PN switch NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 4133 of 4331

SB

N

O P

• The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

• The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage or distortion and repair as necessary before installing a new seat belt assembly.

• Anchor bolts are deformed or worn out.

• The seat belt pre-tensioner should be replaced even if the seat belts are not in use during a frontal collision

in which the air bags are deployed.

PRELIMINARY CHECKS 1. Check the seat belt warning lamp/chime for proper operation as follows:

a. Switch ignition ON. The seat belt warning lamp should illuminate. Also, the seat belt warning chime should sound for about seven seconds.

b. Fasten driver's seat belt. The seat belt warni ng lamp should go out and the chime (if sounding) should

stop.

2. If the air bag warning lamp is blinking, conduct self-diagnosis using CONSULT-II, and air bag warning

lamp. Refer to SRS-19, " SRS Operation Check " .

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are securely attached.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Make sure guide

swivels freely and that webbing lays flat and does not bind in guide. Make sure height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Make sure that webbing returns smoothly and completely into the retractor. If the seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up

in the loops of the upper anchors can caus e the seat belts to retract slowly.

c. Fasten the seat belt. Check the seat belt returns sm oothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accu mulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt though-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Use a clip or other device to attach t he seat belt at the center pillar webbing opening.

3. Pass a thin wire though the D-ring anchor webbing opening. Hold both ends of the wire and pull taut while moving it up and down several times along the webbing opening surface to remove matter stuck

there.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbing contacts the though-anchor webbing opening. NOTE:

Apply the tape so that there is no looseness or wrinkling.

6. Remove the clip attaching the seat bel t and check that the webbing returns smoothly.

6. Repeat steps above as necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are of the Emergency Locki ng Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver's seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors using the following test(s ) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check Grasp the shoulder webbing and pull it forward quickly . The retractor should lock and prevent the belt from

extending further.

Page 4139 of 4331

SC

N

O P

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 4145 of 4331

SC

N

O P

STARTING SYSTEM

System Description INFOID:0000000004306821

M/T Models Power is supplied at all times

• to starter motor terminal B, and

• through 40A fusible link (letter h, located in the fuse and fusible link box)

• to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

• from ignition switch terminal ST

• to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 49, located in the IPDM E/R)

• to the clutch interlock switch terminal 1.

With the clutch pedal depressed, power is supplied

• through the clutch interlock switch terminal 2

• to IPDM E/R terminal 35.

Ground is supplied at all times

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

• through terminal 19 of the IPDM E/R

• to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

A/T Models Power is supplied at all times

• to starter motor terminal B, and

• through 40A fusible link (letter h, located in the fuse and fusible link box)

• to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

• from ignition switch terminal ST

• to IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 54, located in the IPDM E/R)

• to park/neutral position (PNP) switch terminal 1.

With the selector lever in the P or N position, power is supplied

• through PNP switch terminal 2

• to IPDM E/R terminal 35.

Ground is supplied at all times

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN communication lines,

the IPDM E/R grounds the starter relay and power is supplied

• through terminal 19 of the IPDM E/R

• to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

CVT Models Power is supplied at all times

• to starter motor terminal B, and

• through 40A fusible link (letter h, located in the fuse and fusible link box)

• to ignition switch terminal B.

