engine coolant NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 913 of 4331

CO

NP

O

Removal and Installation

INFOID:0000000004784360

REMOVAL 1. Drain engine coolant from radiator. Refer to CO-11, " Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove air duct (inlet). Refer to EM-26, " Exploded View " .

3. Remove reservoir tank.

4. Disconnect radiator hose (upper) at radiator side. Refer to CO-16, " Component " .

5. Disconnect harness connectors from fan motor, and move harness to aside.

6. Remove cooling fan assembly. CAUTION:

Be careful not to damage or scratch the radiator core.

INSTALLATION Installation is the reverse order of removal.

• Cooling fans are controlled by ECM. For details, refer to EC-422, " Description " .

CAUTION:

Be careful not to damage or scratch the radiator core.

Page 914 of 4331

Changing Engine Coolant " .

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belts.

2. Steer front wheel to the right.

3. Remove front fender protector (RH). Refer to EI-24, " Removal and Installation " .

4. Loosen mounting bolts of water pump pulley before loosening belt tension of drive belt.

5. Remove drive belt. Refer to EM-15, " Removal and Installation " .

6. Remove water pump pulley.

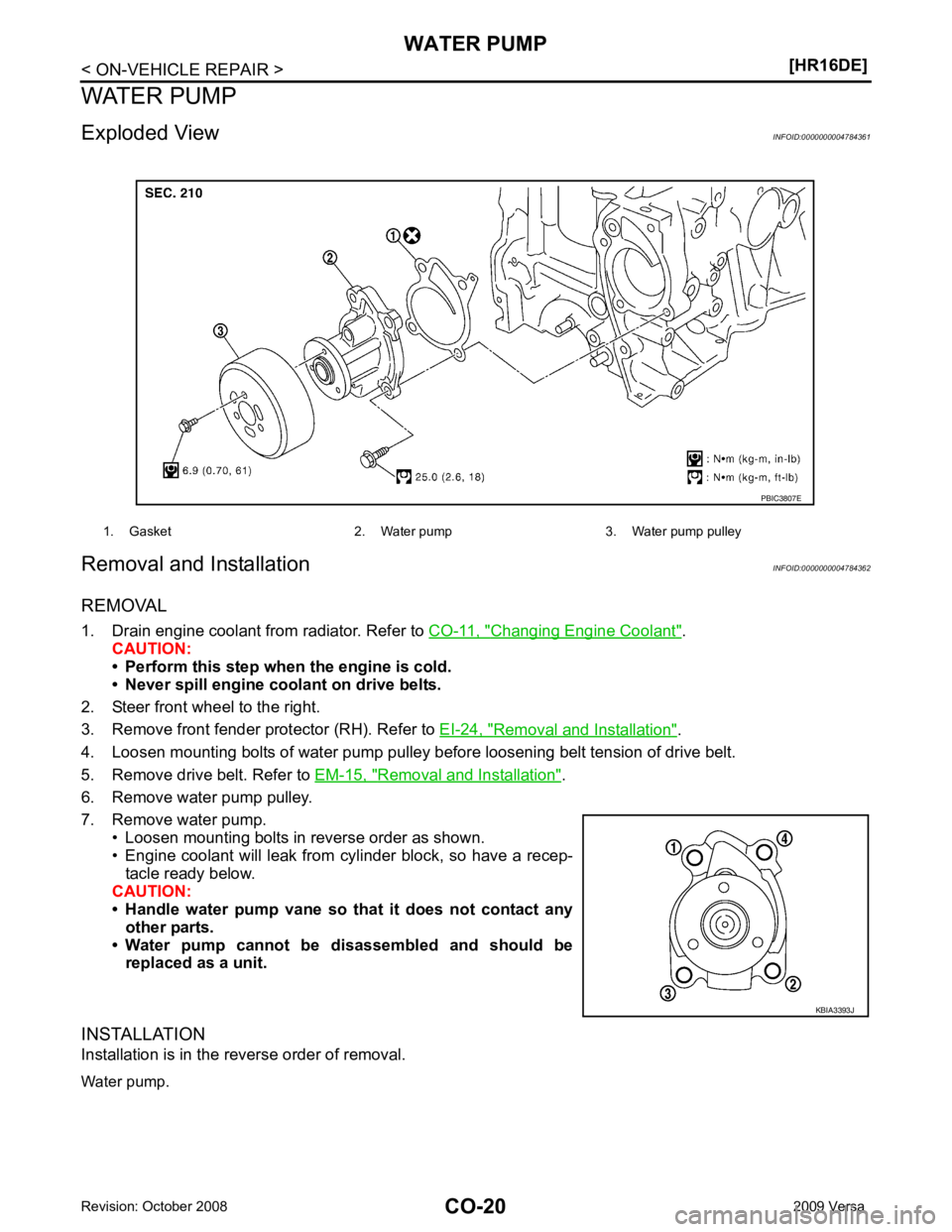

7. Remove water pump. • Loosen mounting bolts in reverse order as shown.

• Engine coolant will leak from cylinder block, so have a recep-

tacle ready below.

CAUTION:

• Handle water pump vane so that it does not contact any

other parts.

• Water pump cannot be disassembled and should be replaced as a unit.

INSTALLATION

Installation is in the reverse order of removal.

Water pump. 1. Gasket 2. Water pump 3. Water pump pulley

KBIA3393J

Page 915 of 4331

CO

NP

O

• Tighten bolts in numerical order as shown.

Water pump pulley. CAUTION:

Never install mounting bolts (A) to oblong holes (B).

• Water pump pulley (1)

