ESP NISSAN TIIDA 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1138 of 4331

CONSULT-III

Function (TRANSMISSION) " for the indicator used to display each self-diagnostic result.

• The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure on CVT-209, " OBD-II Diagnostic Trouble Code (DTC) " to complete the

repair and avoid unnecessary blinking of the MIL.

For details of OBD-II, refer to EC-1051, " Introduction " .

• Certain systems and components, esp ecially those related to OBD, may use the new style slide-lock-

ing type harness connector. For descrip tion and how to disconnect, refer to PG-64 .

Page 1147 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT SYSTEM

CVT-203

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Hydraulic Control System

INFOID:0000000004305575

TCM Function INFOID:0000000004305576

The function of the TCM is NISSAN TIIDA 2009 Service Owners Manual CVT SYSTEM

CVT-203

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

Hydraulic Control System

INFOID:0000000004305575

TCM Function INFOID:0000000004305576

The function of the TCM is](/img/5/57398/w960_57398-1146.png)

CVT SYSTEM

CVT-203

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

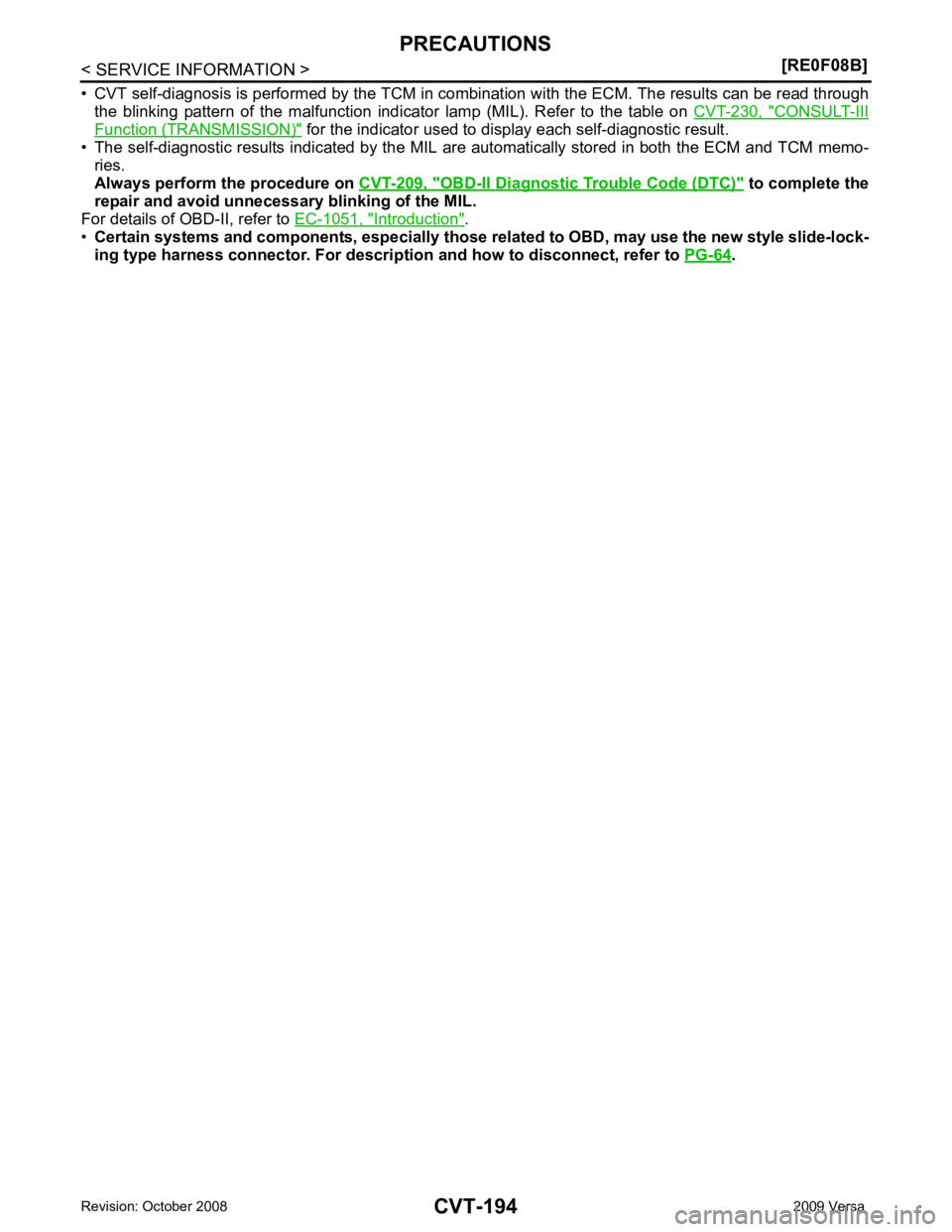

Hydraulic Control System

INFOID:0000000004305575

TCM Function INFOID:0000000004305576

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting point, and lock-up operation.

