compressor NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3974 of 4331

MTC

N

O P

Check all around the service valves. Ensure service valve caps are secured on the service valves (to

prevent leaks).

NOTE:

After removing A/C manifold gauge set from service va lves, wipe any residue from valves to prevent any

false readings by leak detector.

• Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in

the cooling unit. Wait a minimum of 10 minutes ac cumulation time (refer to the manufacturer’s recom-

mended procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use c aution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7-10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Mode control dial position: VENT (Ventilation)

c. Intake door lever position: Recirculation

d. Max. cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

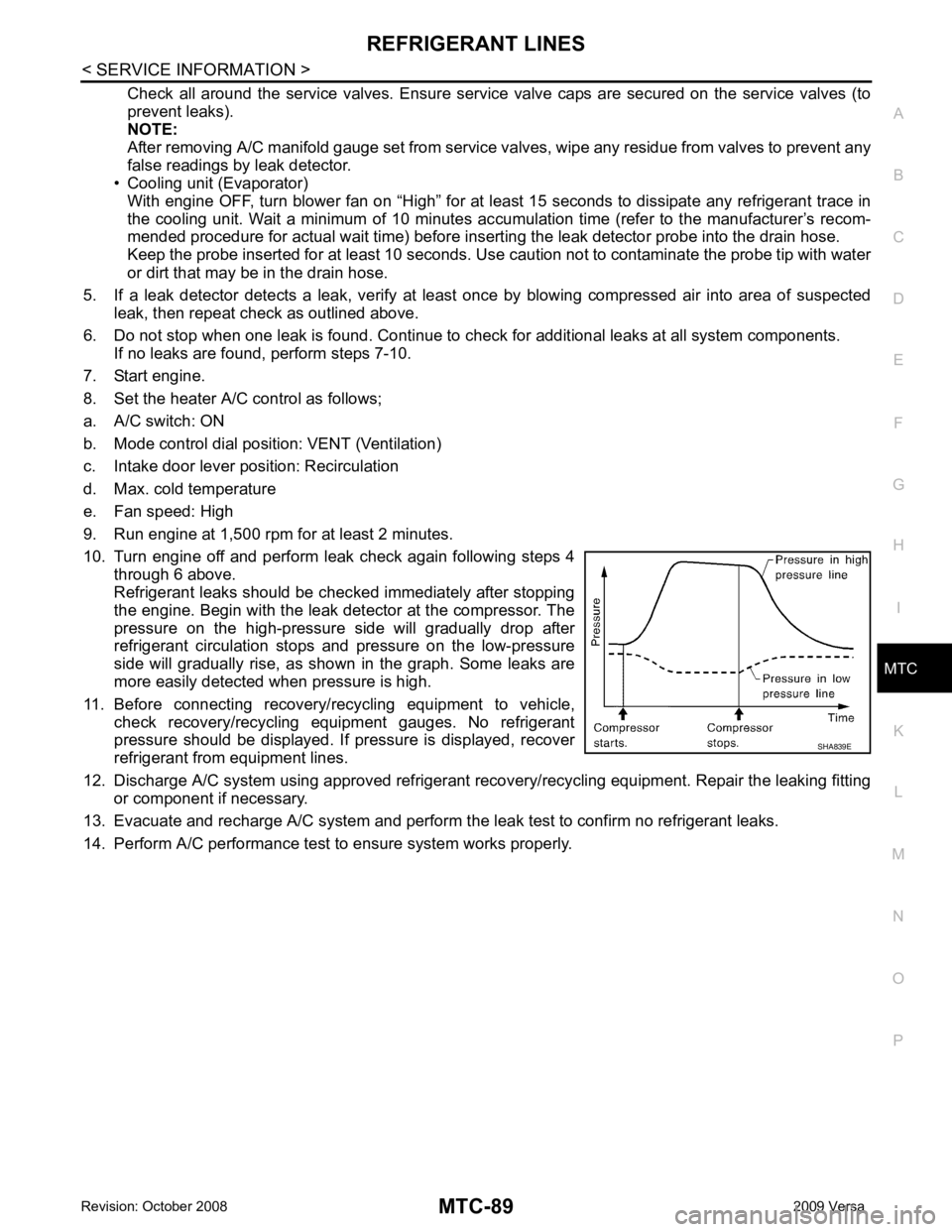

10. Turn engine off and perform leak check again following steps 4 through 6 above.

Refrigerant leaks should be chec ked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

11. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges. No refrigerant

pressure should be displayed. If pressure is displayed, recover

refrigerant from equipment lines.

