engine control NISSAN TIIDA 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 166 of 4331

DTC BATT/FLUID TEMP SEN (A/T FLU

ID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

AT-161

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 7.

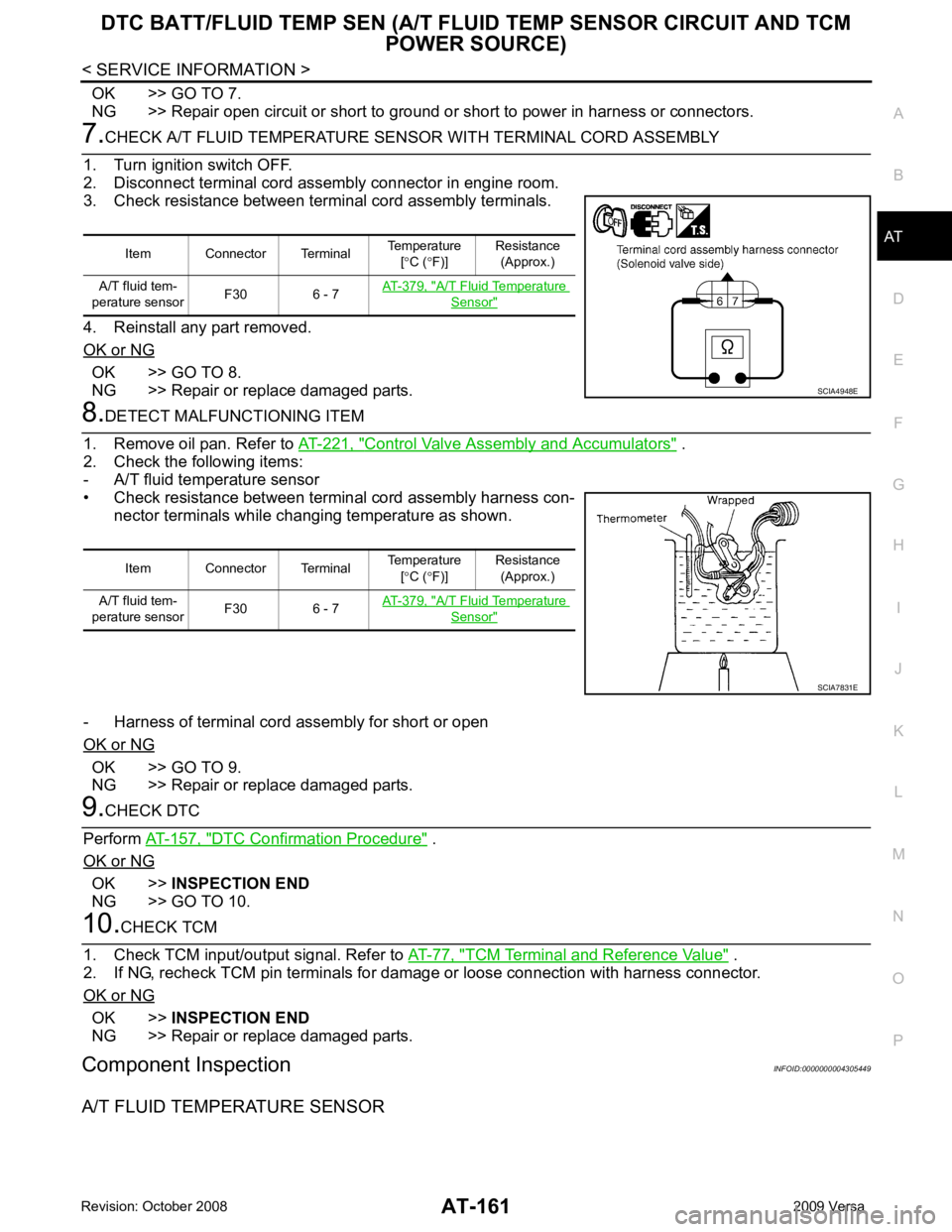

CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly connector in engine room.

3. Check resistance between terminal cord assembly terminals.

4. Reinstall any part removed.

OK or NG OK >> GO TO 8.

NG >> Repair or replace damaged parts. 8.

DETECT MALFUNCTIONING ITEM

1. Remove oil pan. Refer to AT-221, " Control Valve Assembly and Accumulators " .

2. Check the following items:

- A/T fluid temperature sensor

• Check resistance between terminal cord assembly harness con- nector terminals while changing temperature as shown.

- Harness of terminal cord assembly for short or open

OK or NG OK >> GO TO 9.

NG >> Repair or replace damaged parts. 9.

CHECK DTC

Perform AT-157, " DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 10. 10.

CHECK TCM

1. Check TCM input/output signal. Refer to AT-77, " TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Component Inspection INFOID:0000000004305449

A/T FLUID TEMPERATURE SENSOR Item Connector Terminal

Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 AT-379, " A/T Fluid Temperature

Sensor "

SCIA4948E

Item Connector Terminal

Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 AT-379, " A/T Fluid Temperature

Sensor "

SCIA7831E

Page 179 of 4331

AT-174< SERVICE INFORMATION >

PNP, OD SWITCH AND CLOSED THRO

TTLE, WIDE OPEN THROTTLE POSI-

TION SIGNAL CIRCUIT 4.

