engine control NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 913 of 4331

CO

NP

O

Removal and Installation

INFOID:0000000004784360

REMOVAL 1. Drain engine coolant from radiator. Refer to CO-11, " Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove air duct (inlet). Refer to EM-26, " Exploded View " .

3. Remove reservoir tank.

4. Disconnect radiator hose (upper) at radiator side. Refer to CO-16, " Component " .

5. Disconnect harness connectors from fan motor, and move harness to aside.

6. Remove cooling fan assembly. CAUTION:

Be careful not to damage or scratch the radiator core.

INSTALLATION Installation is the reverse order of removal.

• Cooling fans are controlled by ECM. For details, refer to EC-422, " Description " .

CAUTION:

Be careful not to damage or scratch the radiator core.

Page 918 of 4331

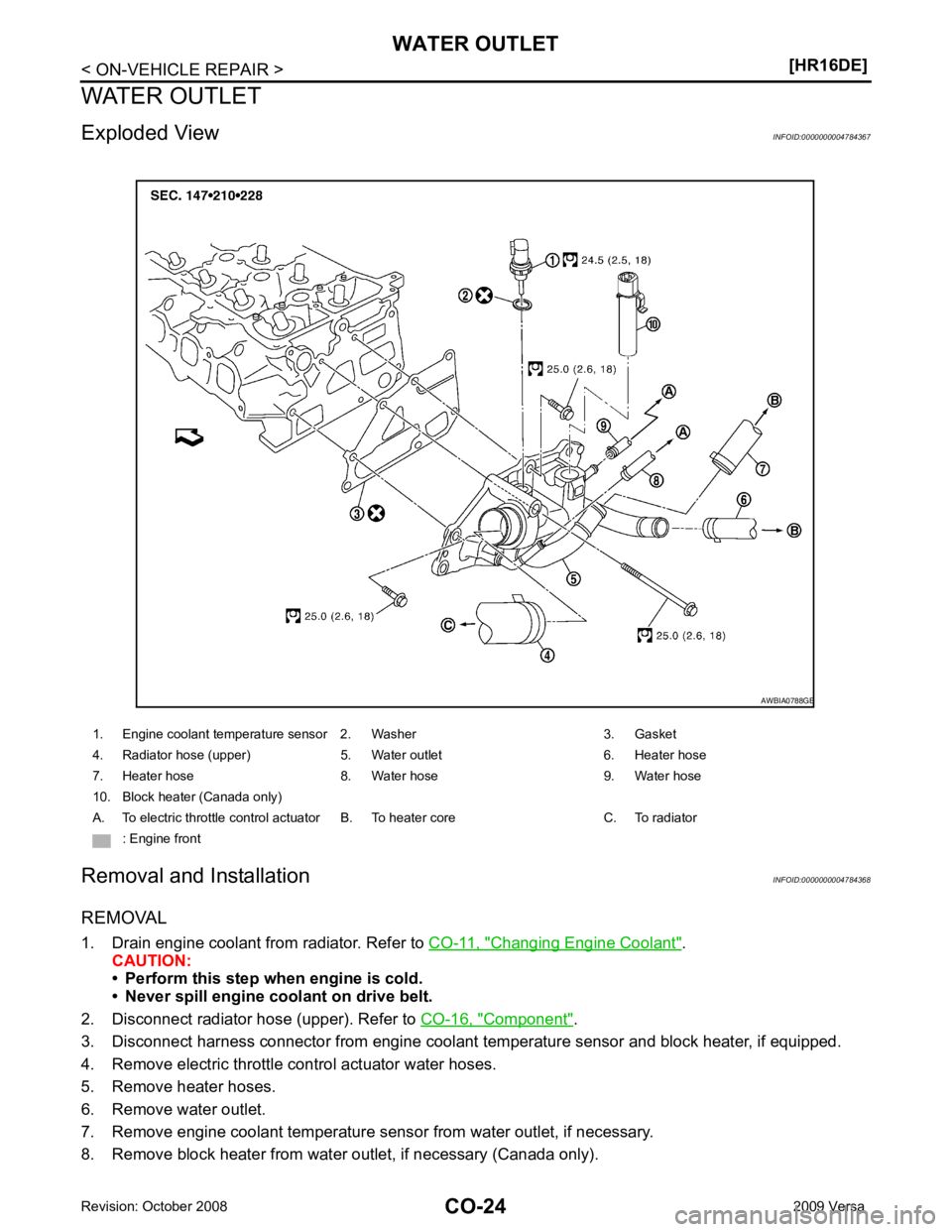

Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Never spill engine coolant on drive belt.

