engine control NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 954 of 4331

.

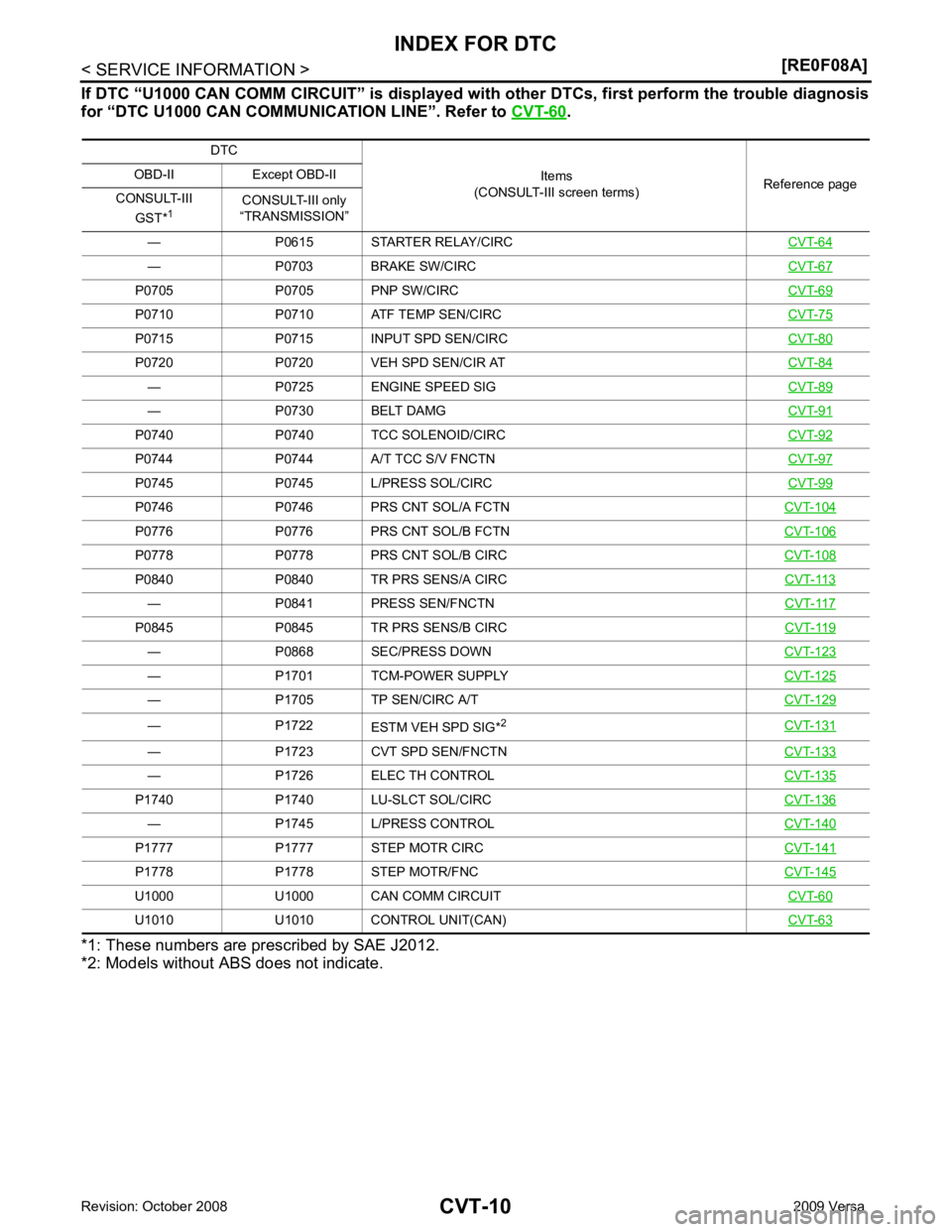

*1: These numbers are pr escribed by SAE J2012.