12. Discharge A/C system using approved refrigerant reco very/recycling equipment. Repair the leaking fitting

or component if necessary.

13. Evacuate and recharge A/C system and perform the l eak test to confirm no refrigerant leaks.

14. Perform A/C performance test to ensure system works properly.

Page 3975 of 4331

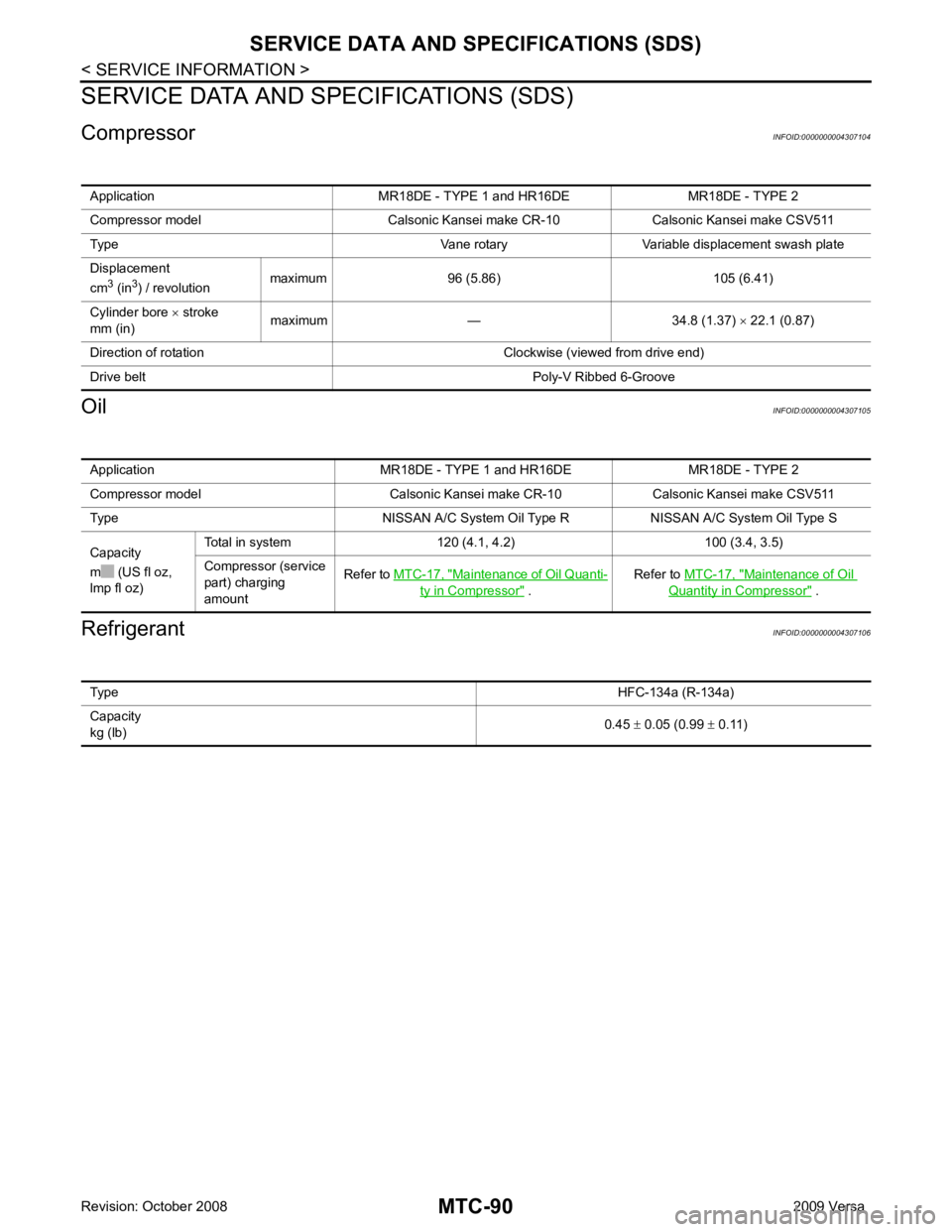

Application MR18DE - TYPE

1 and HR16DE MR18DE - TYPE 2

Compressor model Calsonic Kansei make CR-10 Calsonic Kansei make CSV511

Type NISSAN A/C System Oil Type R NISSAN A/C System Oil Type S

Capacity

m (US fl oz,

lmp fl oz) Total in system 120 (4.1, 4.2) 100 (3.4, 3.5)

Compressor (service

part) charging

amount Refer to

MTC-17, " Maintenance of Oil Quanti-

ty in Compressor " .

