compressor NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1823 of 4331

![NISSAN TIIDA 2009 Service User Guide EC

NP

O

41 GR Refrigerant pressure sensor

[Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates.) 1.0 - 4.0 V

42 V EVAP control system pres-

sur NISSAN TIIDA 2009 Service User Guide EC

NP

O

41 GR Refrigerant pressure sensor

[Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates.) 1.0 - 4.0 V

42 V EVAP control system pres-

sur](/img/5/57398/w960_57398-1822.png)

EC

NP

O

41 GR Refrigerant pressure sensor

[Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates.) 1.0 - 4.0 V

42 V EVAP control system pres-

sure sensor [Ignition switch: ON]

Approximately 1.8 - 4.8 V

43 P Fuel tank temperature sen-

sor [Engine is running] Approximately 0 - 4.8 V

Output voltage varies with fuel

tank temperature

44 B Sensor ground

(Engine coolant temperature

sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

45 G Mass air flow sensor [Engine is running]

• Warm-up condition

• Idle speed 0.9 - 1.3 V

[Engine is running]

• Warm-up condition

• Engine speed: 2,500 rpm 1.4 - 1.9 V

46 V Intake air temperature

sensor [Engine is running] Approximately 0 - 4.8 V

Output voltage varies with intake

air temperature.

48 BR Sensor ground

(Refrigerant pressure sen-

sor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

49 W A/F sensor 1 [Engine is running]

• Warm-up condition

• Engine speed: 2,000 rpm Approximately 1.8 V

Output voltage varies with air fuel

ratio.

50 W Heated oxygen sensor 2 [Engine is running]

• Revving engine from idle to 3,000 rpm quickly after the following conditions are

met.

- Engine: After warming up

- Keeping the engine speed between 3,500

and 4,000 rpm for 1 minute and at idle for 1

minute under no load. 0 - 1.0 V

51 O Sensor ground

(EVAP control system pres-

sure sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

52 LG Sensor ground

(Mass air flow sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

53 B A/F sensor 1 [Ignition switch: ON]Approximately 2.2 V

55 O Sensor ground

(Intake air temperature sen-

sor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

59 O Sensor ground

(Heated oxygen sensor 2) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0 V

TERMI-

NAL

NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

Page 1970 of 4331

.

