NISSAN TIIDA 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3601 of 4331

YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the combination meter branch line. Power Supply and

Ground Circuit Inspection " .

Is the inspection result normal? YES (Present error)>>Replace the combination meter. Refer to

IP-12, " Removal and Installation " .

YES (Past error)>>Error was detected in the combination meter branch line.

NO >> Repair the power supply and the ground circuit. Combination meter harness connector

Resistance (Ω)

Connector No. Terminal No.

M24 1 2 Approx. 54 – 66

Page 3602 of 4331

LAN

N

O P

ABS BRANCH LINE CIRCUIT

Diagnosis Procedure INFOID:0000000004749347YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the ABS actuator and electric unit (control unit) branch line. ABS Control Unit Power and Ground Systems Inspection " .

Is the inspection result normal? YES (Present error)>>Replace the ABS actuator

and electric unit (control unit). Refer to BRC-35, " Removal

and Installation " .

YES (Past error)>>Error was detected in the ABS ac tuator and electric unit (control unit) branch line.

NO >> Repair the power supply and the ground circuit. ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E33 26 15 Approx. 54 – 66

Page 3603 of 4331

YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the TCM branch line. Diagnosis Procedure "

• CVT models:

CVT-297, " Diagnosis Procedure "

Is the inspection result normal?

YES (Present error)>>Replace the TCM. Refer to the following.

• A/T models: AT-211, " Removal and Installation "

• CVT models:

CVT-340, " Removal and Installation "

YES (Past error)>>Error was detected in the TCM branch line.

NO >> Repair the power supply and the ground circuit. TCM harness connector

Resistance (Ω)

Connector No. Terminal No.

