NISSAN TIIDA 2009 Service Repair Manual

TIIDA 2009

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57398/w960_57398-0.png

NISSAN TIIDA 2009 Service Repair Manual

Trending: electrical diagram, oil capacity, Keyless, wheel bolt torque, roof rack, power window system, keyless entry

Page 3621 of 4331

LT

N

O P

OK or NG OK >> GO TO 7.

NG >> GO TO 8. OK >> Check front combination lamp connector for damage or

poor connection. Repair as necessary.

NG >> Repair harness. OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and

Installation of IPDM E/R " .

NG >> Repair harness or connector.

Headlamp High Beam Does No t Illuminate (One Side) INFOID:0000000004306532OK >> GO TO 2.

NG >> Repair harness. OK >> GO TO 3.

NG >> Replace bulb. Refer to LT-22, " Bulb Replacement " .Headlamp connector Terminal

Ground Continuity

RH E26 2 Yes

LH E25

Page 3622 of 4331

LT-16< SERVICE INFORMATION >

HEADLAMP (FOR USA)

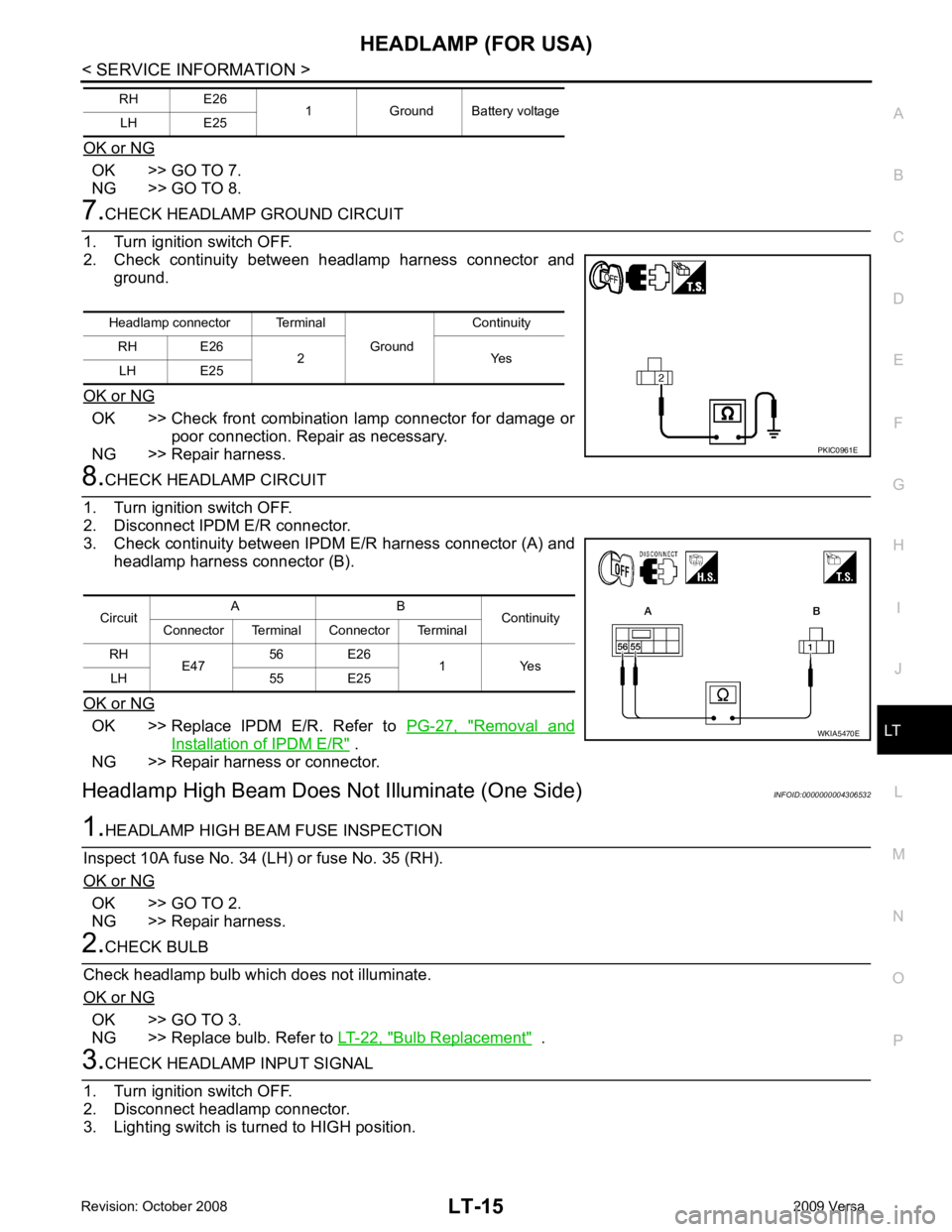

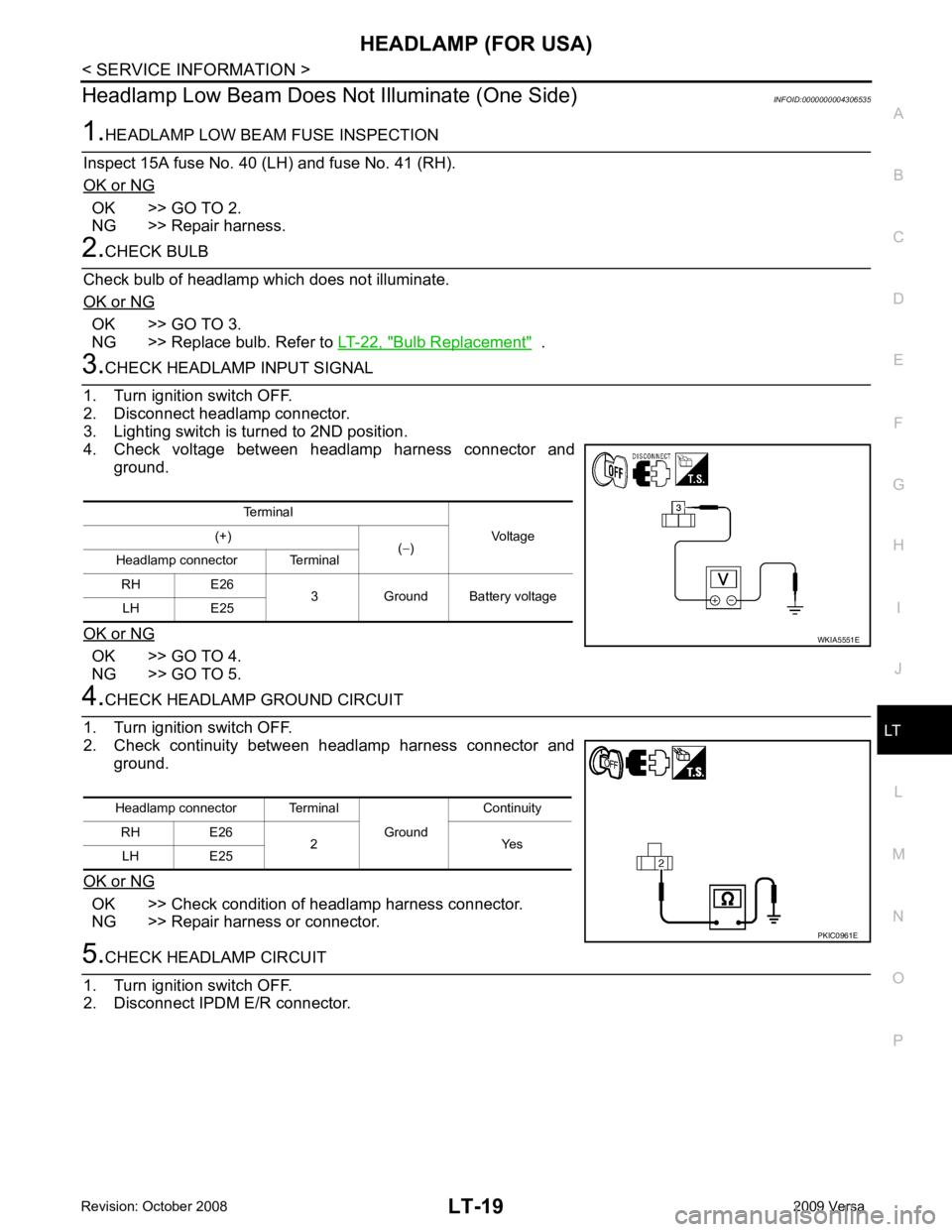

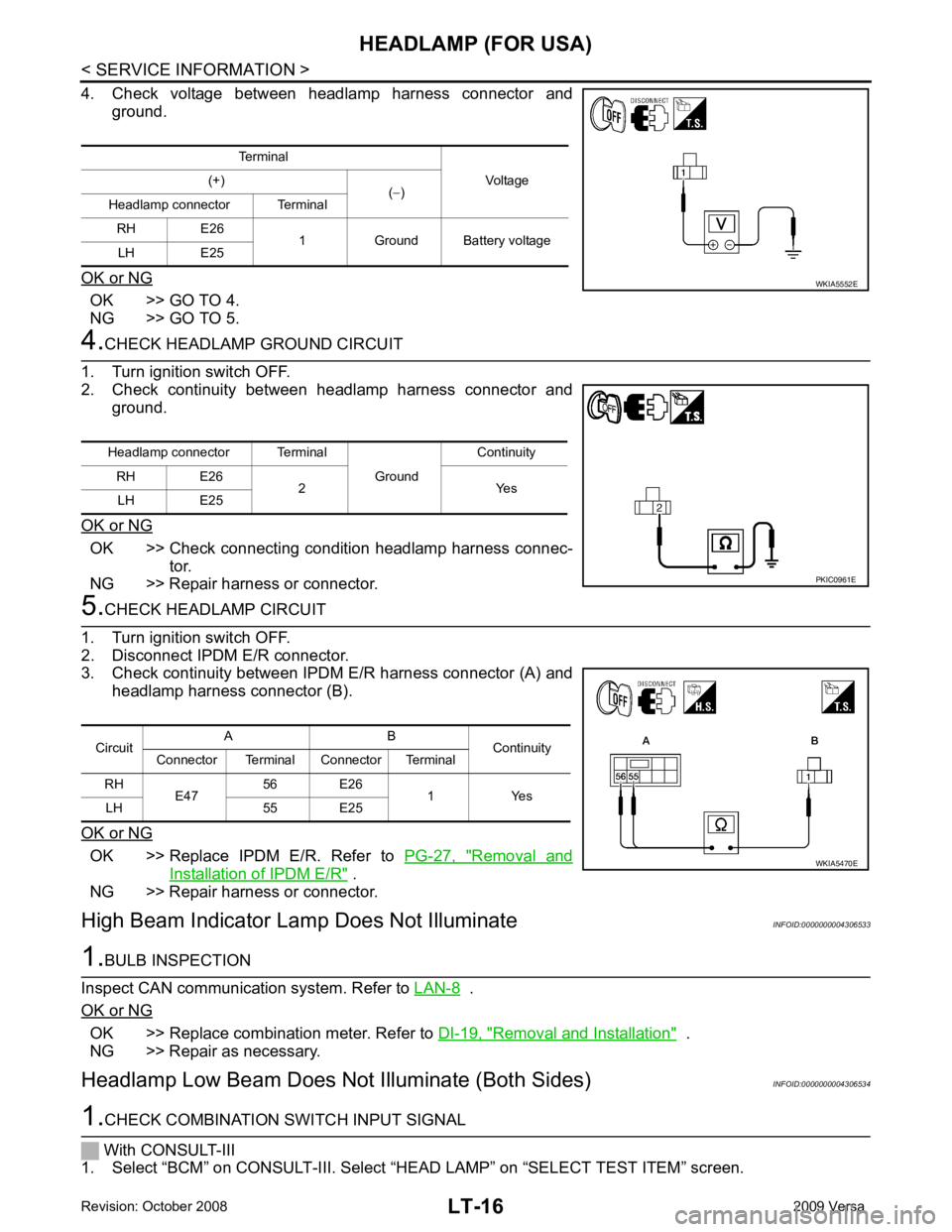

4. Check voltage between headlamp harness connector and ground.

OK or NG OK >> GO TO 4.

NG >> GO TO 5. 4.

