NISSAN TIIDA 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3931 of 4331

YES >> Perform diagnostic work flow. Refer to "DIAGNOSTIC WORK FLOW".

NO >> GO TO 8. OK >> GO TO 9.

NG >> Perform diagnostic work flow. Refer to "DIAGNOSTIC WORK FLOW". OK >> If the symptom still exists, perform

a complete operational check. Refer to MTC-30, " Operational

Check " . If other symptoms exist, refer to

MTC-22, " How to Perform Trouble Diagnosis for Quick

and Accurate Repair " .

NG >> Repair air leaks.

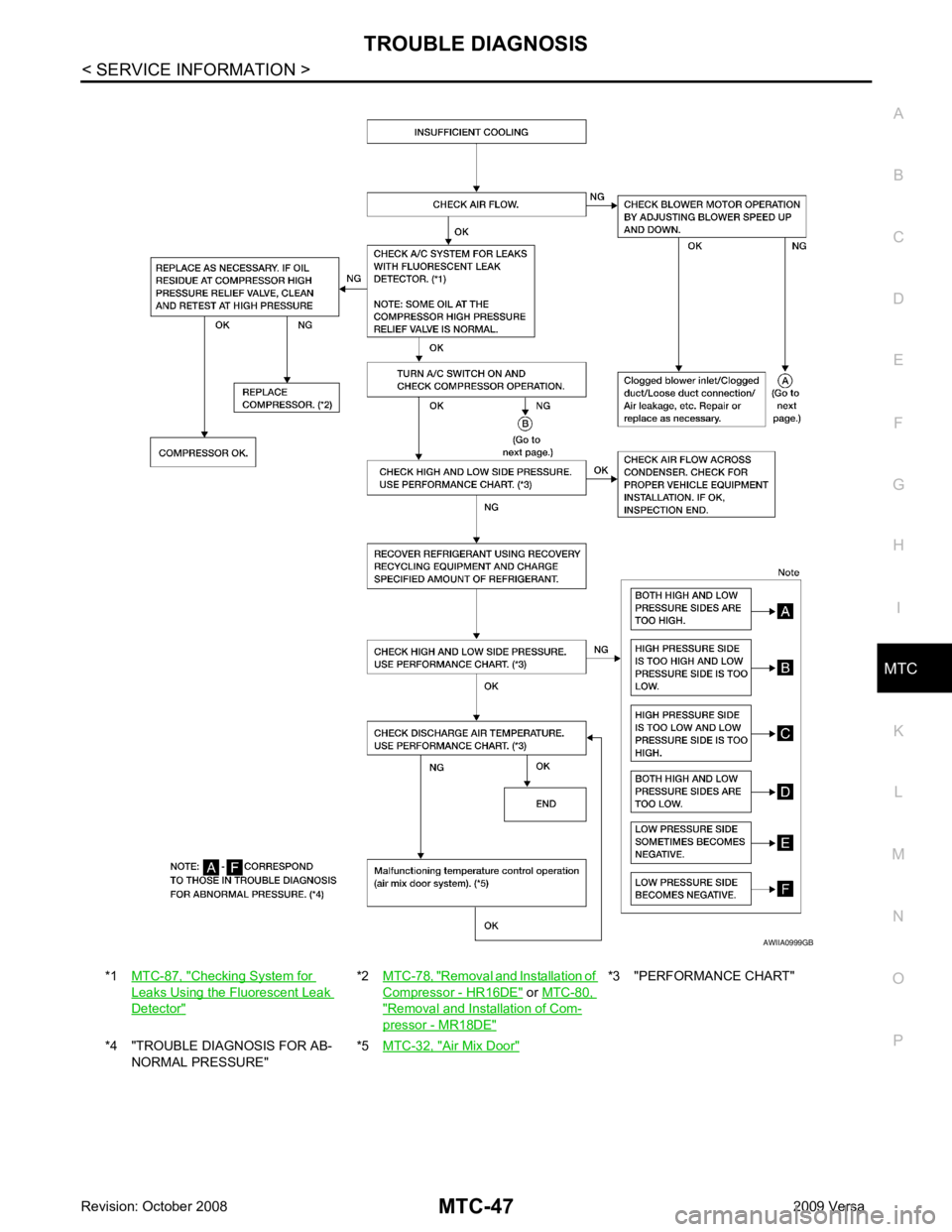

DIAGNOSTIC WORK FLOW

Page 3932 of 4331

MTC

N

O P

*1

MTC-87, " Checking System for

Leaks Using the Fluorescent Leak

Detector " *2

MTC-78, " Removal and Installation of

Compressor - HR16DE " or

MTC-80, " Removal and Installation of Com-

pressor - MR18DE " *3 "PERFORMANCE CHART"

*4 "TROUBLE DIAGNOSIS FOR AB- NORMAL PRESSURE" *5

MTC-32, " Air Mix Door "