2. Disconnect radiator hose (upper). Refer to CO-16, " Component " .

3. Disconnect harness connector from engine coolant temperature sensor and block heater, if equipped.

4. Remove electric throttle control actuator water hoses.

5. Remove heater hoses.

6. Remove water outlet.

7. Remove engine coolant temperature sens or from water outlet, if necessary.

8. Remove block heater from water outlet, if necessary (Canada only). 1. Engine coolant temperature sensor 2. Washer 3. Gasket

4. Radiator hose (upper) 5. Water outlet 6. Heater hose

7. Heater hose 8. Water hose 9. Water hose

10. Block heater (Canada only)

A. To electric throttle control actuator B. To heater core C. To radiator : Engine front

Page 930 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

syst NISSAN TIIDA 2009 Service Workshop Manual CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

syst](/img/5/57398/w960_57398-929.png)

CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

Radiator drain plug : Refer to

CO-38, " Component " .

Cylinder block drain plug : Refer to EM-200, " Disassembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi) LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum LLIA0057E

Page 936 of 4331

Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove air duct (inlet). Refer to EM-139, " Component " .

3. Remove reservoir tank. Refer to CO-38, " Component " .

4. Disconnect radiator hose (upper) at radiator side. Refer to CO-38, " Component " .

5. Disconnect harness connectors from fan motor, and move harness aside.

6. Remove cooling fan assembly. CAUTION:

Be careful not to damage or scratch the radiator core.

INSTALLATION

Installation is in the reverse order of removal.

• Cooling fans are controlled by ECM. For details, refer to EC-886, " System Description " .

CAUTION:

Be careful not to damage or scratch the radiator core.

Disassembly and Assembly INFOID:0000000004305243

DISASSEMBLY

1. Remove cooling fan from fan motor.

2. Remove fan motor from fan shroud.

INSPECTION AFTER DISASSEMBLY

Inspect cooling fan for crack or unusual bend.

• If anything is found, replace cooling fan.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Page 941 of 4331