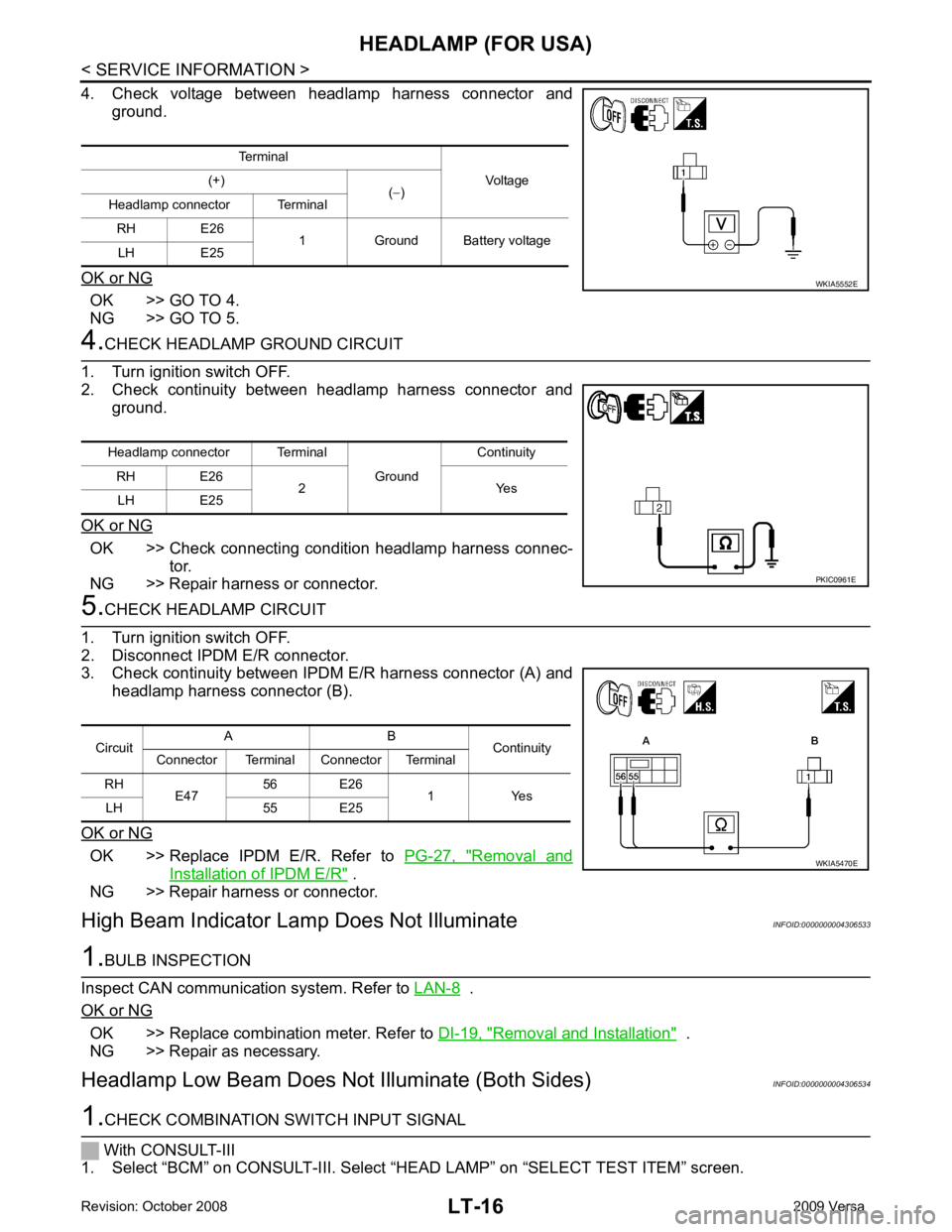

CHECK HEADLAMP GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between headlamp harness connector and ground.

OK or NG OK >> Check connecting condition headlamp harness connec-

tor.

NG >> Repair harness or connector. 5.

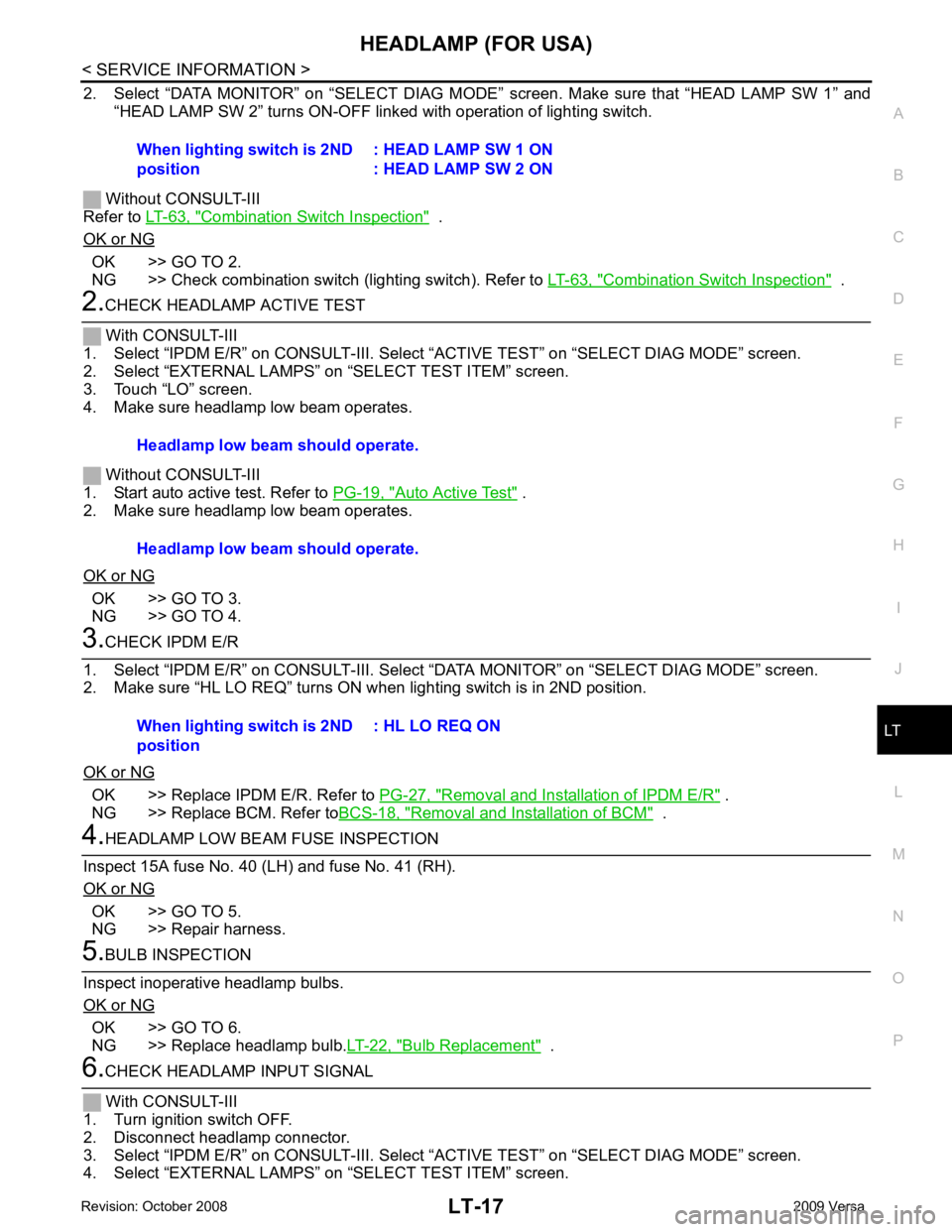

CHECK HEADLAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector (A) and

headlamp harness connector (B).