Page 3933 of 4331

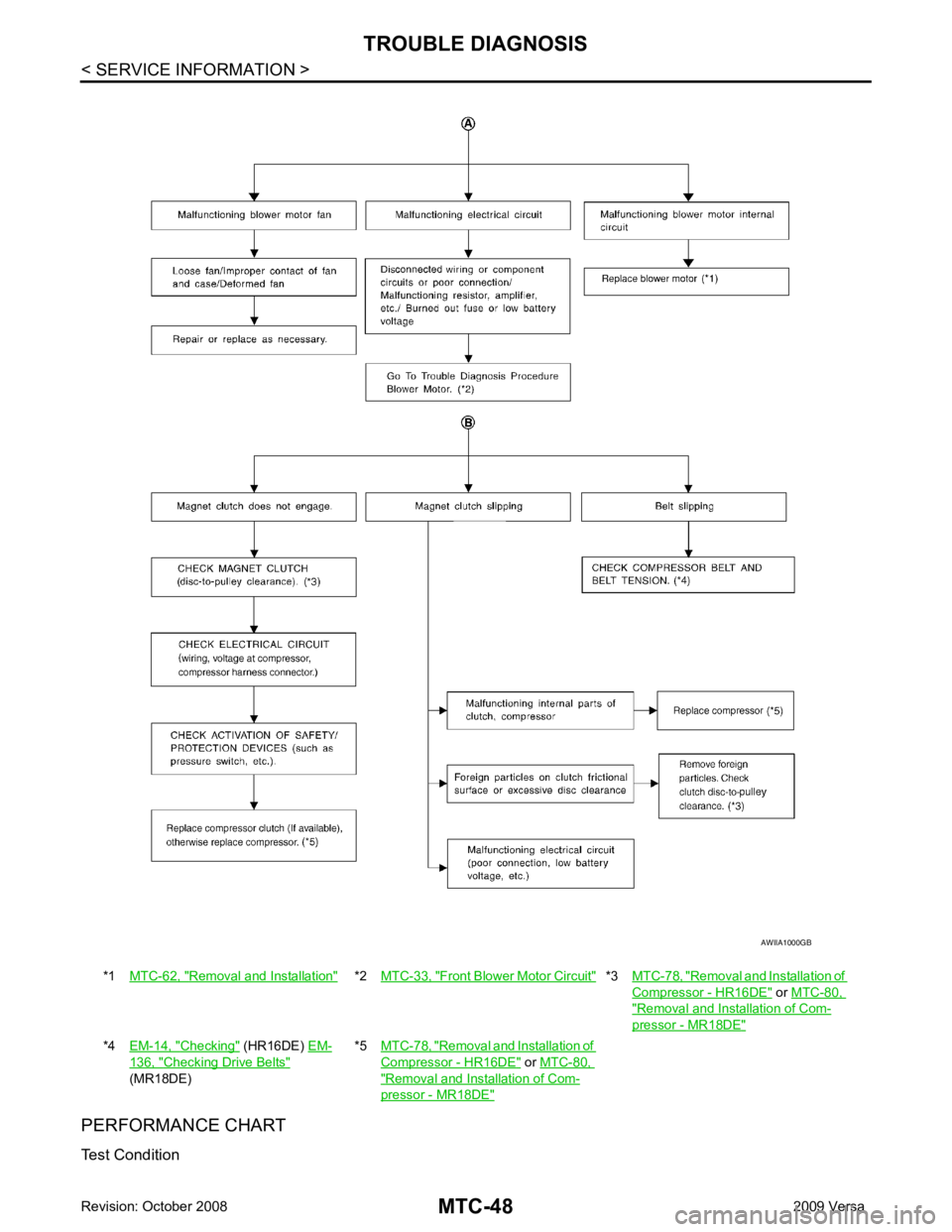

Removal and Installation " *2

MTC-33, " Front Blower Motor Circuit " *3

MTC-78, " Removal and Installation of

Compressor - HR16DE " or

MTC-80, " Removal and Installation of Com-

pressor - MR18DE "

*4

EM-14, " Checking " (HR16DE)

EM- 136, " Checking Drive Belts "

(MR18DE) *5

MTC-78, " Removal and Installation of

Compressor - HR16DE " or

MTC-80, " Removal and Installation of Com-

pressor - MR18DE "