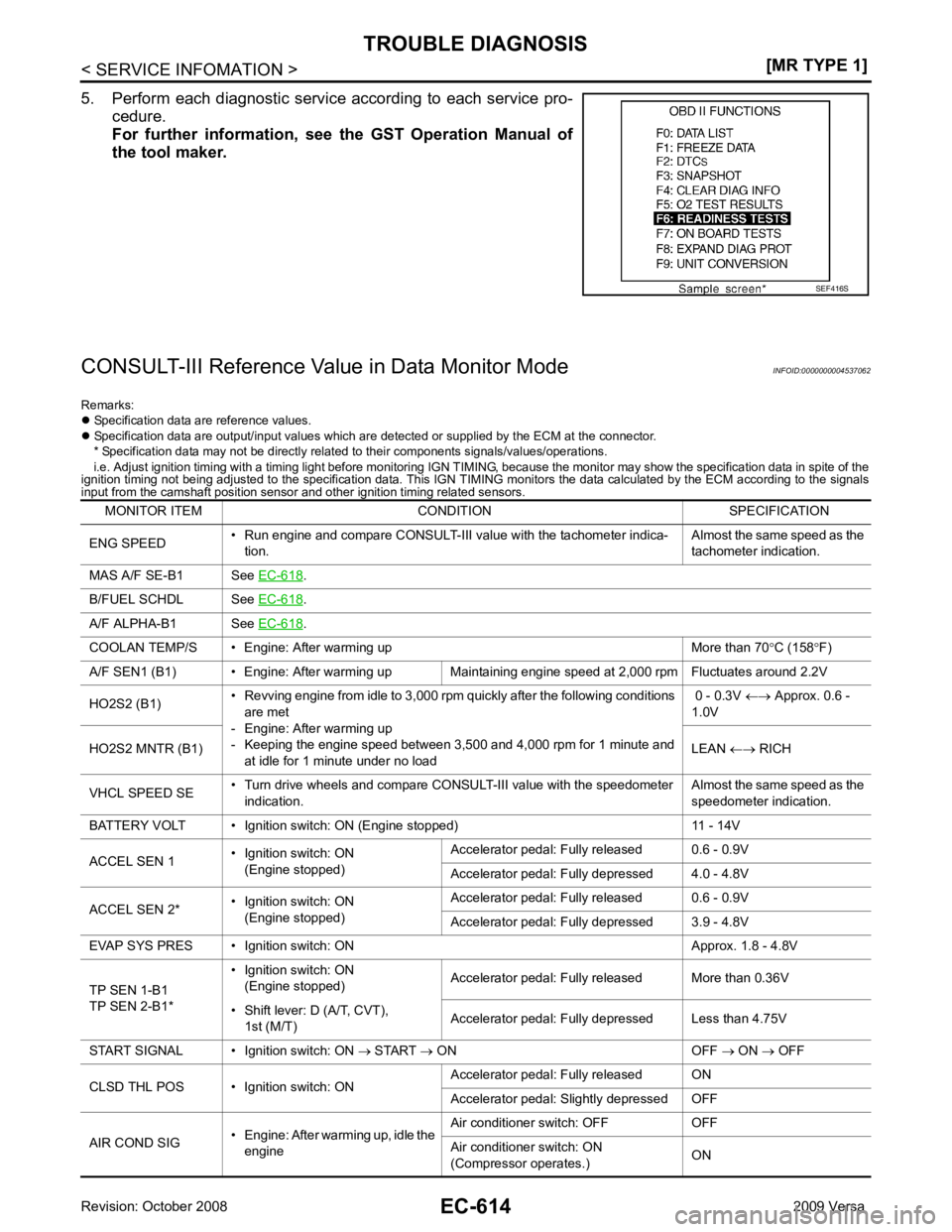

B/FUEL SCHDL See EC-618 .

A/F ALPHA-B1 See EC-618 .

COOLAN TEMP/S • Engine: After warming up More than 70 °C (158 °F)

A/F SEN1 (B1) • Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 2.2V

HO2S2 (B1) • Revving engine from idle to 3,000 rpm quickly after the following conditions

are met

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load 0 - 0.3V

←→ Approx. 0.6 -

1.0V

HO2S2 MNTR (B1) LEAN ←→ RICH

VHCL SPEED SE • Turn drive wheels and compare CONSULT-III value with the speedometer

indication. Almost the same speed as the

speedometer indication.

BATTERY VOLT • Ignition switch: ON (Engine stopped) 11 - 14V

ACCEL SEN 1 • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 4.0 - 4.8V

ACCEL SEN 2* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 3.9 - 4.8V

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8V

TP SEN 1-B1

TP SEN 2-B1* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released More than 0.36V

• Shift lever: D (A/T, CVT), 1st (M/T) Accelerator pedal: Fully depressed Less than 4.75V

START SIGNAL • Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS • Ignition switch: ON Accelerator

pedal: Fully released ON

Accelerator pedal: Slightly depressed OFF

AIR COND SIG • Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.) ON

Page 1971 of 4331

EC

NP

O

P/N POSI SW • Ignition switch: ON

Shift lever: P or N (A/T, CVT),

Neutral (M/T) ON

Shift lever: Except above OFF

PW/ST SIGNAL • Engine: After warming up, idle the

engine Steering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ON Rear window defogger switch: ON

and/or Lighting switch: 2nd ON

Rear window defogger switch and light-

ing switch: OFF OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW • Ignition switch: ON Heater fan: Operating ON

Heater fan: Not operating OFF

BRAKE SW • Ignition switch: ON Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle 2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle 8

° - 18 ° BTDC

2,000 rpm 25 ° - 45 ° BTDC

CAL/LD VALUE • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• No load Idle 10% - 35%

2,500 rpm 10% - 35%

MASS AIRFLOW • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle 1.0 - 4.0 g·m/s

2,500 rpm 2.0 - 10.0 g·m/s

PURG VOL C/V • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle

(Accelerator pedal is not depressed

even slightly, after engine starting) 0%

2,000 rpm 0 - 50%

INT/V TIM (B1) • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle

−5 ° - 5 °CA

When revving engine up to 2,000 rpm

quickly Approx. 0

° - 40 °CA

INT/V SOL (B1) • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• No load Idle 0% - 2%