CO

NP

O

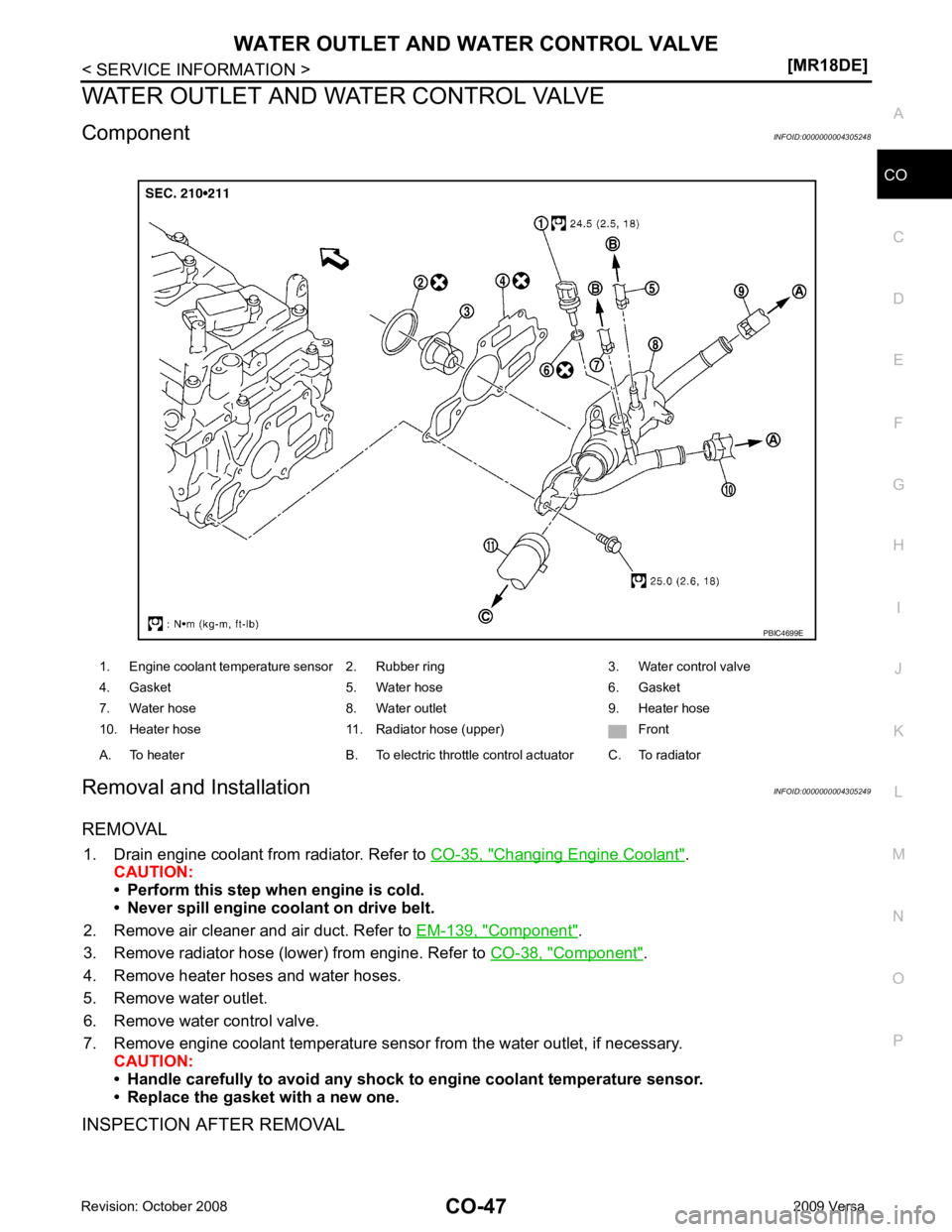

WATER OUTLET AND WATER CONTROL VALVE

Component INFOID:0000000004305248

Removal and Installation INFOID:0000000004305249

REMOVAL 1. Drain engine coolant from radiator. Refer to CO-35, " Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Never spill engine coolant on drive belt.

2. Remove air cleaner and air duct. Refer to EM-139, " Component " .

3. Remove radiator hose (lower) from engine. Refer to CO-38, " Component " .

4. Remove heater hoses and water hoses.

5. Remove water outlet.

6. Remove water control valve.

7. Remove engine coolant temperature sensor from the water outlet, if necessary. CAUTION:

• Handle carefully to avoid any shock to engine coolant temperature sensor.

• Replace the gasket with a new one.

INSPECTION AFTER REMOVAL 1. Engine coolant temperature sensor 2. Rubber ring 3. Water control valve