With the ignition switch in the START position, power is supplied

• from ignition switch terminal ST

Page 4154 of 4331

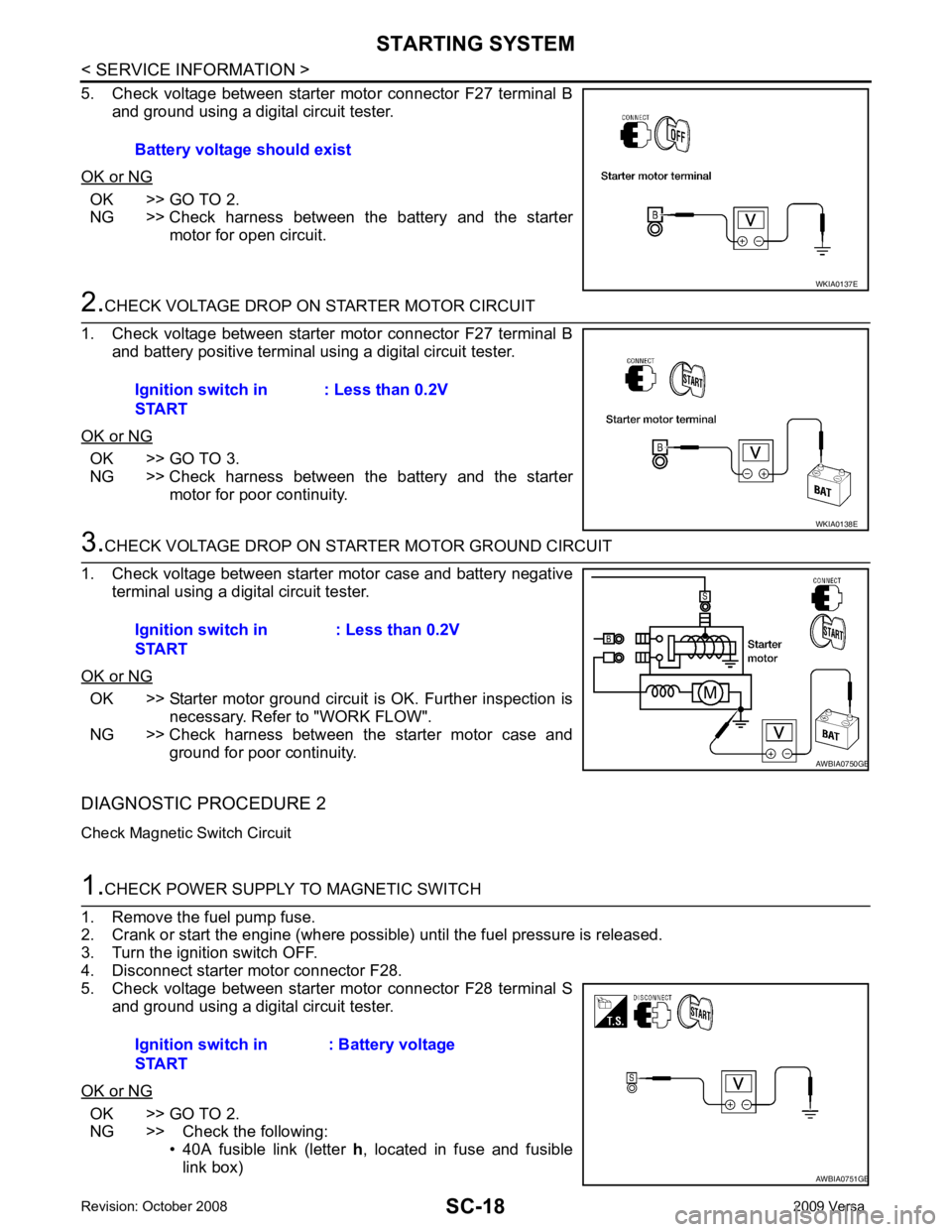

OK >> GO TO 2.

NG >> Check harness between the battery and the starter motor for open circuit. OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity. OK >> Starter motor ground circuit is OK. Further inspection is

necessary. Refer to "WORK FLOW".

NG >> Check harness between the starter motor case and

ground for poor continuity.