*2: Models without ABS does not indicate. DTC

Items

(CONSULT-III screen terms) Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

— P0615 STARTER RELAY/CIRC CVT-64— P0703 BRAKE SW/CIRC

CVT-67P0705 P0705 PNP SW/CIRC

CVT-69P0710 P0710 ATF TEMP SEN/CIRC

CVT-75P0715 P0715 INPUT SPD SEN/CIRC

CVT-80P0720 P0720 VEH SPD SEN/CIR AT

CVT-84— P0725 ENGINE SPEED SIG

CVT-89— P0730 BELT DAMG

CVT-91P0740 P0740 TCC SOLENOID/CIRC

CVT-92P0744 P0744 A/T TCC S/V FNCTN

CVT-97P0745 P0745 L/PRESS SOL/CIRC

CVT-99P0746 P0746 PRS CNT SOL/A FCTN

CVT-104P0776 P0776 PRS CNT SOL/B FCTN

CVT-106P0778 P0778 PRS CNT SOL/B CIRC

CVT-108P0840 P0840 TR PRS SENS/A CIRC

CVT-113— P0841 PRESS SEN/FNCTN

CVT-117P0845 P0845 TR PRS SENS/B CIRC

CVT-119— P0868 SEC/PRESS DOWN

CVT-123— P1701 TCM-POWER SUPPLY

CVT-125— P1705 TP SEN/CIRC A/T

CVT-129— P1722

ESTM VEH SPD SIG*2

CVT-131— P1723 CVT SPD SEN/FNCTN

CVT-133— P1726 ELEC TH CONTROL

CVT-135P1740 P1740 LU-SLCT SOL/CIRC

CVT-136— P1745 L/PRESS CONTROL

CVT-140P1777 P1777 STEP MOTR CIRC

CVT-141P1778 P1778 STEP MOTR/FNC

CVT-145U1000 U1000 CAN COMM CIRCUIT

CVT-60U1010 U1010 CONTROL UNIT(CAN)

CVT-63

Page 955 of 4331

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004800719

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004666854

NOTE:

• This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 971 of 4331

CVT

N

O P

Optimize the line pressure and secondary pressure, dependi

ng on driving conditions, on the basis of the throt-

tle position, the engine speed, the primary pulley (input ) revolution speed, the secondary pulley (output) revo-

lution speed, the brake signal, the PNP switch signal, the lock-up signal, the voltage, the target gear ratio, the

fluid temperature, and the fluid pressure.

FEEDBACK CONTROL When controlling the normal fluid pressure or the sele cted fluid pressure, the secondary pressure can be set

more accurately by using the fluid pressure sensor to detect the secondary pressure and controlling the feed-

back.

