wiring diagram NISSAN TIIDA 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 180 of 4331

AT

N

O P

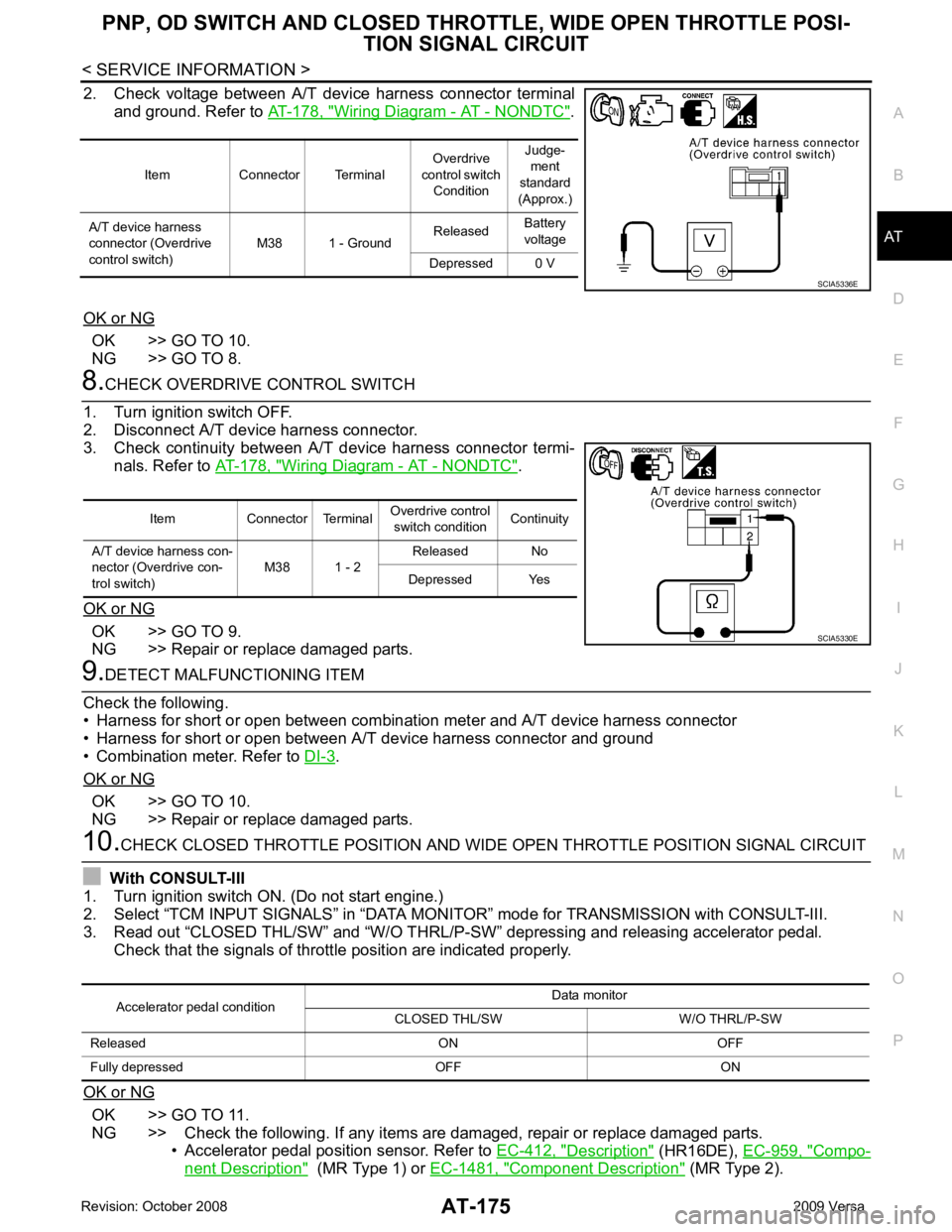

2. Check voltage between A/T device harness connector terminal

and ground. Refer to AT-178, " Wiring Diagram - AT - NONDTC " .

OK or NG OK >> GO TO 10.

NG >> GO TO 8. Wiring Diagram - AT - NONDTC " .

OK or NG OK >> GO TO 9.

NG >> Repair or replace damaged parts. .

OK or NG OK >> GO TO 10.

NG >> Repair or replace damaged parts. OK >> GO TO 11.

NG >> Check the following. If any items are damaged, repair or replace damaged parts. • Accelerator pedal position sensor. Refer to EC-412, " Description " (HR16DE),

EC-959, " Compo-

nent Description " (MR Type 1) or

EC-1481, " Component Description " (MR Type 2).

Item Connector Terminal

Overdrive

control switch Condition Judge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0 V

Page 187 of 4331

AT-182< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OD OFF indicator lamp does not come on for about 2 seconds when turning ignition switch to ON.

