weight NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1651 of 4331

![NISSAN TIIDA 2009 Service User Guide P0443 EVAP CANISTER PURGE VOLU

ME CONTROL SOLENOID VALVE

EC-295

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Reconnect harness connectors disconnected.

3. Start engine.

4. Perfo NISSAN TIIDA 2009 Service User Guide P0443 EVAP CANISTER PURGE VOLU

ME CONTROL SOLENOID VALVE

EC-295

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Reconnect harness connectors disconnected.

3. Start engine.

4. Perfo](/img/5/57398/w960_57398-1650.png)

P0443 EVAP CANISTER PURGE VOLU

ME CONTROL SOLENOID VALVE

EC-295

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Reconnect harness connectors disconnected.

3. Start engine.

4. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT- III. Check that engine speed var-

ies according to the valve opening.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

CHECK EVAP CANISTER PURGE VO LUME CONTROL SOLENOID VALVE

Refer to EC-296, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP canister purge volume control solenoid valve. 8.

CHECK RUBBER TUBE FOR CLOGGING

1. Disconnect rubber tube connected to EV AP canister vent control valve.

2. Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 9.

NO >> Clean the rubber tube using an air blower. 9.

CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-304, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace EVAP canister vent control valve. 10.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?YES >> GO TO 11.

NO >> GO TO 13. 11.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EV AP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 13.

NO >> GO TO 12. 12.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehi cle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. 13.

CHECK INTERMITTENT INCIDENT PBIB1213E

Page 1665 of 4331

![NISSAN TIIDA 2009 Service User Guide P0448 EVAP CANISTER VENT CONTROL VALVE

EC-309

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Is the inspection result normal? YES >> GO TO 2.

NO >> Clean rubber tube using an air blo NISSAN TIIDA 2009 Service User Guide P0448 EVAP CANISTER VENT CONTROL VALVE

EC-309

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Is the inspection result normal? YES >> GO TO 2.

NO >> Clean rubber tube using an air blo](/img/5/57398/w960_57398-1664.png)

P0448 EVAP CANISTER VENT CONTROL VALVE

EC-309

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

Is the inspection result normal? YES >> GO TO 2.

NO >> Clean rubber tube using an air blower. 2.

CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-310, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace EVAP canister vent control valve. 3.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Check if water will drain from the EVAP canister.

Does water drain from EVAP canister? YES >> GO TO 4.

NO >> GO TO 6. 4.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EV AP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5. 5.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehi cle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. 6.

CHECK EVAP CONTRO L SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check connectors for water.

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace EVAP control system pressure sensor. 7.

CHECK EVAP CONTROL SYS TEM PRESSURE SENSOR

Refer to EC-314, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP control system pressure sensor. 8.

CHECK INTERMITTENT INCIDENT

Refer to EC-120, " Diagnosis Procedure " . PBIB1213E

Water should not exist.

Page 1684 of 4331

![NISSAN TIIDA 2009 Service User Guide EC-328< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR 18.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pres NISSAN TIIDA 2009 Service User Guide EC-328< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR 18.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pres](/img/5/57398/w960_57398-1683.png)

EC-328< COMPONENT DIAGNOSIS >

[HR16DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR 18.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 15.

NO >> GO TO 14. 19.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. 20.

CHECK INTERMITTENT INCIDENT

Refer to EC-120, " Diagnosis Procedure " .

>> INSPECTION END

Component Inspection INFOID:00000000047804521.

CHECK EVAP CONTROL SY STEM PRESSURE SENSOR

1. Turn ignition switch OFF.

2. Remove EVAP control system pressure sensor wit h its harness connector connected from EVAP canister.

Always replace O-ring with a new one.

3. Install a vacuum pump to EVAP control system pressure sensor.

4. Turn ignition switch ON and check output voltage between ECM

harness connector and ground under the following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Do not apply below -93.3 kPa (-0.952 kg/cm 2

, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/

cm 2

, 14.69 psi).