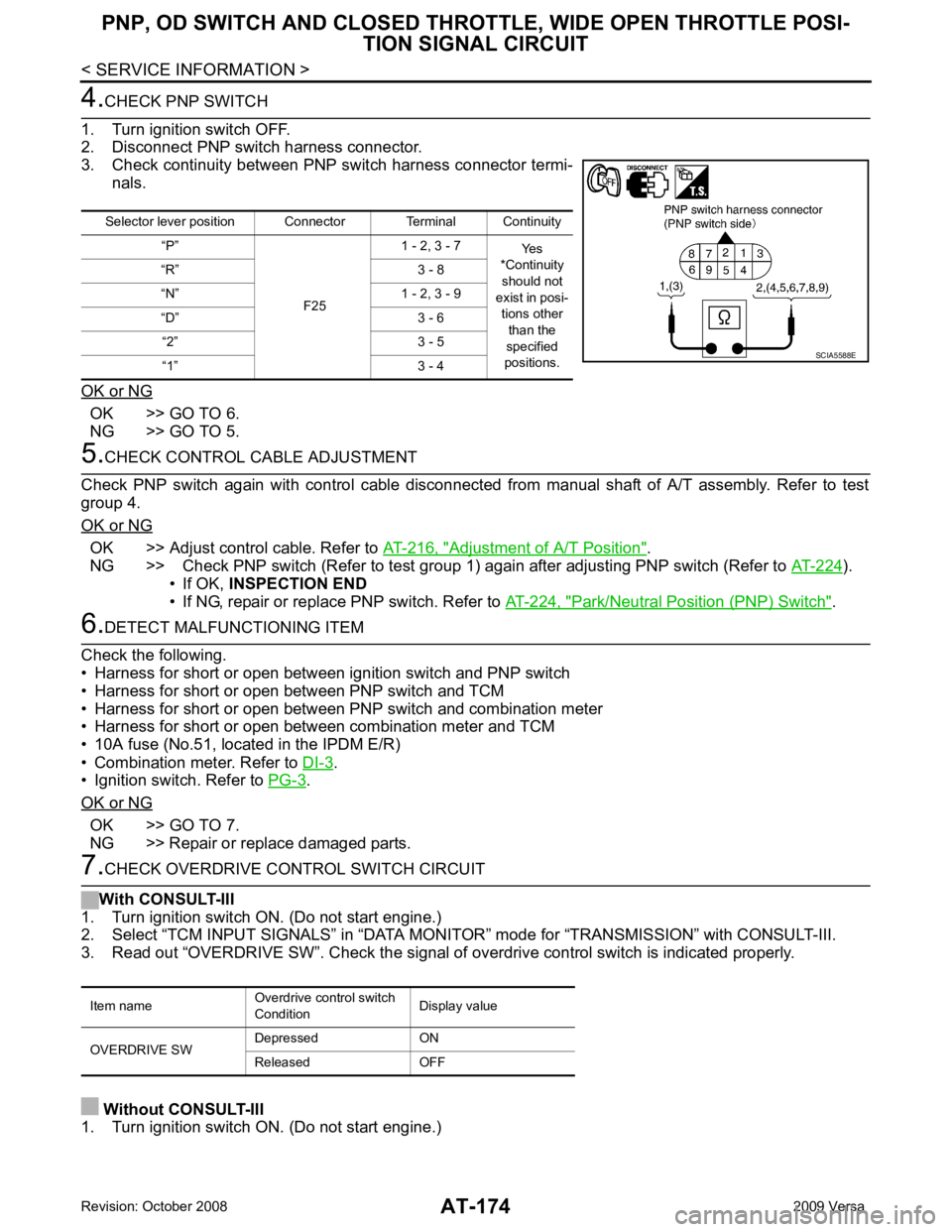

CHECK PNP SWITCH

1. Turn ignition switch OFF.

2. Disconnect PNP switch harness connector.

3. Check continuity between PNP switch harness connector termi- nals.

OK or NG OK >> GO TO 6.

NG >> GO TO 5. 5.

CHECK CONTROL CABLE ADJUSTMENT

Check PNP switch again with control cable disconnected from manual shaft of A/T assembly. Refer to test

group 4.

OK or NG OK >> Adjust control cable. Refer to

AT-216, " Adjustment of A/T Position " .

NG >> Check PNP switch (Refer to test group 1) again after adjusting PNP switch (Refer to AT-224 ).

• If OK, INSPECTION END

• If NG, repair or replace PNP switch. Refer to AT-224, " Park/Neutral Position (PNP) Switch " .

6.

DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and PNP switch

• Harness for short or open between PNP switch and TCM

• Harness for short or open between PNP switch and combination meter

• Harness for short or open between combination meter and TCM

• 10A fuse (No.51, located in the IPDM E/R)

• Combination meter. Refer to DI-3 .

• Ignition switch. Refer to PG-3 .

OK or NG OK >> GO TO 7.

NG >> Repair or replace damaged parts. 7.

CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “OVERDRIVE SW”. Check the signal of ov erdrive control switch is indicated properly.

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.) Selector lever position Connector Terminal Continuity

“P”

F251 - 2, 3 - 7

Yes

*Continuity

should not

exist in posi-

tions other than the

specified

positions.

“R” 3 - 8

“N” 1 - 2, 3 - 9

“D” 3 - 6 “2” 3 - 5

“1” 3 - 4 SCIA5588E

Item name

Overdrive control switch

Condition Display value

OVERDRIVE SW Depressed ON

Released OFF

Page 202 of 4331

AT

N

O P

Check again. Refer to

AT-58, " Cruise Test - Part 1 " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 3. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

