ESP NISSAN TIIDA 2009 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 468 of 4331

BL

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

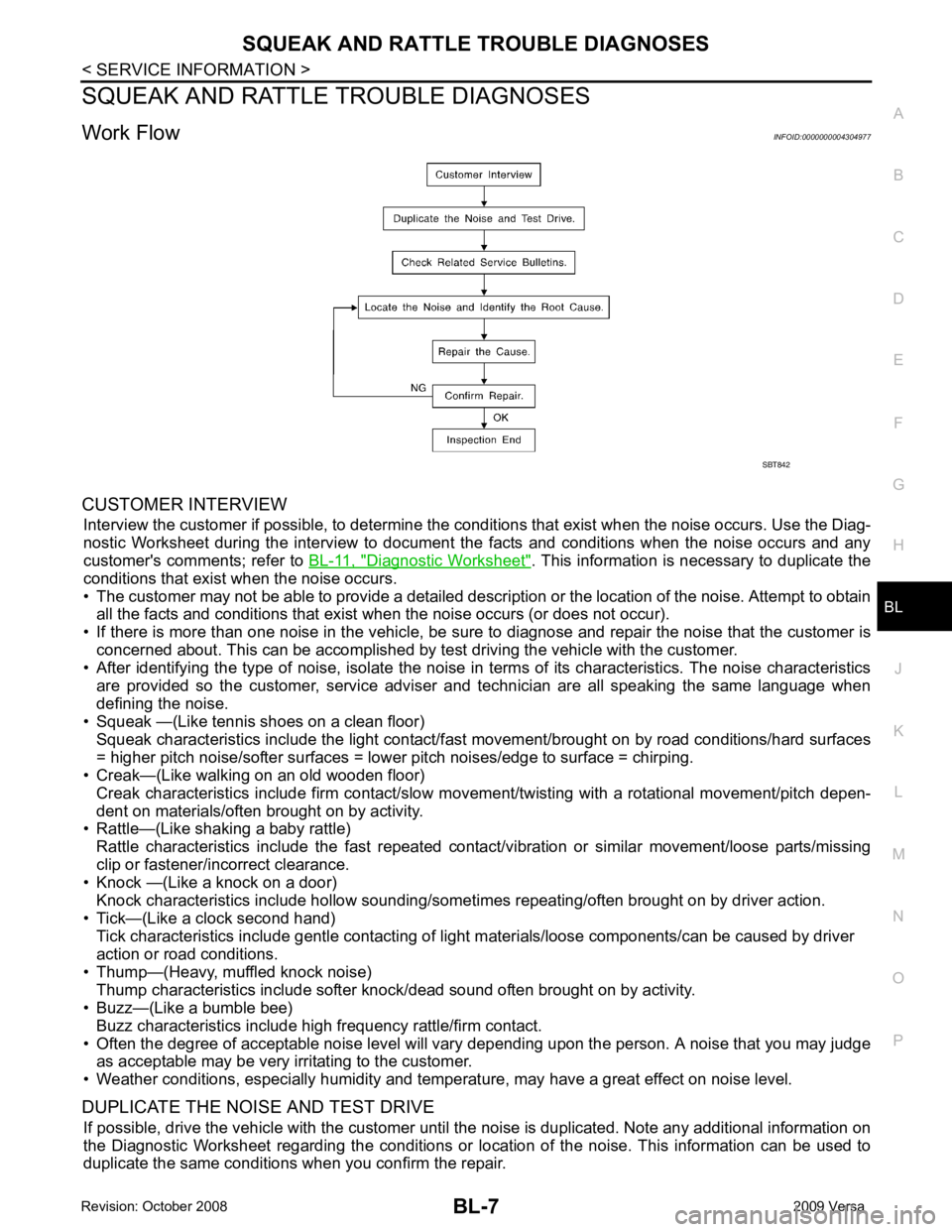

Work Flow INFOID:0000000004304977

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-11, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

Page 534 of 4331

BL

N

O P

With CONSULT-III

Check keyfob function in “DATA MONITOR” mode wit h CONSULT-III. When pushing each button of keyfob,

the corresponding monitor item should be turned as follows.

