ESP NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1909 of 4331

EC

NP

O

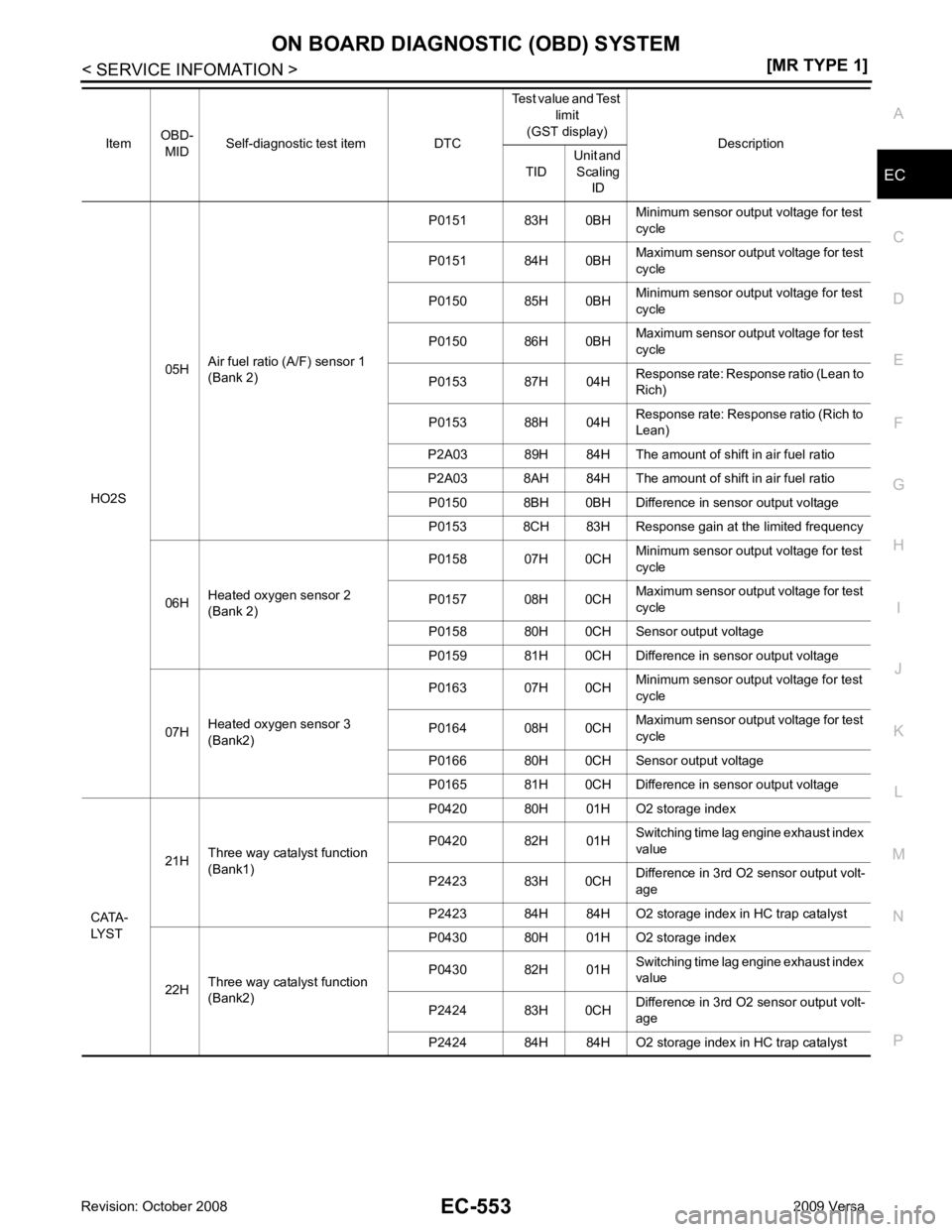

HO2S

05H

Air fuel ratio (A/F) sensor 1

(Bank 2) P0151 83H 0BH

Minimum sensor output voltage for test

cycle

P0151 84H 0BH Maximum sensor output voltage for test

cycle

P0150 85H 0BH Minimum sensor output voltage for test

cycle

P0150 86H 0BH Maximum sensor output voltage for test

cycle

P0153 87H 04H Response rate: Response ratio (Lean to

Rich)