OK or NG OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and

Installation of IPDM E/R " .

NG >> Repair harness or connector.

High Beam Indicator Lam p Does Not Illuminate INFOID:00000000043065331.

BULB INSPECTION

Inspect CAN communication system. Refer to LAN-8 .

OK or NG OK >> Replace combination meter. Refer to

DI-19, " Removal and Installation " .

NG >> Repair as necessary.

Headlamp Low Beam Does Not Illuminate (Both Sides) INFOID:00000000043065341.

CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

Terminal

Voltage

(+)

(− )

Headlamp connector Terminal

RH E26 1 Ground Battery voltage

LH E25 WKIA5552E

Headlamp connector Terminal

Ground Continuity

RH E26 2 Yes

LH E25 PKIC0961E

Circuit

A B

Continuity

Connector Terminal Connector Terminal

RH E47 56 E26

1 Yes

LH 55 E25 WKIA5470E

Page 3623 of 4331

LT

N

O P

2. Select “DATA MONITOR” on “SELECT DIAG MODE”

screen. Make sure that “HEAD LAMP SW 1” and

“HEAD LAMP SW 2” turns ON-OFF li nked with operation of lighting switch.

Without CONSULT-III

Refer to LT-63, " Combination Switch Inspection " .

OK or NG OK >> GO TO 2.

NG >> Check combination switch (lighting switch). Refer to LT-63, " Combination Switch Inspection " .

Auto Active Test " .

2. Make sure headlamp low beam operates.

OK or NG OK >> GO TO 3.

NG >> GO TO 4. OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

NG >> Replace BCM. Refer to BCS-18, " Removal and Installation of BCM " .

OK >> GO TO 5.

NG >> Repair harness. OK >> GO TO 6.

NG >> Replace headlamp bulb. LT-22, " Bulb Replacement " .When lighting switch is 2ND

position : HL LO REQ ON

Page 3624 of 4331

Auto Active Test " .

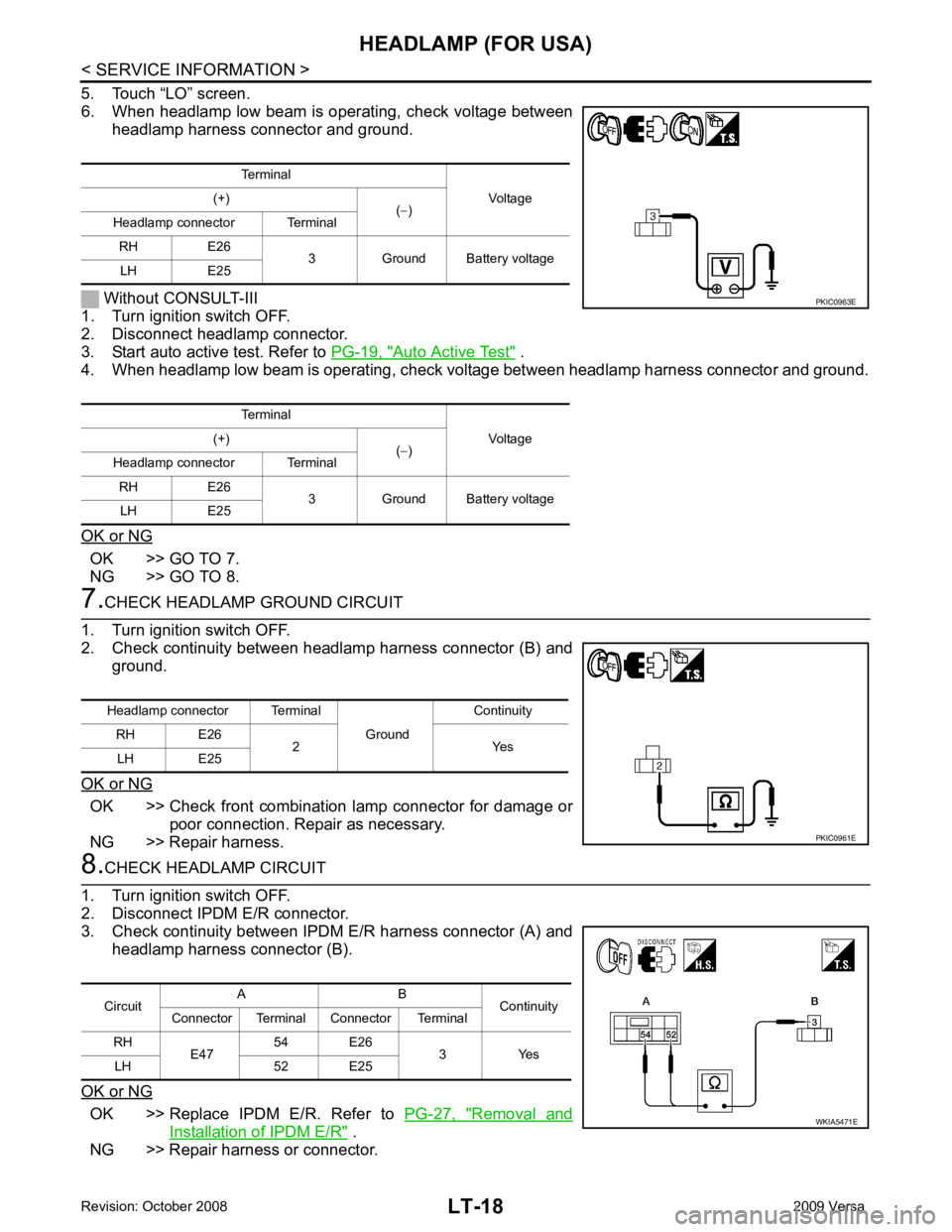

4. When headlamp low beam is operating, chec k voltage between headlamp harness connector and ground.

OK or NG OK >> GO TO 7.

NG >> GO TO 8. OK >> Check front combination lamp connector for damage or

poor connection. Repair as necessary.

NG >> Repair harness. OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and

Installation of IPDM E/R " .

NG >> Repair harness or connector. Terminal

Voltage

(+)

(− )

Headlamp connector Terminal

RH E26 3 Ground Battery voltage

LH E25

Terminal Voltage

(+)

(− )

Headlamp connector Terminal

RH E26 3 Ground Battery voltage

LH E25

Page 3625 of 4331

LT

N

O P

Headlamp Low Beam Does

Not Illuminate (One Side) INFOID:0000000004306535OK >> GO TO 2.