• Send required output signals to the step motor and the respective solenoids.

CONTROL SYSTEM OUTLINE The CVT senses vehicle operating conditions through vari ous sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks. SCIA1807E

SENSORS (or SIGNAL)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Overdrive control signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Secondary pressure sensor Shift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III co mmunication

line

Duet-EA control

CAN system

On board diagnosis Step motor

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid

valve

Shift position indicator

O/D OFF indicator lamp

Starter relay

Page 1153 of 4331

CVT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Introduction INFOID:0000000004305583

The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic syst em (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MI L (malfunction indicator lamp) and is stored as a DTC in

the ECM memory, and the TCM memory.

The second is the TCM original self-diagnosis perform ed by the TCM. The malfunction is stored in the TCM

memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail, refer to CVT-230," CONSULT-III Function (TRANSMISSION) " .

OBD-II Function for CVT System INFOID:0000000004305584

The ECM provides emission-related on board diagnostic (O BD-II) functions for the CVT system. One function

is to receive a signal from the TCM used with OBD-relat ed parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indica tor lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to CVT system parts.

One or Two Trip Detection Logic of OBD-II INFOID:0000000004305585

ONE TRIP DETECTION LOGIC If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC) INFOID:0000000004305586

HOW TO READ DTC AND 1ST TRIP DTC DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic troubl e code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONS ULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected curr ently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

Page 1157 of 4331

![NISSAN TIIDA 2009 Service Owners Manual TROUBLE DIAGNOSIS

CVT-213

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

If an unexpected signal is sent from the solenoid to t

he TCM, the CVT lock-up select solenoid is turned O NISSAN TIIDA 2009 Service Owners Manual TROUBLE DIAGNOSIS

CVT-213

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

If an unexpected signal is sent from the solenoid to t

he TCM, the CVT lock-up select solenoid is turned O](/img/5/57398/w960_57398-1156.png)