When revving engine up to 2,000 rpm

quickly Approx. 0% - 90%

AIR COND RLY • Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates) ON

FUEL PUMP RLY • For 1 second after turning ignition switch ON

• Engine running or cranking ON

• Except above conditions OFF

MONITOR ITEM CONDITION SPECIFICATION

Page 2243 of 4331

EC

NP

O

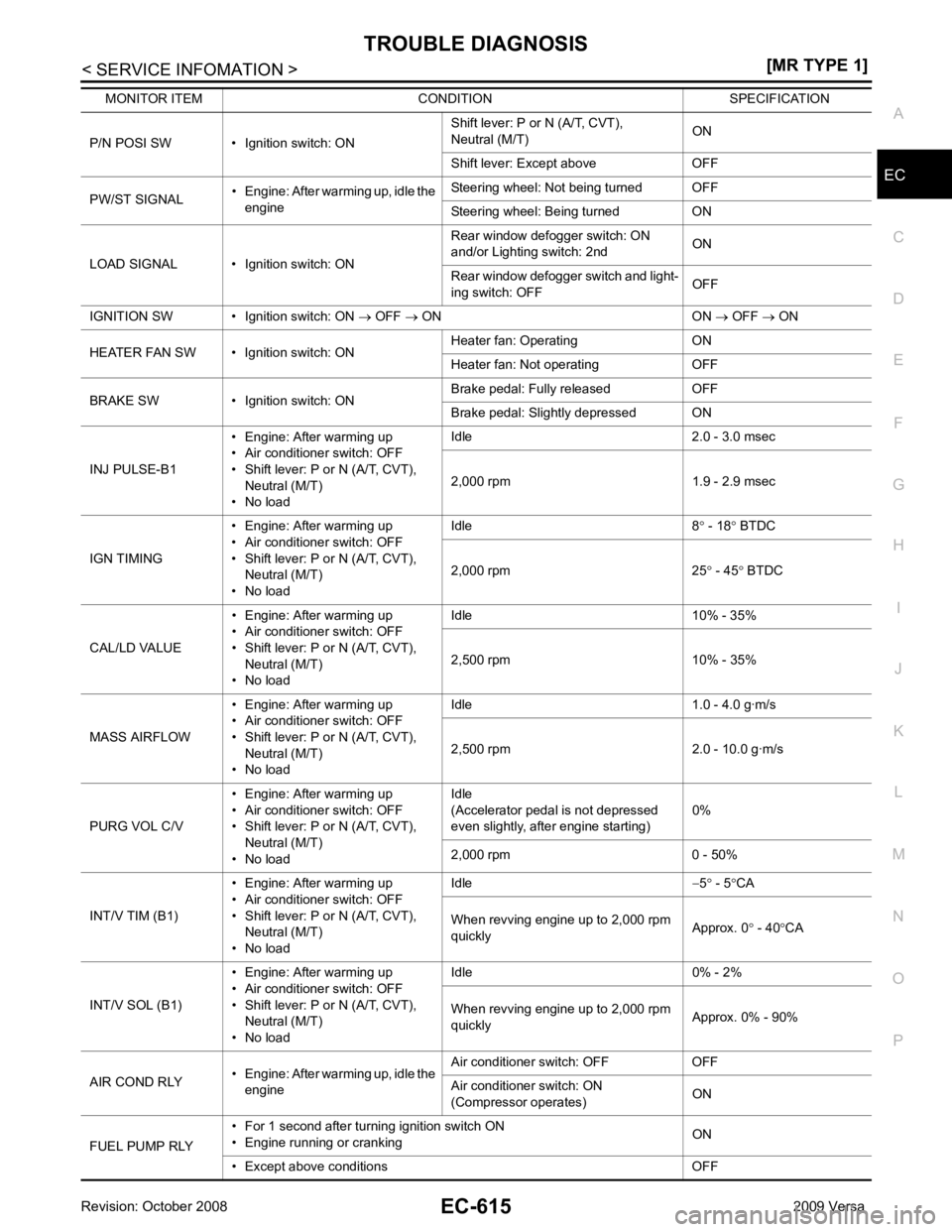

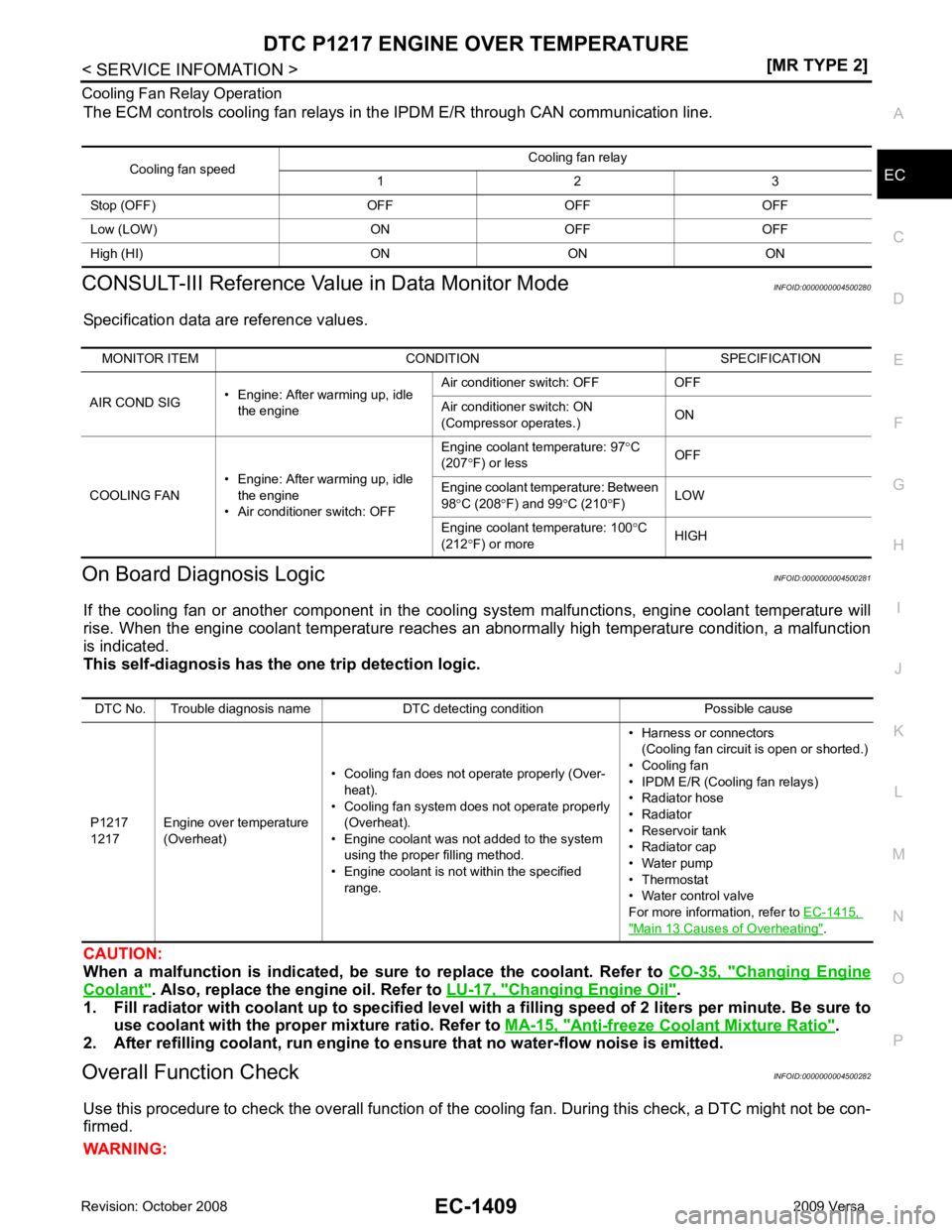

Cooling Fan Relay Operation

The ECM controls cooling fan relays in the IPDM E/R through CAN communication line.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004537394

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004537395

If the cooling fan or another component in the cooli ng system malfunctions, engine coolant temperature will

rise. When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction

is indicated.

This self-diagnosis has the on e trip detection logic.

CAUTION:

When a malfunction is in dicated, be sure to replace the coolant. Refer to CO-35, " Changing Engine

Coolant " . Also, replace the engine oil. Refer to

LU-17, " Changing Engine Oil " .

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

2. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

Overall Function Check INFOID:0000000004537396

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING: Cooling fan speed

Cooling fan relay

1 2 3

Stop (OFF) OFF OFF OFF

Low (LOW) ON OFF OFF

High (HI) ON ON ON MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG • Engine: After warming up, idle

the engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.) ON

COOLING FAN • Engine: After warming up, idle

the engine

• Air conditioner switch: OFF Engine coolant temperature: 97

°C

(207 °F) or less OFF

Engine coolant temperature: Between