NG >> Repair harness. OK >> GO TO 3.

NG >> Replace bulb. Refer to LT-22, " Bulb Replacement " .

OK >> GO TO 4.

NG >> GO TO 5. OK >> Check condition of headlamp harness connector.

NG >> Repair harness or connector.

Page 3626 of 4331

LT-20< SERVICE INFORMATION >

HEADLAMP (FOR USA)

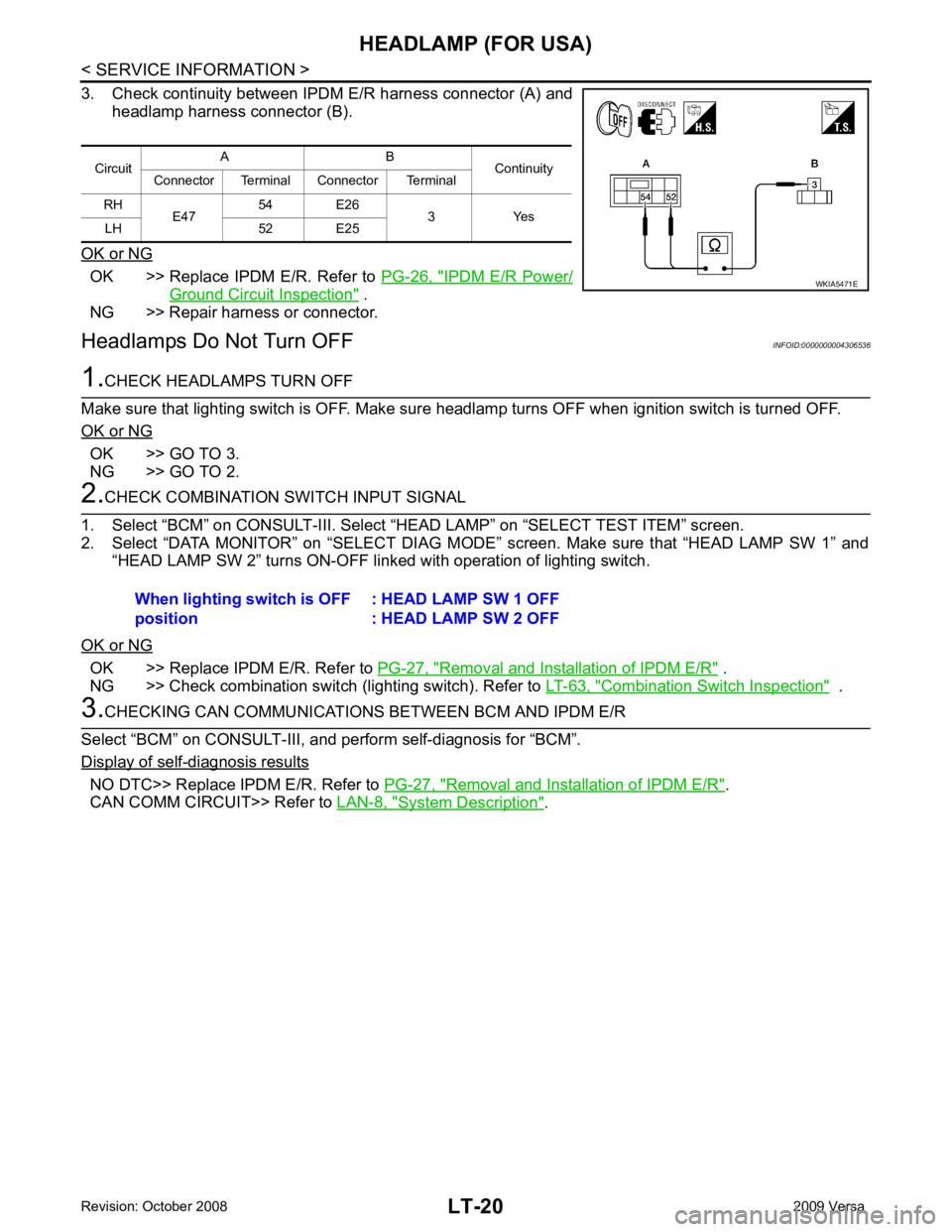

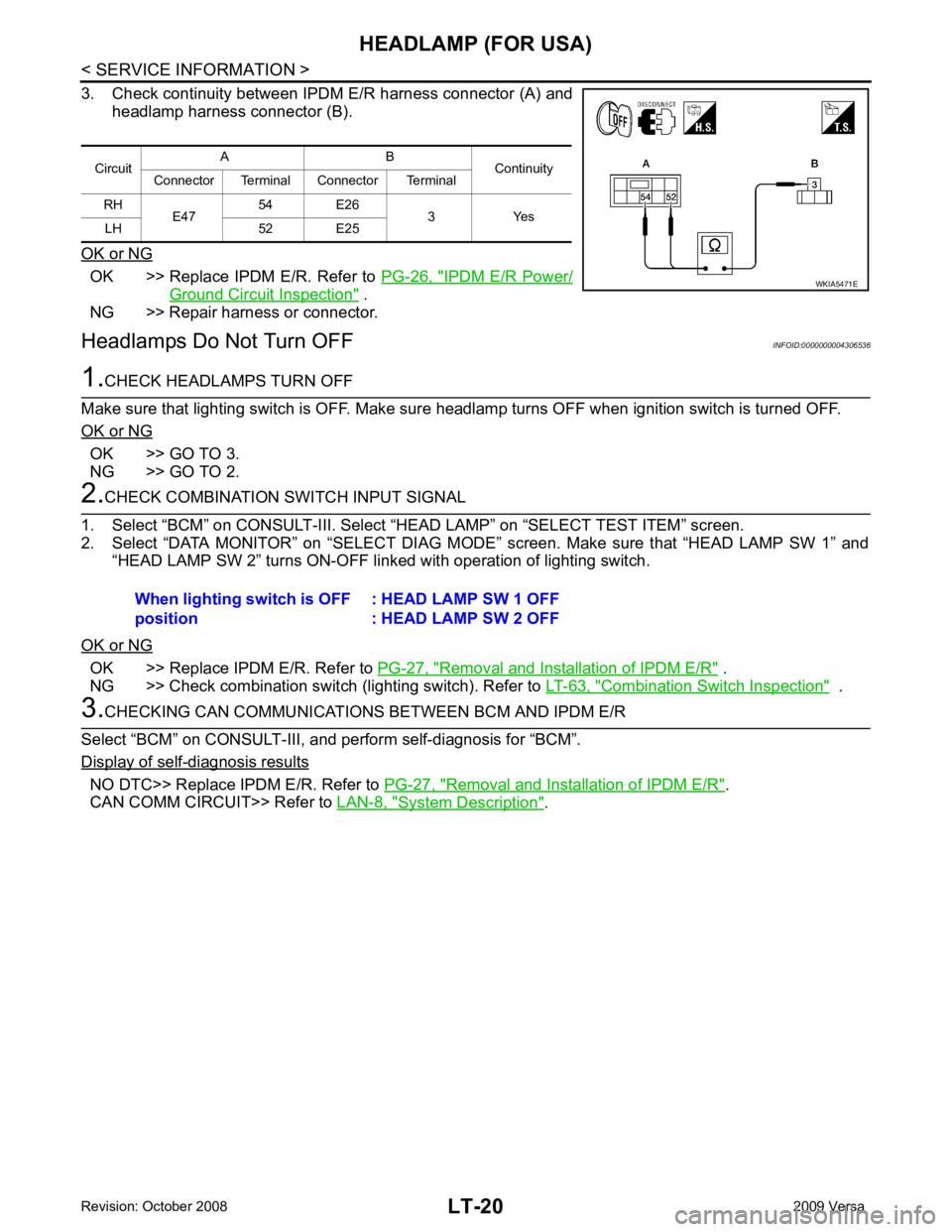

3. Check continuity between IPDM E/R harness connector (A) and

headlamp harness connector (B).

OK or NG OK >> Replace IPDM E/R. Refer to

PG-26, " IPDM E/R Power/

Ground Circuit Inspection " .

NG >> Repair harness or connector.

Headlamps Do Not Turn OFF INFOID:00000000043065361.

CHECK HEADLAMPS TURN OFF

Make sure that lighting switch is OFF. Make sure headlamp turns OFF when ignition switch is turned OFF.

OK or NG OK >> GO TO 3.

NG >> GO TO 2. 2.

CHECK COMBINATION SWITCH INPUT SIGNAL

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen. Make sure that “HEAD LAMP SW 1” and