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVAP control system pressure sensor ECM Condition

[Applied vacuum kPa

(kg/cm 2

, psi) Voltage

Connector Terminal

F11 42

(EVAP control system

pressure sensor signal) Not applied 1.8 - 4.8 V

-26.7 (-0.272, -3.87) 2.1 to 2.5 V lower

than above value PBIB3314E

Page 1694 of 4331

![NISSAN TIIDA 2009 Service User Guide EC-338< COMPONENT DIAGNOSIS >

[HR16DE]

P0456 EVAP CONTROL SYSTEM

Is the inspection result normal? YES >> GO TO 3.

NO >> Open fuel filler cap, then clean cap and fuel filler neck threads us NISSAN TIIDA 2009 Service User Guide EC-338< COMPONENT DIAGNOSIS >

[HR16DE]

P0456 EVAP CONTROL SYSTEM

Is the inspection result normal? YES >> GO TO 3.

NO >> Open fuel filler cap, then clean cap and fuel filler neck threads us](/img/5/57398/w960_57398-1693.png)

EC-338< COMPONENT DIAGNOSIS >

[HR16DE]

P0456 EVAP CONTROL SYSTEM

Is the inspection result normal? YES >> GO TO 3.

NO >> Open fuel filler cap, then clean cap and fuel filler neck threads using air blower. Then retighten

until ratcheting sound is heard. 3.

CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4. 4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-340, " Component Inspection (Fuel filler cap) " .

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace fuel filler cap with a genuine one. 5.

CHECK FOR EVAP LEAK

Refer to EC-500, " Inspection " .

Is there any leak in EVAP line? YES >> Repair or replace.

NO >> GO TO 6. 6.

CHECK DRAIN FILTER

Refer to EC-341, " Component Inspection (Drain filter) " .

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace drain filter. 7.

CHECK EVAP CANISTER VENT CONTROL VALVE

Check the following.

• EVAP canister vent control valve is installed properly.

Refer to EC-502, " Exploded View " .

• EVAP canister vent control valve. Refer to EC-304, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace EVAP cani ster vent control valve and O-ring.8.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2. Check if water will drain from the EVAP canister.

Does water drain from EVAP canister? YES >> GO TO 9.

NO-1 >> With CONSULT-III: GO TO 11.

NO-2 >> Without CONSULT-III: GO TO 12. 9.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 1.9 kg (4.2 lb). PBIB1213E

Page 1807 of 4331

![NISSAN TIIDA 2009 Service User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-451

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

B: Cannot refuel/Fuel odor from the fuel

filler opening is strong while refueling.

Whi NISSAN TIIDA 2009 Service User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-451

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

B: Cannot refuel/Fuel odor from the fuel

filler opening is strong while refueling.

Whi](/img/5/57398/w960_57398-1806.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-451

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

B: Cannot refuel/Fuel odor from the fuel

filler opening is strong while refueling.

Which symptom is present? A >> GO TO 2.

B >> GO TO 8. 2.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 4. 3.

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?YES >> GO TO 4.

NO >> GO TO 7. 4.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 5. 5.

CHECK DRAIN FILTER

Refer to EC-455, " Component Inspection (Drain filter) " .

Is the inspection result normal? OK >> GO TO 6.

NO >> Replace drain filter. 6.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose. 7.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-453, " Component Inspection (Refueling EVAP vapor cut valve) " .

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace refueling EVAP vapor cut valve with fuel tank. 8.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