98 °C (208 °F) and 99 °C (210 °F) LOW

Engine coolant temperature: 100 °C

(212 °F) or more HIGHDTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217 Engine over temperature

(Overheat) • Cooling fan does not operate properly (Over-

heat).

• Cooling fan system does not operate properly (Overheat).

• Engine coolant was not added to the system using the proper filling method.

• Engine coolant is not within the specified

range. • Harness or connectors

(Cooling fan circuit is open or shorted.)

• Cooling fan

• IPDM E/R (Cooling fan relays)

• Radiator hose

• Radiator

• Reservoir tank

• Radiator cap

• Water pump

• Thermostat

• Water control valve

For more information, refer to EC-893, " Main 13 Causes of Overheating " .

Page 2363 of 4331

![NISSAN TIIDA 2009 Service User Guide REFRIGERANT PRESSURE SENSOR

EC-1007

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045375421.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION NISSAN TIIDA 2009 Service User Guide REFRIGERANT PRESSURE SENSOR

EC-1007

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045375421.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION](/img/5/57398/w960_57398-2362.png)

REFRIGERANT PRESSURE SENSOR

EC-1007

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045375421.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check voltage between ECM terminal 41 and ground with CON- SULT-III or tester.

OK or NG OK >>

INSPECTION END

NG >> GO TO 2. 2.

CHECK GROUND CONNECTIONS

1. Turn A/C switch and blower fan switch OFF.

2. Stop engine and turn ignition switch OFF.

3. Loosen and retighten ground screw on the body. Refer to EC-632, " Ground Inspection " .

OK or NG OK >> GO TO 3.

NG >> Repair or replace ground connections. 3.