E31 5 6 Approx. 54 – 66

Page 3604 of 4331

LAN

N

O P

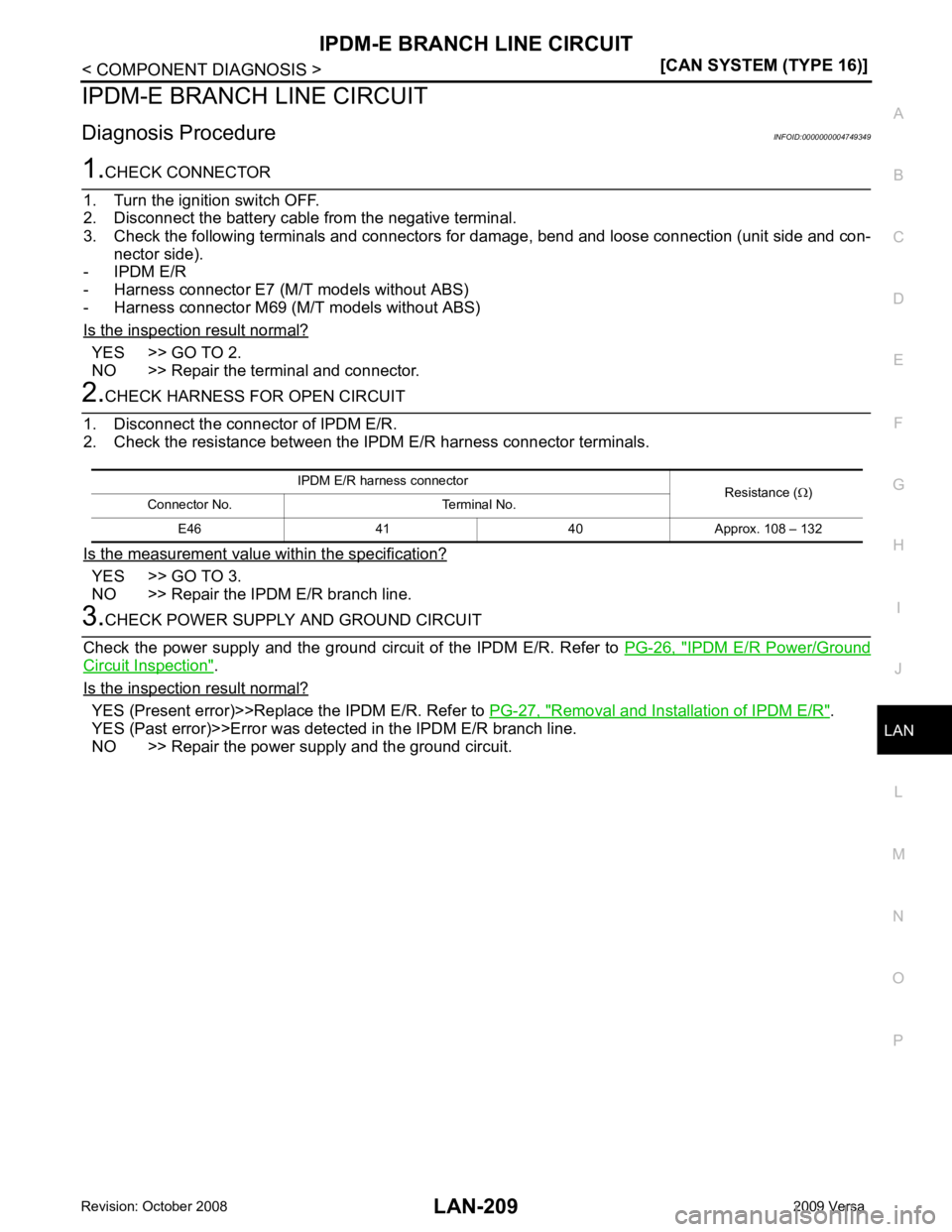

IPDM-E BRANCH

LINE CIRCUIT

Diagnosis Procedure INFOID:0000000004749349YES >> GO TO 2.

NO >> Repair the terminal and connector. YES >> GO TO 3.

NO >> Repair the IPDM E/R branch line. IPDM E/R Power/Ground

Circuit Inspection " .

Is the inspection result normal? YES (Present error)>>Replace the IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

YES (Past error)>>Error was detec ted in the IPDM E/R branch line.

NO >> Repair the power supply and the ground circuit. IPDM E/R harness connector

Resistance (Ω)

Connector No. Terminal No.

E46 41 40 Approx. 108 – 132

Page 3605 of 4331

![NISSAN TIIDA 2009 Service Repair Manual LAN-210< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 16)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000047493501.

CONNECTOR INSPECTION

1. Turn the ignition switch NISSAN TIIDA 2009 Service Repair Manual LAN-210< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 16)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000047493501.

CONNECTOR INSPECTION

1. Turn the ignition switch](/img/5/57398/w960_57398-3604.png)

LAN-210< COMPONENT DIAGNOSIS >

[CAN SYSTEM (TYPE 16)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure INFOID:00000000047493501.

CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

4. Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector. 2.

CHECK HARNESS CONTI NUITY (SHORT CIRCUIT)

Check the continuity between t he data link connector terminals.

Is the inspection result normal? YES >> GO TO 3.

NO >> Check the harness and repair the root cause. 3.

CHECK HARNESS CONTI NUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Check the harness and repair the root cause. 4.

CHECK ECM AND IPDM E/R TERMINATION CIRCUIT

1. Remove the ECM and the IPDM E/R.

2. Check the resistance between the ECM terminals.

3. Check the resistance between the IPDM E/R terminals.

Is the measurement value within the specification? YES >> GO TO 5.

NO >> Replace the ECM and/or the IPDM E/R. 5.

CHECK SYMPTOM

Connect all the connectors. Check if the symptoms descri bed in the “Symptom (Results from interview with

customer)” are reproduced. Data link connector

Continuity

Connector No. Terminal No.

M22 6 14 Not existed Data link connector

GroundContinuity

Connector No. Terminal No.

M22 6 Not existed

14 Not existed ECM

Resistance (Ω)

Terminal No.

84 83 Approx. 108 – 132

IPDM E/R Resistance (Ω)

Terminal No.

41 40 Approx. 108 – 132 LKIA0037E

Page 3606 of 4331

LAN

N

O P

Inspection result Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected. Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3607 of 4331