4. Gasket 5. Water hose 6. Gasket

7. Water hose 8. Water outlet 9. Heater hose

10. Heater hose 11. Radiator hose (upper) Front

A. To heater B. To electric throttle control actuator C. To radiator

Page 943 of 4331

CO

NP

O

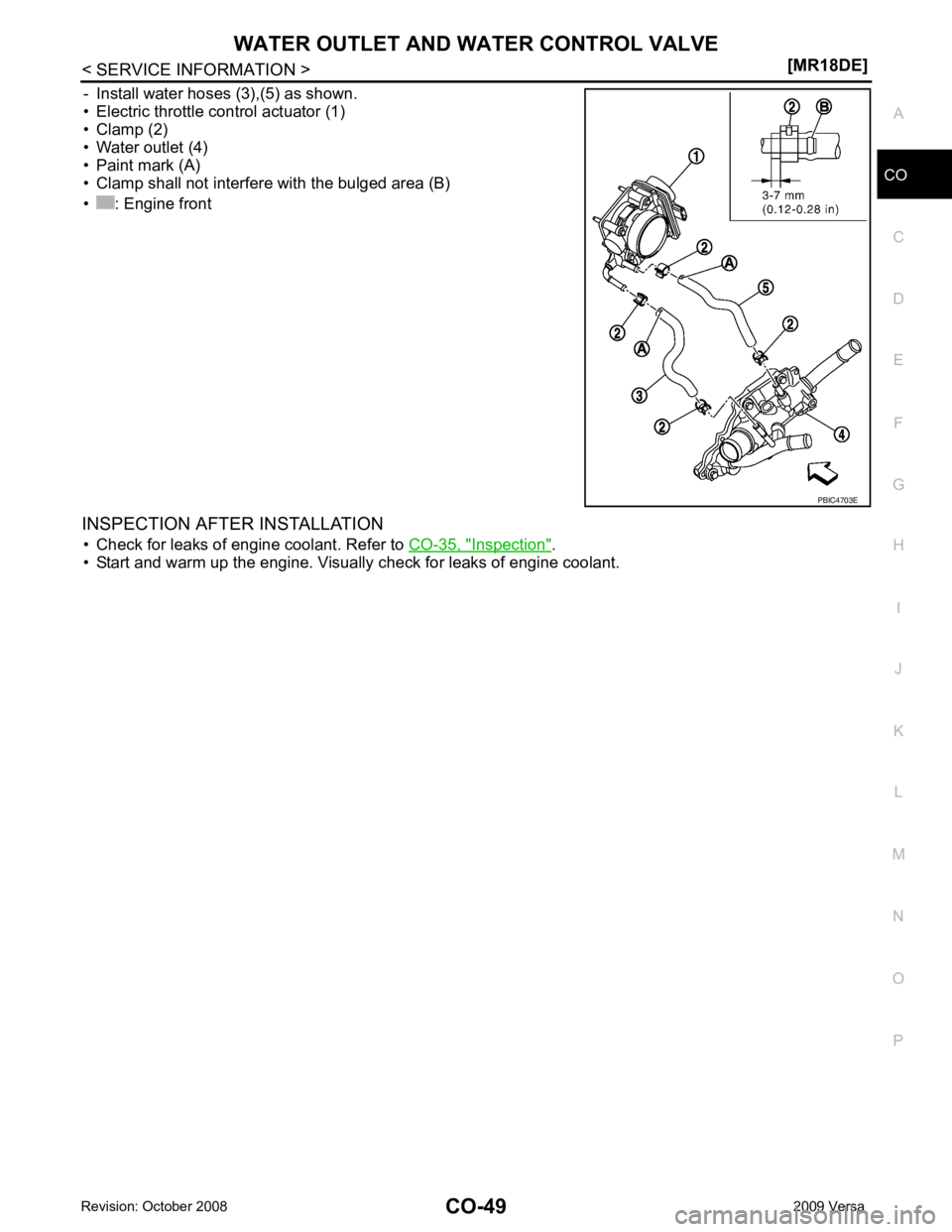

- Install water hoses (3),(5) as shown.

• Electric throttle control actuator (1)

• Clamp (2)

• Water outlet (4)

• Paint mark (A)

• Clamp shall not interfere with the bulged area (B)

• : Engine front

INSPECTION AFTER INSTALLATION • Check for leaks of engine coolant. Refer to CO-35, " Inspection " .

• Start and warm up the engine. Visually check for leaks of engine coolant.

Page 945 of 4331

CVT

N

O P

CONTENTS

CVT

RE0F08A

SERVICE INFORMATION .. ..........................

9

INDEX FOR DTC ............................................ .....9

Alphabetical Index ............................................... ......9

DTC No. Index .................................................... ......9

PRECAUTIONS .............................................. ....11

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

11

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ....

11

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine .............................................. ....

12

Service After Replacing TCM and Transaxle As-

sembly ................................................................. ....

12

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ....

13

Precaution ........................................................... ....14

Service Notice or Precaution ............................... ....15

PREPARATION .............................................. ....16

Special Service Tool ........................................... ....16

Commercial Service Tool .................................... ....16

CVT FLUID ..................................................... ....17

Checking CVT Fluid ............................................ ....17

Changing CVT Fluid ............................................ ....18

CVT Fluid Cooler Cleanin g .....................................18

CVT SYSTEM ... .............................................. ....22

Cross-Sectional View - RE0F08A ....................... ....22

Control System .................................................... ....23

Hydraulic Control System ........................................24

TCM Function ...................................................... ....24

CAN Communication ........................................... ....25

Input/Output Signal of TCM ................................. ....26

Line Pressure and Secondary Pressure Control . ....26

Shift Control ........................................................ ....27

Lock-up and Select Control ................................. ....28 Control Valve .......................................................