Inspection INFOID:0000000004784363

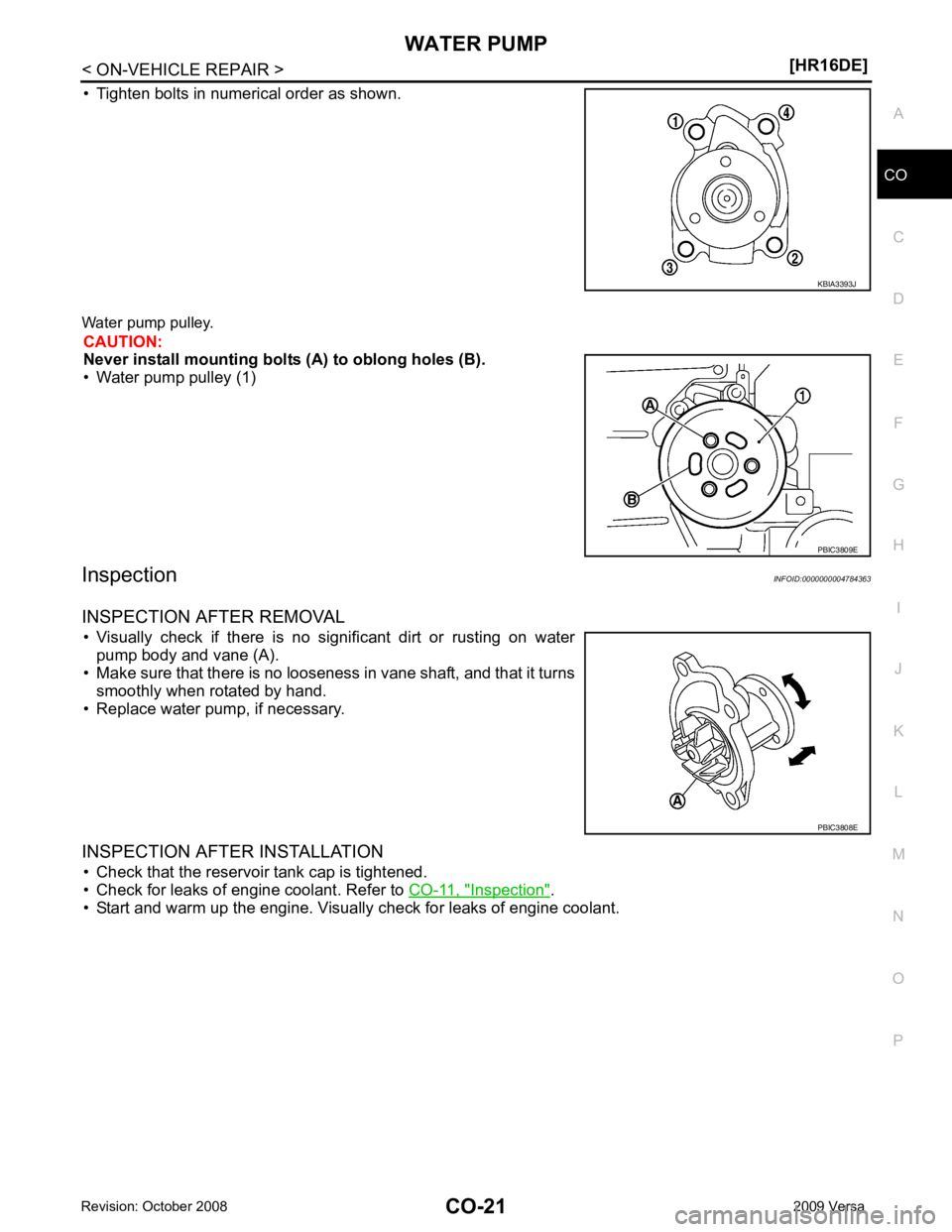

INSPECTION AFTER REMOVAL • Visually check if there is no significant dirt or rusting on water pump body and vane (A).

• Make sure that there is no looseness in vane shaft, and that it turns

smoothly when rotated by hand.

• Replace water pump, if necessary.

INSPECTION AFTER INSTALLATION • Check that the reservoir tank cap is tightened.

• Check for leaks of engine coolant. Refer to CO-11, " Inspection " .

• Start and warm up the engine. Visually check for leaks of engine coolant. PBIC3809E

Page 916 of 4331

Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Never spill engine coolant on drive belt.