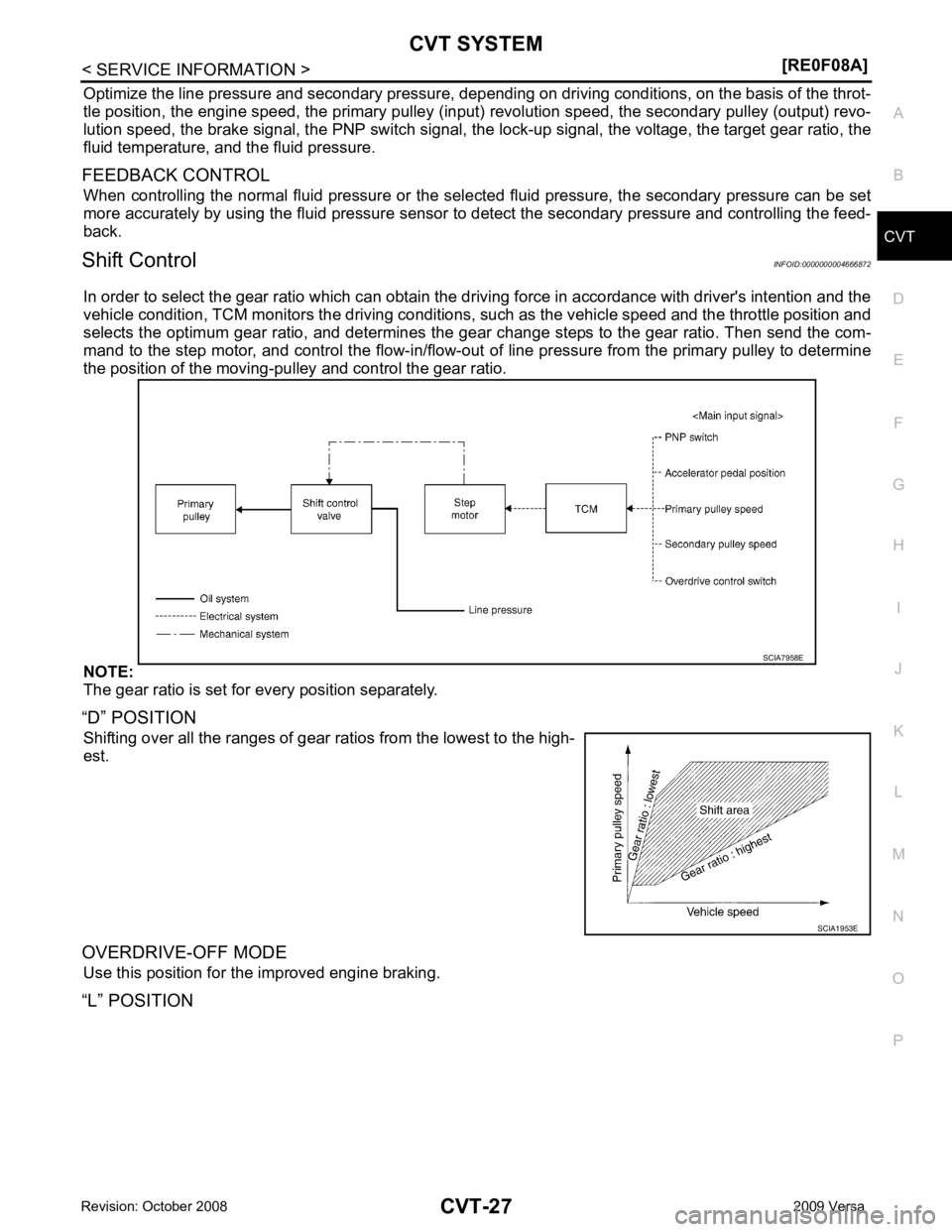

Shift Control INFOID:0000000004666872

In order to select the gear ratio which can obtain the dr iving force in accordance with driver's intention and the

vehicle condition, TCM monitors the driving conditions, such as the vehicle speed and the throttle position and

selects the optimum gear ratio, and determines the gear change steps to the gear ratio. Then send the com-

mand to the step motor, and control the flow-in/flow-out of line pressure from the primary pulley to determine

the position of the moving-pul ley and control the gear ratio.

NOTE:

The gear ratio is set for every position separately.

“D” POSITION Shifting over all the ranges of gear ra tios from the lowest to the high-

est.

OVERDRIVE-OFF MODE Use this position for the improved engine braking.

“L” POSITION

Page 973 of 4331

CVT

N

O P

Lock-up and Select Control System Diagram

Lock-up Released In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the torque

converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

Select Control When shifting between “N” (“P”) ⇔“D” (“R”), optimize the operating pressure on the basis of the throttle posi-

tion, the engine speed, and the secondary pulley (out put) revolution speed to lessen the shift shock.