Refer to

MTC-17, " Maintenance of Oil

Quantity in Compressor " .

Type

HFC-134a (R-134a)

Capacity

kg (lb) 0.45

± 0.05 (0.99 ± 0.11)

Page 4000 of 4331

PG

N

O P

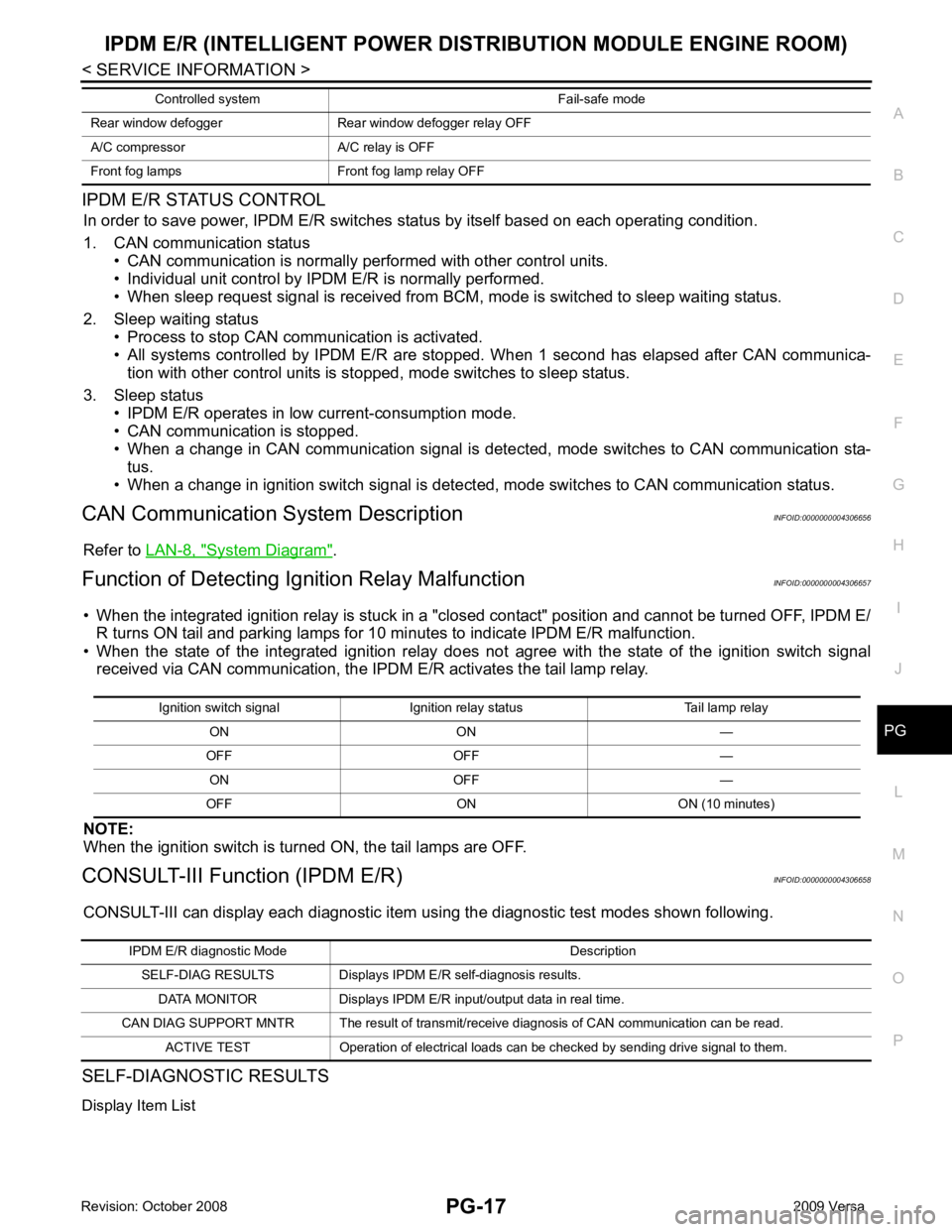

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status • CAN communication is normally performed with other control units.