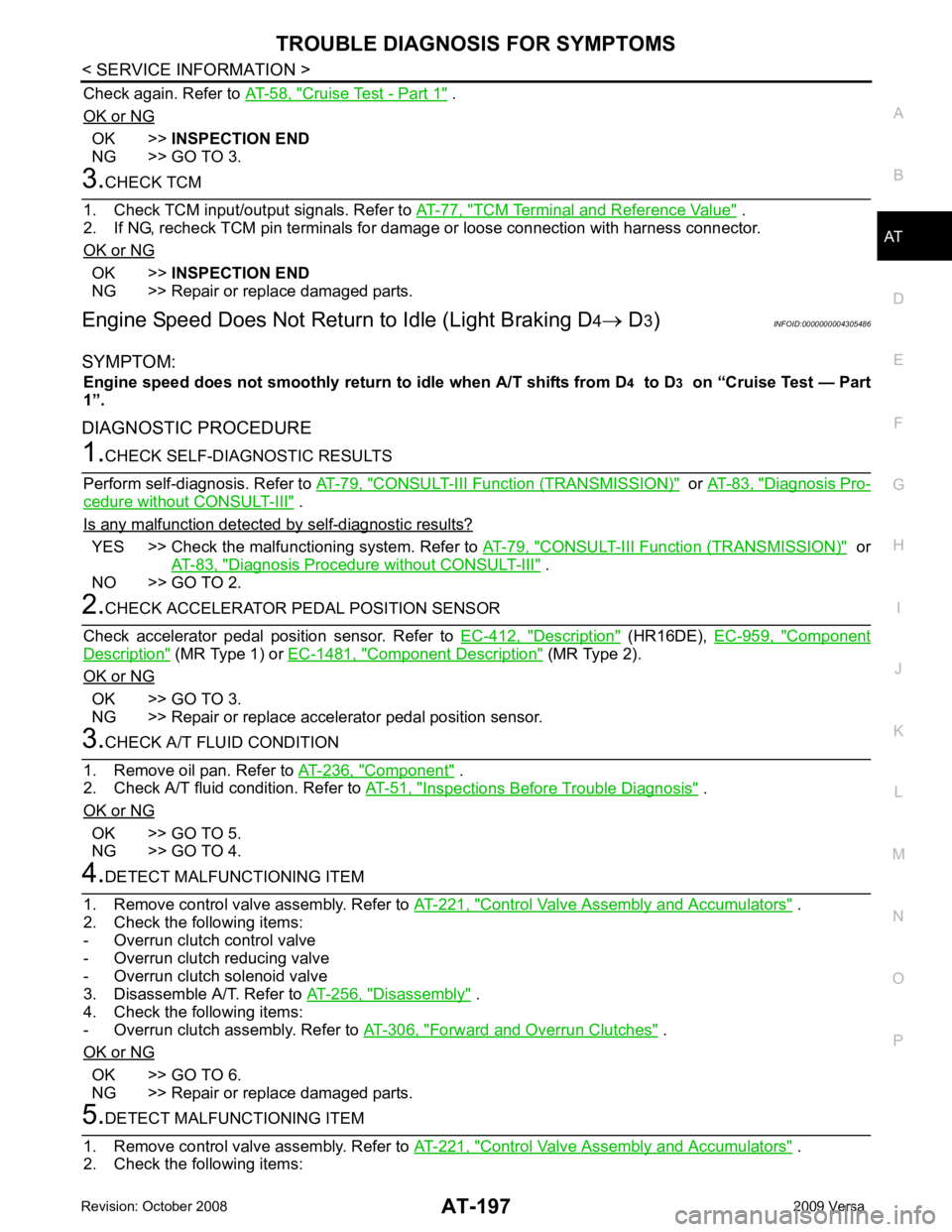

Engine Speed Does Not Return to Idle (Light Braking D4→ D 3) INFOID:0000000004305486

SYMPTOM: Engine speed does not smoothly return to idle when A/T shifts from D4 to D 3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Pro-

cedure without CONSULT-III " .

Is any malfunction detected by self-diagnostic results? YES >> Check the malfuncti

oning system. Refer to AT-79, " CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Procedure without CONSULT-III " .

NO >> GO TO 2. Description " (HR16DE),

EC-959, " Component

Description " (MR Type 1) or

EC-1481, " Component Description " (MR Type 2).

OK or NG OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor. Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 5.

NG >> GO TO 4. Control Valve Assembly and Accumulators " .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-256, " Disassembly " .

4. Check the following items:

- Overrun clutch assembly. Refer to AT-306, " Forward and Overrun Clutches " .

OK or NG OK >> GO TO 6.

NG >> Repair or replace damaged parts. Control Valve Assembly and Accumulators " .

2. Check the following items:

Page 204 of 4331

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

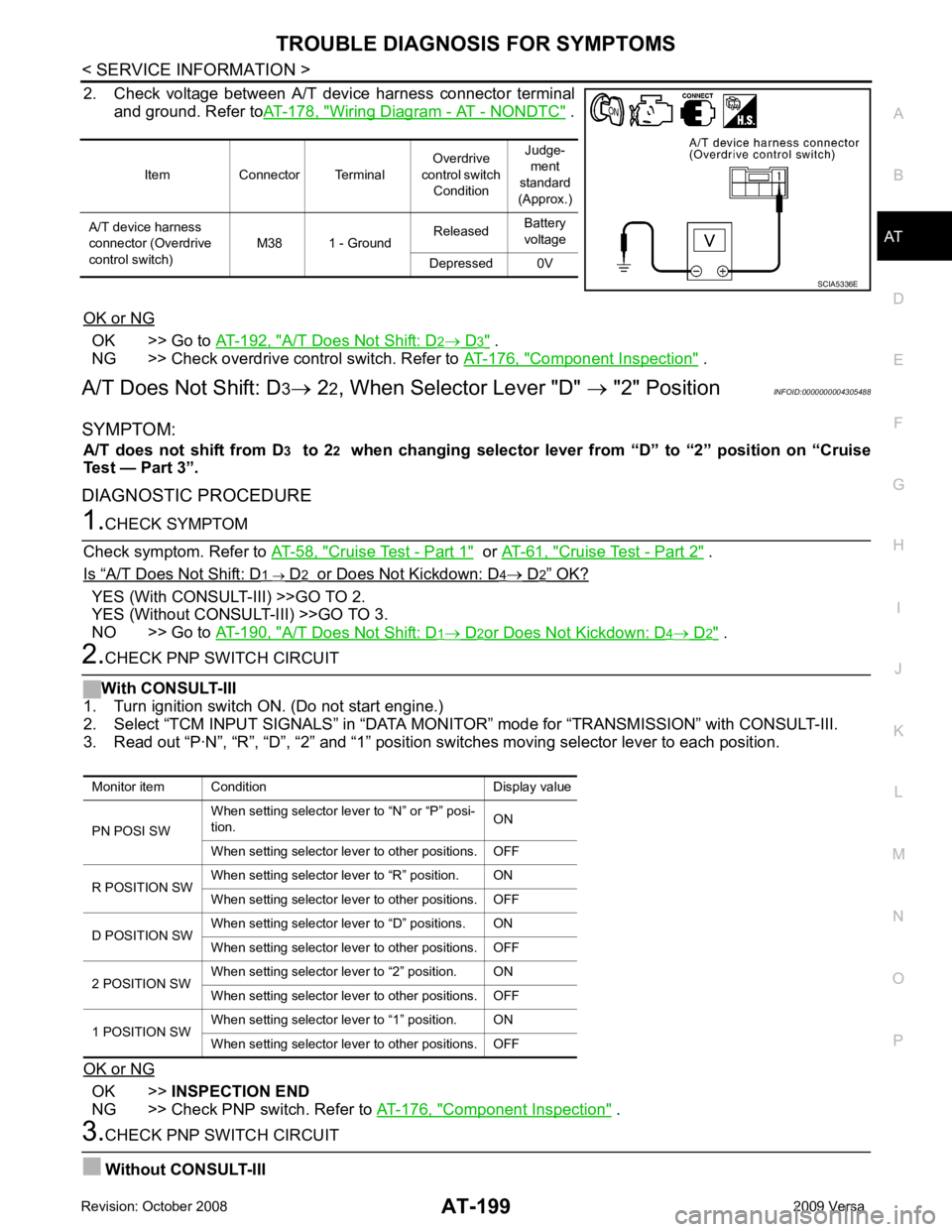

2. Check voltage between A/T device harness connector terminal

and ground. Refer to AT-178, " Wiring Diagram - AT - NONDTC " .

OK or NG OK >> Go to

AT-192, " A/T Does Not Shift: D 2 → D 3 " .