“HEAD LAMP SW 2” turns ON-OFF linked with operation of lighting switch.

OK or NG OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

NG >> Check combination switch (lighting switch). Refer to LT-63, " Combination Switch Inspection " .

3.

CHECKING CAN COMMUNICATIONS BETWEEN BCM AND IPDM E/R

Select “BCM” on CONSULT-III, and perform self-diagnosis for “BCM”.

Display of self - diagnosis results

NO DTC>> Replace IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

CAN COMM CIRCUIT>> Refer to LAN-8, " System Description " .

Circuit

A B

Continuity

Connector Terminal Connector Terminal

RH E47 54 E26

3 Yes

LH 52 E25 WKIA5471E

When lighting switch is OFF

position : HEAD LAMP SW 1 OFF

: HEAD LAMP SW 2 OFF

Page 3627 of 4331

LT

N

O P

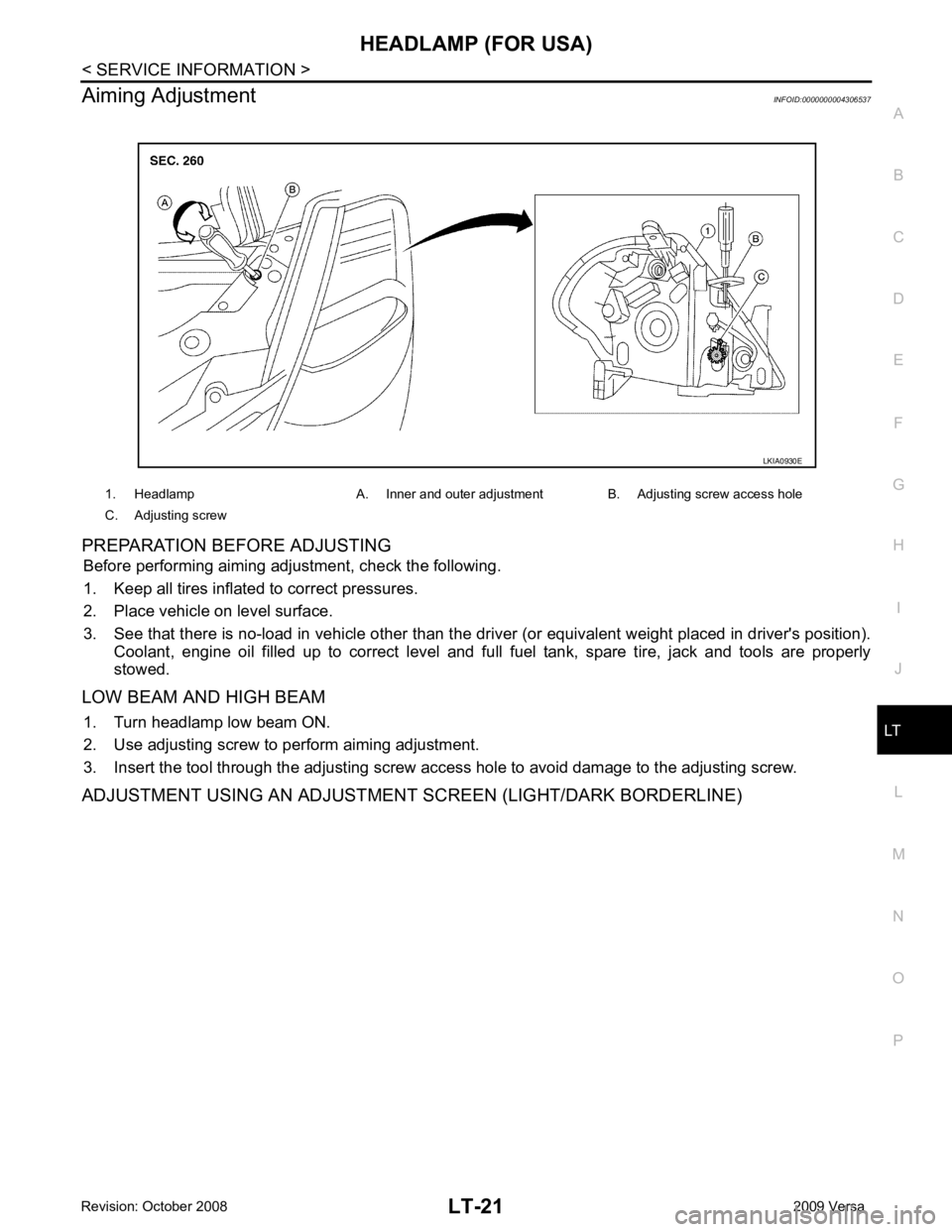

Aiming Adjustment

INFOID:0000000004306537

PREPARATION BEFORE ADJUSTING Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on level surface.