....29

ON BOARD DIAGNOSTIC (OBD) SYSTEM .... 30

Introduction .......................................................... ....30

OBD-II Function for CVT System ........................ ....30

One or Two Trip Detection Logic of OBD-II ......... ....30

OBD-II Diagnostic Trouble Code (DTC) .............. ....30

Malfunction Indicator Lamp (MIL) ............................31

TROUBLE DIAGNOSIS .................................... 33

DTC Inspection Priority Chart .............................. ....33

Fail-Safe .............................................................. ....33

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

34

CVT Electrical Parts Location .............................. ....39

Circuit Diagram .................................................... ....40

Inspections before Trouble Diagnosis ................. ....40

Road Test ............................................................ ....44

Check before Engine Is Started ........................... ....45

Check at Idle ........................................................ ....45

Cruise Test .......................................................... ....47

Vehicle Speed When Shifting Gears ................... ....49

TCM Terminal and Refere nce Value .......................49

CONSULT-III Function (TRANSMISSION) .......... ....51

Diagnosis Procedure withou t CONSULT-III ............59

DTC U1000 CAN COMMUNICATION LINE ..... 60

Description ........................................................... ....60

On Board Diagnosis Logic ................................... ....60

Possible Cause .................................................... ....60

DTC Confirmation Procedure .............................. ....60

Wiring Diagram - CVT - CAN ............................... ....61

Diagnosis Procedure ........................................... ....62

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) ................................................ 63

Description ........................................................... ....63

On Board Diagnosis Logic ................................... ....63

Possible Cause .................................................... ....63

DTC Confirmation Procedure .............................. ....63

Diagnosis Procedure ........................................... ....63

Page 949 of 4331

CVT

N

O

P

N

Precaution Necessary fo

r Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

189

Precaution for On Board Diagnosis (OBD) System

of CVT and Engine .............................................. ..

190

Service After Replacing TCM and Transaxle As-

sembly ................................................................. ..

190

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ..

191

Precaution ........................................................... ..192

Service Notice or Precaution ............................... ..193

PREPARATION .............................................. ..195

Special Service Tool ........................................... ..195

Commercial Service Tool .................................... ..195

CVT FLUID ..................................................... ..196

Checking CVT Fluid ............................................ ..196

Changing CVT Fluid ............................................ ..197

CVT Fluid Cooler Cleanin g ...................................197

CVT SYSTEM ... .............................................. ..201

Cross-Sectional View - RE0F08B ....................... ..201

Control System .................................................... ..202

Hydraulic Control System ......................................203

TCM Function ...................................................... ..203

CAN Communication ........................................... ..204

Input/Output Signal of TCM ................................. ..204

Line Pressure and Secondary Pressure Control . ..205

Shift Control ........................................................ ..205

Lock-up and Select Control ................................. ..207

Control Valve ....................................................... ..207

ON BOARD DIAGNOSTIC (OBD) SYSTEM .. ..209

Introduction ......................................................... ..209

OBD-II Function for CVT System ........................ ..209

One or Two Trip Detection Logic of OBD-II ........ ..209

OBD-II Diagnostic Trouble Code (DTC) .............. ..209

Malfunction Indicator Lamp (MIL) ........................ ..210

TROUBLE DIAGNOSIS ................................. ..212

DTC Inspection Priority Chart ............................. ..212

Fail-Safe .............................................................. ..212

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........... .........................................

213

CVT Electrical Parts Location ............................. ..218

Circuit Diagram ................................................... ..219

Inspections before Trouble Diagnosis ................. ..219

Road Test ............................................................ ..223

Check before Engine Is Started ............................224

Check at Idle ....................................................... ..224

Cruise Test .......................................................... ..226

Vehicle Speed When Shifting Gears ................... ..228

TCM Terminal and Reference Value ................... ..228

CONSULT-III Function (TRANSMISSION) ......... ..230

Diagnosis Procedu re without CONSULT-III ........ ..237

DTC U1000 CAN COMMUNICATION LINE ... ..238

Description .......................................................... ..238

On Board Diagnosis Logic .................................. ..238

Possible Cause ................................................... ..238 DTC Confirmation Procedure ..............................