NG >> Check overdrive control switch. Refer to AT-176, " Component Inspection " .

A/T Does Not Shift: D 3→ 22, When Selector Lever "D" → "2" Position INFOID:0000000004305488

SYMPTOM: A/T does not shift from D 3 to 2 2 when changing selector lever from “D” to “2” position on “Cruise

Test — Part 3”.

DIAGNOSTIC PROCEDURE 1.

CHECK SYMPTOM

Check symptom. Refer to AT-58, " Cruise Test - Part 1 " or

AT-61, " Cruise Test - Part 2 " .

Is “ A/T Does Not Shift: D 1 → D 2 or Does Not Kickdown: D 4 → D 2 ” OK?

YES (With CONSULT-III) >>GO TO 2.

YES (Without CONSULT-III) >>GO TO 3.

NO >> Go to AT-190, " A/T Does Not Shift: D 1 → D 2 or Does Not Kickdown: D 4 → D 2 " .

2.

CHECK PNP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG OK >>

INSPECTION END

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

3.

CHECK PNP SWITCH CIRCUIT

Without CONSULT-III Item Connector Terminal

Overdrive

control switch Condition Judge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0V SCIA5336E

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 206 of 4331

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-201

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

OK >> GO TO 3

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

2.

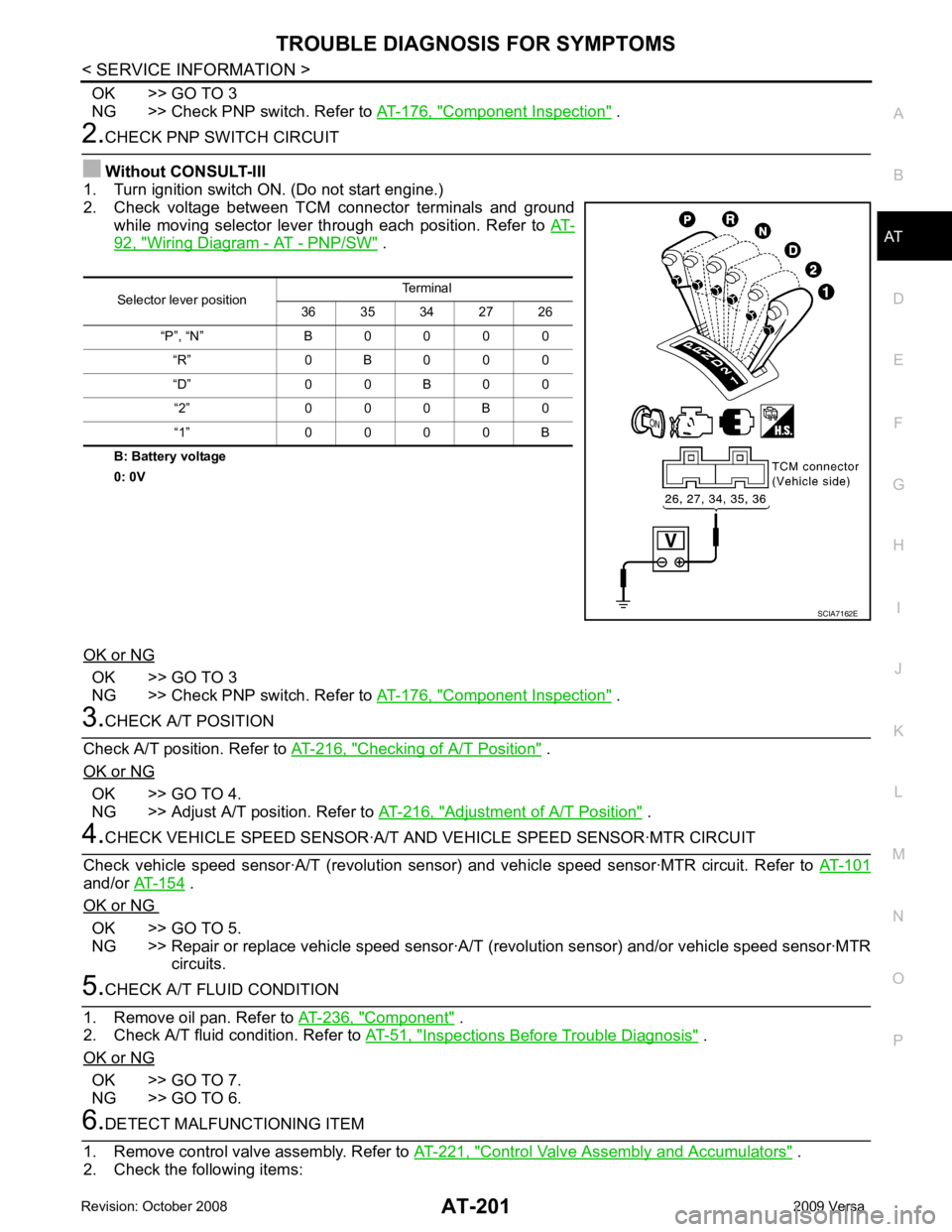

CHECK PNP SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground

while moving selector lever through each position. Refer to AT-92, " Wiring Diagram - AT - PNP/SW " .

B: Battery voltage

0: 0V

OK or NG OK >> GO TO 3

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

3.

CHECK A/T POSITION

Check A/T position. Refer to AT-216, " Checking of A/T Position " .

OK or NG OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-216, " Adjustment of A/T Position " .

4.

CHECK VEHICLE SPEED SENS OR·A/T AND VEHICLE SPEED SENSOR·MTR CIRCUIT

Check vehicle speed sensor·A/T (re volution sensor) and vehicle speed sensor·MTR circuit. Refer to AT-101and/or

AT-154 .

OK or NG OK >> GO TO 5.

NG >> Repair or replace vehicle speed sensor·A/T (revolution sensor) and/or vehicle speed sensor·MTR

circuits. 5.

CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-236, " Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 7.

NG >> GO TO 6. 6.

DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

2. Check the following items: Selector lever position

Terminal

36 35 34 27 26

“P”, “N” B 0 0 0 0 “R” 0 B 0 0 0

“D” 0 0 B 0 0 “2” 0 0 0 B 0

“1” 0 0 0 0 B SCIA7162E

Page 207 of 4331

AT-202< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

- Shift valve A

- Shift solenoid valve A

- Overrun clutch control valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-256, " Disassembly " .

4. Check the following items:

- Servo piston assembly

- Brake band

OK or NG OK >> GO TO 7.

NG >> Repair or replace damaged parts. 7.