P0153 88H 04H Response rate: Response ratio (Rich to

Lean)

P2A03 89H 84H The amount of shift in air fuel ratio

P2A03 8AH 84H The amount of shift in air fuel ratio P0150 8BH 0BH Difference in sensor output voltage

P0153 8CH 83H Response gain at the limited frequency

06H Heated oxygen sensor 2

(Bank 2) P0158 07H 0CH

Minimum sensor output voltage for test

cycle

P0157 08H 0CH Maximum sensor output voltage for test

cycle

P0158 80H 0CH Sensor output voltage

P0159 81H 0CH Difference in sensor output voltage

07H Heated oxygen sensor 3

(Bank2) P0163 07H 0CH

Minimum sensor output voltage for test

cycle

P0164 08H 0CH Maximum sensor output voltage for test

cycle

P0166 80H 0CH Sensor output voltage

P0165 81H 0CH Difference in sensor output voltage

CATA-

LYST 21H

Three way catalyst function

(Bank1) P0420 80H 01H O2 storage index

P0420 82H 01H Switching time lag engine exhaust index

value

P2423 83H 0CH Difference in 3rd O2 sensor output volt-

age

P2423 84H 84H O2 storage index in HC trap catalyst

22H Three way catalyst function

(Bank2) P0430 80H 01H O2 storage index

P0430 82H 01H Switching time lag engine exhaust index

value

P2424 83H 0CH Difference in 3rd O2 sensor output volt-

age

P2424 84H 84H O2 storage index in HC trap catalyst

Item

OBD-

MID Self-diagnostic test item DTC Test value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Page 1922 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs tha NISSAN TIIDA 2009 Service Manual PDF EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs tha](/img/5/57398/w960_57398-1921.png)

EC-566< SERVICE INFOMATION >

[MR TYPE 1]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

Basic Inspection INFOID:00000000045370431.

INSPECTION START

1. Check service records for any recent repairs that ma y indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT-III or GST.

OK or NG OK >> GO TO 3.

NG >> GO TO 2. 2.

REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3. 3.

CHECK TARGET IDLE SPEED

With CONSULT-III

1. Run engine at about 2,000 rpm for about 2 minutes under no load. SEF983U

SEF976U

SEF977U

Page 1933 of 4331

![NISSAN TIIDA 2009 Service Manual PDF TROUBLE DIAGNOSIS

EC-577

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004537051

INTRODUCTION The engine has an ECM NISSAN TIIDA 2009 Service Manual PDF TROUBLE DIAGNOSIS

EC-577

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004537051

INTRODUCTION The engine has an ECM](/img/5/57398/w960_57398-1932.png)

TROUBLE DIAGNOSIS

EC-577

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

TROUBLE DIAGNOSIS

Trouble Diagnosis Introduction INFOID:0000000004537051

INTRODUCTION The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no malfunctions such as vac-

uum leaks, fouled spark plugs, or other malfunctions with the engine.

It is much more difficult to diagnose an incident that occurs intermit-

tently rather than continuously. Most intermittent incidents are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find t he cause of the incidents. A road

test with CONSULT-III (or GST) or a circuit tester connected should

be performed. Follow the Work Flow on "WORK FLOW".

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Diagnostic Worksheet like the example

on "Worksheet Sample" should be used.

Start your diagnosis by looking for conventional malfunctions first.

This will help troubleshoot driveability malfunctions on an electroni-

cally controlled engine vehicle.

WORK FLOW MEF036D

SEF233G

SEF234G

Page 1968 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-612< SERVICE INFOMATION >

[MR TYPE 1]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS NISSAN TIIDA 2009 Service Manual PDF EC-612< SERVICE INFOMATION >

[MR TYPE 1]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS](/img/5/57398/w960_57398-1967.png)

EC-612< SERVICE INFOMATION >

[MR TYPE 1]

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to EC-542, " Emission-related Diagnostic Information " .