..238

Wiring Diagram - CVT - CAN ............................... ..239

Diagnosis Procedure ........................................... ..240

DTC U1010 TRANSMISSION CONTROL

MODULE (CAN) .............................................. 241

Description ........................................................... ..241

On Board Diagnosis Logic ................................... ..241

Possible Cause .................................................... ..241

DTC Confirmation Procedure .............................. ..241

Diagnosis Procedure ........................................... ..241

DTC P0703 STOP LAMP SWITCH CIRCUIT . 242

Description ........................................................... ..242

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

242

On Board Diagnosis Logic ................................... ..242

Possible Cause .................................................... ..242

DTC Confirmation Procedure .............................. ..242

Diagnosis Procedure ........................................... ..242

DTC P0705 PARK/NEUTRAL POSITION

SWITCH ........................................................... 244

Description ........................................................... ..244

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

244

On Board Diagnosis Logic ................................... ..244

Possible Cause .................................................... ..244

DTC Confirmation Procedure .............................. ..244

Wiring Diagram - CVT - PNP/SW ........................ ..245

Diagnosis Procedure ........................................... ..246

Component Inspection ......................................... ..247

DTC P0710 CVT FLUID TEMPERATURE

SENSOR CIRCUIT .......................................... 249

Description ........................................................... ..249

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

249

On Board Diagnosis Logic ................................... ..249

Possible Cause .................................................... ..249

DTC Confirmation Procedure .............................. ..249

Wiring Diagram - CVT - FTS ............................... ..250

Diagnosis Procedure ........................................... ..251

Component Inspection ......................................... ..252

DTC P0715 INPUT SPEED SENSOR CIR-

CUIT (PRI SPEED SENSOR) .......................... 254

Description ........................................................... ..254

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

254

On Board Diagnosis Logic ................................... ..254

Possible Cause .................................................... ..254

DTC Confirmation Procedure .............................. ..254

Wiring Diagram - CVT - PRSCVT ........................ ..255

Diagnosis Procedure ........................................... ..256

DTC P0720 VEHICLE SPEED SENSOR CVT

(SECONDARY SPEED SENSOR) .................. 258

Description ........................................................... ..258

Page 951 of 4331

CVT

N

O

P

N

Description ..........................................................

..

293

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

293

On Board Diagnosis Logic .................................. ..293

Possible Cause ................................................... ..293

DTC Confirmation Procedure .............................. ..293

Diagnosis Procedure ........................................... ..293

DTC P1701 TRANSMISSION CONTROL

MODULE (POWER SUPPLY) ........................ ..295

Description .......................................................... ..295

On Board Diagnosis Logic .................................. ..295

Possible Cause ................................................... ..295

DTC Confirmation Procedure .............................. ..295

Wiring Diagram - CVT - POWER ........................ ..296

Diagnosis Procedure ........................................... ..297

DTC P1705 THROTTLE POSITION SENSOR ..299

Description .......................................................... ..299

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

299

On Board Diagnosis Logic .................................. ..299

Possible Cause ................................................... ..299

DTC Confirmation Procedure .............................. ..299

Diagnosis Procedure ........................................... ..299

DTC P1722 ESTM VEHICLE SPEED SIGNAL ..301

Description .......................................................... ..301

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

301

On Board Diagnosis Logic .................................. ..301

Possible Cause ................................................... ..301

DTC Confirmation Procedure .............................. ..301

Diagnosis Procedure ........................................... ..301

DTC P1723 CVT SPEED SENSOR FUNC-

TION ............................................................... ..303

Description .......................................................... ..303

On Board Diagnosis Logic .................................. ..303

Possible Cause ................................................... ..303

DTC Confirmation Procedure .............................. ..303

Diagnosis Procedure ........................................... ..303

DTC P1726 ELECTRIC THROTTLE CON-

TROL SYSTEM .............................................. ..

305

Description .......................................................... ..305

On Board Diagnosis Logic .................................. ..305

Possible Cause ................................................... ..305

DTC Confirmation Procedure .............................. ..305

Diagnosis Procedure ........................................... ..305

DTC P1740 LOCK-UP SELECT SOLENOID

VALVE CIRCUIT ............................................ ..