Page 3934 of 4331

MTC

N

O P

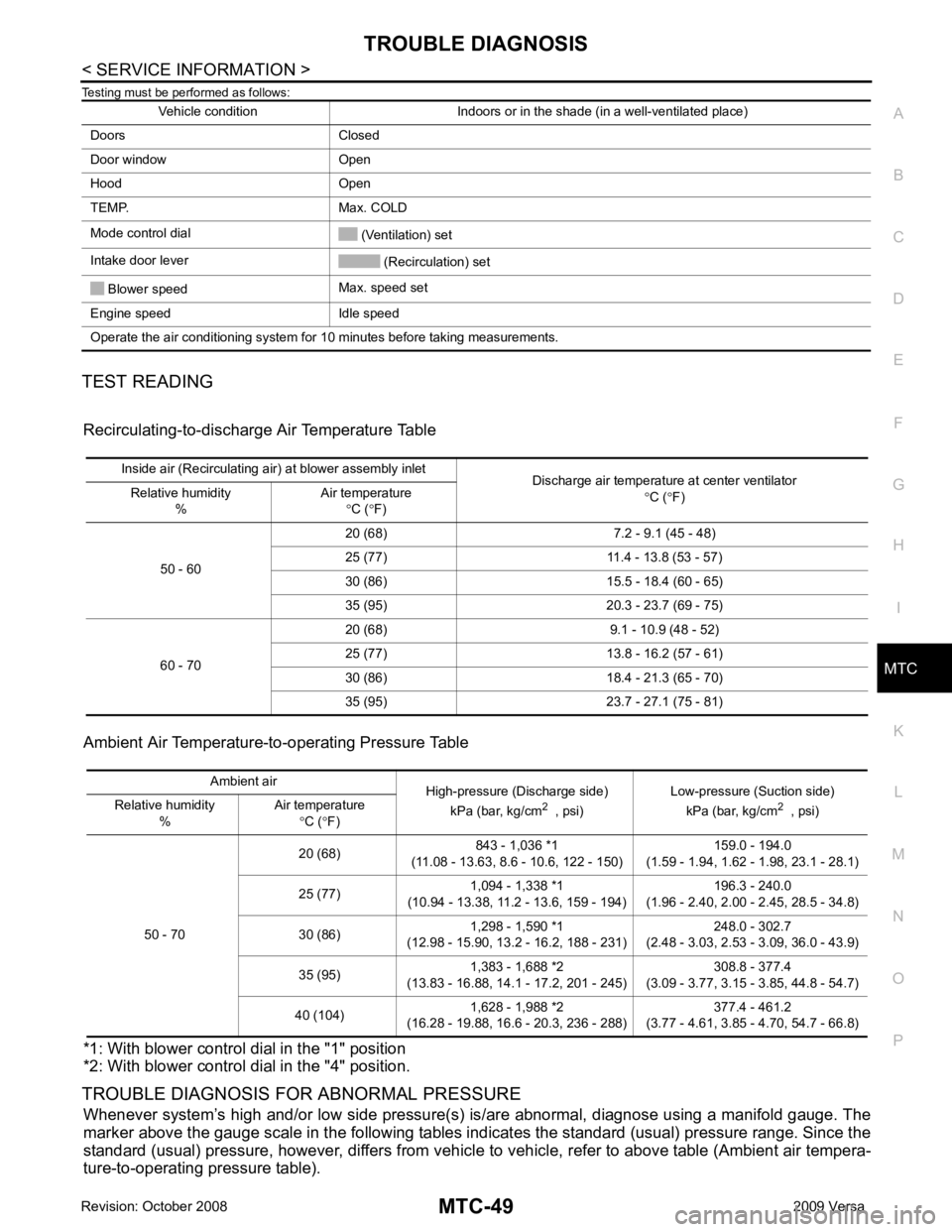

Testing must be performed as follows:

TEST READING Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

*1: With blower control dial in the "1" position

*2: With blower control dial in the "4" position.