CHECK REFRIGERANT PRESSURE SE NSOR POWER SUPPLY CIRCUIT

TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

41 GR Refrigerant pressure sensor [Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates) 1.0 - 4.0V

48 BR Sensor ground

(Refrigerant pressure sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

74 W Sensor power supply

(Refrigerant pressure sensor) [Ignition switch: ON]

Approximately 5VVoltage: 1.0 - 4.0V

PBIA9574J

:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2482 of 4331

![NISSAN TIIDA 2009 Service User Guide EC-1126< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

5. Perform each diagnostic service according to each service pro- cedure.

For further information, see th e GST Operation Manual of

NISSAN TIIDA 2009 Service User Guide EC-1126< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

5. Perform each diagnostic service according to each service pro- cedure.

For further information, see th e GST Operation Manual of](/img/5/57398/w960_57398-2481.png)

EC-1126< SERVICE INFOMATION >

[MR TYPE 2]

TROUBLE DIAGNOSIS

5. Perform each diagnostic service according to each service pro- cedure.

For further information, see th e GST Operation Manual of

the tool maker.

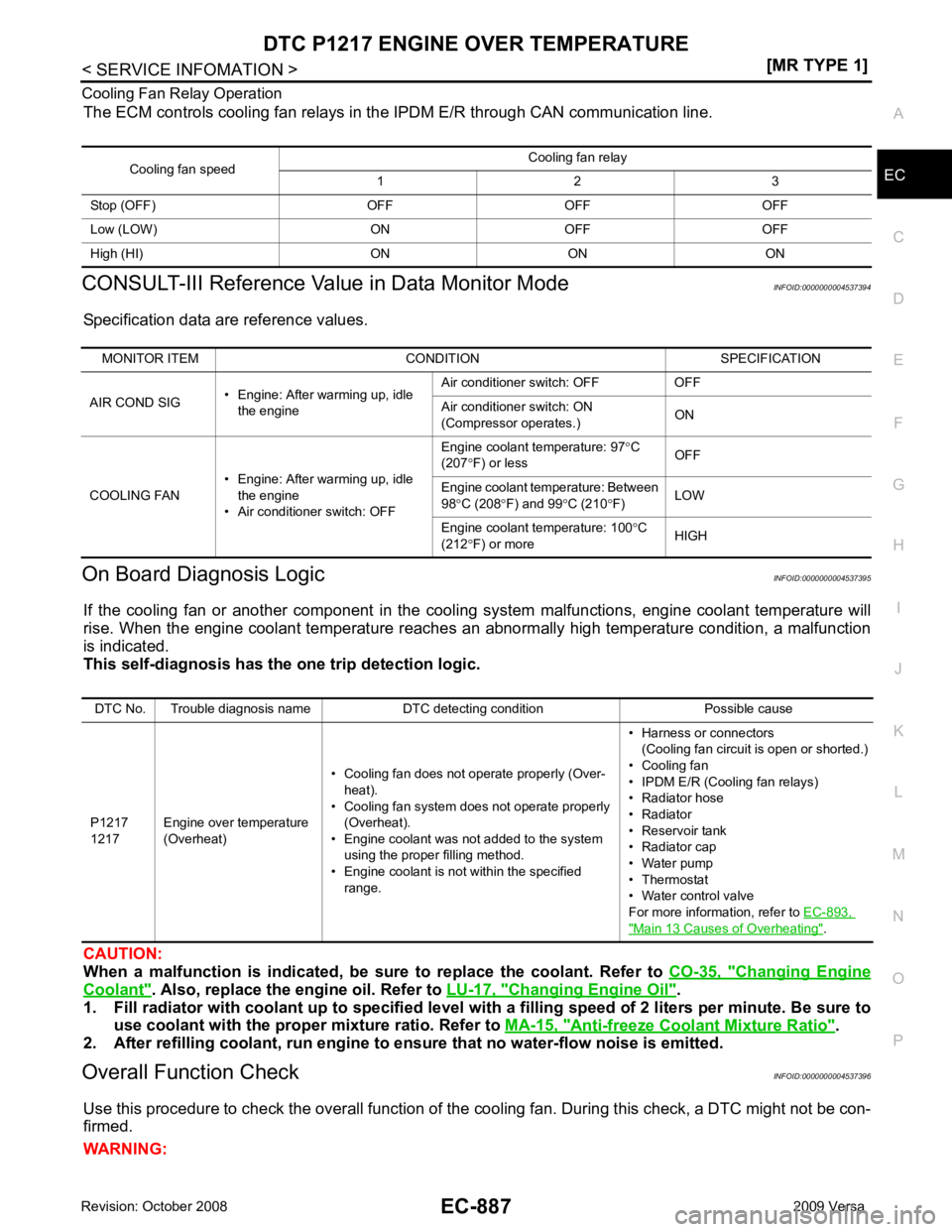

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000004499948

Remarks:

�z Specification data are reference values.

�z Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly relate d to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in spite of the

ignition timing not being adjusted to the specification data. This IGN TIMING moni tors the data calculated by the ECM according to the signals

input from the camshaft position sensor and other ignition timing related sensors. SEF416S

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED • Run engine and compare CONSULT-III value with the tachometer indica-

tion. Almost the same speed as the

tachometer indication.

MAS A/F SE-B1 See EC-1130 .

B/FUEL SCHDL See EC-1130 .

A/F ALPHA-B1 See EC-1130 .