TROUBLE DIAGNOSIS

CVT-213

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

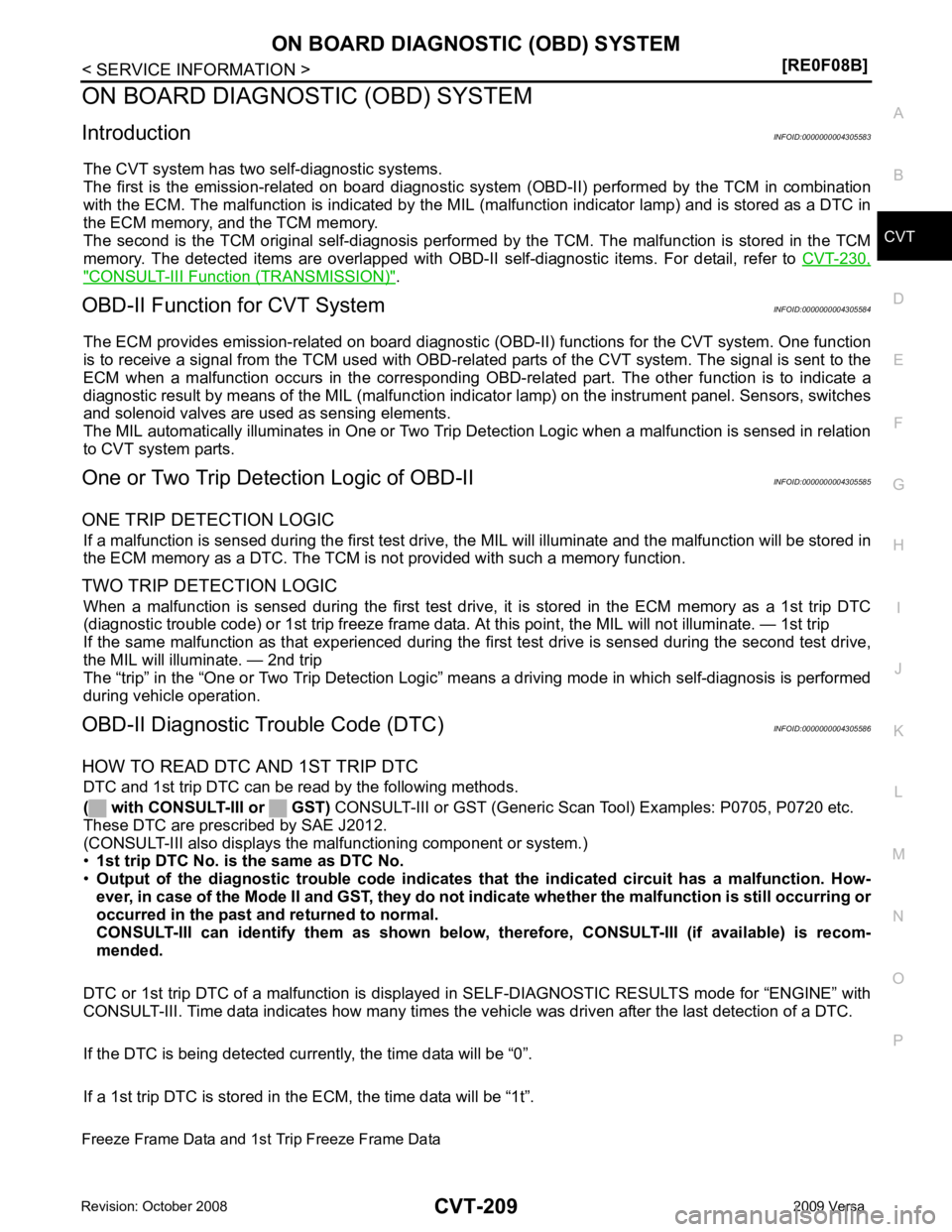

If an unexpected signal is sent from the solenoid to t

he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power Supply (Memory Back-up) Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for

controlling) from the battery is not supplied to TCM. Normal statues is restored when turning the ignition switch

OFF to ON after the normal power supply.

How to Perform Trouble Diagnosis for Quick and Accurate Repair INFOID:0000000004305590

INTRODUCTION The TCM receives a signal from the vehicle speed sensor , PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

CVT system for malfunction-diagnos tic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve mal-

function, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or impr oper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find t he cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “DIAGNOSTIC WORKSHEET” as

shown on the example (Refer to "Diagnostic Worksheet Chart" )

should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

WORK FLOW A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Make good use of the two sheets provided, "Informati on From Customer" and "Diagnostic Worksheet Chart" ,

to perform the best troubleshooting possible.

Work Flow Chart SAT631IB

SAT632I

SEF234G

Page 1217 of 4331

CVT

N

O P

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description INFOID:0000000004305682

• The pressure control solenoid valve A (line pressure solenoid valve) is included in the control valve assem- bly.

• The pressure control solenoid valve A (line pressure solenoid valve) regulates the oil pump discharge pres-

sure to suit the driving condition in response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305683

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305684

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745 L/PRESS SOL/CIRC” with CONSULT-III is detected under the following

conditions.

- TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM compares target value with monitor value and detects an irregularity.

Possible Cause INFOID:0000000004305685

• Harness or connectors (Solenoid circuit is open or shorted.)

• Pressure control solenoid valve A (Line pressure solenoid valve)

DTC Confirmation Procedure INFOID:0000000004305686

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Start engine and wait at least 5 seconds.

3. If DTC is detected, go to CVT-275, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

ISOLT2 Release your foot from the accelerator pedal. 0.8 A

Press the accelerator pedal all the way down. 0.0 A

Page 1237 of 4331

CVT

N

O P

DTC P0868 SECONDARY PRESSURE DOWN

Description INFOID:0000000004305730

• The pressure control solenoid valve B (secondary pressure solenoid valve) is included in the control valve assembly.

• The pressure control solenoid valve B (secondary pressure solenoid valve) regulates the secondary pres-

sure to suit the driving condition in response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305731

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305732

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0868 SEC/PRESS DOWN” with CONSULT-III is detected when secondary fluid

pressure is too low compared with the commanded value while driving.