3. See that there is no-load in vehicle other than the driv er (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank, spare tire, jack and tools are properly

stowed.

LOW BEAM AND HIGH BEAM 1. Turn headlamp low beam ON.

2. Use adjusting screw to perform aiming adjustment.

3. Insert the tool through the adjusting screw acce ss hole to avoid damage to the adjusting screw.

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE) 1. Headlamp A. Inner and outer adjustment B. Adjusting screw access hole

C. Adjusting screw

Page 3628 of 4331

Removal and Installation " .

3. Remove back cover.

4. Unlock retaining spring and remove bulb from headlamp.

PARKING (CLEARANCE) LAMP

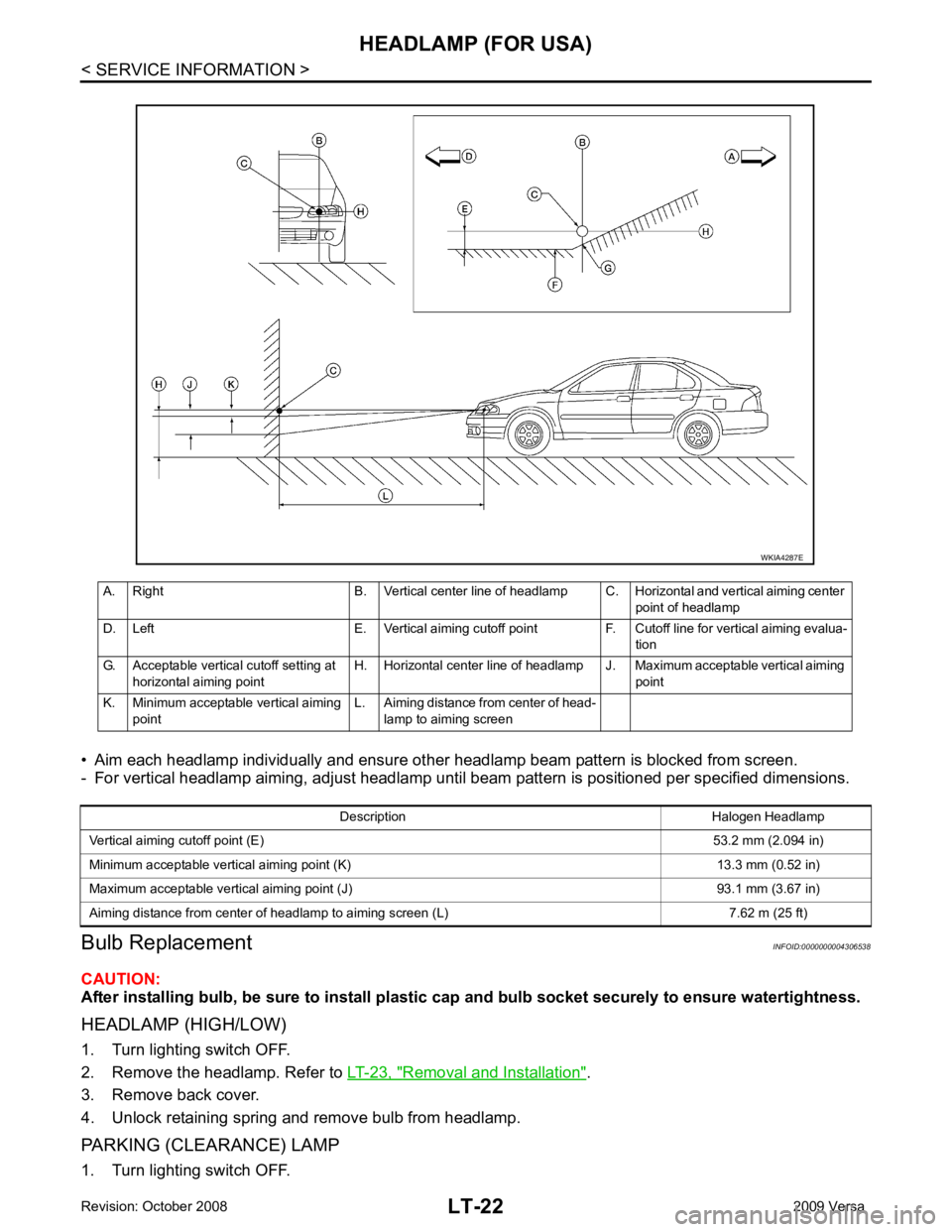

1. Turn lighting switch OFF. A. Right B. Vertical center line of headlamp C. Horizontal and vertical aiming center

point of headlamp

D. Left E. Vertical aiming cutoff point F. Cutoff line for vertical aiming evalua- tion

G. Acceptable vertical cutoff setting at horizontal aiming point H. Horizontal center line of headlamp J. Maximum acceptable vertical aiming

point

K. Minimum acceptable vertical aiming point L. Aiming distance from center of head-

lamp to aiming screen

Page 3629 of 4331

LT

N

O P

2. Remove the headlamp. Refer to

LT-23, " Removal and Installation " .

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP 1. Turn lighting switch OFF.