Control Valve INFOID:0000000004666874

FUNCTION OF CONTROL VALVE

Page 977 of 4331

CVT

N

O P

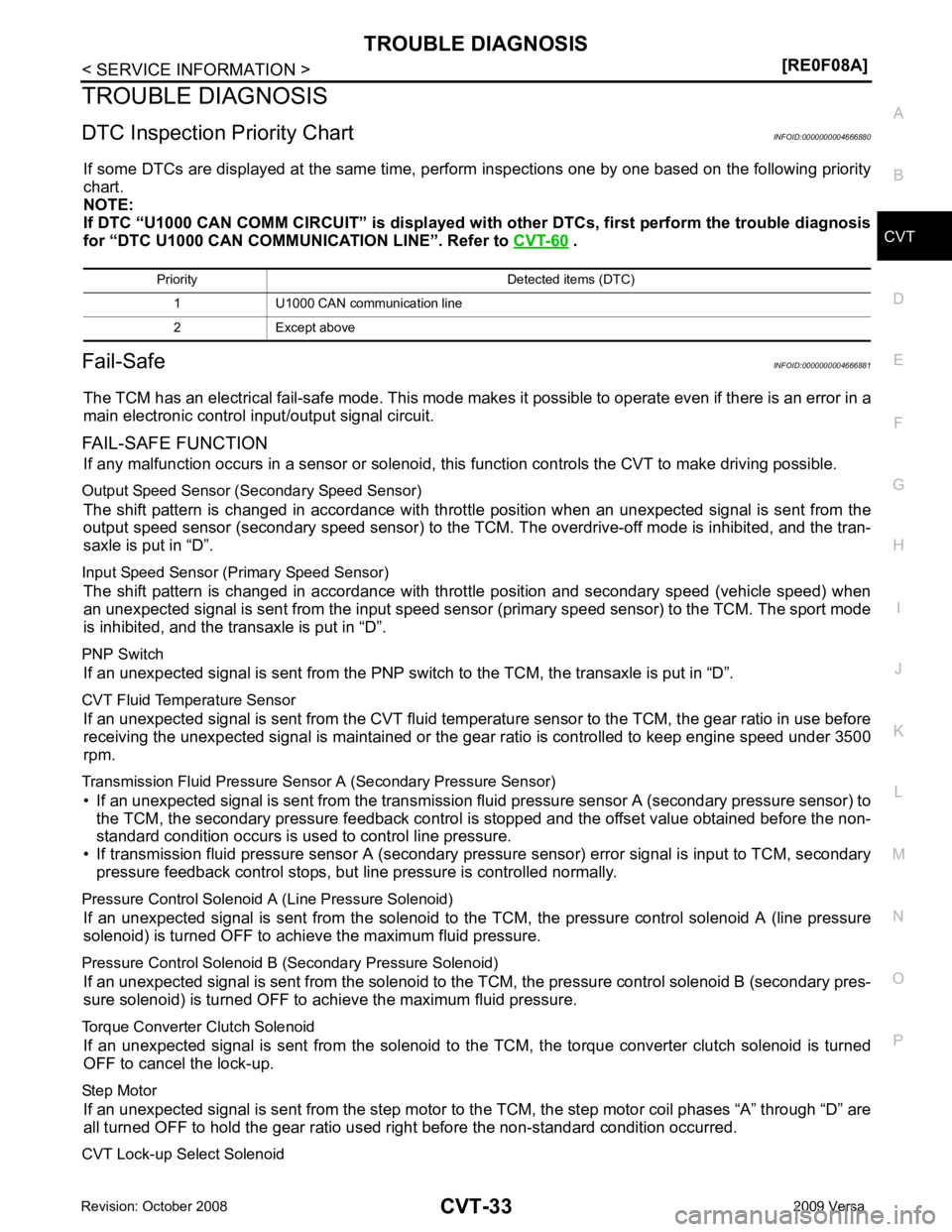

TROUBLE DIAGNOSIS

DTC Inspection Priority Chart INFOID:0000000004666880

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-60 .

Fail-Safe INFOID:0000000004666881

The TCM has an electrical fail-safe mode. This mode make s it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

FAIL-SAFE FUNCTION If any malfunction occurs in a sensor or solenoid, th is function controls the CVT to make driving possible.

Output Speed Sensor (Secondary Speed Sensor) The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

output speed sensor (secondary speed sensor) to the TCM. The overdrive-off mode is inhibited, and the tran-

saxle is put in “D”.

Input Speed Sensor (Primary Speed Sensor) The shift pattern is changed in accordance with throttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the input speed sensor (primary speed sensor) to the TCM. The sport mode

is inhibited, and the transaxle is put in “D”.