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode

*: DTC P1442 and P1456 does not apply to C11 models but appears in DTC Work Support Mode screens.

Generic Scan Tool (GST) Function INFOID:0000000004537061

DESCRIPTION

Generic Scan Tool (OBDII scan tool) complying with SAE J1978 has

8 different functions explained below.

ISO 15765-4 is used as the protocol.

The name GST or Generic Scan Tool is used in this service manual.

FUNCTION VENT CON-

TROL/V • Ignition switch: ON

(Engine stopped)

• Turn solenoid valve “ON” and “OFF” with the CONSULT-III and

listen to operating sound. Solenoid valve makes an operating

sound. • Harness and connectors

• EVAP canister vent control valve

V/T ASSIGN AN-

GLE • Engine: Return to the original

trouble condition

• Change intake valve timing using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Intake valve timing control sole-

noid valve

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY) Test mode Test item Corresponding DTC No. Reference page

EVAPORATIVE SYS-

TEM PURG FLOW P0441 P0441

EC-792EVP SML LEAK P0442/P1442*

P0442

EC-797 P0455

EC-847 EVP V/S LEAK P0456/P1456* P0456

EC-853PURG VOL CN/V P1444 P0443

EC-804A/F SEN1

A/F SEN1 (B1) P1276 P0130

EC-692A/F SEN1 (B1) P1278/P1279 P0133

EC-710HO2S2

HO2S2 (B1) P0139 P0139

EC-733HO2S2 (B1) P1146 P0138

EC-724HO2S2 (B1) P1147 P0137

EC-717 SEF139P

Page 2001 of 4331

EC

NP

O

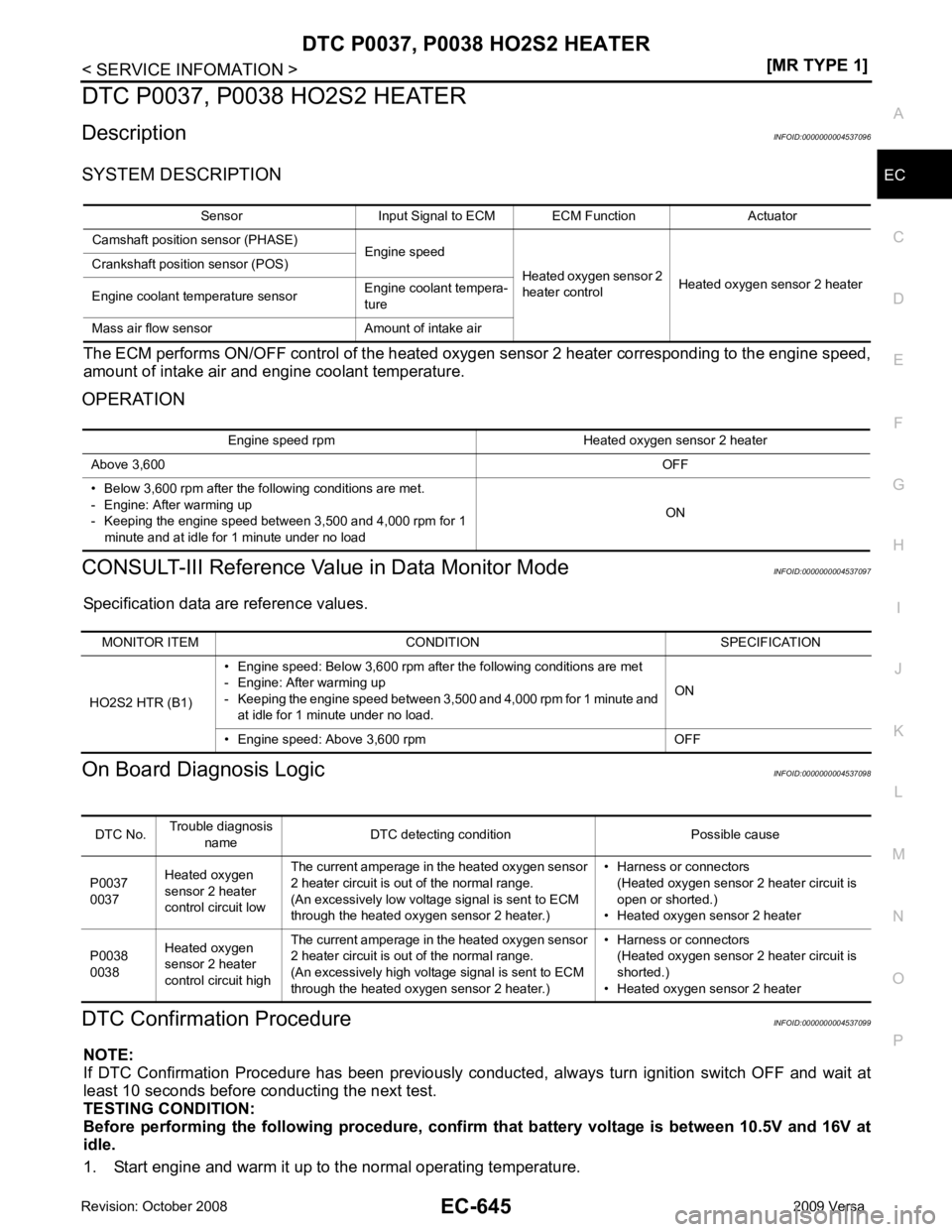

DTC P0037, P0038 HO2S2 HEATER

Description INFOID:0000000004537096

SYSTEM DESCRIPTION

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater corresponding to the engine speed,

amount of intake air and engine coolant temperature.

OPERATION

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004537097

Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004537098

DTC Confirmation Procedure INFOID:0000000004537099

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confi rm that battery voltage is between 10.5V and 16V at

idle.

1. Start engine and warm it up to the normal operating temperature. Sensor Input Signal to ECM ECM Function Actuator