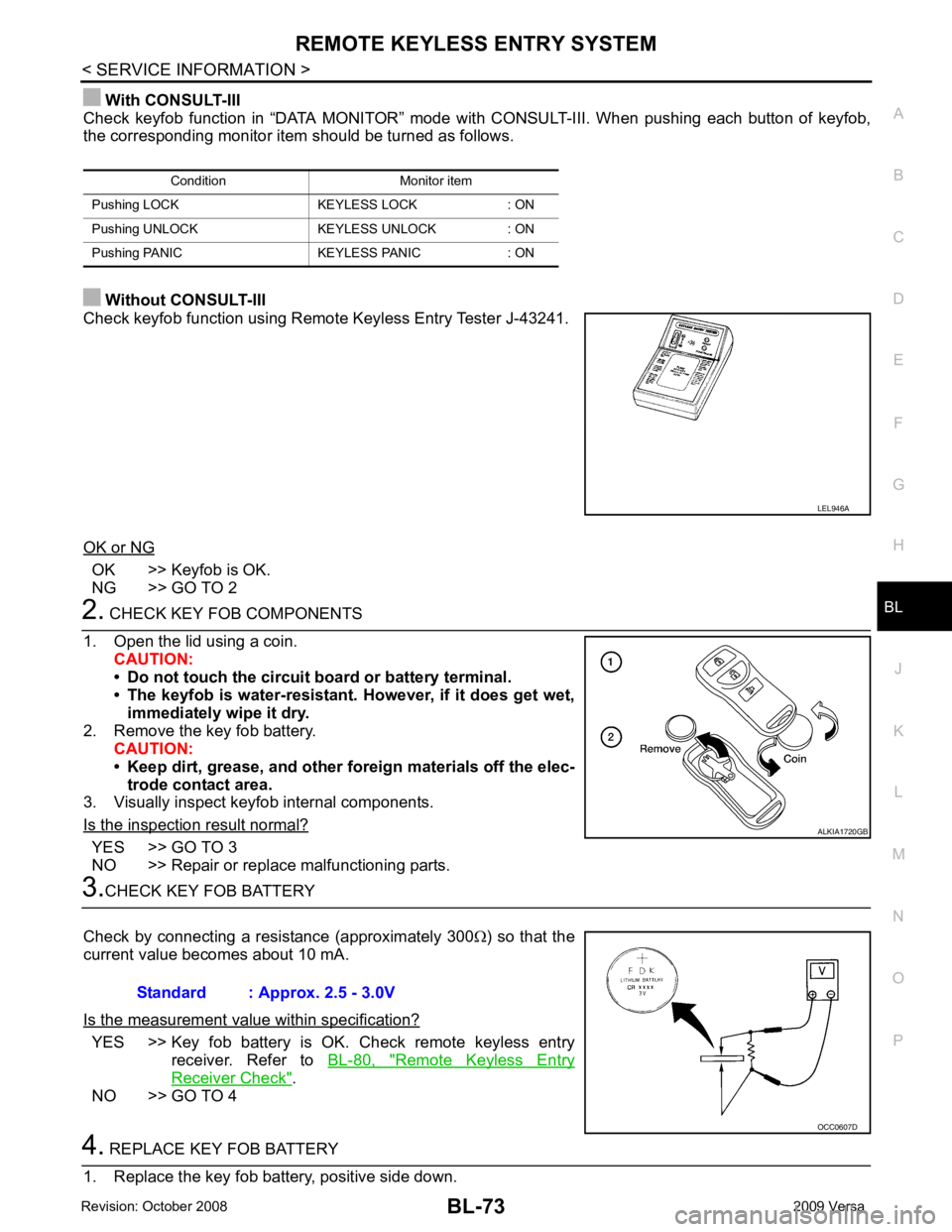

Without CONSULT-III

Check keyfob function using Remote Keyless Entry Tester J-43241.

OK or NG OK >> Keyfob is OK.

NG >> GO TO 2 YES >> GO TO 3

NO >> Repair or replace malfunctioning parts. YES >> Key fob battery is OK. Check remote keyless entry

receiver. Refer to BL-80, " Remote Keyless Entry

Receiver Check " .

NO >> GO TO 4

Page 550 of 4331

BL

N

O P

Operation Description

• When the Intelligent Key unit detects that each request sw itch is pressed, it starts the outside key antenna

and inside key antenna corresponding to the pressed r equest switch and sends the request signal to the

Intelligent Key. And then, make sure that the Intelligent Key is near door.

• If the Intelligent Key is within the outside key ant enna detection area, it receives the request signal and

sends the key ID signal to the Intelligent Key unit.

• Intelligent Key unit receives the key ID signal and compares it with the registered key ID.

• If the key ID check result is OK, the Intelligent Ke y unit sends the door lock/unlock request signal to BCM

(Body control module) via CAN communication line.