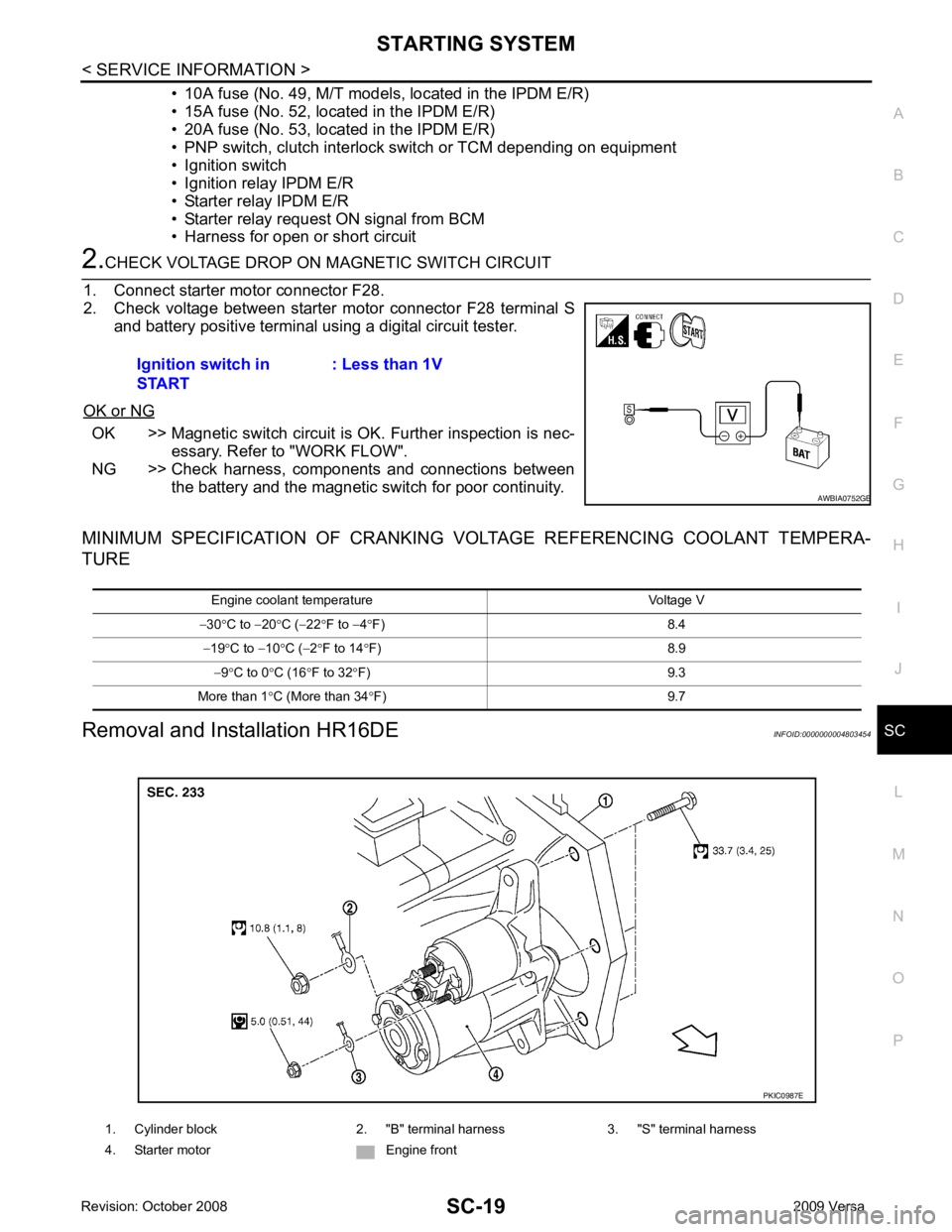

DIAGNOSTIC PROCEDURE 2

Check Magnetic Switch Circuit OK >> GO TO 2.

NG >> Check the following:

• 40A fusible link (letter h, located in fuse and fusible

link box)

Battery voltage should exist

Page 4155 of 4331

SC

N

O P

• 10A fuse (No. 49, M/T model

s, located in the IPDM E/R)

• 15A fuse (No. 52, located in the IPDM E/R)

• 20A fuse (No. 53, located in the IPDM E/R)

• PNP switch, clutch interlock switch or TCM depending on equipment

• Ignition switch

• Ignition relay IPDM E/R

• Starter relay IPDM E/R

• Starter relay request ON signal from BCM

• Harness for open or short circuit OK >> Magnetic switch circuit is

OK. Further inspection is nec-

essary. Refer to "WORK FLOW".

NG >> Check harness, components and connections between the battery and the magnetic switch for poor continuity.

MINIMUM SPECIFICATION OF CRANKING VO LTAGE REFERENCING COOLANT TEMPERA-

TURE

Removal and Installation HR16DE INFOID:0000000004803454

Ignition switch in

START : Less than 1V1. Cylinder block 2. "B" terminal harness 3. "S" terminal harness

4. Starter motor Engine front

Page 4157 of 4331

SC

N

O P

CHARGING SYSTEM

System Description INFOID:0000000004306825

The generator provides DC voltage to operate the vehicl e's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal 3 through

• 10A fuse (No. 29, located in the fuse and fusible link box).

Power is supplied through terminal 1 to charge the batte ry and operate the vehicle's electrical system. Output

voltage is monitored at terminal 3 by the IC regulator. The charging circuit is protected by the 120A fusible link

[letter a , located in the fusible link box (battery)].