LT

N

O P

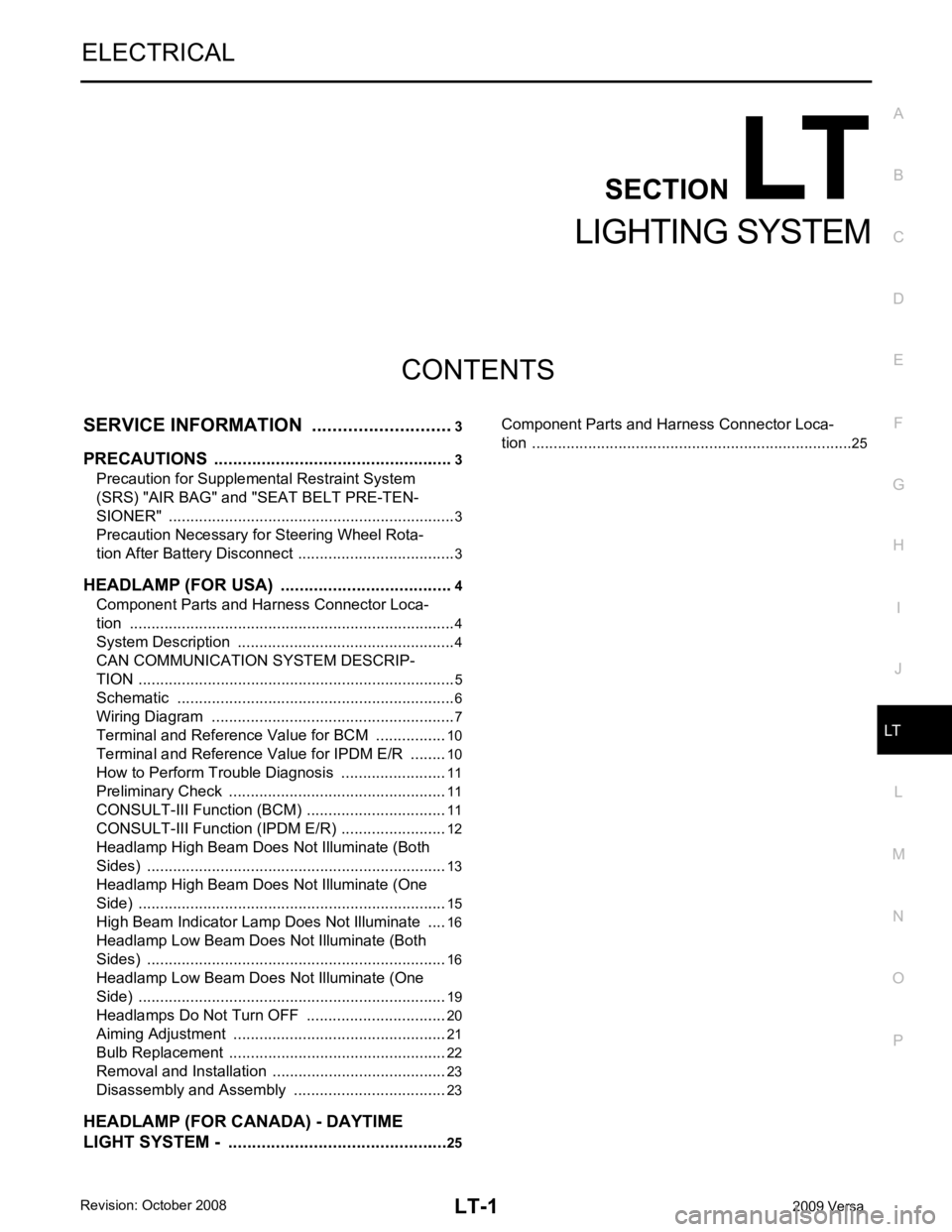

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

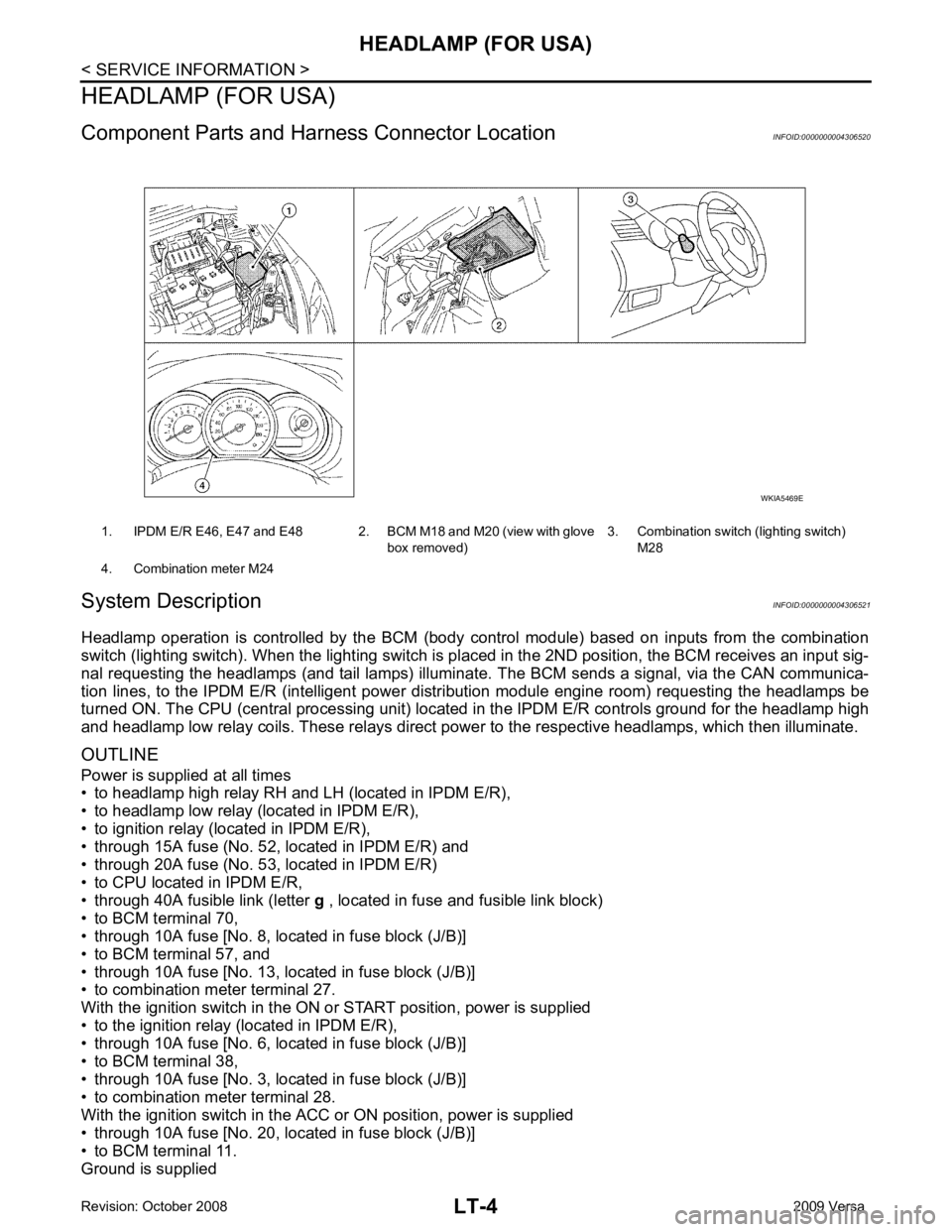

HEADLAMP (FOR USA) ................................ .....4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ............................................. ......4

CAN COMMUNICATION SYSTEM DESCRIP-

TION .................................................................... ......

5

Schematic ........................................................... ......6

Wiring Diagram ................................................... ......7

Terminal and Reference Value for BCM ............. ....10

Terminal and Reference Value for IPDM E/R ..... ....10

How to Perform Trouble Diagnosis ..................... ....11

Preliminary Check ............................................... ....11

CONSULT-III Function (BCM) ............................. ....11

CONSULT-III Function (IPDM E/R) ..................... ....12

Headlamp High Beam Does Not Illuminate (Both

Sides) .................................................................. ....

13

Headlamp High Beam Does Not Illuminate (One

Side) .................................................................... ....

15

High Beam Indicator Lamp Does Not Illuminate .....16

Headlamp Low Beam Does Not Illuminate (Both

Sides) .................................................................. ....

16

Headlamp Low Beam Does Not Illuminate (One

Side) .................................................................... ....

19

Headlamps Do Not Turn OFF ............................. ....20

Aiming Adjustment .............................................. ....21

Bulb Replacement ........ ...........................................22

Removal and Installation .........................................23

Disassembly and Assembly ................................ ....23

HEADLAMP (FOR CANADA) - DAYTIME

LIGHT SYSTEM - ........................................... ....25 Component Parts and Harness Connector Loca-

tion ....................................................................... ....

25

Page 3608 of 4331

Page 3609 of 4331

LT

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004306519

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004683900

NOTE:

• This Procedure is applied only to models with Inte lligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 3610 of 4331