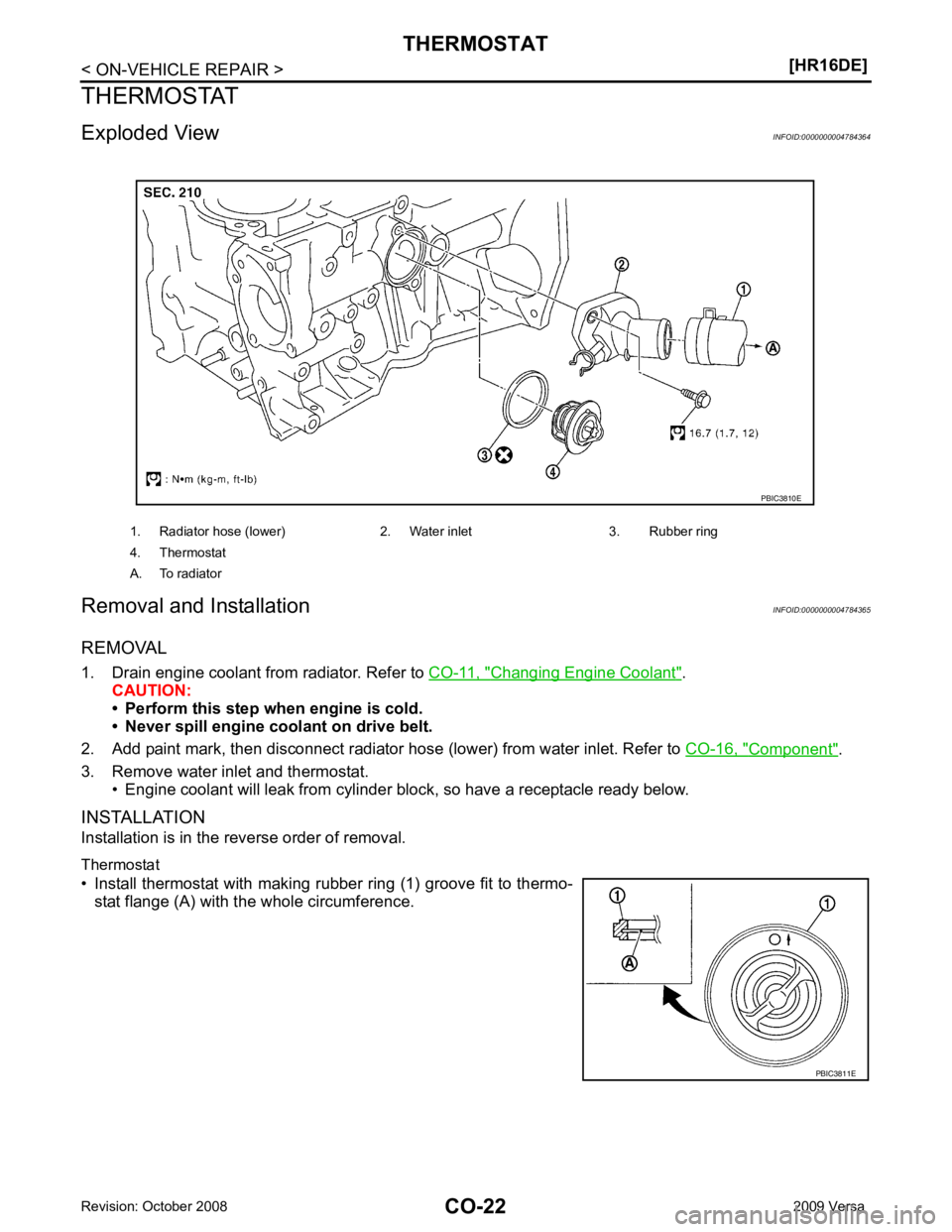

2. Add paint mark, then disconnect radiator hose (lower) from water inlet. Refer to CO-16, " Component " .

3. Remove water inlet and thermostat. • Engine coolant will leak from cylinder block, so have a receptacle ready below.

INSTALLATION

Installation is in the reverse order of removal.

Thermostat

• Install thermostat with making rubber ring (1) groove fit to thermo- stat flange (A) with the whole circumference. 1. Radiator hose (lower) 2. Water inlet 3. Rubber ring