Ground is supplied

• to generator terminal 5

• through body ground F5, and

• through the generator case to the cylinder block

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28 for the charge warning lamp.

The IC regulator controls ground to terminal 38 of the combination meter through terminal 2 of the generator.

When the ignition is turned on and power becomes availabl e at terminal 2, this "wakes up" the regulator. The

regulator monitors charge output and grounds terminal 2 or leaves it open depending on charge output. With

power and ground supplied, the charge warning lamp will il luminate. When the generator is providing sufficient

voltage, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Page 4193 of 4331

SRS

N

O P

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Occupant Classification System Precaution INFOID:0000000004307174

Replace control unit and passenger front seat cushion as an assembly.

Page 4209 of 4331

SRS

N

O P

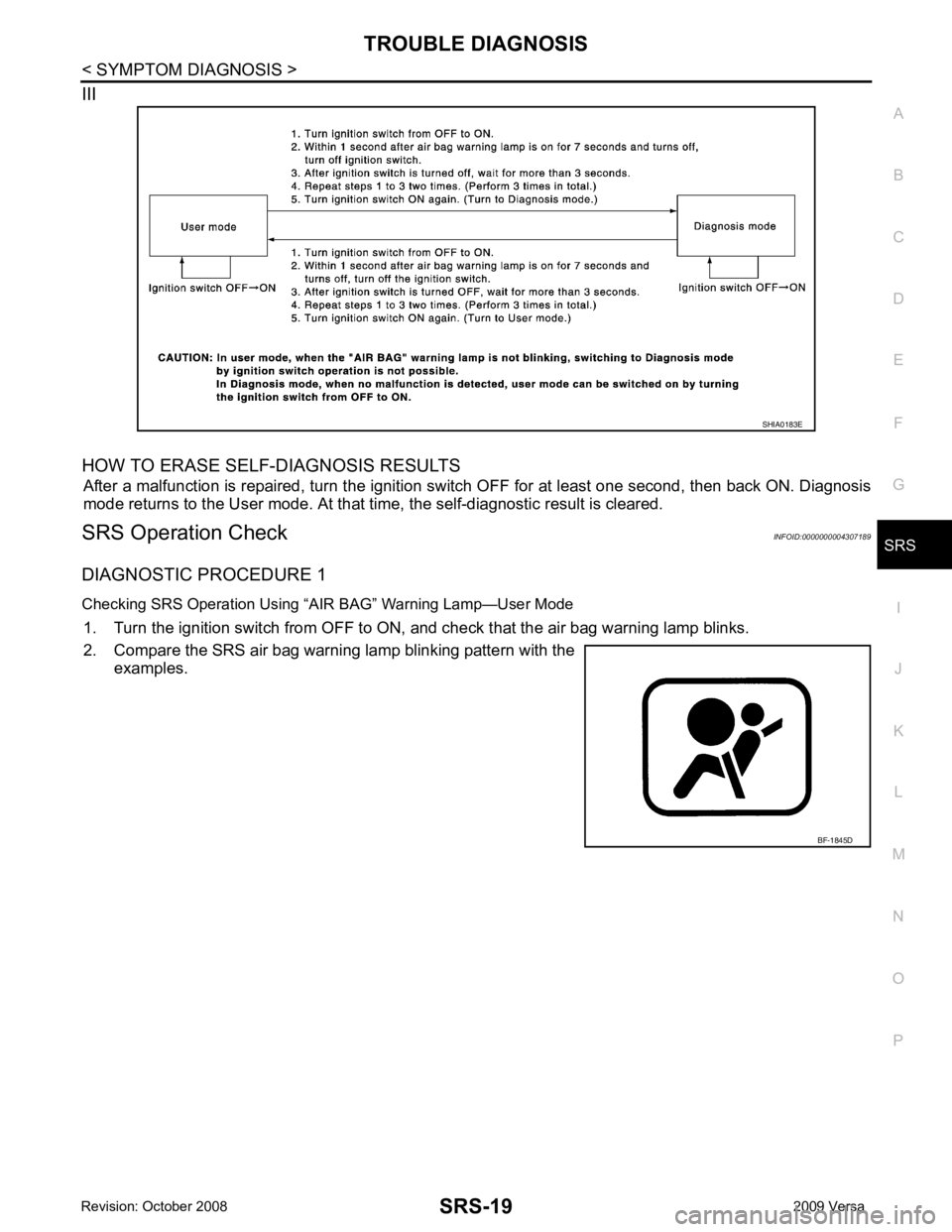

III

HOW TO ERASE SELF-DIAGNOSIS RESULTS After a malfunction is repaired, turn the ignition switch OFF for at least one second, then back ON. Diagnosis

mode returns to the User mode. At that time, the self-diagnostic result is cleared.