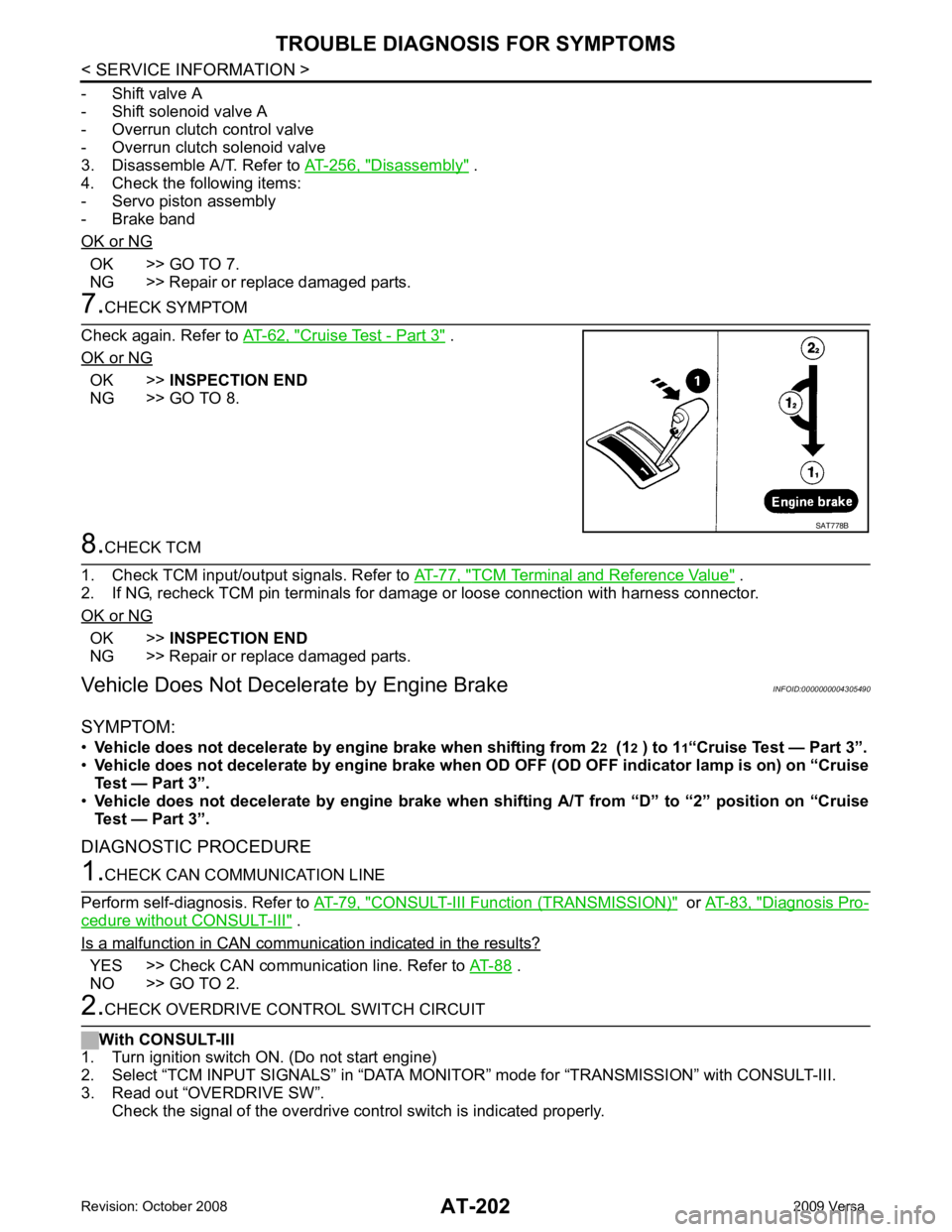

CHECK SYMPTOM

Check again. Refer to AT-62, " Cruise Test - Part 3 " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 8. 8.

CHECK TCM

1. Check TCM input/output signals. Refer to AT-77, " TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Does Not Decele rate by Engine Brake INFOID:0000000004305490

SYMPTOM:

• Vehicle does not decelerate by engi ne brake when shifting from 22 (1 2 ) to 1 1“Cruise Test — Part 3”.

• Vehicle does not decelerate by engine brake when OD OFF (OD OFF indicator lamp is on) on “Cruise

Test — Part 3”.

• Vehicle does not decelerate by engi ne brake when shifting A/T from “D” to “2” position on “Cruise

Test — Part 3”.

DIAGNOSTIC PROCEDURE 1.

CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-79, " CONSULT-III Functi

on (TRANSMISSION) " or

AT-83, " Diagnosis Pro-

cedure without CONSULT-III " .

Is a malfunction in CAN communication indicated in the results? YES >> Check CAN communication line. Refer to

AT-88 .

NO >> GO TO 2. 2.