• Intelligent Key unit sends the door lock/unlock signal and sounds Intelligent Key warning buzzer (lock: 2 times, unlock: 1 time) at the same time.

• When BCM receives the door lock/unlock signal, it oper ates door lock actuator and flashes the hazard warn-

ing lamp (lock: 2 times, unlock: 1 time) at the same time as reminder.

Operation Condition If the following conditions are not satisfied, door lo ck/unlock operations are not performed even if the request

switch is operated.

*: Even with a registered Intelligent Key remaining inside the vehicle, door locks can be unlocked from outside of the vehicle with a spare

Intelligent Key as long as Key IDs are different.

Outside Key Antenna Detection Area The outside key antenna detection area of door lock/unloc k function is in the range of approximately 80 cm

(31.50 in) surrounding the request switch (driver side, passenger side and back door or trunk area).

Hazard and Buzzer Reminder When all doors and trunk (sedan) are locked or unlocked by each request switch, Intelligent Key unit sends

hazard request signal to BCM via CAN communication line.

BCM flashes hazard warning lamps as a reminder and Intelligent Key unit sounds Intelligent Key warning

buzzer(s) as a reminder.

Operating function of hazard and buzzer reminder

* : Sedan only

Auto Door Lock Function When all doors and trunk (sedan) are locked, ignition knob sw itch is OFF (when ignition switch is not pressed)

and key switch is OFF (when mechanical key is out of ignition key cylinder), all doors are unlocked with each

request switch.

When Intelligent Key unit does not receive the following signals within 1 minute, all doors are locked.

• Door switch is ON (door is opened)

• Trunk lamp switch (sedan) is ON (trunk is opened)

• Door lock signal from Intelligent Key button

• Ignition knob switch is ON (ignition switch is pressed)

• Key switch is ON (mechanical key is inserted in ignition key cylinder)

Auto door lock mode can be changed by “AUTO RELOCK TIMER” mode in “WORK SUPPORT”. Refer to BL-117, " CONSULT-III Application Item " .

List of Operation Related Parts Parts marked with × are the parts related to operation.

Each request switch operation Operation condition Operation

Lock operation • All doors and trunk (sedan) are closed

• Intelligent Key is outside of the vehicle

• Intelligent Key is within outside key antenna detection area All doors lock

Unlock Operation • All doors and trunk (sedan) are closed

• Intelligent Key is outside of the vehicle

• Intelligent Key is within outside key antenna detection area* All doors unlockRequest switch operation Hazard warning lamp flash

Intelligent Key warning buzzer (front door LH)

Intelligent Key warning buzzer (trunk) *

Unlock Once Once Lock Twice Twice

Page 959 of 4331

![NISSAN TIIDA 2009 Service User Guide PRECAUTIONS

CVT-15

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

•

Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions pr NISSAN TIIDA 2009 Service User Guide PRECAUTIONS

CVT-15

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

•

Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions pr](/img/5/57398/w960_57398-958.png)

PRECAUTIONS

CVT-15

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

•

Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. CVT-49, " TCM Terminal and Reference Value " .

• After performing each TROUBL E DIAGNOSIS, perform “DTC

Confirmation Procedure”.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

• Always use the specified br and of CVT fluid. Refer to MA-14, " Flu-

ids and Lubricants " .

• Use lint-free paper, not cloth rags, during work.

• After replacing the CVT fluid, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

Service Notice or Precaution INFOID:0000000004666859

CVT FLUID COOLER SERVICE If CVT fluid contains friction material (clutches, brakes , etc.), or if an CVT is replaced, inspect and clean the

CVT fluid cooler mounted in the radiator or replace t he radiator. Flush cooler lines using cleaning solvent and

compressed air after repair. For CVT fluid cooler cleaning procedure, refer to CVT-18, " CVT Fluid Cooler

Cleaning " . For radiator replacement, refer to

CO-38 .

OBD-II SELF-DIAGNOSIS • CVT self-diagnosis is performed by the TCM in comb ination with the ECM. The results can be read through

the blinking pattern of the malfunction indi cator lamp (MIL). Refer to the table on CVT-51, " CONSULT-III

Function (TRANSMISSION) " for the indicator used to display each self-diagnostic result.

• The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure on CVT-30, " OBD-II Diagnostic Trouble Code (DTC) " to complete the

repair and avoid unnecessary blinking of the MIL.

For details of OBD-II, refer to EC-541, " Introduction " .

• Certain systems and components, especially those re lated to OBD, may use the new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to PG-64 . MEF040DA

SEF217U

Page 974 of 4331

" CONSULT-III Function (TRANSMISSION) " .