Camshaft position sensor (PHASE) Engine speed

Heated oxygen sensor 2

heater control Heated oxygen sensor 2 heater

Crankshaft position sensor (POS)

Engine coolant temperature sensor Engine coolant tempera-

ture

Mass air flow sensor Amount of intake air Engine speed rpm Heated oxygen sensor 2 heater

Above 3,600 OFF

• Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at idle for 1 minute under no load ONMONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1) • Engine speed: Below 3,600 rpm after the following conditions are met

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no load. ON

• Engine speed: Above 3,600 rpm OFF DTC No.

Trouble diagnosis

name DTC detecting condition Possible cause

P0037

0037 Heated oxygen

sensor 2 heater

control circuit low The current amperage in the heated oxygen sensor

2 heater circuit is out of the normal range.

(An excessively low voltage signal is sent to ECM

through the heated oxygen sensor 2 heater.) • Harness or connectors

(Heated oxygen sensor 2 heater circuit is

open or shorted.)

• Heated oxygen sensor 2 heater

P0038

0038 Heated oxygen

sensor 2 heater

control circuit high The current amperage in the heated oxygen sensor

2 heater circuit is out of the normal range.

(An excessively high voltage signal is sent to ECM

through the heated oxygen sensor 2 heater.) • Harness or connectors

(Heated oxygen sensor 2 heater circuit is

shorted.)

• Heated oxygen sensor 2 heater

Page 2012 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-656< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0101 MAF SENSOR

PROCEDURE FOR MALFUNCTION A

NOTE:

If engine will not start or stops soon, wait at leas t 10 seconds with engine stopped (Ignition switch O NISSAN TIIDA 2009 Service Manual PDF EC-656< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0101 MAF SENSOR

PROCEDURE FOR MALFUNCTION A

NOTE:

If engine will not start or stops soon, wait at leas t 10 seconds with engine stopped (Ignition switch O](/img/5/57398/w960_57398-2011.png)