PNP Switch If an unexpected signal is sent from the PNP switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor If an unexpected signal is sent from the CVT fluid temper ature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or the gear ratio is controlled to keep engine speed under 3500

rpm.

Transmission Fluid Pressure Sens or A (Secondary Pressure Sensor)

• If an unexpected signal is sent from the transmission fl uid pressure sensor A (secondary pressure sensor) to

the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-

standard condition occurs is used to control line pressure.

• If transmission fluid pressure sensor A (secondary pre ssure sensor) error signal is input to TCM, secondary

pressure feedback control stops, but line pressure is controlled normally.

Pressure Control Solenoid A (Line Pressure Solenoid) If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid A (line pressure

solenoid) is turned OFF to achieve the maximum fluid pressure.

Pressure Control Solenoid B (Secondary Pressure Solenoid) If an unexpected signal is sent from the solenoid to t he TCM, the pressure control solenoid B (secondary pres-

sure solenoid) is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid If an unexpected signal is sent from the solenoid to t he TCM, the torque converter clutch solenoid is turned

OFF to cancel the lock-up.

Step Motor If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used right before the non-standard condition occurred.

CVT Lock-up Select Solenoid Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 978 of 4331

![NISSAN TIIDA 2009 Service Manual PDF CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power NISSAN TIIDA 2009 Service Manual PDF CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power](/img/5/57398/w960_57398-977.png)

CVT-34< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

If an unexpected signal is sent from the solenoid to t he TCM, the CVT lock-up select solenoid is turned OFF to

cancel the lock-up.

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for

controlling) from the battery is not supplied to TCM. Normal statues is restored when turning the ignition switch

OFF to ON after the normal power supply.

How to Perform Trouble Diagnosis for Quick and Accurate Repair INFOID:0000000004666882

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

CVT system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve mal-

function, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Mo st intermittent errors are caused

by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits ma y help prevent the replacement of

good parts.

A visual check only may not find the cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the "WORK FLOW" .

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “DIAGNOSTIC WORKSHEET” as

shown on the example (Refer to "Diagnostic Worksheet Chart" )

should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

WORK FLOW

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malf unction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Make good use of the two sheets provided, "Informati on From Customer" and "Diagnostic Worksheet Chart" ,

to perform the best troubleshooting possible.

Work Flow Chart SAT631IB

SAT632I

SEF234G

Page 988 of 4331

![NISSAN TIIDA 2009 Service Manual PDF CVT-44< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

Road Test INFOID:0000000004666886

DESCRIPTION

• The purpose of the test is to determine overall performance of CVT and analyze causes of pro NISSAN TIIDA 2009 Service Manual PDF CVT-44< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

Road Test INFOID:0000000004666886

DESCRIPTION

• The purpose of the test is to determine overall performance of CVT and analyze causes of pro](/img/5/57398/w960_57398-987.png)

CVT-44< SERVICE INFORMATION >

[RE0F08A]

TROUBLE DIAGNOSIS

Road Test INFOID:0000000004666886

DESCRIPTION

• The purpose of the test is to determine overall performance of CVT and analyze causes of problems.

• The road test consists of the following three parts:

1. “Check Before Engine Is Started” CVT-45 .

2. “Check at Idle” CVT-45 .

3. “Cruise Test” CVT-47 .

Judgement Possible cause

Idle speed Low for all positions

(“P”, “R”, “N”, “D”, “L”) Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

• Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer ⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

High Possible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example

• Accelerator pedal position signal malfunction

• CVT fluid temperature sensor malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (sticking in OFF state, filter

clog, cut line)

• Pressure regulator valve or plug sticking

Stall speed Line pressure does

not rise higher than

the line pressure for

idle. Possible causes include a sensor malfunction or malfunction in the pressure adjustment func-

tion.

For example

• Accelerator pedal position signal malfunction

• TCM malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (shorting, sticking in ON state)

• Pressure regulator valve or plug sticking

The pressure rises,

but does not enter the

standard position. Possible causes include malfunctions in the pressure supply system and malfunction in the pres-

sure adjustment function.