Is the inspection result normal? PBIB1213E

Page 1845 of 4331

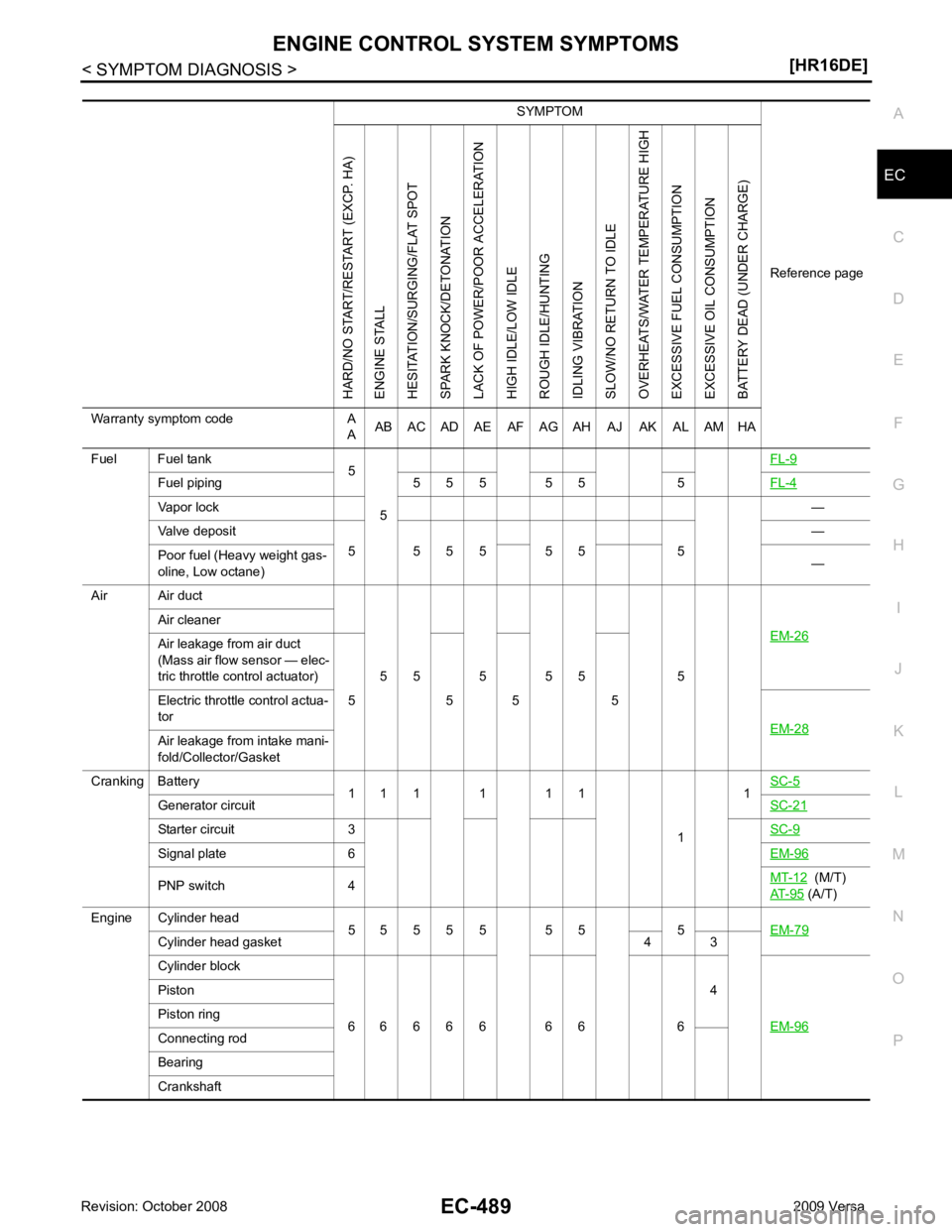

EC

NP

O

SYMPTOM

Reference pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code A AAB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-9Fuel piping 5 5 5 5 5 5

FL-4Vapor lock

—

Valve deposit 5 5 5 5 5 5 5 —

Poor fuel (Heavy weight gas-

oline, Low octane) —

Air Air duct

5 5 5 5 5 5 EM-26Air cleaner

Air leakage from air duct

(Mass air flow sensor — elec-

tric throttle control actuator)

5 5 5 5

Electric throttle control actua-

tor EM-28Air leakage from intake mani-

fold/Collector/Gasket

Cranking Battery 1 1 1 1 1 1

11

SC-5 Generator circuit

SC-21Starter circuit 3

SC-9Signal plate 6

EM-96PNP switch 4

MT-12 (M/T)

AT-95 (A/T)

Engine Cylinder head 5 5 5 5 5 5 5 5 EM-79Cylinder head gasket 4 3

Cylinder block

6 6 6 6 6 6 6 6 4

EM-96 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Page 1890 of 4331

![NISSAN TIIDA 2009 Service User Guide EC-534< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace NISSAN TIIDA 2009 Service User Guide EC-534< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace](/img/5/57398/w960_57398-1889.png)

EC-534< SERVICE INFOMATION >

[MR TYPE 1]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 4. 4.

DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose. 5.

CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-535, " Component Inspection " .

OK or NG OK >>

INSPECTION END

NG >> Replace refueling EVAP vapor cut valve with fuel tank.

SYMPTOM: CANNOT REFUEL/FUEL ODOR FROM THE FUEL FILLER OPENING IS STRONG

WHILE REFUELING. 1.

CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.9 kg (4.2 lb).

OK or NG OK >> GO TO 2.

NG >> GO TO 3. 2.

CHECK IF EVAP CANISTER SATURATED WITH WATER

Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 3.

No >> GO TO 5. 3.

REPLACE EVAP CANISTER

Replace EVAP canister with a new one. PBIB1213E

PBIB1213E

Page 1912 of 4331

), skip step 1.

1. Erase DTC in TCM.

2. Select "ENGINE" with CONSULT-III.

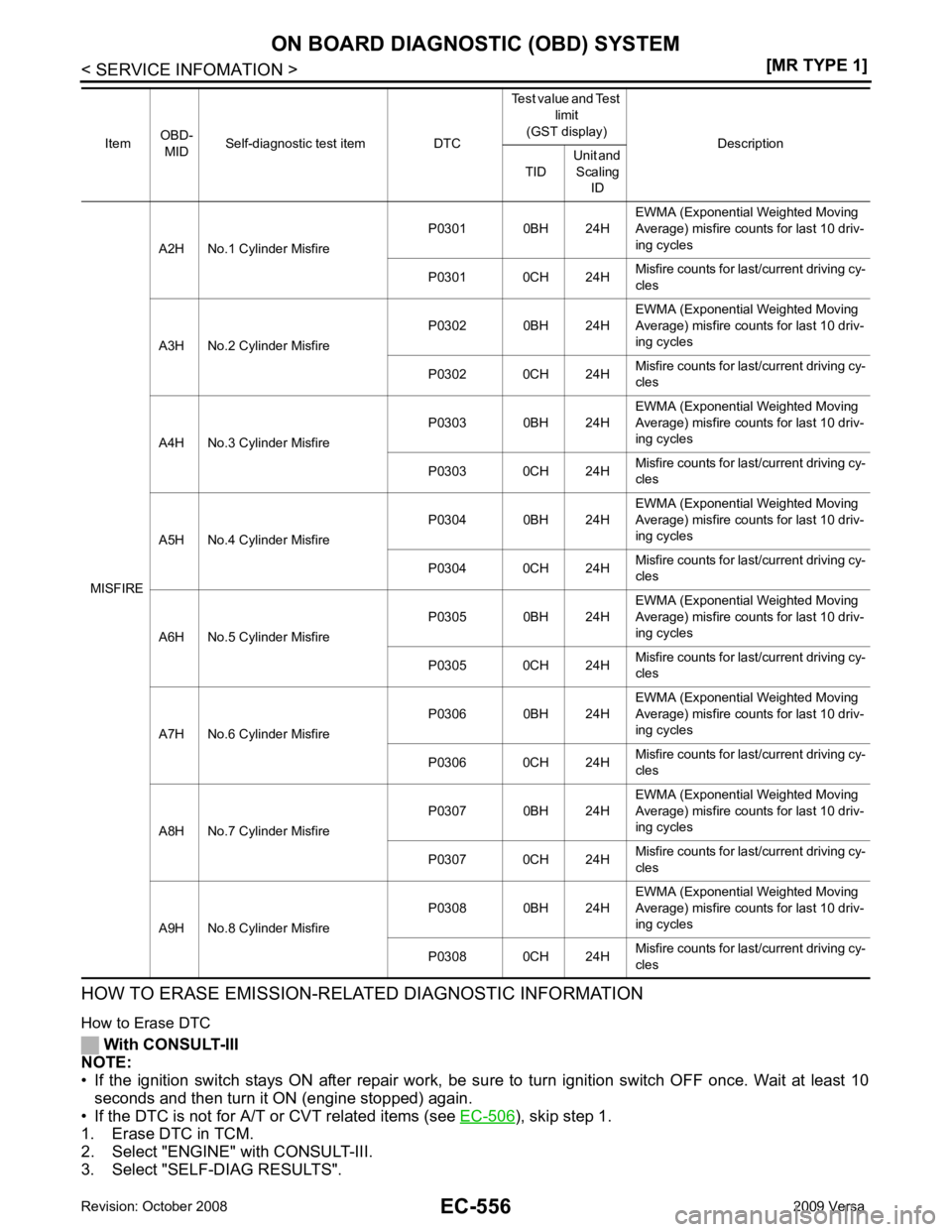

3. Select "SELF-DIAG RESULTS". MISFIRE

A2H No.1 Cylinder Misfire

P0301 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0301 0CH 24H Misfire counts for last/current driving cy-

cles

A3H No.2 Cylinder Misfire P0302 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0302 0CH 24H Misfire counts for last/current driving cy-

cles

A4H No.3 Cylinder Misfire P0303 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0303 0CH 24H Misfire counts for last/current driving cy-

cles

A5H No.4 Cylinder Misfire P0304 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0304 0CH 24H Misfire counts for last/current driving cy-

cles

A6H No.5 Cylinder Misfire P0305 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0305 0CH 24H Misfire counts for last/current driving cy-

cles

A7H No.6 Cylinder Misfire P0306 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0306 0CH 24H Misfire counts for last/current driving cy-

cles

A8H No.7 Cylinder Misfire P0307 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0307 0CH 24H Misfire counts for last/current driving cy-

cles

A9H No.8 Cylinder Misfire P0308 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0308 0CH 24H Misfire counts for last/current driving cy-

cles

Item

OBD-

MID Self-diagnostic test item DTC Test value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Page 1941 of 4331