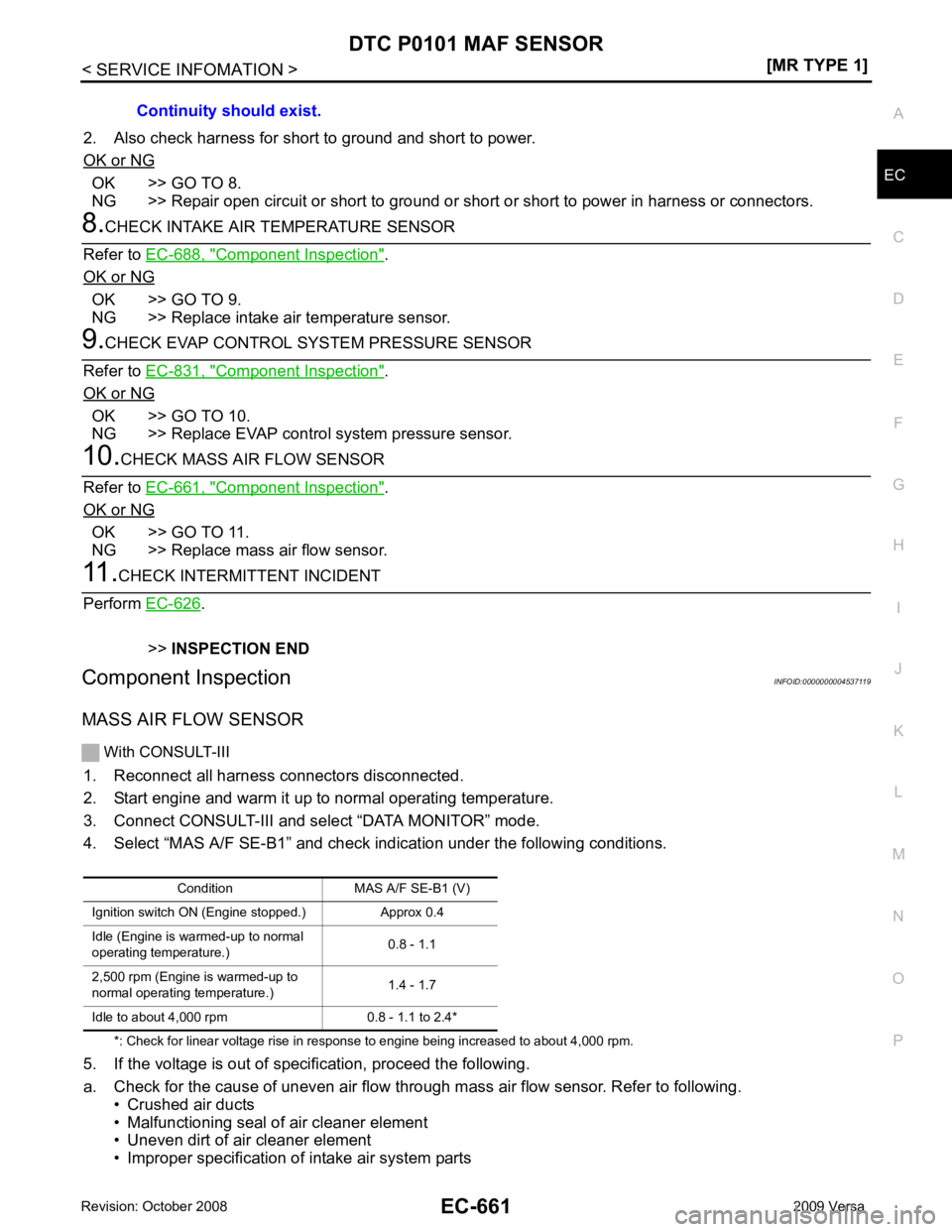

EC-656< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0101 MAF SENSOR

PROCEDURE FOR MALFUNCTION A

NOTE:

If engine will not start or stops soon, wait at leas t 10 seconds with engine stopped (Ignition switch ON) instead

of running engine at idle speed.