For example

• Accelerator pedal position signal malfunction

• Pressure control solenoid A (line pressure solenoid) malfunction (sticking, filter clog)

• Pressure regulator valve or plug sticking

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve. SAT786A

Page 993 of 4331

![NISSAN TIIDA 2009 Service Manual PDF TROUBLE DIAGNOSIS

CVT-49

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P 9.

CHECK ENGINE BRAKE FUNCTION — PART 3

1. Move selector lever to “L” position.

2. Check engine brake NISSAN TIIDA 2009 Service Manual PDF TROUBLE DIAGNOSIS

CVT-49

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P 9.

CHECK ENGINE BRAKE FUNCTION — PART 3

1. Move selector lever to “L” position.

2. Check engine brake](/img/5/57398/w960_57398-992.png)

TROUBLE DIAGNOSIS

CVT-49

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P 9.

CHECK ENGINE BRAKE FUNCTION — PART 3

1. Move selector lever to “L” position.

2. Check engine brake.

Does engine braking effectively reduce speed in “ L ” position?

YES >> 1. Stop the vehicle.

2. Perform self-diagnosis. Refer to CVT-51, " CONSULT-III Function (TRANSMISSION) " .

NO >> Mark the box of CVT-163, " Vehicle Does Not Decelerate by Engine Brake " on the

CVT-34, " How

to Perform Trouble Diagnosis for Quick and Accurate Repair " . Then continue trouble diagnosis.

Vehicle Speed When Shifting Gears INFOID:0000000004666890

Numerical value data are reference values.

CAUTION:

Lock-up clutch is engaged when vehi cle speed is approximately 18 km/h (11 MPH) to 90 km/h (56 MPH).

TCM Terminal and Reference Value INFOID:0000000004666891

TCM HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUES FOR TCM Data are reference values and are measured between each terminal and ground.

Engine type Throttle position Shift pattern

Engine speed (rpm)

At 40 km/h (25 MPH) At 60 km/h (37 MPH)

MR18DE 8/8

“D” position

Overdrive-off mode “L” position 3,600 - 4,500 4,400 - 5,300

2/8 “D” position 1,300 - 3,100 1,400 - 3,500

Overdrive-off mode 2,200 - 3,000 2,800 - 3,600 “L” position 3,200 - 4,100 3,900 - 4,800 WCIA0717E

Terminal

Wire

color Item Condition Data (Approx.)

1 GR Pressure control

solenoid valve A

(Line pressure

solenoid valve)

and Release your foot from the accelerator pedal. 5.0 - 7.0 V

Press the accelerator pedal all the way down. 1.0 - 3.0 V

2 LG Pressure control

solenoid valve B

(Secondary

pressure sole-

noid valve) Release your foot from the accelerator pedal. 5.0 - 7.0 V

Press the accelerator pedal all the way down. 3.0 - 4.0 V

3 SB Torque converter

clutch solenoid

valve When vehi-

cle cruises in

“D” position. When CVT performs lock-up. 6.0 V

When CVT does not perform lock-up. 1.0 V

Page 998 of 4331

How to Perform Trouble Diag-

nosis for Quick and Accurate Repair " . Reference pages are provided following the items.