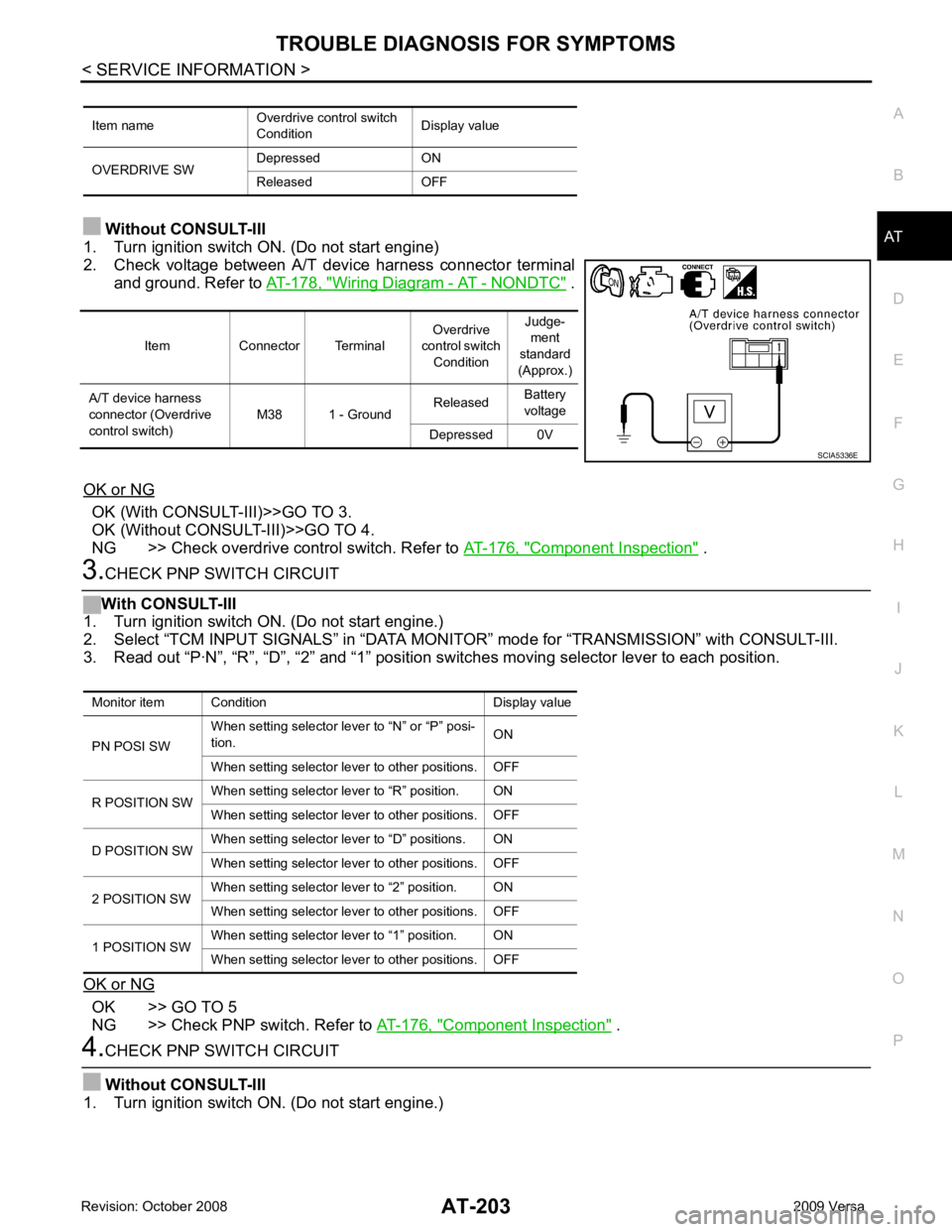

CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

2. Select “TCM INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “OVERDRIVE SW”. Check the signal of the overdrive c ontrol switch is indicated properly. SAT778B

Page 208 of 4331

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-203

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T device harness connector terminal and ground. Refer to AT-178, " Wiring Diagram - AT - NONDTC " .

OK or NG OK (With CONSULT-III)>>GO TO 3.

OK (Without CONSULT-III)>>GO TO 4.

NG >> Check overdrive control switch. Refer to AT-176, " Component Inspection " .

3.

CHECK PNP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG OK >> GO TO 5

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

4.

CHECK PNP SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.) Item name

Overdrive control switch

Condition Display value

OVERDRIVE SW Depressed ON

Released OFF Item Connector Terminal

Overdrive

control switch Condition Judge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0V SCIA5336E

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 221 of 4331

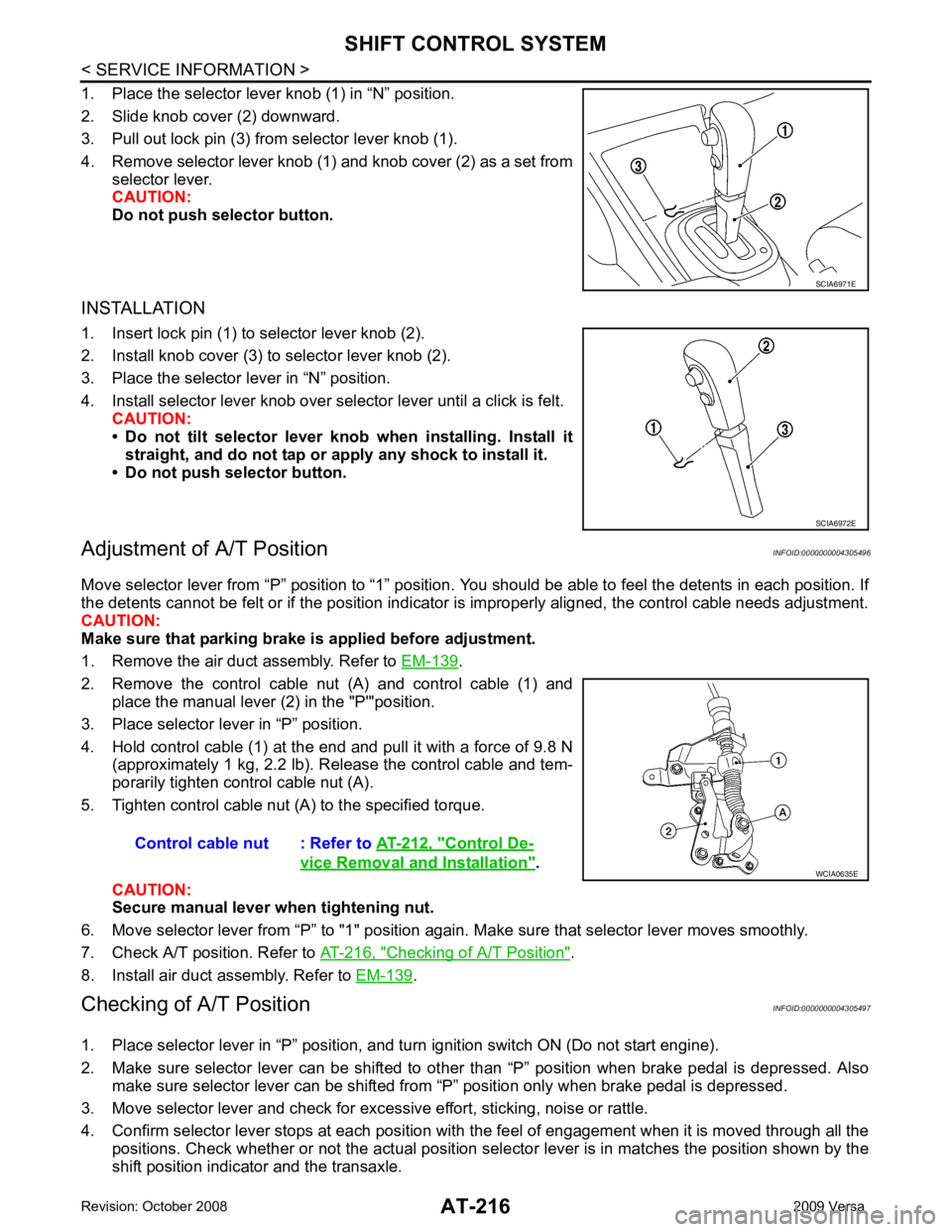

.