2. Remove the headlamp. Refer to LT-23, " Removal and Installation " .

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

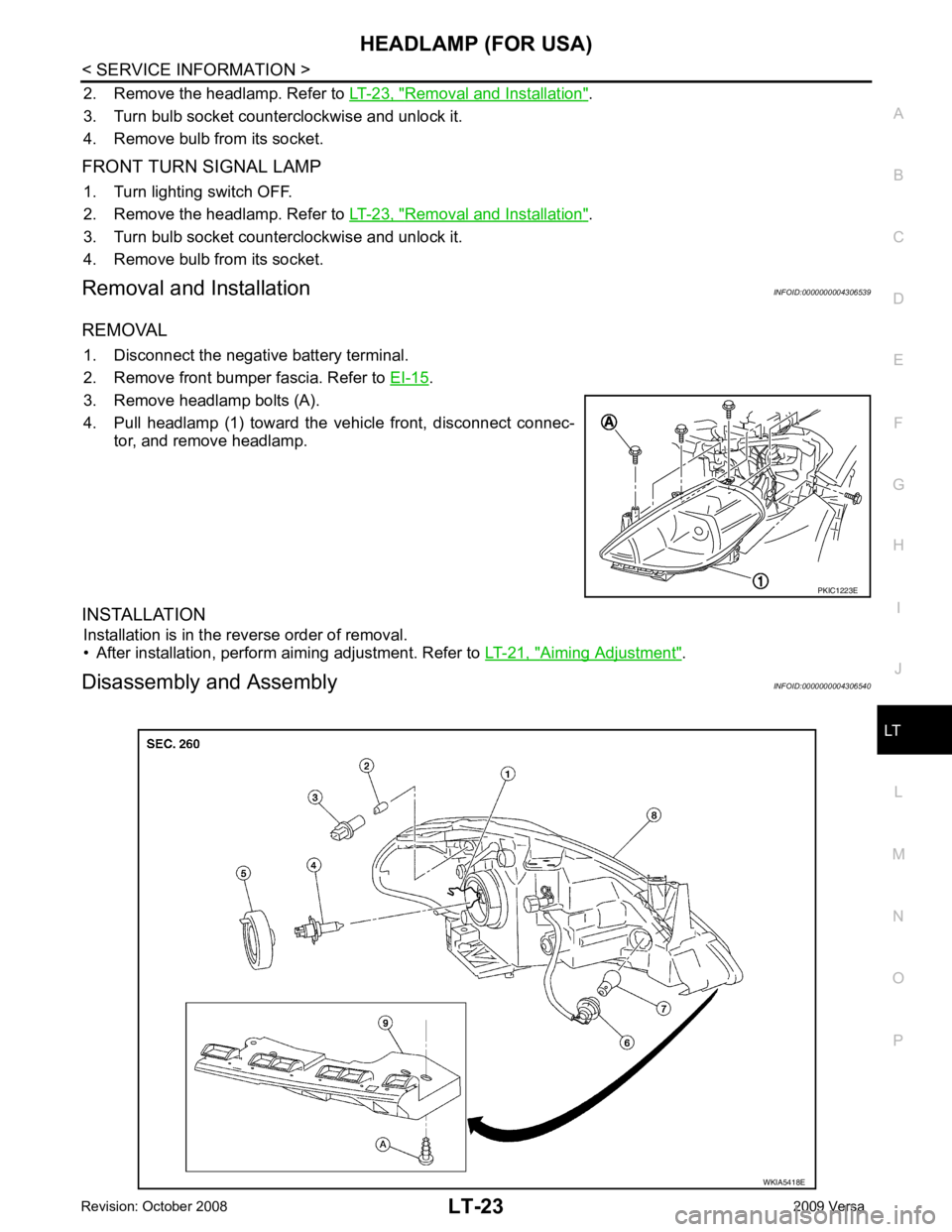

Removal and Installation INFOID:0000000004306539

REMOVAL 1. Disconnect the negative battery terminal.

2. Remove front bumper fascia. Refer to EI-15 .

3. Remove headlamp bolts (A).

4. Pull headlamp (1) toward the vehicle front, disconnect connec- tor, and remove headlamp.

INSTALLATION Installation is in the reverse order of removal.

• After installation, perform aiming adjustment. Refer to LT-21, " Aiming Adjustment " .

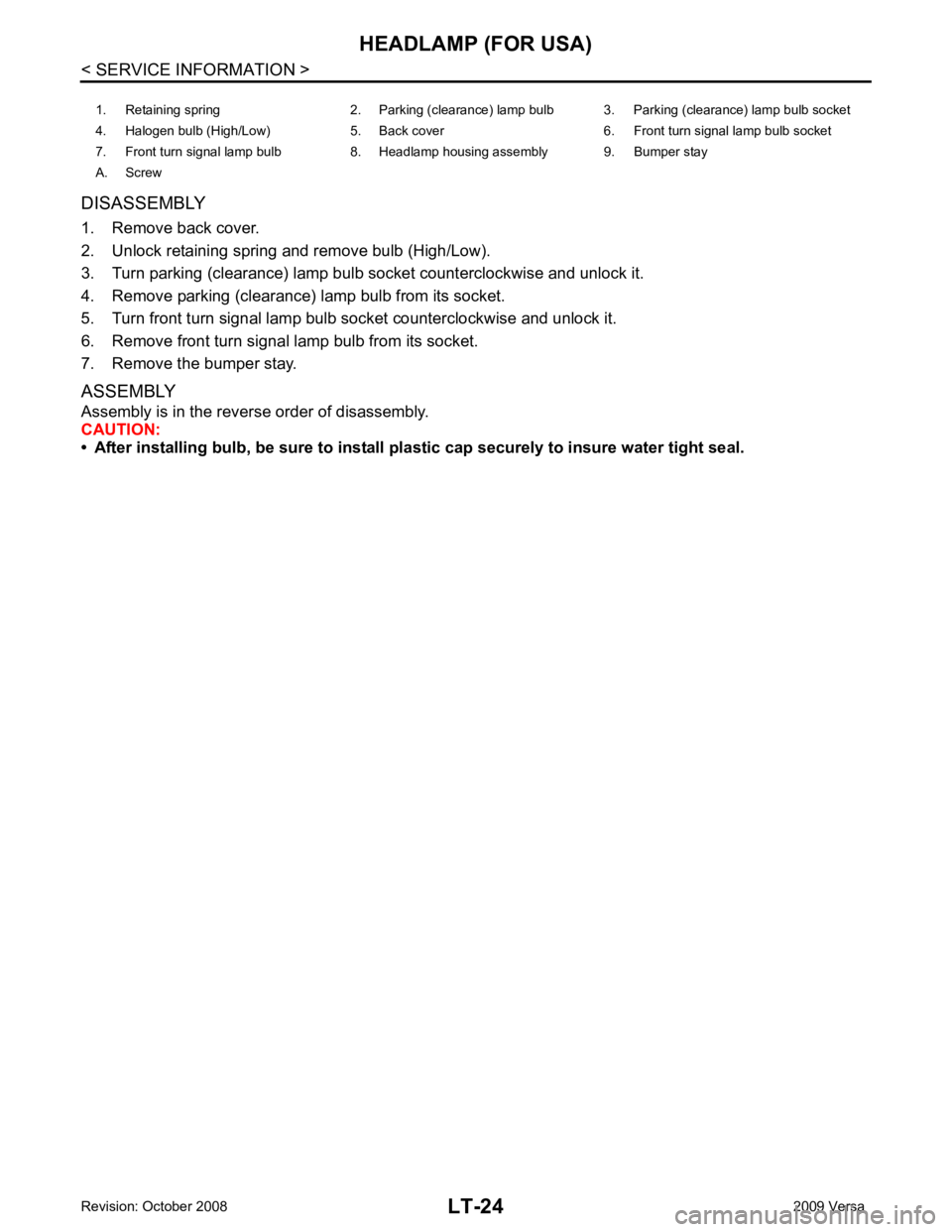

Disassembly and Assembly INFOID:0000000004306540 WKIA5418E

Page 3630 of 4331

Trending: display, maintenance schedule, door, service indicator, Camshaft position sensor, brake sensor, fuse box