SRS Operation Check INFOID:0000000004307189

DIAGNOSTIC PROCEDURE 1

Checking SRS Operation Using “AIR BAG” Warning Lamp—User Mode 1. Turn the ignition switch from OFF to ON, and check that the air bag warning lamp blinks.

2. Compare the SRS air bag warning lamp blinking pattern with the examples.

Page 4215 of 4331

SRS

N

O P

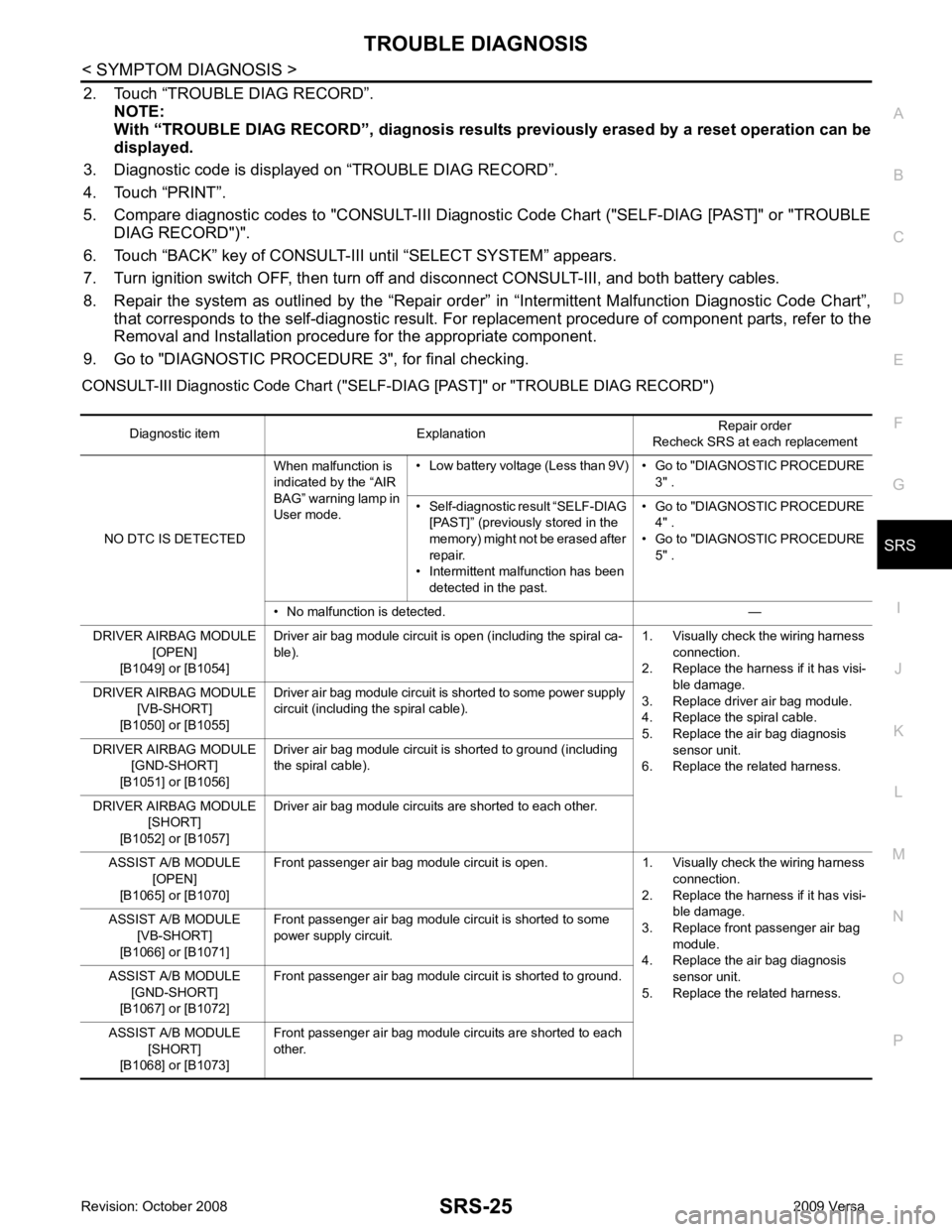

2. Touch “TROUBLE DIAG RECORD”.

NOTE:

With “TROUBLE DIAG RECORD”, di agnosis results previously erased by a reset operation can be

displayed.