2. Remove the control cable nut (A) and control cable (1) and place the manual lever (2) in the "P'"position.

3. Place selector lever in “P” position.

4. Hold control cable (1) at the end and pull it with a force of 9.8 N (approximately 1 kg, 2.2 lb). Release the control cable and tem-

porarily tighten control cable nut (A).

5. Tighten control cable nut (A) to the specified torque.

CAUTION:

Secure manual lever when tightening nut.

6. Move selector lever from “P” to "1" position again. Make sure that selector lever moves smoothly.

7. Check A/T position. Refer to AT-216, " Checking of A/T Position " .

8. Install air duct assembly. Refer to EM-139 .

Checking of A/T Position INFOID:0000000004305497

1. Place selector lever in “P” position, and tu rn ignition switch ON (Do not start engine).

2. Make sure selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

make sure selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move selector lever and check for excessive effort, sticking, noise or rattle.

4. Confirm selector lever stops at each position with the feel of engagement when it is moved through all the

positions. Check whether or not the actual position sele ctor lever is in matches the position shown by the

shift position indicator and the transaxle. SCIA6972E

Control De-

vice Removal and Installation " .

Page 226 of 4331

AT

N

O P

ON-VEHICLE SERVICE

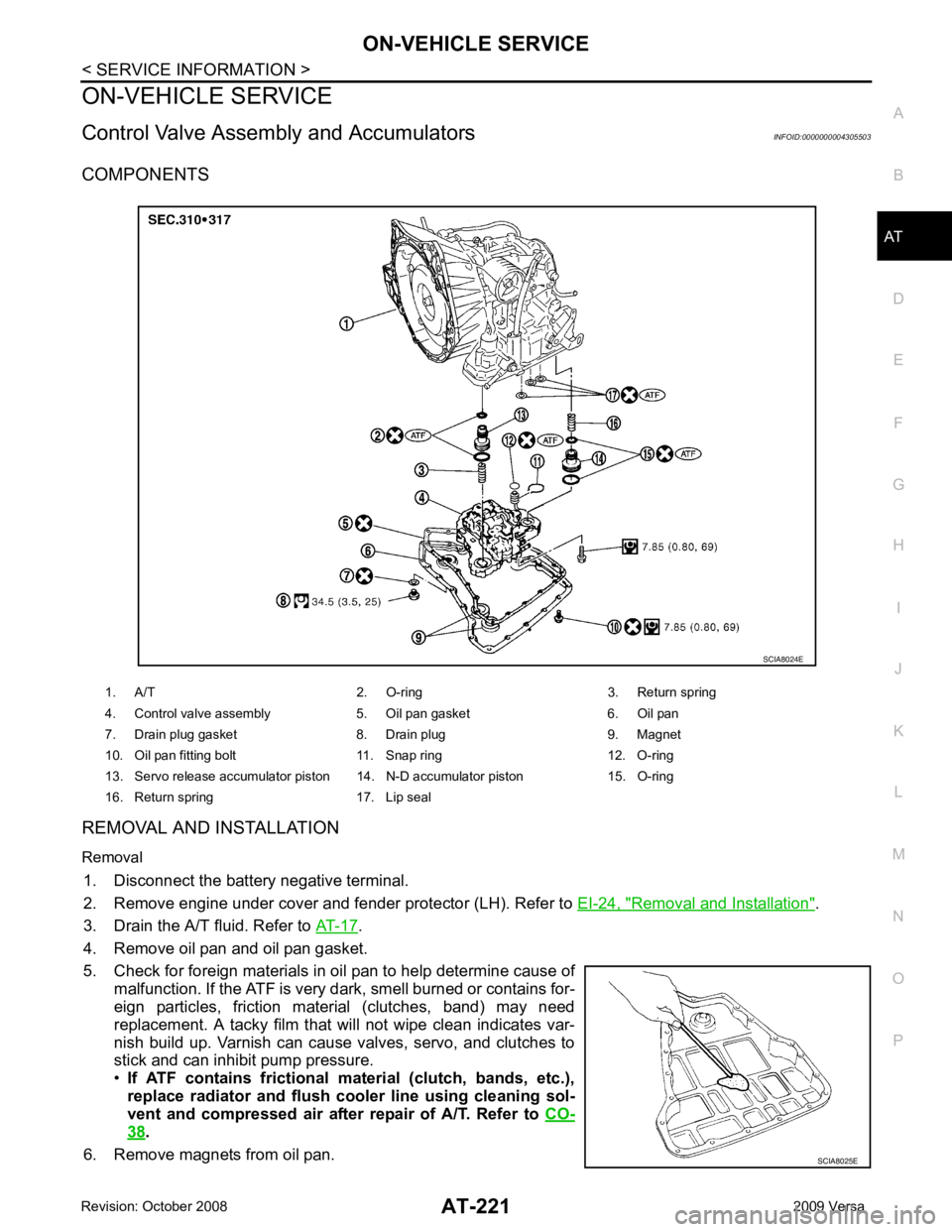

Control Valve Assembly and Accumulators INFOID:0000000004305503

COMPONENTS

REMOVAL AND INSTALLATION

Removal 1. Disconnect the battery negative terminal.

2. Remove engine under cover and fender protector (LH). Refer to EI-24, " Removal and Installation " .

3. Drain the A/T fluid. Refer to AT-17 .

4. Remove oil pan and oil pan gasket.

5. Check for foreign materials in oil pan to help determine cause of malfunction. If the ATF is very dark, smell burned or contains for-

eign particles, friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

• If ATF contains frictional material (clutch, bands, etc.),

replace radiator and flush cooler line using cleaning sol-

vent and compressed air after repair of A/T. Refer to CO-38 .