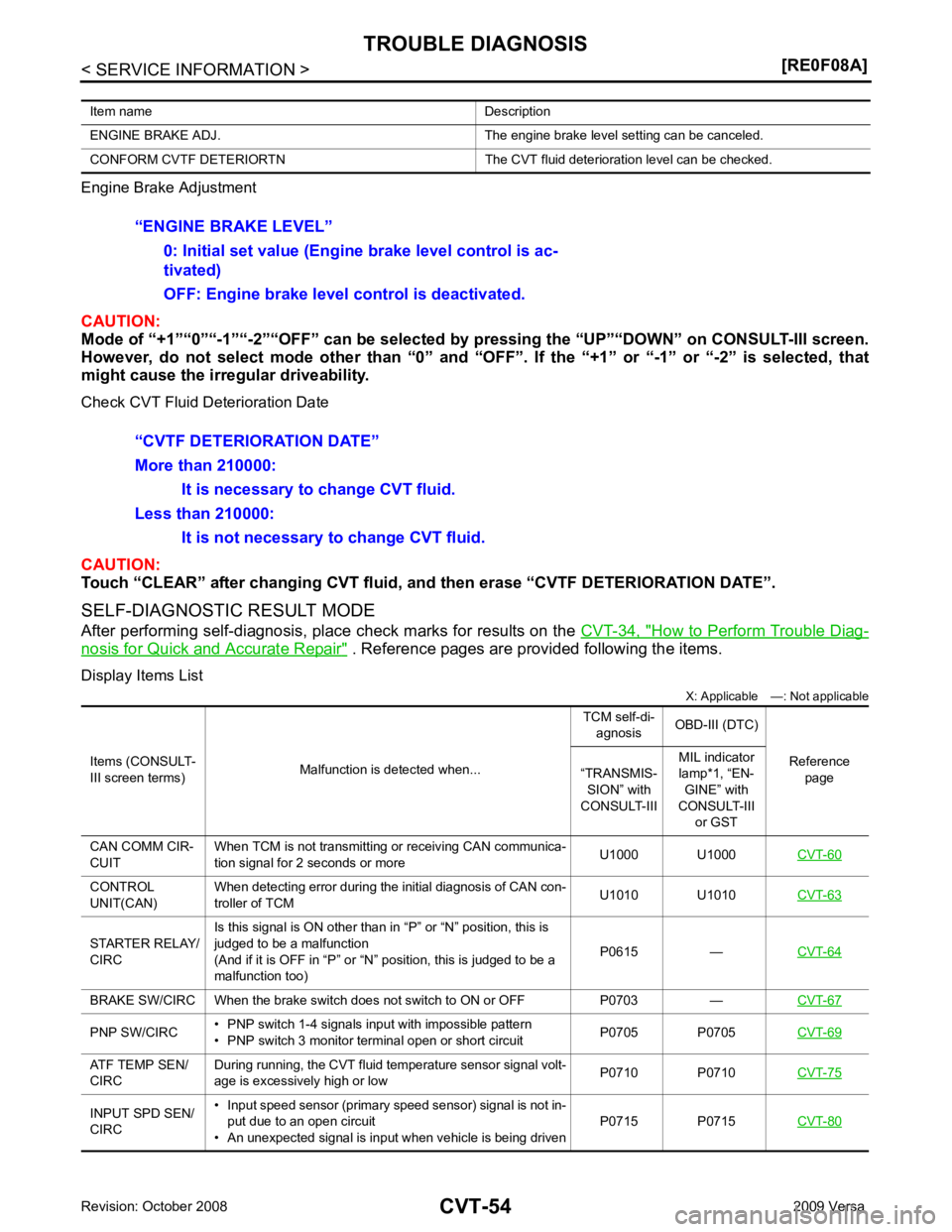

Display Items List X: Applicable —: Not applicable

Item name Description

ENGINE BRAKE ADJ. The engine brake level setting can be canceled.

CONFORM CVTF DETERIORTN The CVT fluid deterioration level can be checked. CONTROL