1. Start engine and warm it up to normal operating temperature.

2. Run engine for at least 10 seconds at idle speed.

3. Check 1st trip DTC.

4. If 1st trip DTC is detected, go to EC-659, " Diagnosis Procedure " .

PROCEDURE FOR MALFUNCTION B

CAUTION:

Always drive vehicle at a safe speed.

With CONSULT-III

1. Turn ignition switch ON.

2. Start engine and warm it up to normal operating temperature.

If engine cannot be started, go to EC-659, " Diagnosis Procedure " .

3. Select “DATA MONITOR” mode with CONSULT-III.

4. Check the voltage of “MAS A/F SE-B1” with “DATA MONITOR”.

5. Increases engine speed to about 4,000 rpm.

6. Monitor the linear voltage rise in response to engine speed

increases.

If NG, go to EC-659, " Diagnosis Procedure " .

If OK, go to following step.

7. Maintain the following conditions for at least 10 consecutive seconds.

8. Check 1st trip DTC.

9. If 1st trip DTC is detected, go to EC-659, " Diagnosis Procedure " .

Overall Function Check INFOID:0000000004537116

PROCEDURE FOR MALFUNCTION B

Use this procedure to check the overall function of the ma ss air flow sensor circuit. During this check, a 1st

DTC might not be confirmed.

With GST PBIB3457E

ENG SPEED More than 2,000 rpm

THRTL SEN 1 More than 3V

THRTL SEN 2 More than 3V

Shift lever Suitable position

Driving location Driving vehicle uphill (Increased engine load) will help

maintain the driving conditions required for this test.

Page 2013 of 4331

![NISSAN TIIDA 2009 Service Manual PDF DTC P0101 MAF SENSOR

EC-657

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Select Service $01 with GST.

3. Check NISSAN TIIDA 2009 Service Manual PDF DTC P0101 MAF SENSOR

EC-657

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Select Service $01 with GST.

3. Check](/img/5/57398/w960_57398-2012.png)

DTC P0101 MAF SENSOR

EC-657

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Start engine and warm it up to normal operating temperature.