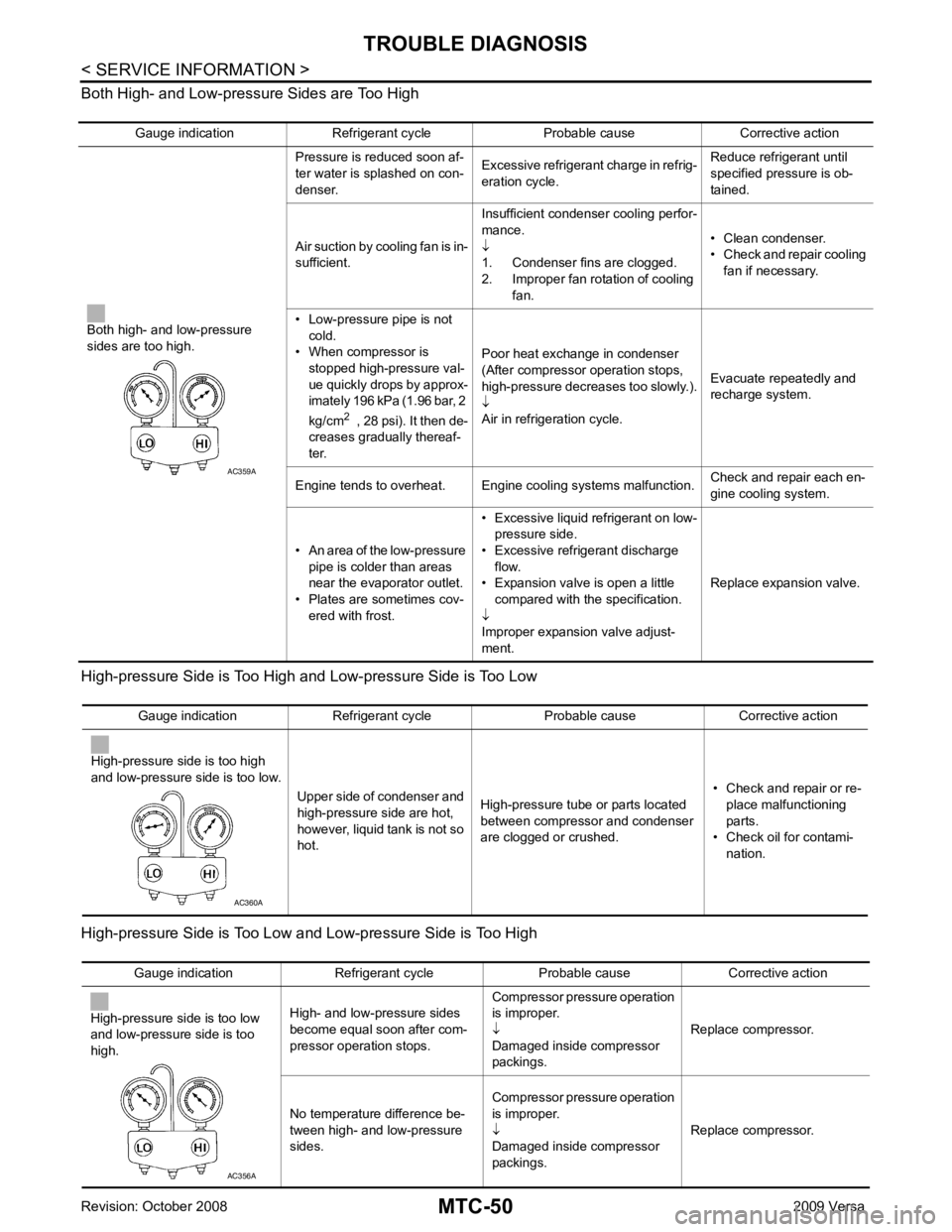

TROUBLE DIAGNOSIS FOR ABNORMAL PRESSURE Whenever system’s high and/or low side pressure(s) is /are abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table). Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode control dial (Ventilation) set

Intake door lever (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements. Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68) 7.2 - 9.1 (45 - 48)

25 (77) 11.4 - 13.8 (53 - 57)

30 (86) 15.5 - 18.4 (60 - 65)

35 (95) 20.3 - 23.7 (69 - 75)

60 - 70 20 (68) 9.1 - 10.9 (48 - 52)

25 (77) 13.8 - 16.2 (57 - 61)

30 (86) 18.4 - 21.3 (65 - 70)

35 (95) 23.7 - 27.1 (75 - 81) Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm 2

, psi) Low-pressure (Suction side)

kPa (bar, kg/cm 2

, psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

843 - 1,036 *1

(11.08 - 13.63, 8.6 - 10.6, 122 - 150) 159.0 - 194.0

(1.59 - 1.94, 1.62 - 1.98, 23.1 - 28.1)

25 (77) 1,094 - 1,338 *1

(10.94 - 13.38, 11.2 - 13.6, 159 - 194) 196.3 - 240.0

(1.96 - 2.40, 2.00 - 2.45, 28.5 - 34.8)

30 (86) 1,298 - 1,590 *1

(12.98 - 15.90, 13.2 - 16.2, 188 - 231) 248.0 - 302.7

(2.48 - 3.03, 2.53 - 3.09, 36.0 - 43.9)

35 (95) 1,383 - 1,688 *2

(13.83 - 16.88, 14.1 - 17.2, 201 - 245) 308.8 - 377.4

(3.09 - 3.77, 3.15 - 3.85, 44.8 - 54.7)

40 (104) 1,628 - 1,988 *2

(16.28 - 19.88, 16.6 - 20.3, 236 - 288) 377.4 - 461.2

(3.77 - 4.61, 3.85 - 4.70, 54.7 - 66.8)