COOLAN TEMP/S • Engine: After warming up More than 70 °C (158 °F)

A/F SEN1 (B1) • Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 2.2V

HO2S2 (B1) • Revving engine from idle to 3,000 rpm quickly after the following conditions

are met

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load 0 - 0.3V

←→ Approx. 0.6 -

1.0V

HO2S2 MNTR (B1) LEAN ←→ RICH

VHCL SPEED SE • Turn drive wheels and compare CONSULT-III value with the speedometer

indication. Almost the same speed as the

speedometer indication.

BATTERY VOLT • Ignition switch: ON (Engine stopped) 11 - 14V

ACCEL SEN 1 • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 4.0 - 4.8V

ACCEL SEN 2* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released 0.6 - 0.9V

Accelerator pedal: Fully depressed 3.9 - 4.8V

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8V

TP SEN 1-B1

TP SEN 2-B1* • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released More than 0.36V

• Shift lever: D (A/T, CVT), 1st (M/T) Accelerator pedal: Fully depressed Less than 4.75V

START SIGNAL • Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS • Ignition switch: ON Accelerator

pedal: Fully released ON

Accelerator pedal: Slightly depressed OFF

AIR COND SIG • Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.) ON

Page 2483 of 4331

EC

NP

O

P/N POSI SW • Ignition switch: ON

Shift lever: P or N (A/T, CVT),

Neutral (M/T) ON

Shift lever: Except above OFF

PW/ST SIGNAL • Engine: After warming up, idle the

engine Steering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ON Rear window defogger switch: ON

and/or Lighting switch: 2nd ON

Rear window defogger switch and light-

ing switch: OFF OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW • Ignition switch: ON Heater fan: Operating ON

Heater fan: Not operating OFF

BRAKE SW • Ignition switch: ON Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle 2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle 8

° - 18 ° BTDC

2,000 rpm 25 ° - 45 ° BTDC

CAL/LD VALUE • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• No load Idle 10% - 35%

2,500 rpm 10% - 35%

MASS AIRFLOW • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle 1.0 - 4.0 g·m/s

2,500 rpm 2.0 - 10.0 g·m/s

PURG VOL C/V • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle

(Accelerator pedal is not depressed

even slightly, after engine starting) 0%

2,000 rpm 0 - 50%

INT/V TIM (B1) • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT), Neutral (M/T)

• No load Idle

−5 ° - 5 °CA

When revving engine up to 2,000 rpm

quickly Approx. 0

° - 40 °CA

INT/V SOL (B1) • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• No load Idle 0% - 2%