4. Thermostat

A. To radiator PBIC3811E

Page 917 of 4331

CO

NP

O

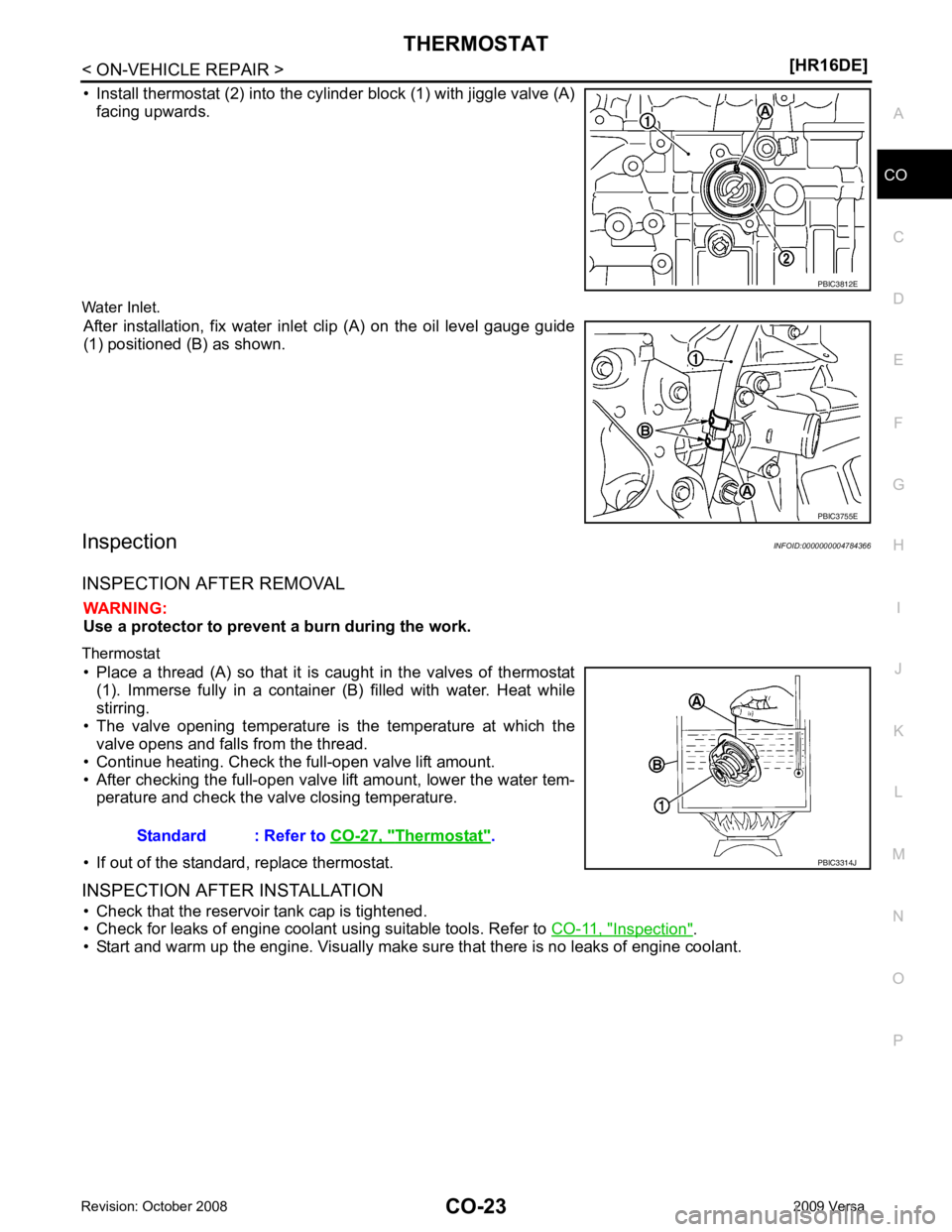

• Install thermostat (2) into the cylinder block (1) with jiggle valve (A)

facing upwards.

Water Inlet. After installation, fix water inlet clip (A) on the oil level gauge guide

(1) positioned (B) as shown.

Inspection INFOID:0000000004784366

INSPECTION AFTER REMOVAL WARNING:

Use a protector to prevent a burn during the work.

Thermostat • Place a thread (A) so that it is caught in the valves of thermostat (1). Immerse fully in a container (B) filled with water. Heat while

stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full-open valve lift amount.

• After checking the full-open valve lift amount, lower the water tem- perature and check the valve closing temperature.

• If out of the standard, replace thermostat.

INSPECTION AFTER INSTALLATION • Check that the reservoir tank cap is tightened.

• Check for leaks of engine coolant using suitable tools. Refer to CO-11, " Inspection " .

• Start and warm up the engine. Visually make sure that there is no leaks of engine coolant. PBIC3755E

Thermostat " .