Page 3935 of 4331

Page 3936 of 4331

MTC

N

O P

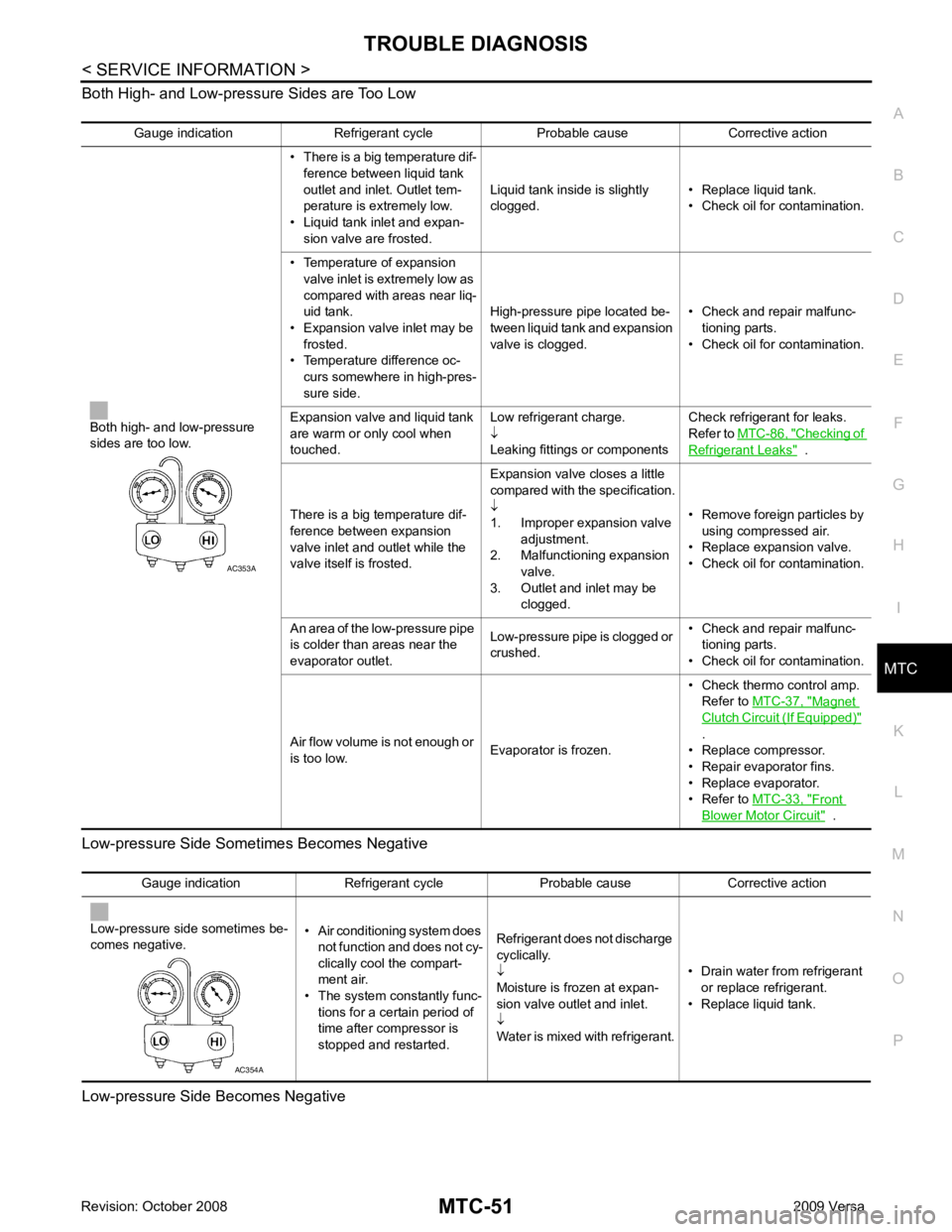

Both High- and Low-pressure Sides are Too Low

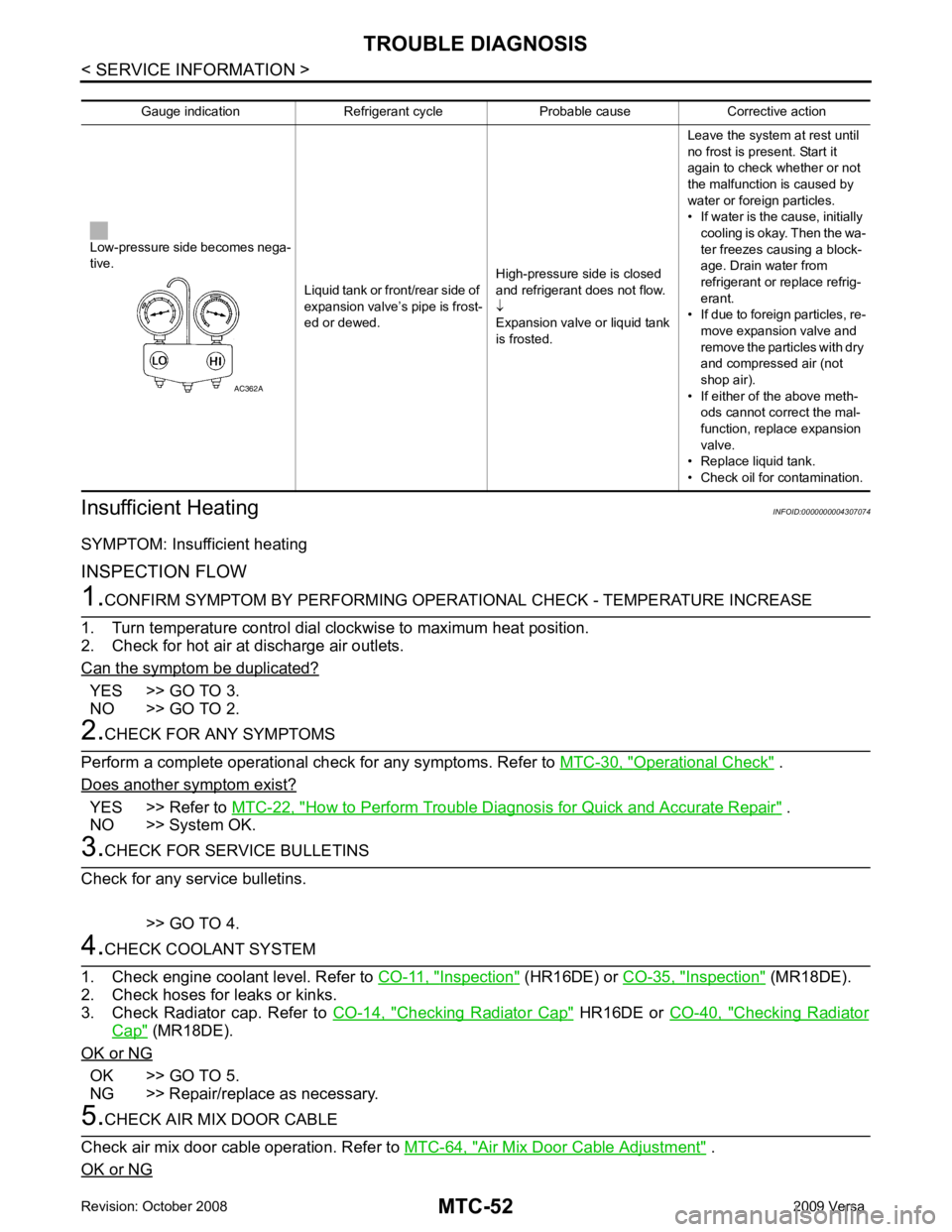

Low-pressure Side Some times Becomes Negative

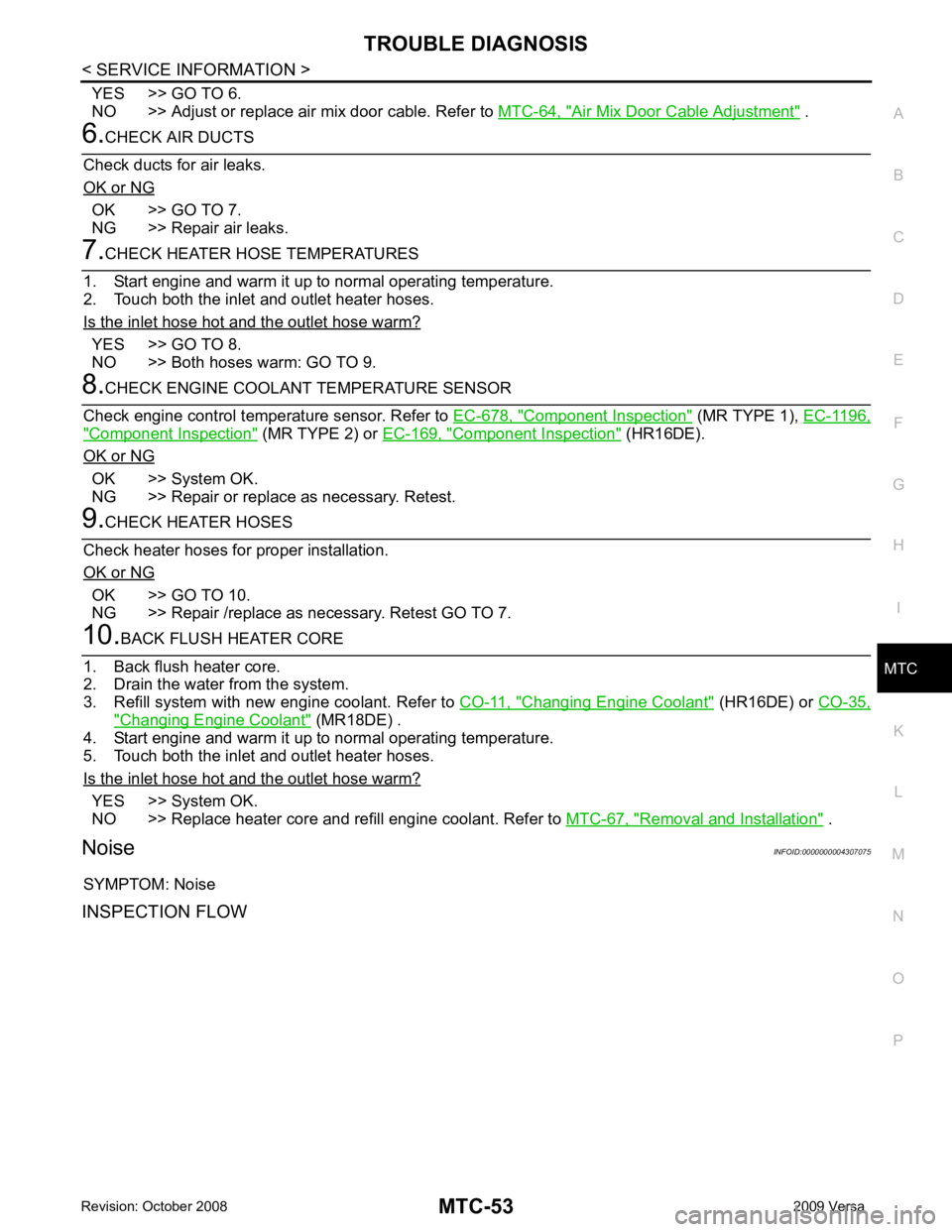

Low-pressure Side Becomes Negative Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. • There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

• Liquid tank inlet and expan- sion valve are frosted. Liquid tank inside is slightly

clogged. • Replace liquid tank.

• Check oil for contamination.

• Temperature of expansion valve inlet is extremely low as

compared with areas near liq-

uid tank.

• Expansion valve inlet may be

frosted.

• Temperature difference oc- curs somewhere in high-pres-

sure side. High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. • Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched. Low refrigerant charge.

↓

Leaking fittings or components Check refrigerant for leaks.

Refer to MTC-86, " Checking of

Refrigerant Leaks " .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted. Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion valve.

3. Outlet and inlet may be clogged. • Remove foreign particles by

using compressed air.

• Replace expansion valve.

• Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet. Low-pressure pipe is clogged or

crushed. • Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Air flow volume is not enough or

is too low. Evaporator is frozen.• Check thermo control amp.

Refer to MTC-37, " Magnet

Clutch Circuit (If Equipped) "

.

• Replace compressor.

• Repair evaporator fins.

• Replace evaporator.

• Refer to MTC-33, " Front

Blower Motor Circuit " .

Page 3937 of 4331

YES >> GO TO 3.

NO >> GO TO 2. Operational Check " .

Does another symptom exist? YES >> Refer to

MTC-22, " How to Perform Trouble Diagnosis for Quick and Accurate Repair " .

NO >> System OK. Inspection " (HR16DE) or

CO-35, " Inspection " (MR18DE).

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to CO-14, " Checking Radiator Cap " HR16DE or

CO-40, " Checking Radiator

Cap " (MR18DE).