OBD-II Function for CVT System INFOID:0000000004666876

The ECM provides emission-related on board diagnostic (O BD-II) functions for the CVT system. One function

is to receive a signal from the TCM used with OBD-relat ed parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indi cator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to CVT system parts.

One or Two Trip Detection Logic of OBD-II INFOID:0000000004666877

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC) INFOID:0000000004666878

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic troubl e code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”. Freeze Frame Data and 1st Trip Freeze Frame Data

Page 978 of 4331

![NISSAN TIIDA 2009 Service User Guide CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power NISSAN TIIDA 2009 Service User Guide CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power](/img/5/57398/w960_57398-977.png)

CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for

controlling) from the battery is not supplied to TCM. Normal statues is restored when turning the ignition switch

OFF to ON after the normal power supply.

How to Perform Trouble Diagnosis for Quick and Accurate Repair INFOID:0000000004666882

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

CVT system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve mal-

function, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Mo st intermittent errors are caused

by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits ma y help prevent the replacement of

good parts.

A visual check only may not find the cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “DIAGNOSTIC WORKSHEET” as

shown on the example (Refer to "Diagnostic Worksheet Chart" )

should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

WORK FLOW

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Make good use of the two sheets provided, "Informati on From Customer" and "Diagnostic Worksheet Chart" ,

to perform the best troubleshooting possible.

Work Flow Chart SAT631IB

SAT632I

SEF234G

Page 1043 of 4331

CVT

N

O P

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description INFOID:0000000004666974

• The pressure control solenoid valve A (line pressure solenoid valve) is included in the control valve assem- bly.

• The pressure control solenoid valve A (line pressure solenoid valve) regulates the oil pump discharge pres-

sure to suit the driving condition in response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004666975

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004666976

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745 L/PRESS SOL/CIRC” with CONSULT-III is detected under the following

conditions.

- TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM compares target value with monitor value and detects an irregularity.

Possible Cause INFOID:0000000004666977

• Harness or connectors (Solenoid circuit is open or shorted.)

• Pressure control solenoid valve A (Line pressure solenoid valve)

DTC Confirmation Procedure INFOID:0000000004666978

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Start engine and wait at least 5 seconds.

3. If DTC is detected, go to CVT-101, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

ISOLT2 Release your foot from the accelerator pedal. 0.8 A

Press the accelerator pedal all the way down. 0.0 A

Page 1067 of 4331

CVT

N

O P

DTC P0868 SECONDARY PRESSURE DOWN

Description INFOID:0000000004667022

• The pressure control solenoid valve B (secondary pressure solenoid valve) is included in the control valve assembly.

• The pressure control solenoid valve B (secondary pressure solenoid valve) regulates the secondary pres-

sure to suit the driving condition in response to a signal sent from the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004667023

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004667024

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0868 SEC/PRESS DOWN” with CONSULT-III is detected when secondary fluid

pressure is too low compared with the commanded value while driving.

Possible Cause INFOID:0000000004667025

• Harness or connectors (Solenoid circuit is open or shorted.)

• Pressure control solenoid valve B (Secondary pressure solenoid valve) system

• Transmission fluid pressure sensor A (Secondary pressure sensor)

• Line pressure control system

DTC Confirmation Procedure INFOID:0000000004667026

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Start engine and maintain the following conditions for at least 10 consecutive seconds. VEHICLE SPEED (accelerate slowly): 0 → 50 km/h (31 MPH)

ACC PEDAL OPEN: 0.5/8 - 1.0/8

RANGE: “D” position

4. If DTC is detected, go to CVT-123, " Diagnosis Procedure " .

Diagnosis Procedure INFOID:0000000004667027

Page 1085 of 4331

CVT

N

O P

DTC P1777 STEP MOTOR - CIRCUIT

Description INFOID:0000000004667069

• The step motor is included in the control valve assembly.

• The step motor changes the step with turning 4 coils ON/OF F according to the signal from TCM. As a result,

the flow of line pressure to primary pu lley is changed and pulley ratio is controlled

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004667070

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004667071

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1777 STEP MOTR CIRC” with CONSULT-III is detected under the following con-

ditions.

- When operating step motor ON and OFF, there is no proper change in the voltage of TCM terminal which corresponds to it.

Possible Cause INFOID:0000000004667072

• Step motor

• Harness or connectors

(Step motor circuit is open or shorted.)

DTC Confirmation Procedure INFOID:0000000004667073

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESU LTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Drive vehicle for at least 5 consecutive seconds.