Page 918 of 4331

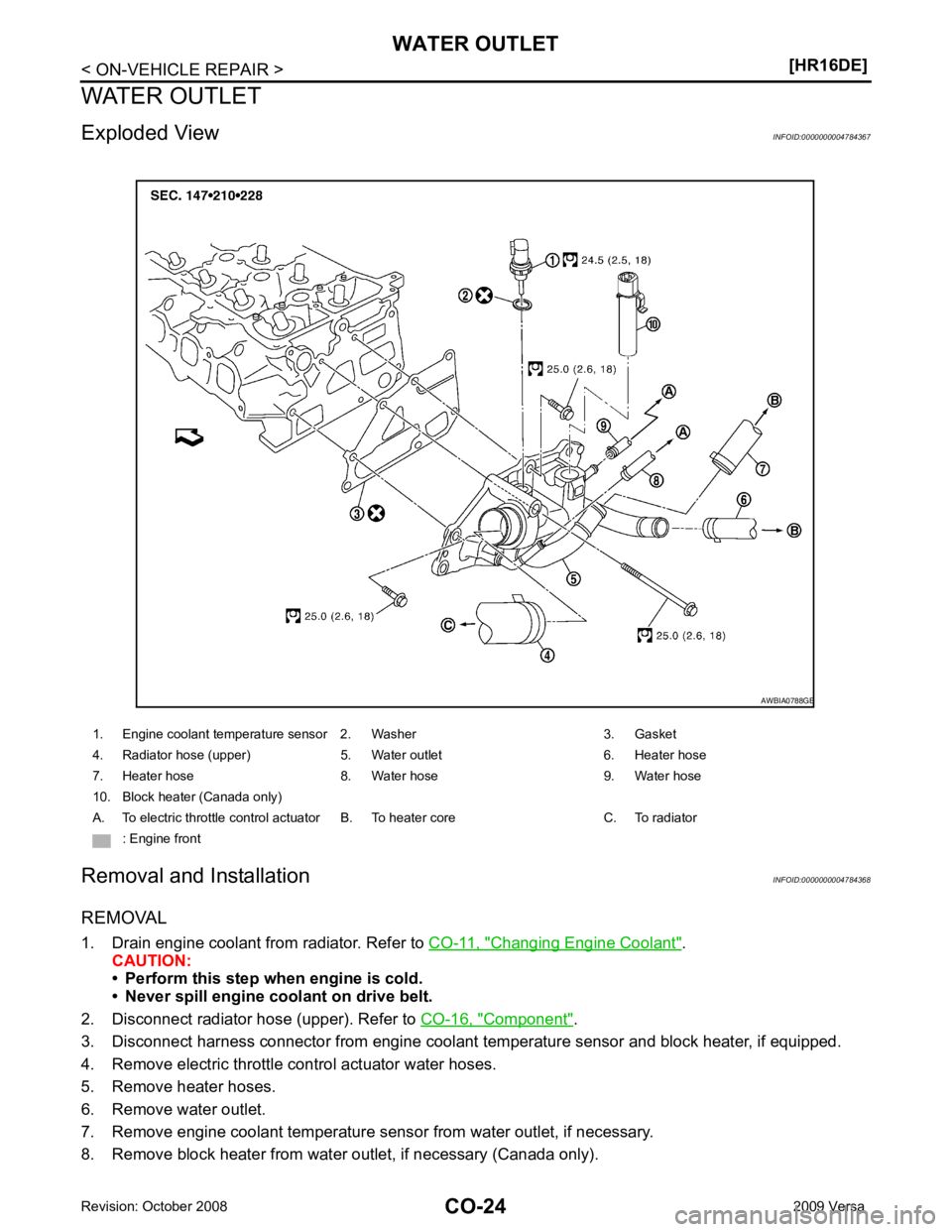

Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Never spill engine coolant on drive belt.

2. Disconnect radiator hose (upper). Refer to CO-16, " Component " .

3. Disconnect harness connector from engine coolant temperature sensor and block heater, if equipped.

4. Remove electric throttle control actuator water hoses.

5. Remove heater hoses.

6. Remove water outlet.

7. Remove engine coolant temperature sens or from water outlet, if necessary.

8. Remove block heater from water outlet, if necessary (Canada only). 1. Engine coolant temperature sensor 2. Washer 3. Gasket

4. Radiator hose (upper) 5. Water outlet 6. Heater hose

7. Heater hose 8. Water hose 9. Water hose

10. Block heater (Canada only)

A. To electric throttle control actuator B. To heater core C. To radiator : Engine front

Page 919 of 4331

CO

NP

O

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Insert the block heater into the water outlet until the clip is fully locked (Canada only).

Inspection INFOID:0000000004784369

INSPECTION AFTER INSTALLATION • Check that the reservoir tank cap is tightened.

• Check for leaks of engine coolant using suitable tool. Refer to CO-11, " Inspection " .

• Start and warm up the engine. Visually make sure that there is no leaks of engine coolant.