OK or NG OK >> GO TO 5.

NG >> Repair/replace as necessary. Air Mix Door Cable Adjustment " .

OK or NG

Page 3938 of 4331

MTC

N

O P

YES >> GO TO 6.

NO >> Adjust or replace air mix door cable. Refer to MTC-64, " Air Mix Door Cable Adjustment " .

OK >> GO TO 7.

NG >> Repair air leaks. YES >> GO TO 8.

NO >> Both hoses warm: GO TO 9. Component Inspection " (MR TYPE 1),

EC-1196," Component Inspection " (MR TYPE 2) or

EC-169, " Component Inspection " (HR16DE).

OK or NG OK >> System OK.

NG >> Repair or replace as necessary. Retest. OK >> GO TO 10.

NG >> Repair /replace as necessary. Retest GO TO 7. Changing Engine Coolant " (HR16DE) or

CO-35, " Changing Engine Coolant " (MR18DE) .

4. Start engine and warm it up to normal operating temperature.

5. Touch both the inlet and outlet heater hoses.

Is the inlet hose hot and the outlet hose warm? YES >> System OK.

NO >> Replace heater core and refill engine coolant. Refer to MTC-67, " Removal and Installation " .

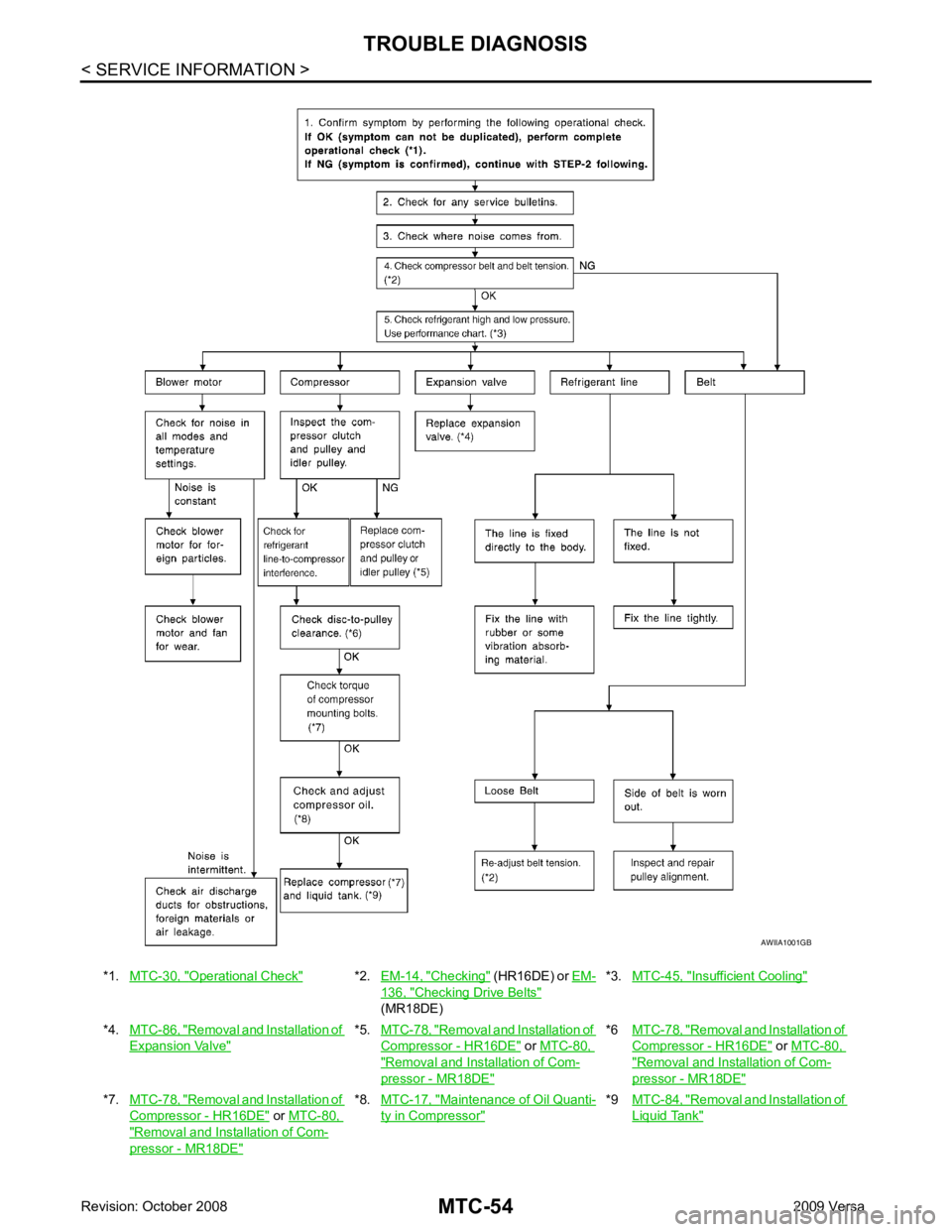

Noise INFOID:0000000004307075

SYMPTOM: Noise

INSPECTION FLOW

Page 3939 of 4331

Operational Check " *2.

EM-14, " Checking " (HR16DE) or

EM- 136, " Checking Drive Belts "

(MR18DE) *3.

MTC-45, " Insufficient Cooling "

*4.