When revving engine up to 2,000 rpm

quickly Approx. 0% - 90%

AIR COND RLY • Engine: After warming up, idle the

engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates) ON

FUEL PUMP RLY • For 1 second after turning ignition switch ON

• Engine running or cranking ON

• Except above conditions OFF

MONITOR ITEM CONDITION SPECIFICATION

Page 2765 of 4331

EC

NP

O

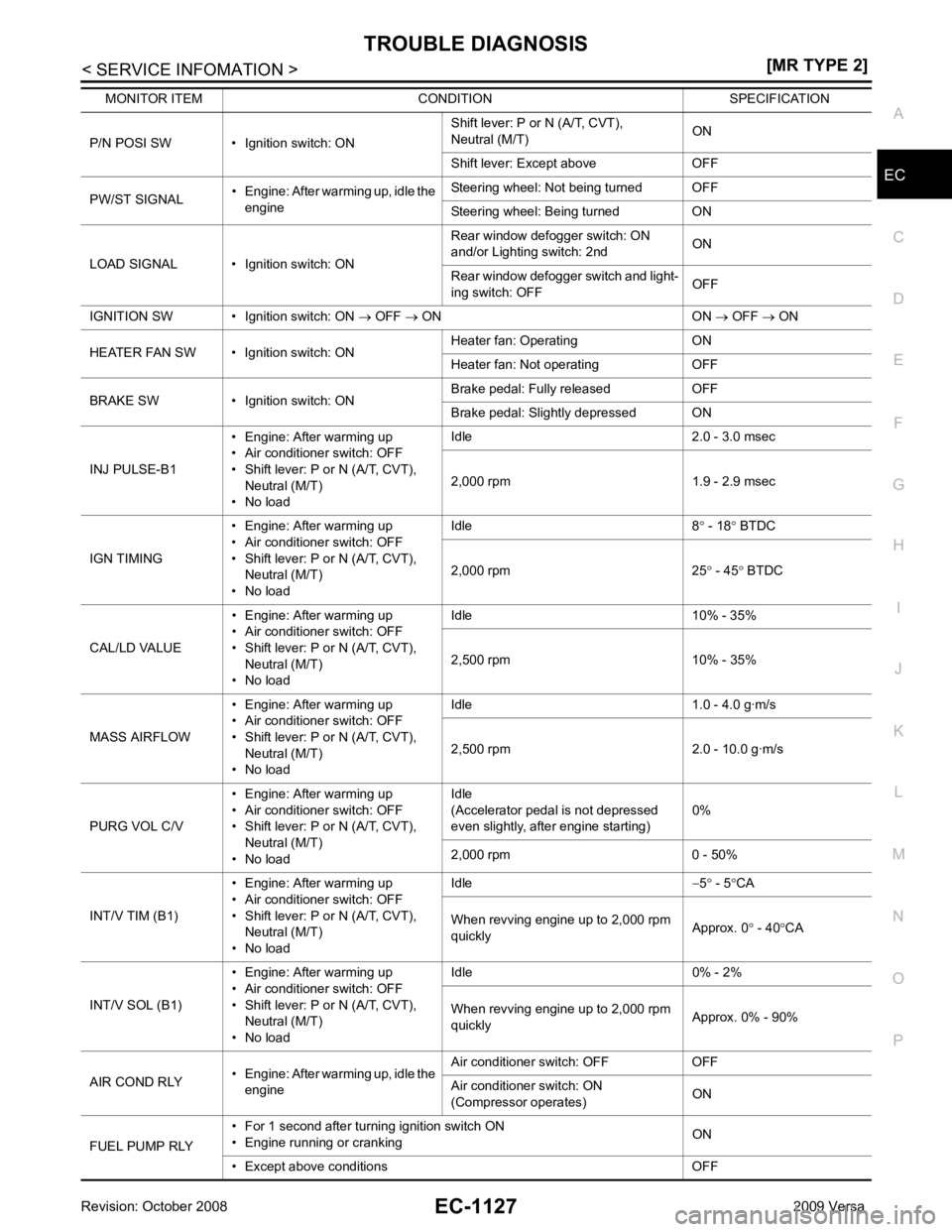

Cooling Fan Relay Operation

The ECM controls cooling fan relays in the IPDM E/R through CAN communication line.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004500280

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004500281

If the cooling fan or another component in the cooli ng system malfunctions, engine coolant temperature will

rise. When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction

is indicated.

This self-diagnosis has the on e trip detection logic.

CAUTION:

When a malfunction is in dicated, be sure to replace the coolant. Refer to CO-35, " Changing Engine

Coolant " . Also, replace the engine oil. Refer to

LU-17, " Changing Engine Oil " .

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

2. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

Overall Function Check INFOID:0000000004500282

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING: Cooling fan speed

Cooling fan relay

1 2 3

Stop (OFF) OFF OFF OFF

Low (LOW) ON OFF OFF

High (HI) ON ON ON MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG • Engine: After warming up, idle

the engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.) ON

COOLING FAN • Engine: After warming up, idle

the engine

• Air conditioner switch: OFF Engine coolant temperature: 97

°C

(207 °F) or less OFF

Engine coolant temperature: Between

98 °C (208 °F) and 99 °C (210 °F) LOW

Engine coolant temperature: 100 °C

(212 °F) or more HIGHDTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217 Engine over temperature

(Overheat) • Cooling fan does not operate properly (Over-

heat).

• Cooling fan system does not operate properly (Overheat).

• Engine coolant was not added to the system using the proper filling method.

• Engine coolant is not within the specified

range. • Harness or connectors

(Cooling fan circuit is open or shorted.)

• Cooling fan

• IPDM E/R (Cooling fan relays)

• Radiator hose

• Radiator

• Reservoir tank

• Radiator cap

• Water pump

• Thermostat

• Water control valve

For more information, refer to EC-1415, " Main 13 Causes of Overheating " .

Page 2885 of 4331

![NISSAN TIIDA 2009 Service User Guide REFRIGERANT PRESSURE SENSOR

EC-1529

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045004281.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION NISSAN TIIDA 2009 Service User Guide REFRIGERANT PRESSURE SENSOR

EC-1529

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045004281.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION](/img/5/57398/w960_57398-2884.png)

REFRIGERANT PRESSURE SENSOR

EC-1529

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

Diagnosis Procedure

INFOID:00000000045004281.

CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check voltage between ECM terminal 41 and ground with CON- SULT-III or tester.

OK or NG OK >>

INSPECTION END

NG >> GO TO 2. 2.

CHECK GROUND CONNECTIONS

1. Turn A/C switch and blower fan switch OFF.

2. Stop engine and turn ignition switch OFF.

3. Loosen and retighten ground screw on the body. Refer to EC-1144, " Ground Inspection " .

OK or NG OK >> GO TO 3.

NG >> Repair or replace ground connections. 3.