Possible Cause INFOID:0000000004305733

• Harness or connectors (Solenoid circuit is open or shorted.)

• Pressure control solenoid valve B (Secondary pressure solenoid valve) system

• Transmission fluid pressure sensor A (Secondary pressure sensor)

• Line pressure control system

DTC Confirmation Procedure INFOID:0000000004305734

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Start engine and maintain the following conditions for at least 10 consecutive seconds. VEHICLE SPEED (accelerate slowly): 0 → 50 km/h (31 MPH)

ACC PEDAL OPEN: 0.5/8 - 1.0/8

RANGE: “D” position

4. If DTC is detected, go to CVT-293, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004305735

Page 1255 of 4331

CVT

N

O P

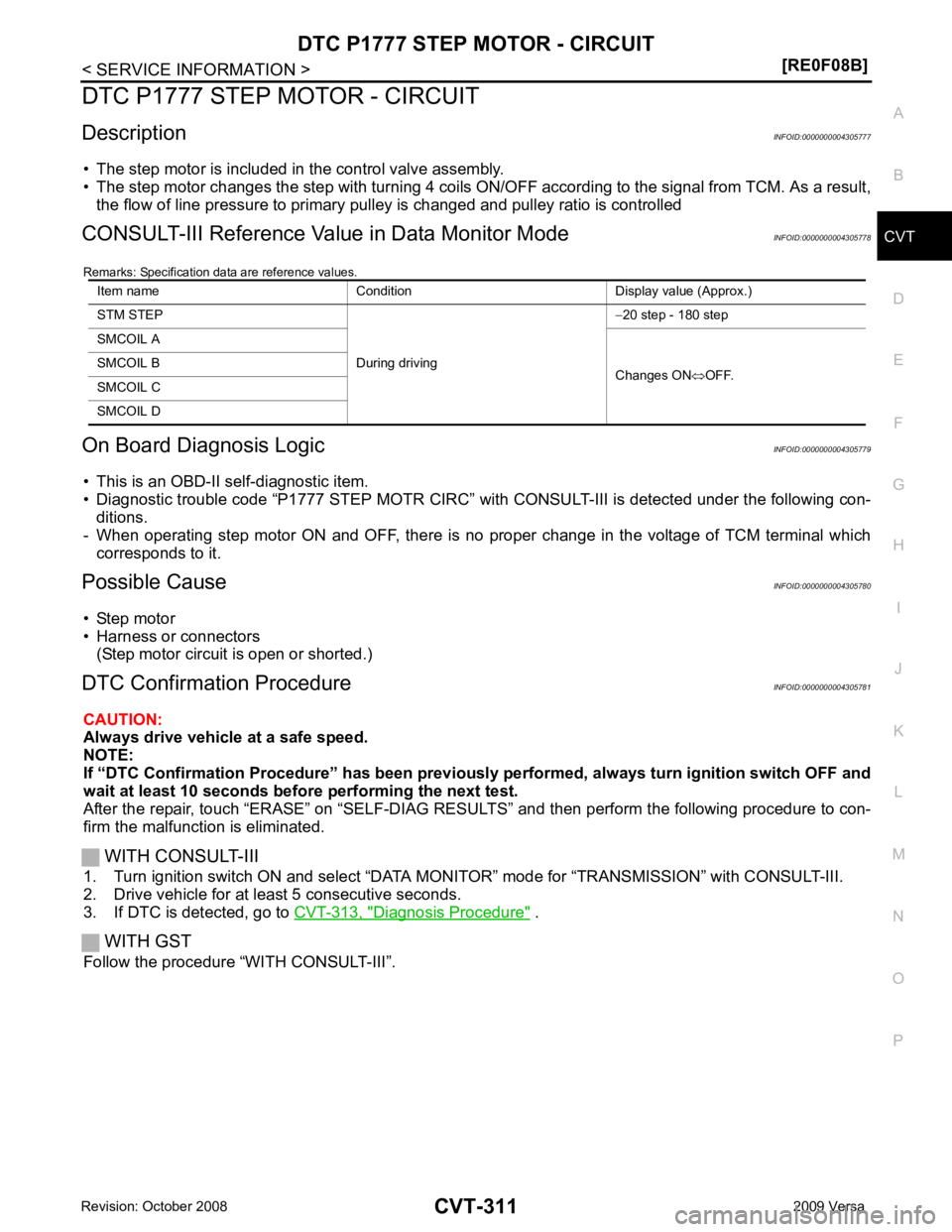

DTC P1777 STEP MOTOR - CIRCUIT

Description INFOID:0000000004305777

• The step motor is included in the control valve assembly.