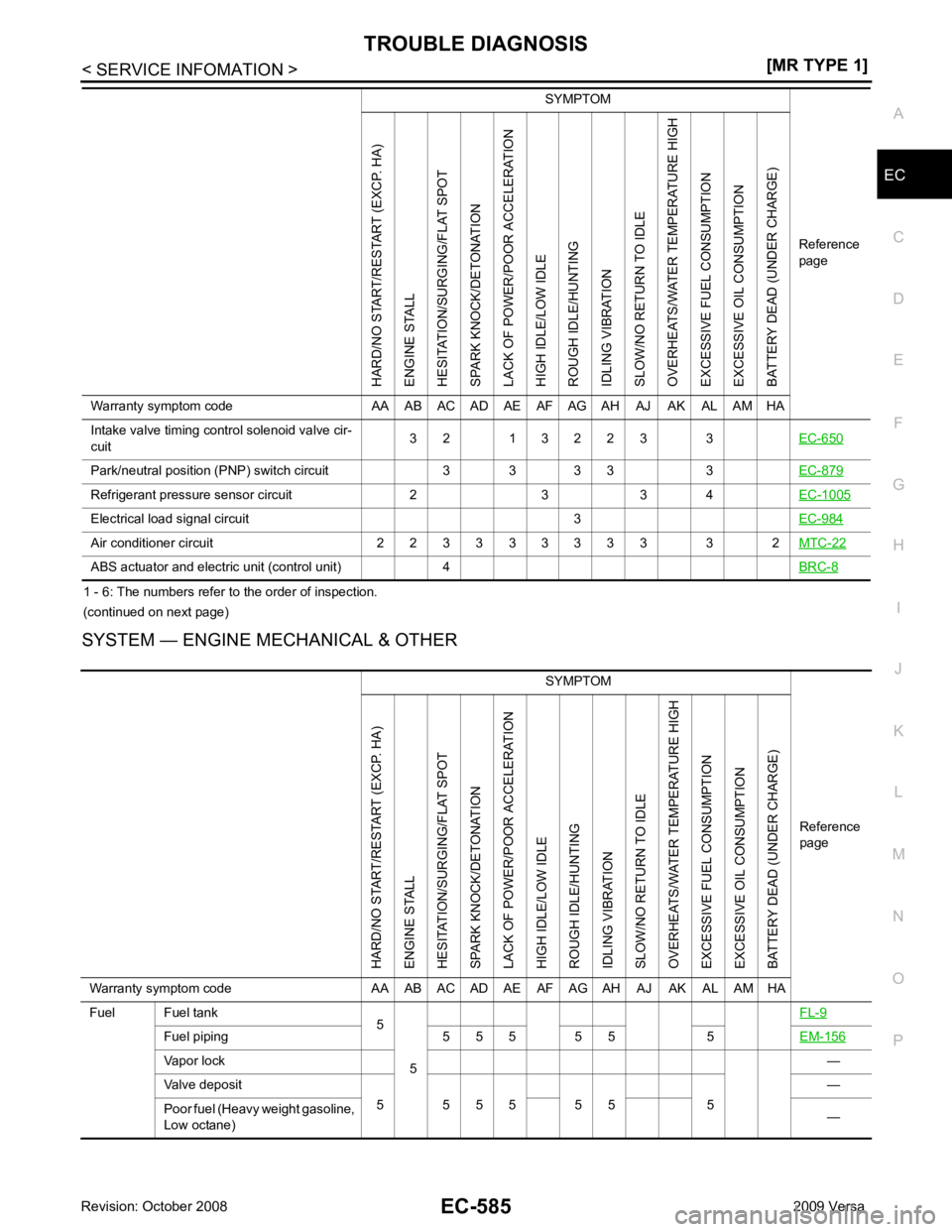

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER Intake valve timing control solenoid valve cir-

cuit 3 2 1 3 2 2 3 3

EC-650Park/neutral position (P

NP) switch circuit 3 3 3 3 3 EC-879Refrigerant pressure sensor circuit 2 3 3 4

EC-1005Electrical load signal circuit 3

EC-984Air conditioner circuit 2 2 3 3 3 3 3 3 3 3 2

MTC-22ABS actuator and electric unit (control unit) 4

BRC-8SYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-9Fuel piping 5 5 5 5 5 5

EM-156Vapor lock

—

Valve deposit 5 5 5 5 5 5 5 —

Poor fuel (Heavy weight gasoline,

Low octane) —

Page 2157 of 4331

![NISSAN TIIDA 2009 Service User Guide DTC P0442 EVAP CONTROL SYSTEM

EC-801

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 10.

No (With CONSULT-III)>> NISSAN TIIDA 2009 Service User Guide DTC P0442 EVAP CONTROL SYSTEM

EC-801

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 10.

No (With CONSULT-III)>>](/img/5/57398/w960_57398-2156.png)

DTC P0442 EVAP CONTROL SYSTEM

EC-801

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Does water drain from the EVAP canister?

Yes or No Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>>GO TO 13. 10.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sen-

sorattached.

The weight should be less than 1.9 kg (4.2 lb).

OK or NG OK (With CONSULT-III)>>GO TO 12.

OK (Without CONSULT-III)>>GO TO 13.

NG >> GO TO 11. 11.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose connected to EVAP canister for clogging or poor connection

>> Repair hose or replace EVAP canister. 12.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

1. Disconnect vacuum hose to EVAP canister purge volu me control solenoid valve at EVAP service port.

2. Start engine.

3. Perform “PURG VOL CONT/V ” in “ACTIVE TEST” mode.

4. Touch “Qu” on CONSULT-III screen to increase “PURG VOL CONT/V” opening to 100%.

5. Check vacuum hose for vacuum.

OK or NG OK >> GO TO 15.

NG >> GO TO 14. 13.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volu me control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG OK >> GO TO 16.

NG >> GO TO 14. 14.

CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to EC-594, " Vacuum Hose Drawing " .

OK or NG PBIB1213E

Vacuum should exist.

Vacuum should exist.