2. Select Service $01 with GST.

3. Check the mass air flow sensor signal with Service $01.

4. Check for linear mass air flow sensor signal value rise in response to increases to about 4,000 rpm in engine speed.

5. If NG, go to EC-659, " Diagnosis Procedure " .

SEF534P

Page 2017 of 4331

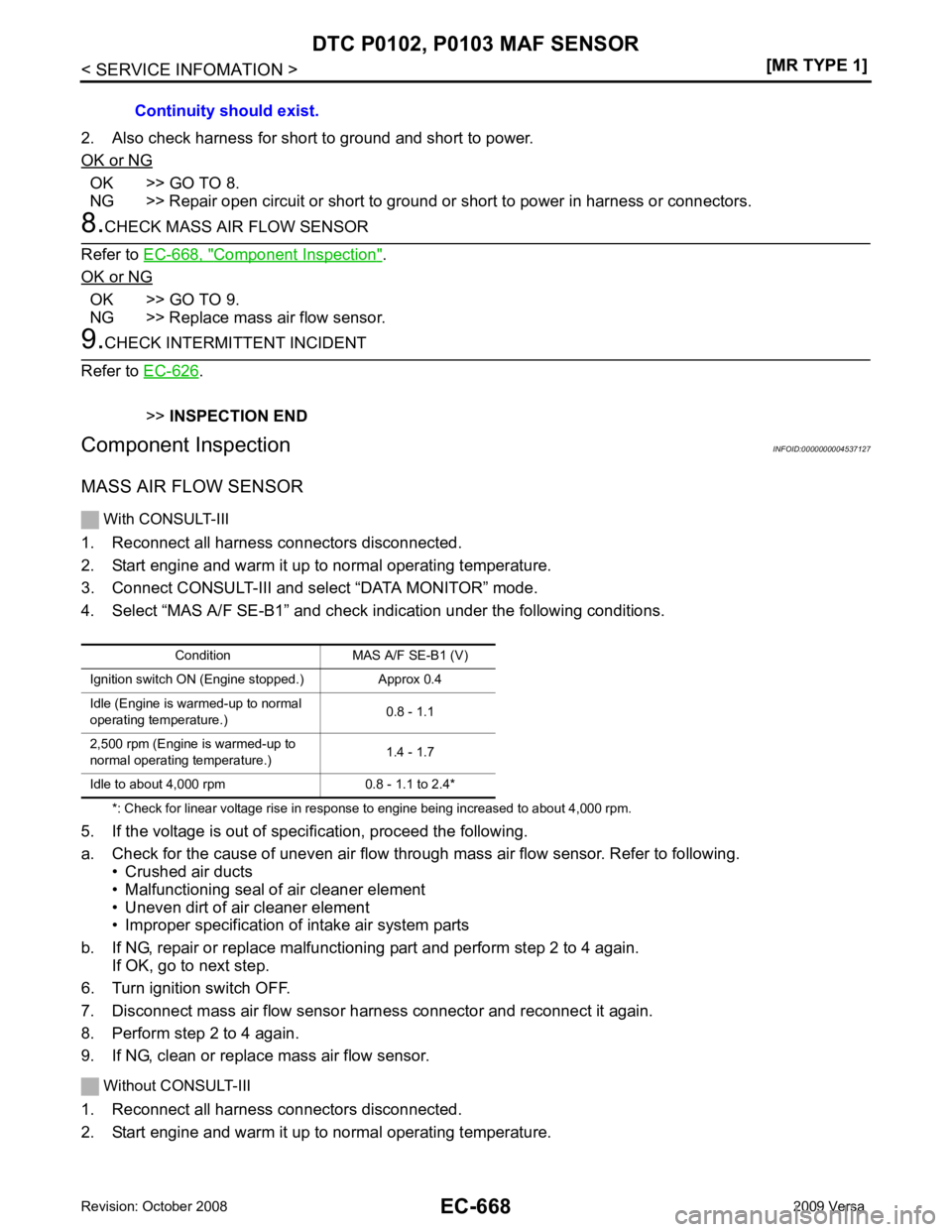

EC

NP

O

2. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short or short to power in harness or connectors. Component Inspection " .

OK or NG OK >> GO TO 9.

NG >> Replace intake air temperature sensor. Component Inspection " .

OK or NG OK >> GO TO 10.

NG >> Replace EVAP control system pressure sensor. Component Inspection " .

OK or NG OK >> GO TO 11.

NG >> Replace mass air flow sensor. .

>> INSPECTION END

Component Inspection INFOID:0000000004537119

MASS AIR FLOW SENSOR With CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-III and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check i ndication under the following conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of spec ification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following. • Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts Continuity should exist.

Page 2018 of 4331

![NISSAN TIIDA 2009 Service Manual PDF EC-662< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0101 MAF SENSOR

b. If NG, repair or replace malfunc tioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Di NISSAN TIIDA 2009 Service Manual PDF EC-662< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0101 MAF SENSOR

b. If NG, repair or replace malfunc tioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Di](/img/5/57398/w960_57398-2017.png)

EC-662< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0101 MAF SENSOR

b. If NG, repair or replace malfunc tioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 45 (Mass air flow sensor signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

4. If the voltage is out of spec ification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following. • Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunc tioning part and perform step 2 and 3 again.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and Installation INFOID:0000000004537120

MASS AIR FLOW SENSOR

Refer to EM-139 .Condition Voltage V

Ignition switch ON (Engine stopped.) Approx 0.4

Idle (Engine is warmed-up to normal

operating temperature.) 0.8 - 1.1

2,500 rpm (Engine is warmed-up to

normal operating temperature.) 1.4 - 1.7

Idle to about 4,000 rpm 0.8 - 1.1 to 2.4* PBIA9564J

Page 2024 of 4331

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

OK or NG OK >> GO TO 9.

NG >> Replace mass air flow sensor. .

>> INSPECTION END

Component Inspection INFOID:0000000004537127

MASS AIR FLOW SENSOR With CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-III and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check i ndication under the following conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of spec ification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following. • Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunc tioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-III

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature. Continuity should exist.