• The step motor changes the step with turning 4 coils ON/OF F according to the signal from TCM. As a result,

the flow of line pressure to primary pu lley is changed and pulley ratio is controlled

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305778

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305779

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1777 STEP MOTR CIRC” with CONSULT-III is detected under the following con-

ditions.

- When operating step motor ON and OFF, there is no proper change in the voltage of TCM terminal which corresponds to it.

Possible Cause INFOID:0000000004305780

• Step motor

• Harness or connectors

(Step motor circuit is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004305781

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Drive vehicle for at least 5 consecutive seconds.

3. If DTC is detected, go to CVT-313, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

STM STEP

During driving−

20 step - 180 step

SMCOIL A

Changes ON⇔OFF.

SMCOIL B

SMCOIL C

SMCOIL D

Page 1279 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT SHIFT LOCK SYSTEM

CVT-335

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

CVT SHIFT LOCK SYSTEM

Description INFOID:0000000004305812

• The mechanical key interlock mechanism a NISSAN TIIDA 2009 Service Owners Manual CVT SHIFT LOCK SYSTEM

CVT-335

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

CVT SHIFT LOCK SYSTEM

Description INFOID:0000000004305812

• The mechanical key interlock mechanism a](/img/5/57398/w960_57398-1278.png)

CVT SHIFT LOCK SYSTEM

CVT-335

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

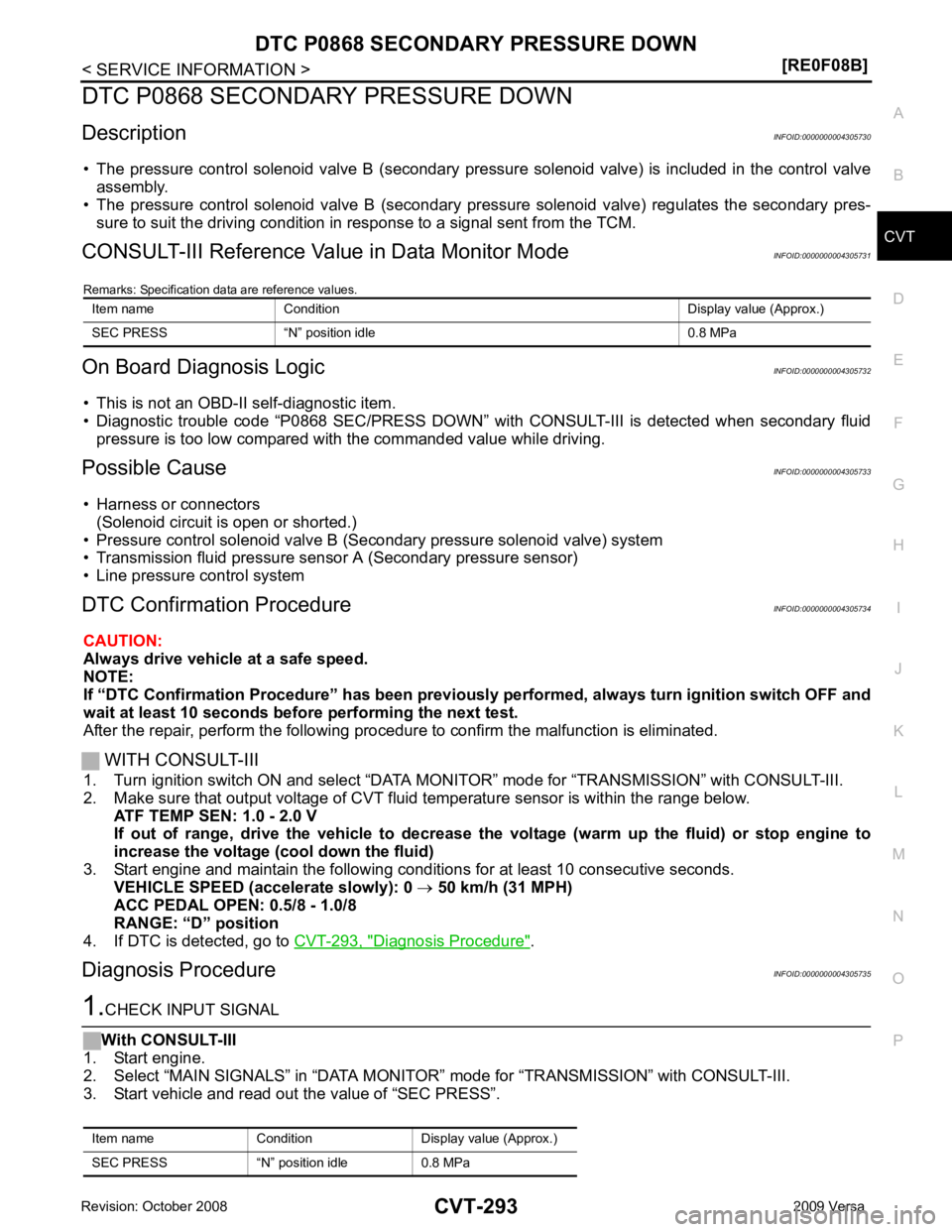

CVT SHIFT LOCK SYSTEM

Description INFOID:0000000004305812

• The mechanical key interlock mechanism also operates as a shift lock: With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and sli der located inside key cylinder, respectively.