3. Diagnostic code is displayed on “TROUBLE DIAG RECORD”.

4. Touch “PRINT”.

5. Compare diagnostic codes to "CONSULT-III Diagnos tic Code Chart ("SELF-DIAG [PAST]" or "TROUBLE

DIAG RECORD")".

6. Touch “BACK” key of CONSULT- III until “SELECT SYSTEM” appears.

7. Turn ignition switch OFF, then turn off and disconnect CONSULT-III, and both battery cables.

8. Repair the system as outlined by the “Repair orde r” in “Intermittent Malfunction Diagnostic Code Chart”,

that corresponds to the self-diagnostic result. For r eplacement procedure of component parts, refer to the

Removal and Installation procedure for the appropriate component.

9. Go to "DIAGNOSTIC PROCEDURE 3", for final checking.

CONSULT-III Diagnostic Code Chart ("SELF-DI AG [PAST]" or "TROUBLE DIAG RECORD")

Diagnostic item Explanation Repair order

Recheck SRS at each replacement

NO DTC IS DETECTED When malfunction is

indicated by the “AIR

BAG” warning lamp in

User mode. • Low battery voltage (L

ess than 9V) • Go to "DIAGNOSTIC PROCEDURE

3" .

• Self-diagnostic result “SELF-DIAG [PAST]” (previously stored in the

memory) might not be erased after

repair.

• Intermittent malfunction has been detected in the past. • Go to "DIAGNOSTIC PROCEDURE

4" .

• Go to "DIAGNOSTIC PROCEDURE

5" .

• No malfunction is detected. —

DRIVER AIRBAG MODULE [OPEN]

[B1049] or [B1054] Driver air bag module circuit is open (including the spiral ca-

ble). 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi- ble damage.

3. Replace driver air bag module.

4. Replace the spiral cable.

5. Replace the air bag diagnosis

sensor unit.

6. Replace the related harness.

DRIVER AIRBAG MODULE

[VB-SHORT]

[B1050] or [B1055] Driver air bag module circuit is shorted to some power supply

circuit (including the spiral cable).

DRIVER AIRBAG MODULE [GND-SHORT]

[B1051] or [B1056] Driver air bag module circuit is shorted to ground (including

the spiral cable).

DRIVER AIRBAG MODULE [SHORT]

[B1052] or [B1057] Driver air bag module circuits are shorted to each other.

ASSIST A/B MODULE [OPEN]

[B1065] or [B1070] Front passenger air bag module circuit is open. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visi-

ble damage.

3. Replace front passenger air bag module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

ASSIST A/B MODULE

[VB-SHORT]

[B1066] or [B1071] Front passenger air bag module circuit is shorted to some

power supply circuit.

ASSIST A/B MODULE [GND-SHORT]

[B1067] or [B1072] Front passenger air bag module circuit is shorted to ground.

ASSIST A/B MODULE [SHORT]

[B1068] or [B1073] Front passenger air bag module circuits are shorted to each

other.