UNIT(CAN) When detecting error during the initial diagnosis of CAN con-

troller of TCM U1010 U1010

CVT-63STARTER RELAY/

CIRC Is this signal is ON other than in “P” or “N” position, this is

judged to be a malfunction

(And if it is OFF in “P” or “N” position, this is judged to be a

malfunction too) P0615 —

CVT-64BRAKE SW/CIRC When the brake switch does

not switch to ON or OFF P0703 — CVT-67PNP SW/CIRC

• PNP switch 1-4 signals input with impossible pattern

• PNP switch 3 monitor terminal open or short circuit P0705 P0705

CVT-69ATF TEMP SEN/

CIRC During running, the CVT fluid temperature sensor signal volt-

age is excessively high or low P0710 P0710

CVT-75INPUT SPD SEN/

CIRC • Input speed sensor (primary speed sensor) signal is not in-

put due to an open circuit

• An unexpected signal is input when vehicle is being driven P0715 P0715

CVT-80

Page 999 of 4331

![NISSAN TIIDA 2009 Service Manual PDF CVT

N

O P

VEH SPD SEN/

CIR AT • Signal from vehicle speed sensor CVT [Output speed sen-

sor (Secondary speed sensor)] not input due to open or

short circuit

• Unexpected signal input during runni NISSAN TIIDA 2009 Service Manual PDF CVT

N

O P

VEH SPD SEN/

CIR AT • Signal from vehicle speed sensor CVT [Output speed sen-

sor (Secondary speed sensor)] not input due to open or

short circuit

• Unexpected signal input during runni](/img/5/57398/w960_57398-998.png)

CVT

N

O P

VEH SPD SEN/

CIR AT • Signal from vehicle speed sensor CVT [Output speed sen-

sor (Secondary speed sensor)] not input due to open or

short circuit

• Unexpected signal input during running P0720 P0720

CVT-84ENGINE SPEED

SIG • TCM does not receive the CAN communication signal from

the ECM

• Engine speed is too low while driving P0725 —

CVT-89BELT DAMG Unexpected gear ratio detected P0730 —

CVT-91TCC SOLENOID/

CIRC Normal voltage not applied to solenoid due to open or short

circuit P0740 P0740

CVT-92A/T TCC S/V

FNCTN • CVT cannot perform lock-up even if electrical circuit is good

• TCM detects as irregular by comparing difference value with slip rotation

• There is big difference engine speed and primary speed when TCM lock-up signal is on P0744 P0744

CVT-97L/PRESS SOL/

CIRC • Normal voltage not applied to solenoid due to open or short

circuit

• TCM detects as irregular by comparing target value with monitor value P0745 P0745

CVT-99PRS CNT SOL/A

FCTN Unexpected gear ratio was detected in the LOW side due to

excessively low line pressure P0746 P0746

CVT-104PRS CNT SOL/B

FCTN Secondary pressure is too high or too low compared with the

commanded value while driving P0776 P0776

CVT-106PRS CNT SOL/B

CIRC • Normal voltage not applied to solenoid due to cut line,

short, or the like

• TCM detects as irregular by comparing target value with

monitor value P0778 P0778

CVT-108TR PRS SENS/A

CIRC Signal voltage of the transmission fluid pressure sensor A

(secondary pressure sensor) is too high or too low while driv-

ing P0840 P0840

CVT-113PRESS SEN/

FNCTN Correlation between the values of the transmission fluid pres-

sure sensor A (secondary pressure sensor) and the tranmis-

sion fluid pressure sensor B (primary pressure sensor) is out

of specification P0841 —

CVT-117TR PRS SENS/B

CIRC Signal voltage of the transmission fluid pressure sensor B

(primary pressure sensor) is too high or too low while driving P0845 P0845

CVT-119SEC/PRESS

DOWN Secondary fluid pressure is too low compared with the com-

manded value while driving P0868 —

CVT-123TCM-POWER

SUPPLY • When the power supply to the TCM is cut OFF, for example

because the battery is removed, and the self-diagnosis

memory function stops

• This is not a malfunction message (Whenever shutting OFF a power supply to the TCM, this message appears on

the screen) P1701 —

CVT-125TP SEN/CIRC A/T

TCM does not receive the proper accelerator pedal position

signals (input by CAN communication) from ECM P1705 —

CVT-129ESTM VEH SPD

SIG*2 • CAN communication with the ABS actuator and the electric

unit (control unit) is malfunctioning

• There is a great difference between the vehicle speed sig-

nal from the ABS actuator and the electric unit (control

unit), and the vehicle speed sensor signal P1722 —

CVT-131Items (CONSULT-

III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-III (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN- GINE” with

CONSULT-III

or GST