3. If DTC is detected, go to CVT-143, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value (Approx.)

STM STEP

During driving−

20 step - 180 step

SMCOIL A

Changes ON⇔OFF.

SMCOIL B

SMCOIL C

SMCOIL D

Page 1109 of 4331

CVT

N

O P

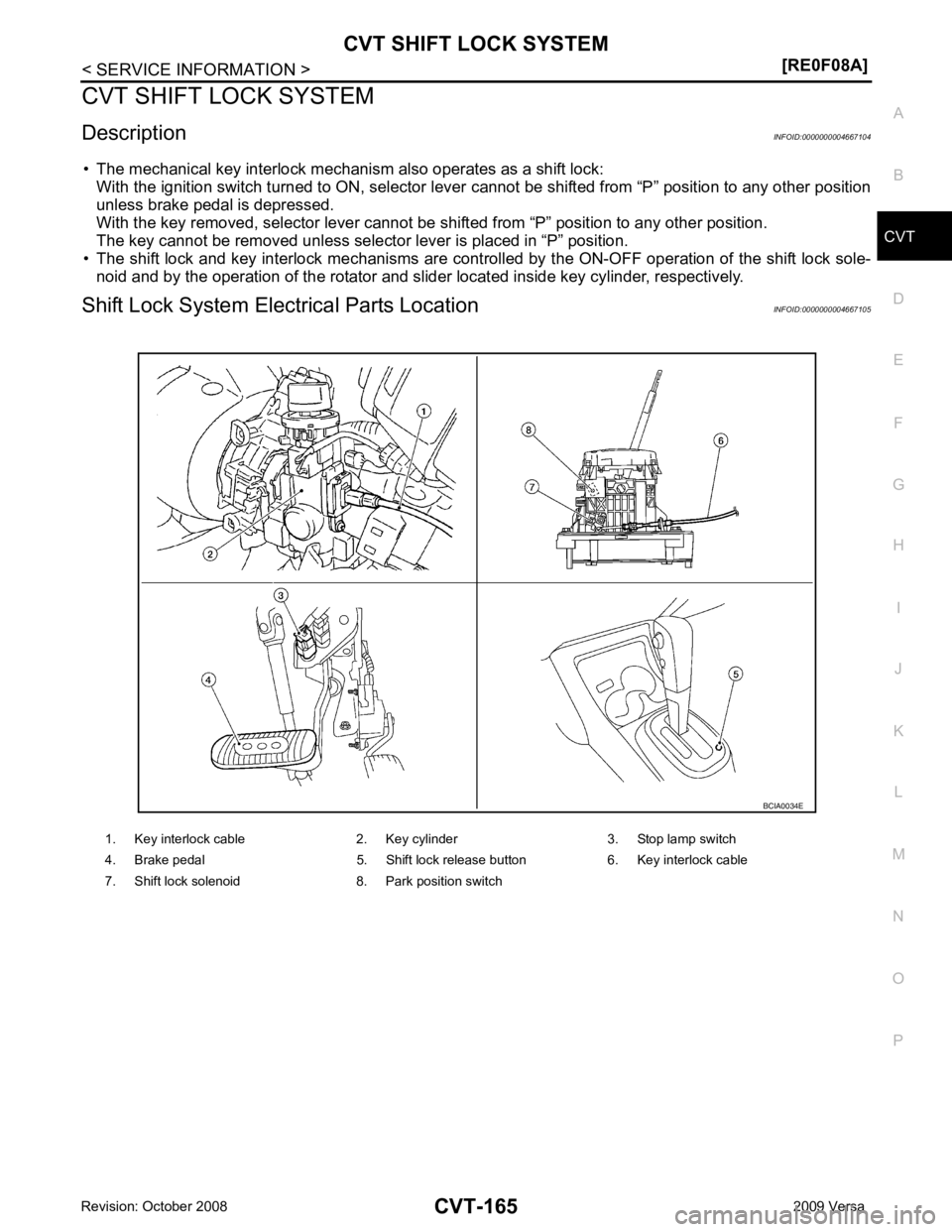

CVT SHIFT LOCK SYSTEM

Description INFOID:0000000004667104

• The mechanical key interlock mechanism also operates as a shift lock: With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and sli der located inside key cylinder, respectively.

Shift Lock System Electrical Parts Location INFOID:0000000004667105

1. Key interlock cable 2. Key cylinder 3. Stop lamp switch

4. Brake pedal 5. Shift lock release button 6. Key interlock cable

7. Shift lock solenoid 8. Park position switch