Page 921 of 4331

CO

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

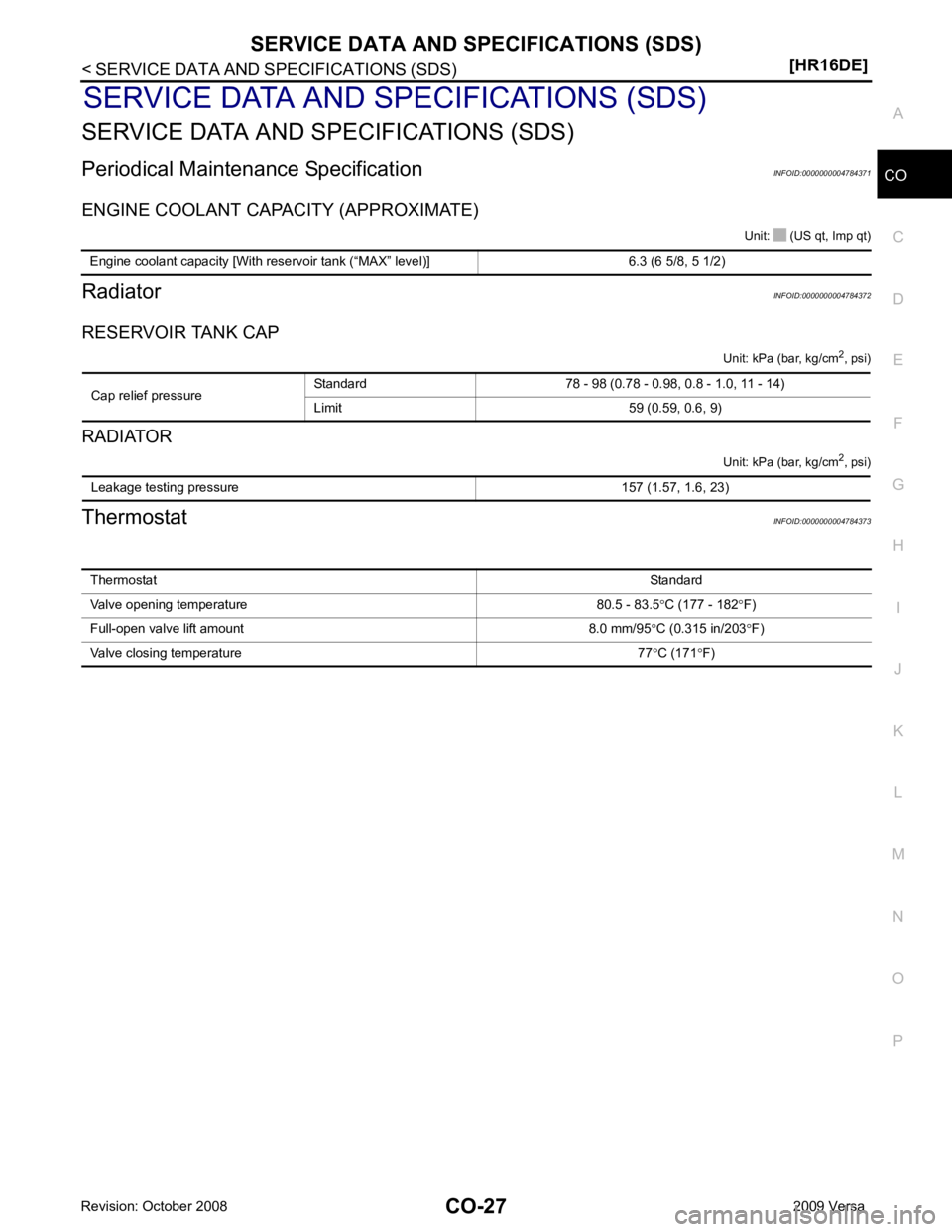

Periodical Maintenance Specification INFOID:0000000004784371

ENGINE COOLANT CAPACITY (APPROXIMATE) Unit: (US qt, Imp qt)

Radiator INFOID:0000000004784372

RESERVOIR TANK CAP Unit: kPa (bar, kg/cm2

, psi)

RADIATOR Unit: kPa (bar, kg/cm2

, psi)

Thermostat INFOID:0000000004784373Cap relief pressure

Standard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 (0.59, 0.6, 9) Leakage testing pressure 157 (1.57, 1.6, 23)

Thermostat

Standard

Valve opening temperature 80.5 - 83.5 °C (177 - 182 °F)

Full-open valve lift amount 8.0 mm/95 °C (0.315 in/203 °F)

Valve closing temperature 77°C (171 °F)

Page 923 of 4331

![NISSAN TIIDA 2009 Service User Guide PRECAUTIONS

CO-29

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Precaution for Liquid Gasket

INFOID:0000000004305229

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bol NISSAN TIIDA 2009 Service User Guide PRECAUTIONS

CO-29

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Precaution for Liquid Gasket

INFOID:0000000004305229

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bol](/img/5/57398/w960_57398-922.png)

PRECAUTIONS

CO-29

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Precaution for Liquid Gasket

INFOID:0000000004305229

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE 1. Remove old liquid gasket adhering to the liquid gasket applica- tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-42, " Recommended Chemical Prod-

uct and Sealant " .

4. Apply liquid gasket without breaks to the spec ified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

• As for the bolt holes, normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 924 of 4331

![NISSAN TIIDA 2009 Service User Guide CO-30< SERVICE INFORMATION >

[MR18DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004673018

The actual shapes of Kent-Moore tools may from those of special service tools illustrated he NISSAN TIIDA 2009 Service User Guide CO-30< SERVICE INFORMATION >

[MR18DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004673018

The actual shapes of Kent-Moore tools may from those of special service tools illustrated he](/img/5/57398/w960_57398-923.png)

CO-30< SERVICE INFORMATION >

[MR18DE]

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000004673018

The actual shapes of Kent-Moore tools may from those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004673019

Tool number

(Kent-Moore No.)

Tool name Description

WS39930000

( — )

Tube pressure Pressing the tube of liquid gasket

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV10111100

(J-37228)

Seal cutter Removing chain tensioner cover and water

pump cover

—

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant S-NT052

LMA053

S-NT564

NT046

WBIA0539E