306

Description .......................................................... ..306

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

306

On Board Diagnosis Logic .................................. ..306

Possible Cause ................................................... ..306

DTC Confirmation Procedure .............................. ..306

Wiring Diagram - CVT - L/USSV ......................... ..307 Diagnosis Procedure ...........................................

..308

Component Inspection ......................................... ..309

DTC P1745 LINE PRESSURE CONTROL ..... 310

Description ........................................................... ..310

On Board Diagnosis Logic ................................... ..310

Possible Cause .................................................... ..310

DTC Confirmation Procedure .............................. ..310

Diagnosis Procedure ........................................... ..310

DTC P1777 STEP MOTOR - CIRCUIT ........... 311

Description ........................................................... ..311

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

311

On Board Diagnosis Logic ................................... ..311

Possible Cause .................................................... ..311

DTC Confirmation Procedure .............................. ..311

Wiring Diagram - CVT - STM ............................... ..312

Diagnosis Procedure ........................................... ..313

Component Inspection ......................................... ..314

DTC P1778 STEP MOTOR - FUNCTION ....... 315

Description ........................................................... ..315

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

315

On Board Diagnosis Logic ................................... ..315

Possible Cause .................................................... ..315

DTC Confirmation Procedure .............................. ..315

Diagnosis Procedure ........................................... ..316

OVERDRIVE CONTROL SWITCH .................. 317

Description ........................................................... ..317

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

317

Wiring Diagram - CVT - ODSW ........................... ..318

Diagnosis Procedure ........................................... ..318

Component Inspection ......................................... ..320

SHIFT POSITION INDICATOR CIRCUIT ........ 322

Description ........................................................... ..322

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

322

Diagnosis Procedure ........................................... ..322

TROUBLE DIAGNOSIS FOR SYMPTOMS .... 323

Wiring Diagram - CVT - NONDTC ....................... ..323

O/D OFF Indicator Lamp Does Not Come On ..... ..325

Engine Cannot Be Started in "P" and "N" Position ..327

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ............................................. ..

327

In "N" Position, Vehicle Moves ............................ ..328

Large Shock "N" → "R" Position .......................... ..328

Vehicle Does Not Creep Backward in "R" Position ..329

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition .................................................................... ..

330

Vehicle Speed Does Not Change in "L" Position . ..331

Vehicle Speed Does Not Change in overdrive-off

mode .................................................................... ..