MTC-86, " Removal and Installation of

Expansion Valve " *5.

MTC-78, " Removal and Installation of

Compressor - HR16DE " or

MTC-80, " Removal and Installation of Com-

pressor - MR18DE " *6

MTC-78, " Removal and Installation of

Compressor - HR16DE " or

MTC-80, " Removal and Installation of Com-

pressor - MR18DE "

*7.

MTC-78, " Removal and Installation of

Compressor - HR16DE " or

MTC-80, " Removal and Installation of Com-

pressor - MR18DE " *8.

MTC-17, " Maintenance of Oil Quanti-

ty in Compressor " *9

MTC-84, " Removal and Installation of

Liquid Tank "

Page 3940 of 4331

MTC

N

O P

CONTROLLER

Removal and Installation INFOID:0000000004307076

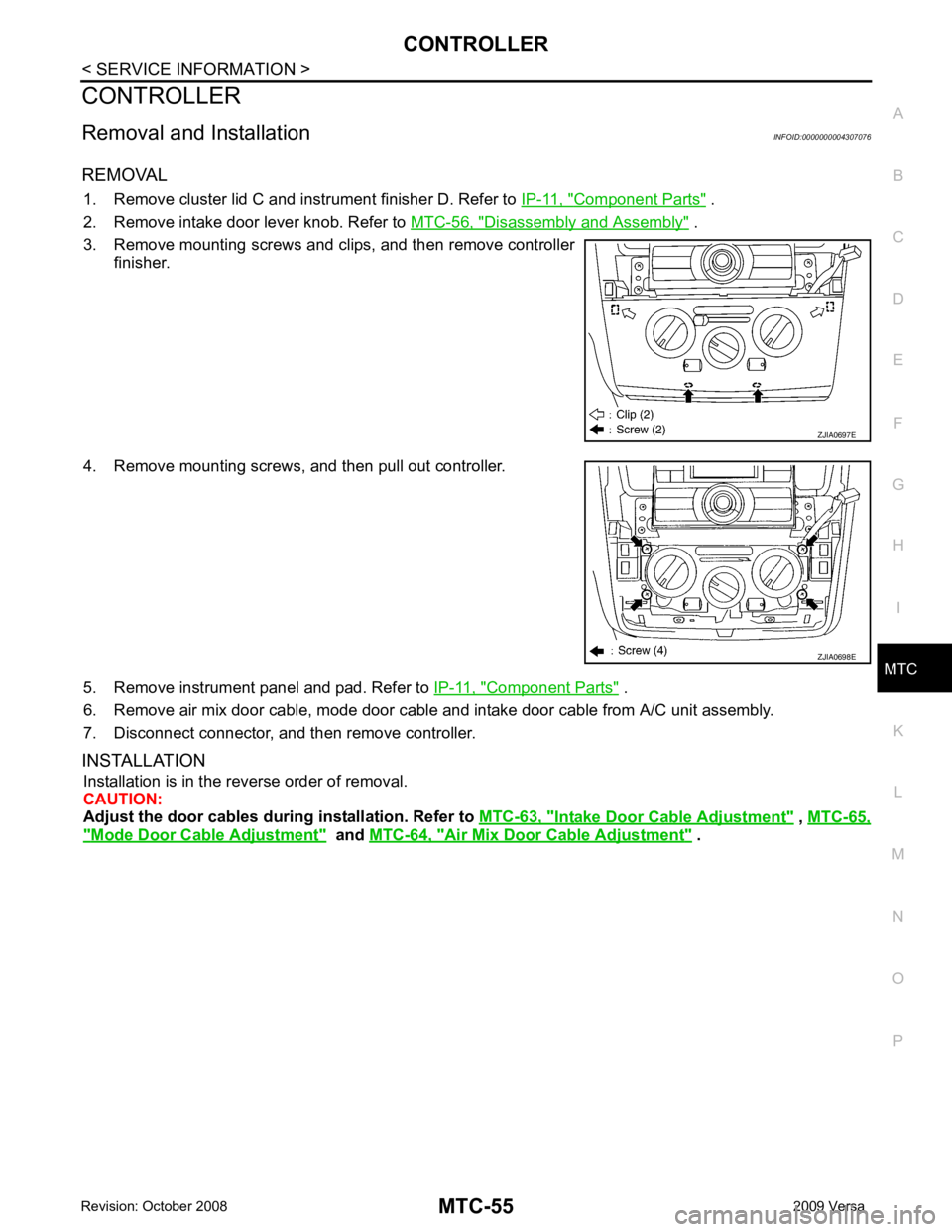

REMOVAL 1. Remove cluster lid C and instrument finisher D. Refer to IP-11, " Component Parts " .

2. Remove intake door lever knob. Refer to MTC-56, " Disassembly and Assembly " .

3. Remove mounting screws and clips, and then remove controller finisher.

4. Remove mounting screws, and then pull out controller.

5. Remove instrument panel and pad. Refer to IP-11, " Component Parts " .

6. Remove air mix door cable, mode door cable and intake door cable from A/C unit assembly.

7. Disconnect connector, and then remove controller.

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

Adjust the door cables during installation. Refer to MTC-63, " Intake Door Cable Adjustment " ,

MTC-65, " Mode Door Cable Adjustment " and

MTC-64, " Air Mix Door Cable Adjustment " .