6. Remove magnets from oil pan. 1. A/T 2. O-ring 3. Return spring

4. Control valve assembly 5. Oil pan gasket 6. Oil pan

7. Drain plug gasket 8. Drain plug 9. Magnet

10. Oil pan fitting bolt 11. Snap ring 12. O-ring

13. Servo release accumulator piston 14. N-D accumulator piston 15. O-ring

16. Return spring 17. Lip seal SCIA8025E

Page 580 of 4331

BL

N

O P

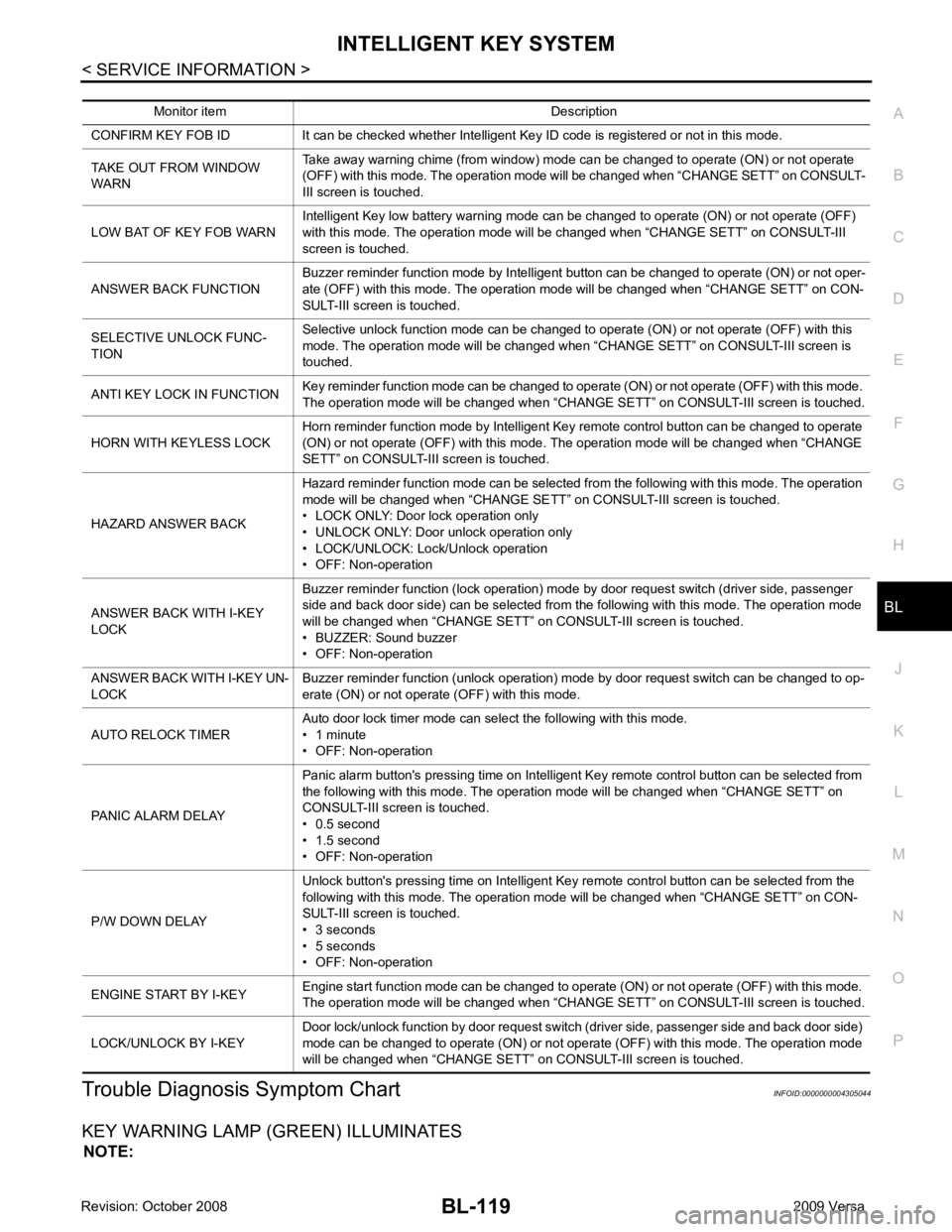

Trouble Diagnosis Symptom Chart INFOID:0000000004305044

KEY WARNING LAMP (GREEN) ILLUMINATES NOTE: Monitor item Description

CONFIRM KEY FOB ID It can be checked whether Intelligent Key ID code is registered or not in this mode.

TAKE OUT FROM WINDOW

WARN Take away warning chime (from window) mode can be changed to operate (ON) or not operate

(OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-

III screen is touched.

LOW BAT OF KEY FOB WARN Intelligent Key low battery warning mode can be changed to operate (ON) or not operate (OFF)

with this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-III

screen is touched.

ANSWER BACK FUNCTION Buzzer reminder function mode by Intelligent button can be changed to operate (ON) or not oper-

ate (OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CON-

SULT-III screen is touched.

SELECTIVE UNLOCK FUNC-

TION Selective unlock function mode can be changed to operate (ON) or not operate (OFF) with this

mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is

touched.

ANTI KEY LOCK IN FUNCTION Key reminder function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is touched.

HORN WITH KEYLESS LOCK Horn reminder function mode by Intelligent Key remote control button can be changed to operate

(ON) or not operate (OFF) with this mode. The operation mode will be changed when “CHANGE

SETT” on CONSULT-III screen is touched.

HAZARD ANSWER BACK Hazard reminder function mode can be selected from the following with this mode. The operation

mode will be changed when “CHANGE SE TT” on CONSULT-III screen is touched.

• LOCK ONLY: Door lock operation only

• UNLOCK ONLY: Door unlock operation only

• LOCK/UNLOCK: Lock/Unlock operation

• OFF: Non-operation

ANSWER BACK WITH I-KEY

LOCK Buzzer reminder function (lock operation) mode by door request switch (driver side, passenger

side and back door side) can be selected from the following with this mode. The operation mode

will be changed when “ CHANGE SETT” on CONSULT- III screen is touched.

• BUZZER: Sound buzzer

• OFF: Non-operation

ANSWER BACK WITH I-KEY UN-

LOCK Buzzer reminder function (unlock operation) mode by door request switch can be changed to op-

erate (ON) or not operate (OFF) with this mode.

AUTO RELOCK TIMER Auto door lock timer mode can select the following with this mode.

• 1 minute

• OFF: Non-operation

PANIC ALARM DELAY Panic alarm button's pressing time on Intelligent Key remote control button can be selected from

the following with this mode. The operation mode will be changed when “CHANGE SETT” on

CONSULT-III screen is touched.

• 0.5 second

• 1.5 second

• OFF: Non-operation

P/W DOWN DELAY Unlock button's pressing time on Intelligent Key remote control button can be selected from the

following with this mode. The operation mode will be changed when “CHANGE SETT” on CON-

SULT-III screen is touched.

• 3 seconds

• 5 seconds

• OFF: Non-operation

ENGINE START BY I-KEY Engine start function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-III screen is touched.

LOCK/UNLOCK BY I-KEY Door lock/unlock function by door request switch (driver side, passenger side and back door side)

mode can be changed to operate (ON) or not operate (OFF) with this mode. The operation mode

will be changed when “ CHANGE SETT” on CONSULT- III screen is touched.