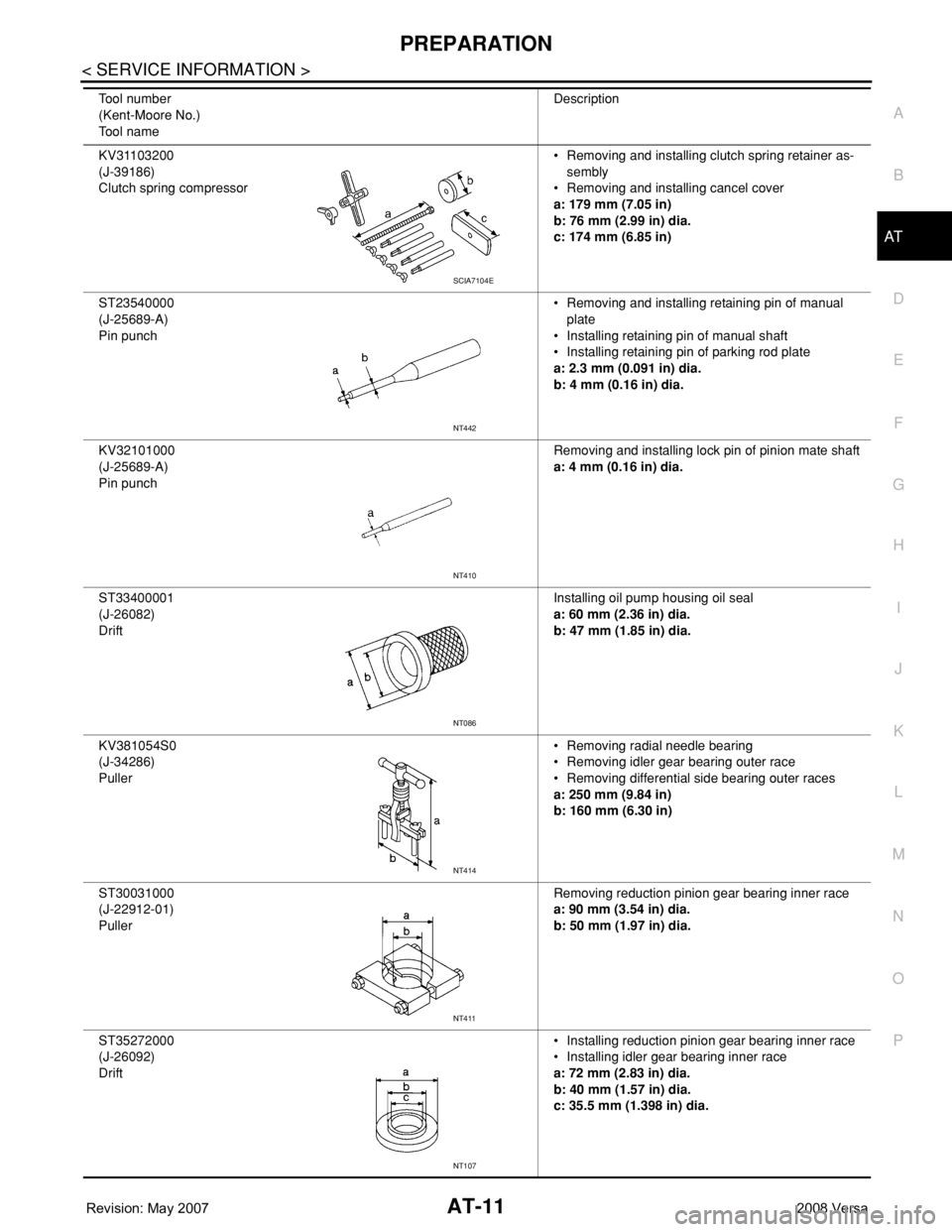

KV31103200

(J-39186)

Clutch spring compressor• Removing and installing clutch spring retainer as-

sembly

• Removing and installing cancel cover

a: 179 mm (7.05 in)

b: 76 mm (2.99 in) dia.

c: 174 mm (6.85 in)

ST23540000

(J-25689-A)

Pin punch• Removing and installing retaining pin of manual

plate

• Installing retaining pin of manual shaft

• Installing retaining pin of parking rod plate

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

KV32101000

(J-25689-A)

Pin punchRemoving and installing lock pin of pinion mate shaft

a: 4 mm (0.16 in) dia.

ST33400001

(J-26082)

DriftInstalling oil pump housing oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

KV381054S0

(J-34286)

Puller• Removing radial needle bearing

• Removing idler gear bearing outer race

• Removing differential side bearing outer races

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST30031000

(J-22912-01)

PullerRemoving reduction pinion gear bearing inner race

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST35272000

(J-26092)

Drift• Installing reduction pinion gear bearing inner race

• Installing idler gear bearing inner race

a: 72 mm (2.83 in) dia.

b: 40 mm (1.57 in) dia.

c: 35.5 mm (1.398 in) dia. Tool number

(Kent-Moore No.)

Tool nameDescription

SCIA7104E

NT442

NT410

NT086

NT414

NT411

NT107