Page 4227 of 4331

SRS

N

O P

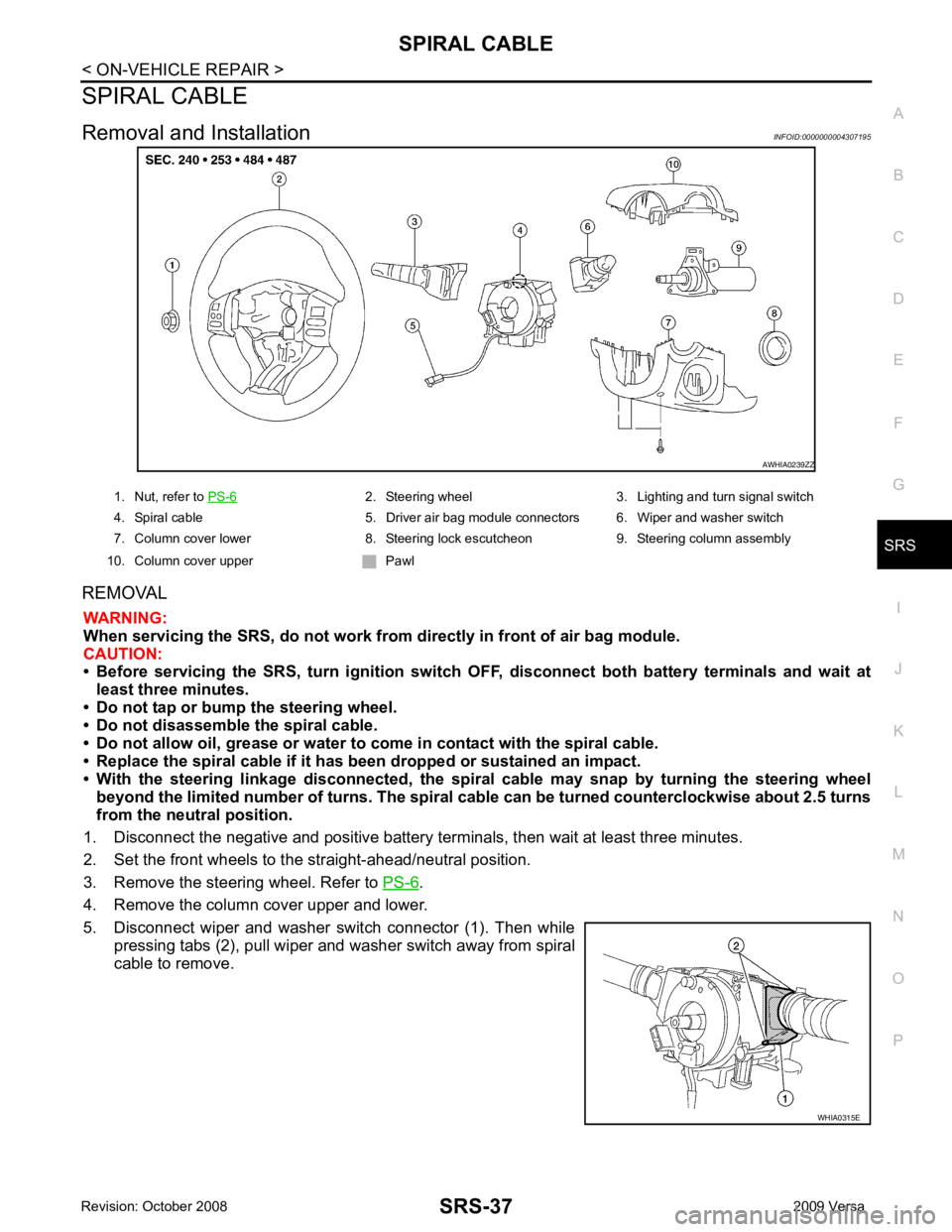

SPIRAL CABLE

Removal and Installation INFOID:0000000004307195

REMOVAL WARNING:

When servicing the SRS, do not work from directly in front of air bag module.

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery terminals and wait at

least three minutes.

• Do not tap or bump the steering wheel.

• Do not disassemble the spiral cable.

• Do not allow oil, grease or water to co me in contact with the spiral cable.

• Replace the spiral cable if it has b een dropped or sustained an impact.

• With the steering linkage disconn ected, the spiral cable may snap by turning the steering wheel

beyond the limited number of turns. The spiral cable can be turned counterclockwise about 2.5 turns

from the neutral position.

1. Disconnect the negative and positive battery term inals, then wait at least three minutes.

2. Set the front wheels to the straight-ahead/neutral position.

3. Remove the steering wheel. Refer to PS-6 .

4. Remove the column cover upper and lower.

5. Disconnect wiper and washer switch connector (1). Then while pressing tabs (2), pull wiper and washer switch away from spiral

cable to remove. 2. Steering wheel 3. Lighting and turn signal switch

4. Spiral cable 5. Driver air bag module connectors 6. Wiper and washer switch

7. Column cover lower 8. Steering lock escutcheon 9. Steering column assembly

10. Column cover upper Pawl