CHECK REFRIGERANT PRESSURE SE NSOR POWER SUPPLY CIRCUIT

TERMI-

NAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

41 GR Refrigerant pressure sensor [Engine is running]

• Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates) 1.0 - 4.0V

48 BR Sensor ground

(Refrigerant pressure sensor) [Engine is running]

• Warm-up condition

• Idle speed Approximately 0V

74 W Sensor power supply

(Refrigerant pressure sensor) [Ignition switch: ON]

Approximately 5VVoltage: 1.0 - 4.0V

PBIA9574J

:

Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15 BBIA0698E

Page 2956 of 4331

EM

NP

O

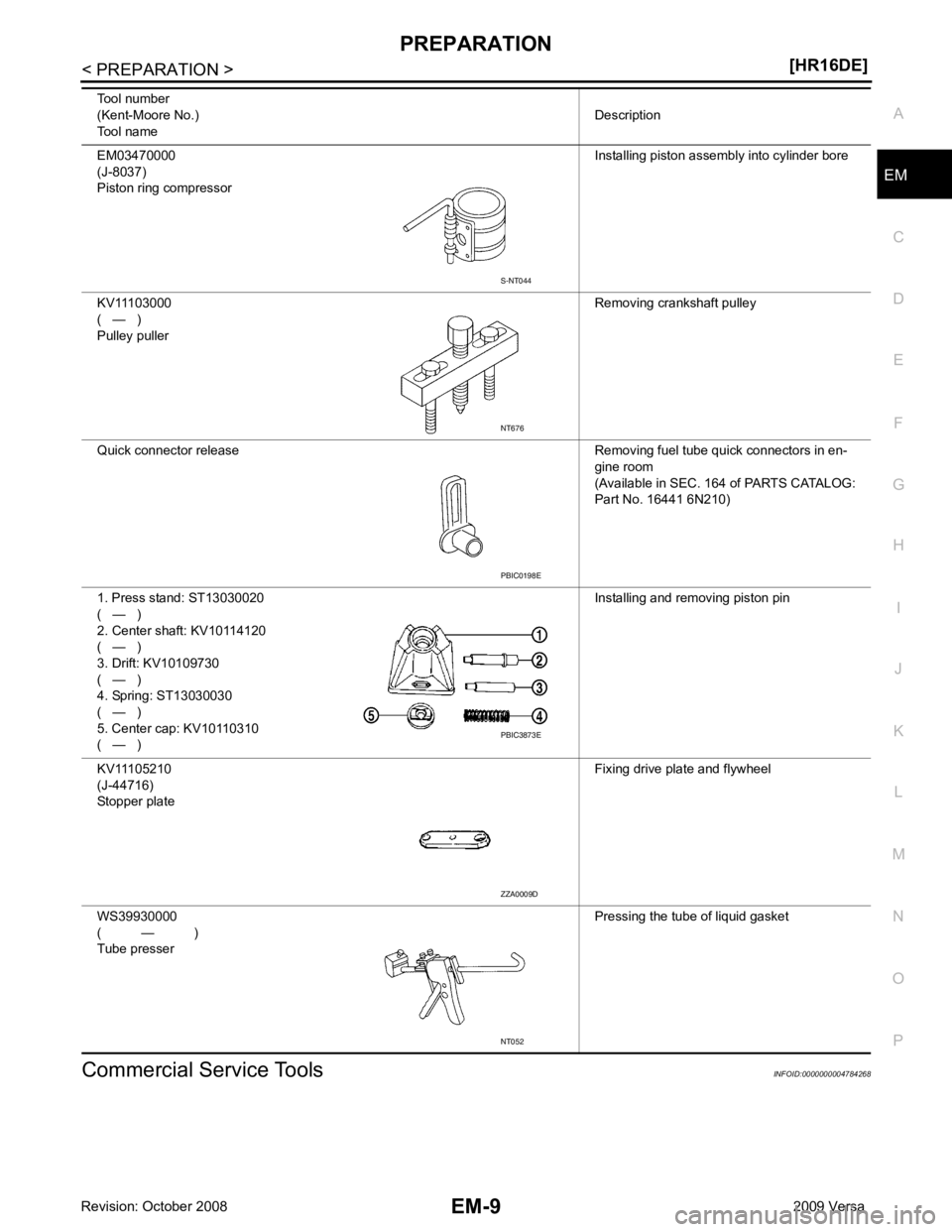

Commercial Service Tools INFOID:0000000004784268

EM03470000

(J-8037)

Piston ring compressor Installing piston assembly into cylinder bore

KV11103000

( — )

Pulley puller Removing crankshaft pulley

Quick connector release Removing fuel tube quick connectors in en- gine room

(Available in SEC. 164 of PARTS CATALOG:

Part No. 16441 6N210)

1. Press stand: ST13030020

( — )

2. Center shaft: KV10114120

( — )

3. Drift: KV10109730

( — )

4. Spring: ST13030030

( — )

5. Center cap: KV10110310

( — ) Installing and removing piston pin

KV11105210

(J-44716)

Stopper plate Fixing drive plate and flywheel

WS39930000

( — )

Tube presser Pressing the tube of liquid gasket

Tool number

(Kent-Moore No.)

Tool name Description PBIC0198E

PBIC3873E

ZZA0009D

NT052