• Individual unit control by IPDM E/R is normally performed.

• When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status • Process to stop CAN communication is activated.

• All systems controlled by IPDM E/R are stopped. When 1 second has elapsed after CAN communica-

tion with other control units is st opped, mode switches to sleep status.

3. Sleep status • IPDM E/R operates in low current-consumption mode.

• CAN communication is stopped.

• When a change in CAN communication signal is detec ted, mode switches to CAN communication sta-

tus.

• When a change in ignition switch signal is detect ed, mode switches to CAN communication status.

CAN Communication System Description INFOID:0000000004306656

Refer to LAN-8, " System Diagram " .

Function of Detecting Ig nition Relay Malfunction INFOID:0000000004306657

• When the integrated ignition relay is stuck in a "clo sed contact" position and cannot be turned OFF, IPDM E/

R turns ON tail and parking lamps for 10 mi nutes to indicate IPDM E/R malfunction.

• When the state of the integrated ignition relay does not agree with the state of the ignition switch signal

received via CAN communication, the IPDM E/R activates the tail lamp relay.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

CONSULT-III Function (IPDM E/R) INFOID:0000000004306658

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay is OFF

Front fog lamps Front fog lamp relay OFF Controlled system Fail-safe mode Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF — ON OFF —

OFF ON ON (10 minutes) IPDM E/R diagnostic Mode Description

SELF-DIAG RESULTS Displays IPDM E/R self-diagnosis results.

DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 4001 of 4331

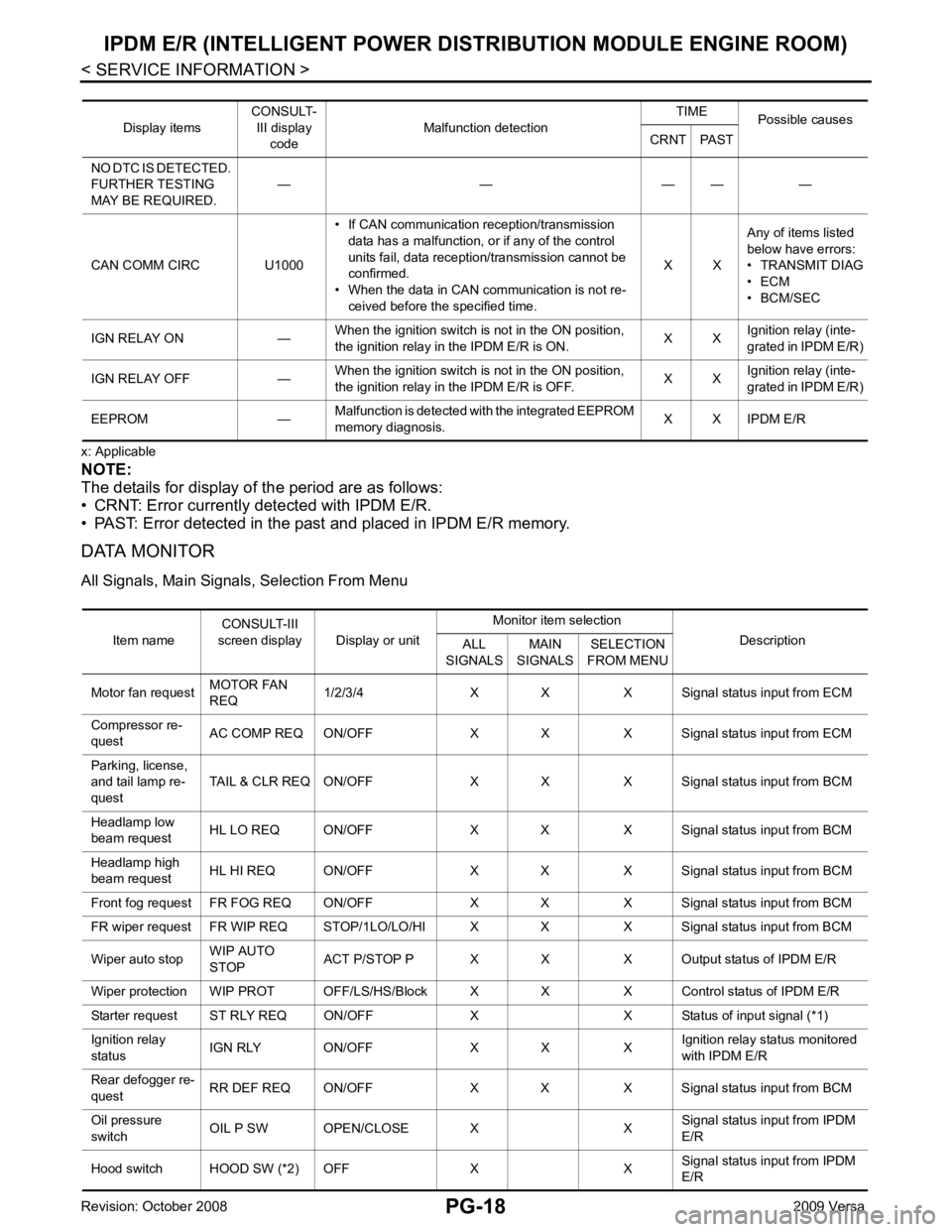

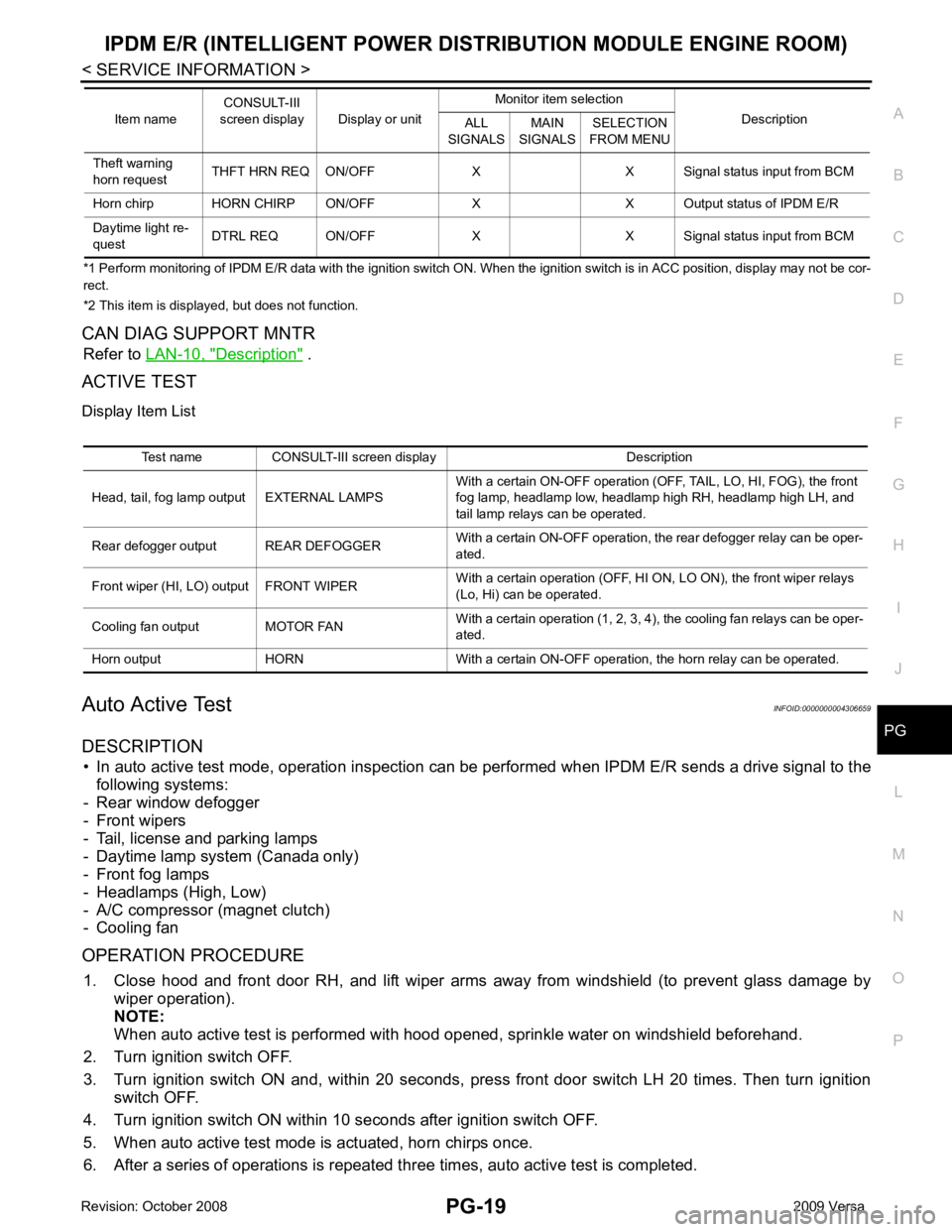

Item name

CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ 1/2/3/4 X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF X X X Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF X X X Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF X X X Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF X X X Signal

status input from BCM

Front fog request FR FOG REQ ON/OFF X X X Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOP ACT P/STOP P X X X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF X X Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF X X X Ignition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF X X X Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X X

Signal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF X X Signal status input from IPDM

E/R

Page 4002 of 4331

PG

N

O P

*1 Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position, display may no

t be cor-

rect.

*2 This item is displayed, but does not function.

CAN DIAG SUPPORT MNTR Refer to LAN-10, " Description " .

ACTIVE TEST

Display Item List

Auto Active Test INFOID:0000000004306659

DESCRIPTION • In auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to the

following systems:

- Rear window defogger

- Front wipers

- Tail, license and parking lamps

- Daytime lamp system (Canada only)

- Front fog lamps

- Headlamps (High, Low)

- A/C compressor (magnet clutch)

- Cooling fan

OPERATION PROCEDURE 1. Close hood and front door RH, and lift wiper arms away from windshield (to prevent glass damage by

wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON and, within 20 seconds, pre ss front door switch LH 20 times. Then turn ignition

switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, horn chirps once.

6. After a series of operations is repeated th ree times, auto active test is completed.

Theft warning

horn request THFT HRN REQ ON/OFF X X Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF X X O utput status of IPDM E/R

Daytime light re-

quest DTRL REQ ON/OFF X X Signal

status input from BCM

Item name

CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU Test name CONSULT-III screen display Description

Head, tail, fog lamp output EXTERNAL LAMPS With a certain ON-OFF operation (OFF, TAIL, LO, HI, FOG), the front

fog lamp, headlamp low, headlamp high RH, headlamp high LH, and

tail lamp relays can be operated.

Rear defogger output REAR DEFOGGER With a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPER With a certain operation (OFF, HI ON, LO ON), the front wiper relays

(Lo, Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan relays can be oper-

ated.