332

Vehicle Speed Does Not Change in "D" Position .. 333

Vehicle Does Not Decelerate by Engine Brake ... ..333

Page 953 of 4331

CVT

N

O P

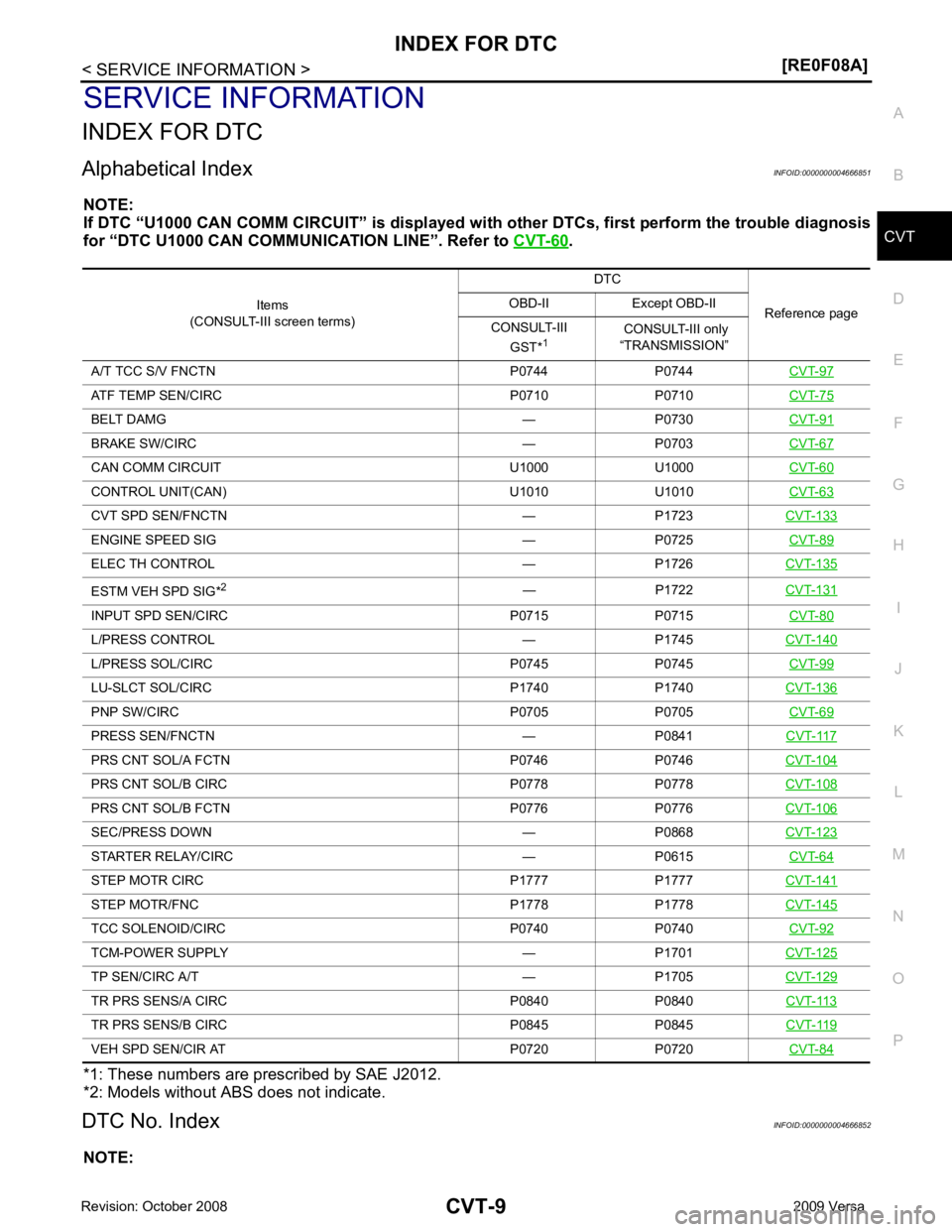

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical Index INFOID:0000000004666851

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to CVT-60 .

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. Index INFOID:0000000004666852

NOTE: Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II Except OBD-II

CONSULT-III GST* 1 CONSULT-III only

“TRANSMISSION”

A/T TCC S/V FNCTN P0744 P0744 CVT-97ATF TEMP SEN/CIRC P0710 P0710

CVT-75BELT DAMG — P0730

CVT-91BRAKE SW/CIRC — P0703

CVT-67CAN COMM CIRCU

IT U1000 U1000 CVT-60CONTROL UNIT(CAN) U1010 U1010

CVT-63CVT SPD SEN/FNCTN — P1723

CVT-133ENGINE SPEED SIG — P0725

CVT-89ELEC TH CONTROL — P1726

CVT-135ESTM VEH SPD SIG*

2

— P1722CVT-131INPUT SPD SEN/CIRC P0715 P0715

CVT-80L/PRESS CONTROL — P1745

CVT-140L/PRESS SOL/CIRC P0745 P0745

CVT-99LU-SLCT SOL/CIRC P1740 P1740

CVT-136PNP SW/CIRC P0705 P0705

CVT-69PRESS SEN/FNCTN — P0841

CVT-117PRS CNT SOL/A FCTN P0746 P0746

CVT-104PRS CNT SOL/B CIRC P0778 P0778

CVT-108PRS CNT SOL/B FCTN P0776 P0776

CVT-106SEC/PRESS DOWN — P0868

CVT-123STARTER RELAY/CIRC — P0615

CVT-64STEP MOTR CIRC P1777 P1777

CVT-141STEP MOTR/FNC P1778 P1778

CVT-145TCC SOLENOID/CIRC P0740 P0740

CVT-92TCM-POWER SUPPLY — P1701

CVT-125TP SEN/CIRC A/T — P1705

CVT-129TR PRS SENS/A CIRC P0840 P0840

CVT-113TR PRS SENS/B CIRC P0845 P0845

CVT-119VEH SPD SEN/CIR AT P0720 P0720

CVT-84