Shift Lock System Electrical Parts Location INFOID:0000000004305813

1. Key interlock cable 2. Key cylinder 3. Stop lamp switch

4. Brake pedal 5. Shift lock release button 6. Key interlock cable

7. Shift lock solenoid 8. Park position switch BCIA0034E

Page 1350 of 4331

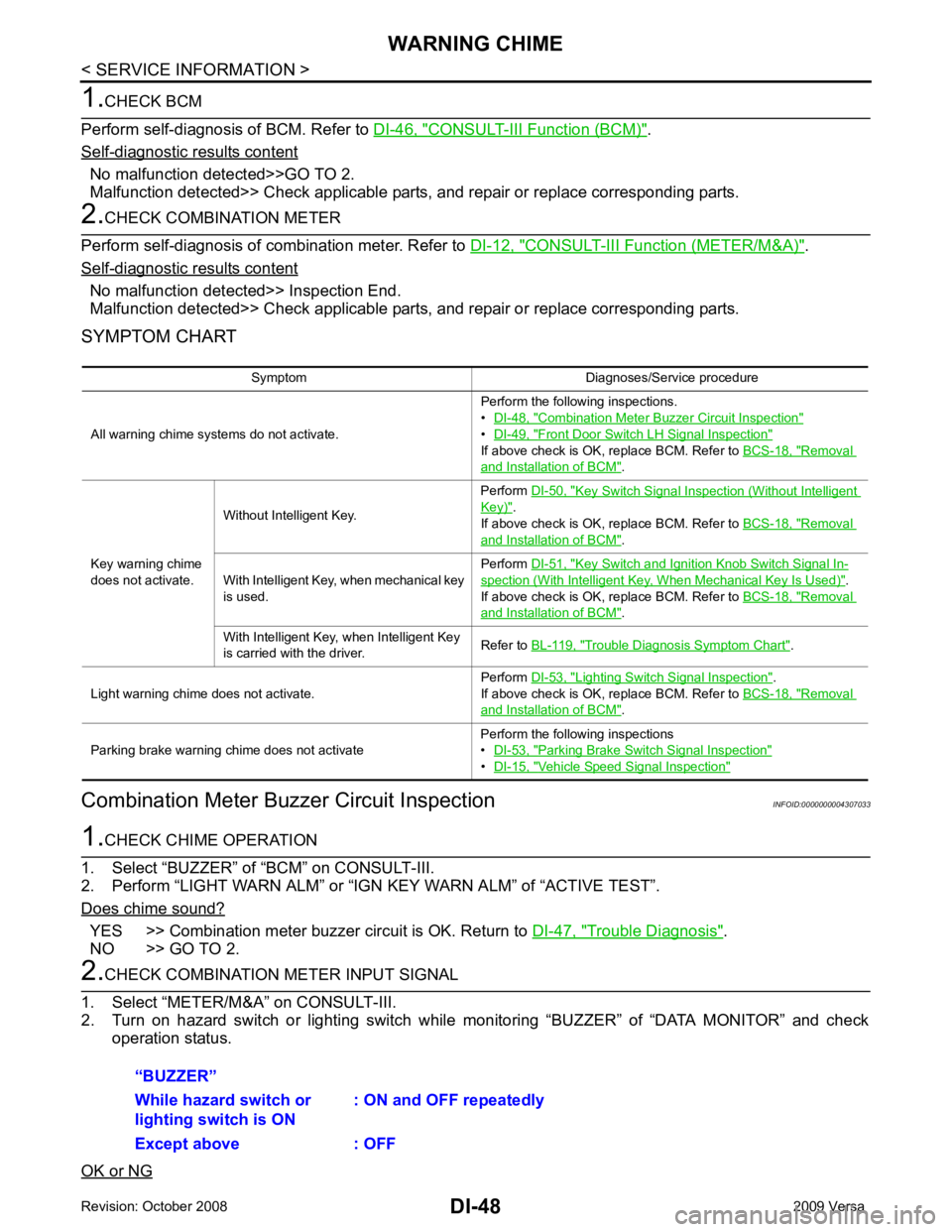

CONSULT-III Function (BCM) " .

Self - diagnostic results content

No malfunction detected>>GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts. CONSULT-III Function (METER/M&A) " .

Self - diagnostic results content

No malfunction detected>> Inspection End.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

SYMPTOM CHART

Combination Meter Buzzer Circuit Inspection INFOID:0000000004307033YES >> Combination meter buzzer circuit is OK. Return to

DI-47, " Trouble Diagnosis " .

NO >> GO TO 2. Combination Meter Buzzer Circuit Inspection "

•

DI-49, " Front Door Switch LH Signal Inspection "

If above check is OK, replace BCM. Refer to

BCS-18, " Removal

and Installation of BCM " .

Key warning chime

does not activate. Without Intelligent Key.

Perform

DI-50, " Key Switch Signal Inspection (Without Intelligent

Key) " .

If above check is OK, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

With Intelligent Key, when mechanical key

is used. Perform

DI-51, " Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical Key Is Used) " .

If above check is OK, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

With Intelligent Key, when Intelligent Key

is carried with the driver. Refer to

BL-119, " Trouble Diagnosis Symptom Chart " .

Light warning chime does not activate. Perform

DI-53, " Lighting Switch Signal Inspection " .

If above check is OK, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

Parking brake warning chime does not activate Perform the following inspections

• DI-53, " Parking Brake Switch Signal Inspection "

•

DI-15, " Vehicle Speed Signal Inspection "