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

Page 4028 of 4331

PG

N

O P

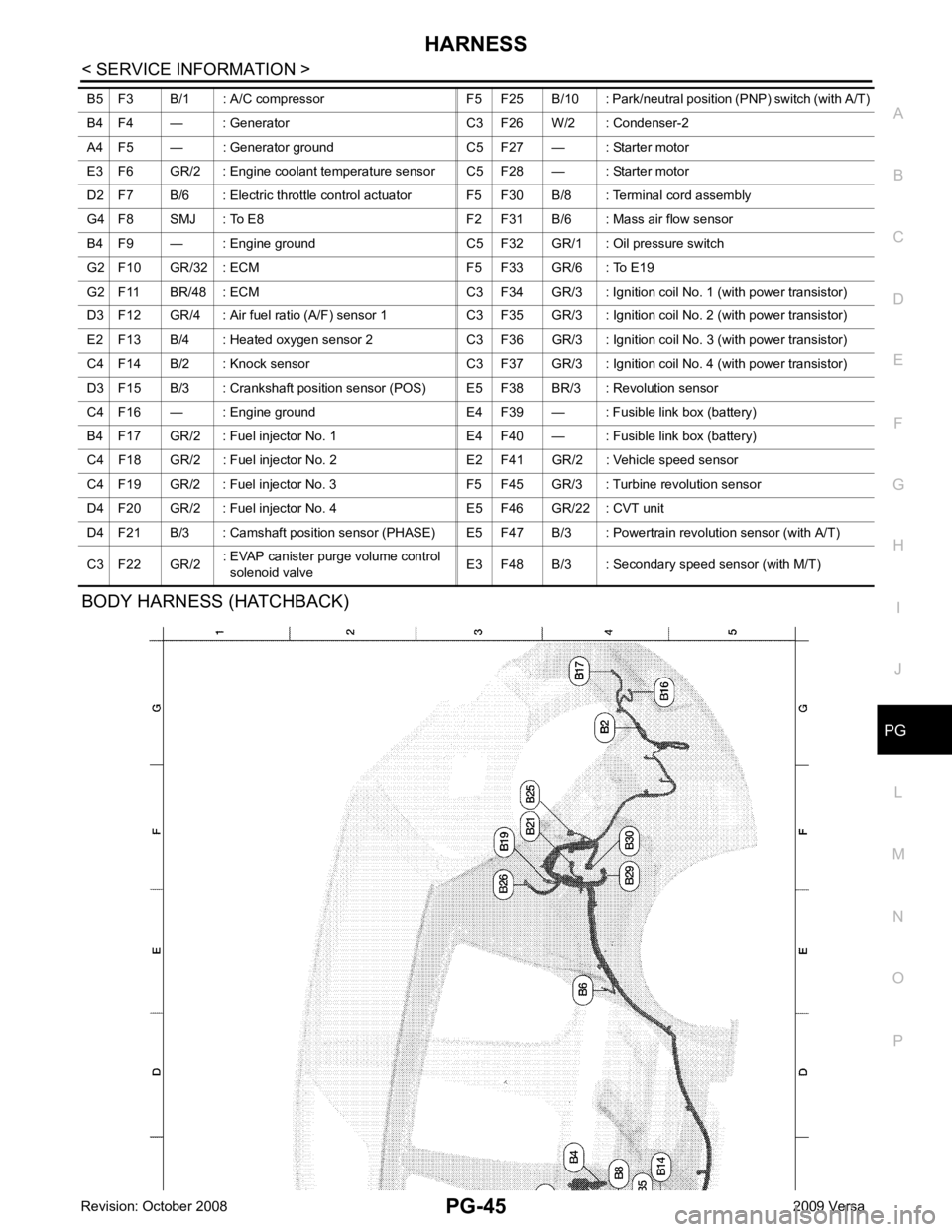

BODY HARNESS (HATCHBACK) B5 F3 B/1 : A/C compressor F5 F25 B/10 : Park/n

eutral position (PNP) switch (with A/T)

B4 F4 — : Generator C3 F26 W/2 : Condenser-2

A4 F5 — : Generator ground C5 F27 — : Starter motor

E3 F6 GR/2 : Engine coolant temperature sensor C5 F28 — : Starter motor

D2 F7 B/6 : Electric throttle control actuator F5 F30 B/8 : Terminal cord assembly

G4 F8 SMJ : To E8 F2 F31 B/6 : Mass air flow sensor

B4 F9 — : Engine ground C5 F32 GR/1 : Oil pressure switch

G2 F10 GR/32 : ECM F5 F33 GR/6 : To E19

G2 F11 BR/48 : ECM C3 F34 GR/3 : Ignition coil No. 1 (with power transistor)

D3 F12 GR/4 : Air fuel ratio (A/F) sensor 1 C3 F35 GR/3 : Ignition coil No. 2 (with power transistor)

E2 F13 B/4 : Heated oxygen sensor 2 C3 F36 GR/3 : Ignition coil No. 3 (with power transistor)

C4 F14 B/2 : Knock sensor C3 F37 GR/3 : Ignition coil No. 4 (with power transistor)

D3 F15 B/3 : Crankshaft position sensor (POS) E5 F38 BR/3 : Revolution sensor

C4 F16 — : Engine ground E4 F39 — : Fusible link box (battery)

B4 F17 GR/2 : Fuel injector No. 1 E4 F40 — : Fusible link box (battery)

C4 F18 GR/2 : Fuel injector No. 2 E2 F41 GR/2 : Vehicle speed sensor

C4 F19 GR/2 : Fuel injector No. 3 F5 F45 GR/3 : Turbine revolution sensor

D4 F20 GR/2 : Fuel injector No. 4 E5 F46 GR/22 : CVT unit

D4 F21 B/3 : Camshaft position sensor (PHASE) E5 F4 7 B/3 : Powertrain revolution sensor (with A/T)

C3 F22 GR/2 : EVAP canister purge volume control

solenoid valve E3 F48 B/3 : Secondary speed sensor (with M/T)