Page 1449 of 4331

EC

NP

O

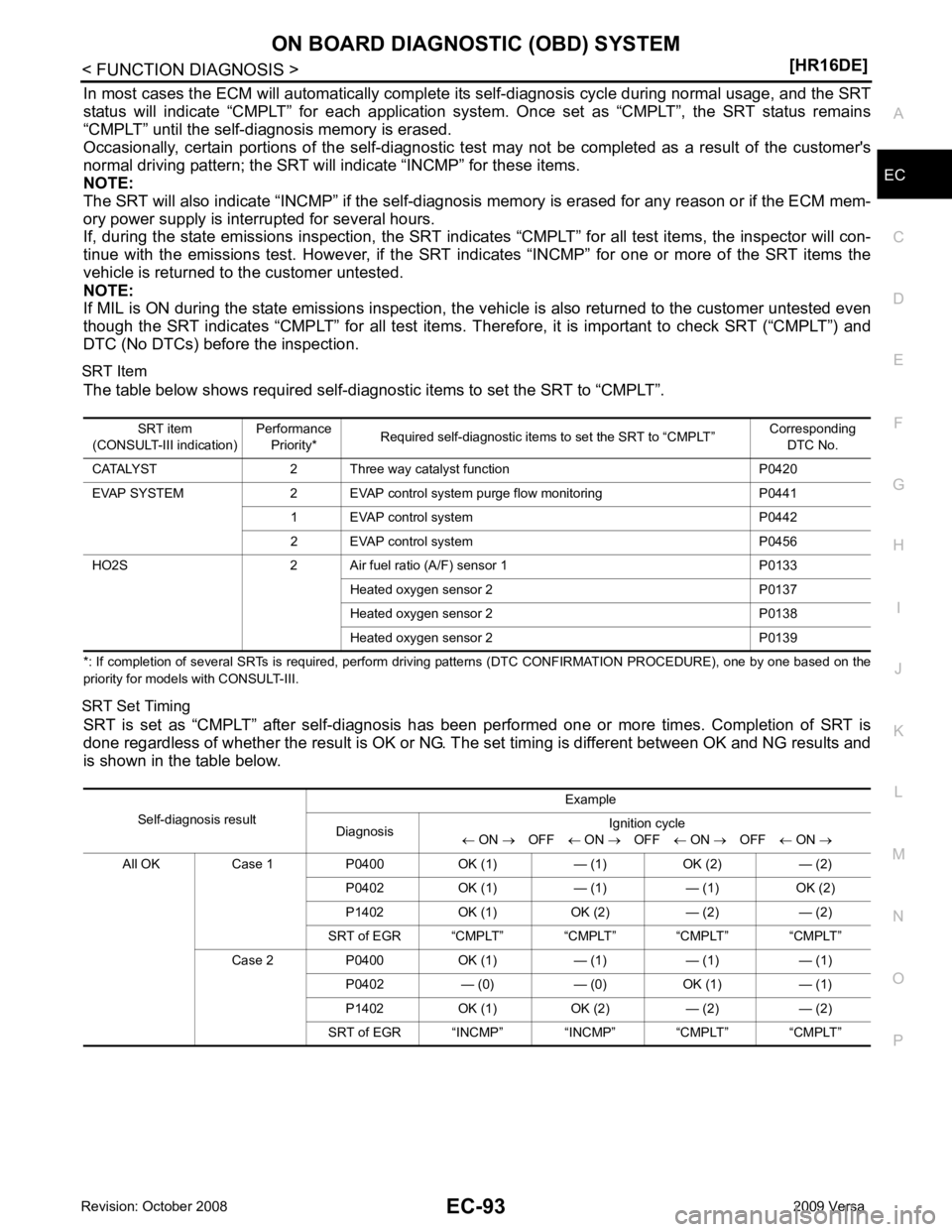

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application syste m. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

NOTE:

The SRT will also indicate “INCMP” if the self-diagnosis memory is erased for any reason or if the ECM mem-

ory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indica tes “CMPLT” for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT i ndicates “INCMP” for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If MIL is ON during the state emissi ons inspection, the vehicle is also returned to the customer untested even

though the SRT indicates “CMPLT” for all test items. T herefore, it is important to check SRT (“CMPLT”) and

DTC (No DTCs) before the inspection.

SRT Item The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

*: If completion of several SRTs is required, perform driving patterns (DTC CONFIRMATION PROCEDURE), one by one based on the

priority for models with CONSULT-III.

SRT Set Timing SRT is set as “CMPLT” after self-diagnosis has been performed one or more times. Completion of SRT is

done regardless of whether the result is OK or NG. T he set timing is different between OK and NG results and

is shown in the table below. SRT item

(CONSULT-III indication) Performance

Priority* Required self-diagnostic items to set the SRT to “CMPLT”

Corresponding

DTC No.

CATALYST 2 Three way catalyst function P0420

EVAP SYSTEM 2 EVAP control system purge flow monitoring P0441

1 EVAP control system P0442

2 EVAP control system P0456

HO2S 2 Air fuel ratio (A/F) sensor 1 P0133 Heated oxygen sensor 2 P0137

Heated oxygen sensor 2 P0138

Heated oxygen sensor 2 P0139 Self-diagnosis result

Example

Diagnosis Ignition cycle

← ON →OFF ← ON →OFF ← ON →OFF ← ON →

All OK Case 1 P0400 OK (1) — (1) OK (2) — (2) P0402 OK (1) — (1) — (1) OK (2)

P1402 OK (1) OK (2) — (2) — (2)

SRT of EGR “CMPLT” “CMPLT” “CMPLT” “CMPLT”

Case 2 P0400 OK (1) — (1) — (1) — (1) P0402 — (0) — (0) OK (1) — (1)

P1402 OK (1) OK (2) — (2) — (2)

SRT of EGR “INCMP” “INCMP” “CMPLT” “CMPLT”