DIAGNOSTIC PROCEDURE 1.

CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-79, " CONSULT-III Function (TRANSMISSION) " .

Is a malfunction in CAN communication indicated in the results? YES >> Check CAN communication line. Refer to

AT-88 .

NO >> GO TO 2. 2.

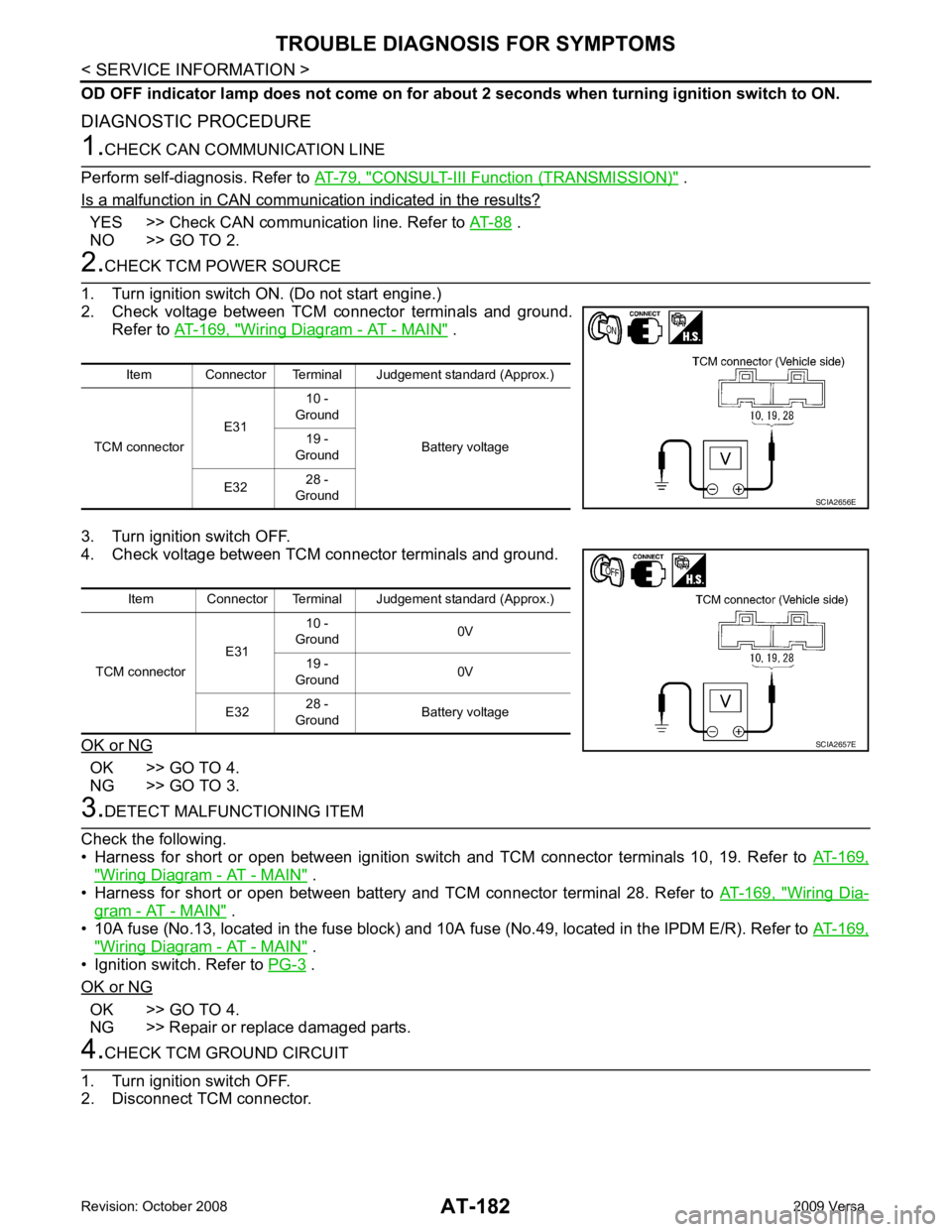

CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground.

Refer to AT-169, " Wiring Diagram - AT - MAIN " .

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG OK >> GO TO 4.

NG >> GO TO 3. 3.

DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and TCM connector terminals 10, 19. Refer to AT-169," Wiring Diagram - AT - MAIN " .

• Harness for short or open between battery and TCM connector terminal 28. Refer to AT-169, " Wiring Dia-

gram - AT - MAIN " .

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R). Refer to AT-169," Wiring Diagram - AT - MAIN " .

• Ignition switch. Refer to PG-3 .

OK or NG OK >> GO TO 4.

NG >> Repair or replace damaged parts. 4.

CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector. Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground

Battery voltage

19 -

Ground

E32 28 -

Ground SCIA2656E

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground 0V

19 -

Ground 0V

E32 28 -

Ground Battery voltage SCIA2657E

Page 188 of 4331

AT

N

O P

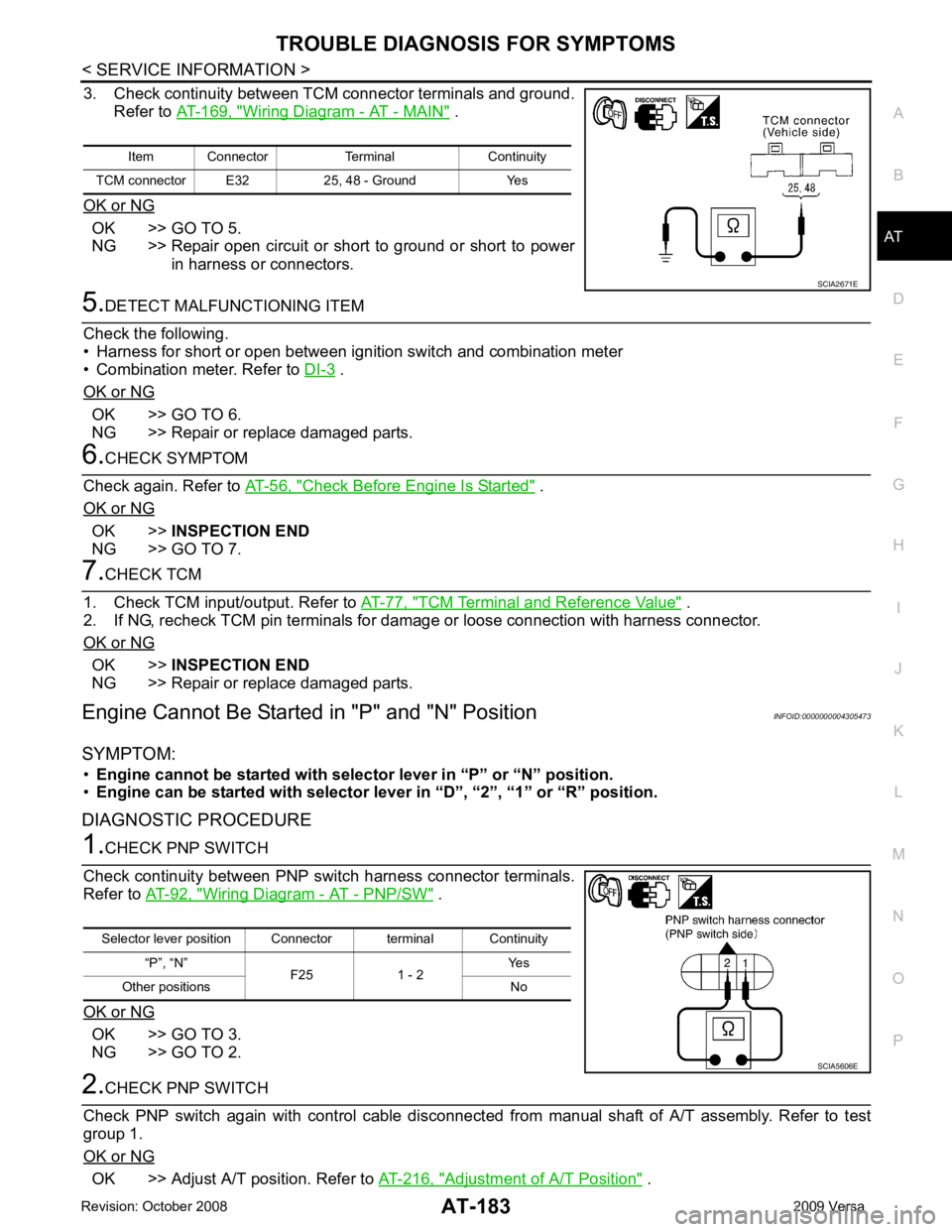

3. Check continuity between TCM connector terminals and ground.

Refer to AT-169, " Wiring Diagram - AT - MAIN " .

OK or NG OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. .

OK or NG OK >> GO TO 6.

NG >> Repair or replace damaged parts. Check Before Engine Is Started " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 7. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Starte d in "P" and "N" Position INFOID:0000000004305473

SYMPTOM: • Engine cannot be started with select or lever in “P” or “N” position.

• Engine can be started with selector l ever in “D”, “2”, “1” or “R” position.

DIAGNOSTIC PROCEDURE Wiring Diagram - AT - PNP/SW " .

OK or NG OK >> GO TO 3.

NG >> GO TO 2. OK >> Adjust A/T position. Refer to

AT-216, " Adjustment of A/T Position " .

Item Connector Terminal Continuity

TCM connector E32 25, 48 - Ground Yes

Page 204 of 4331

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

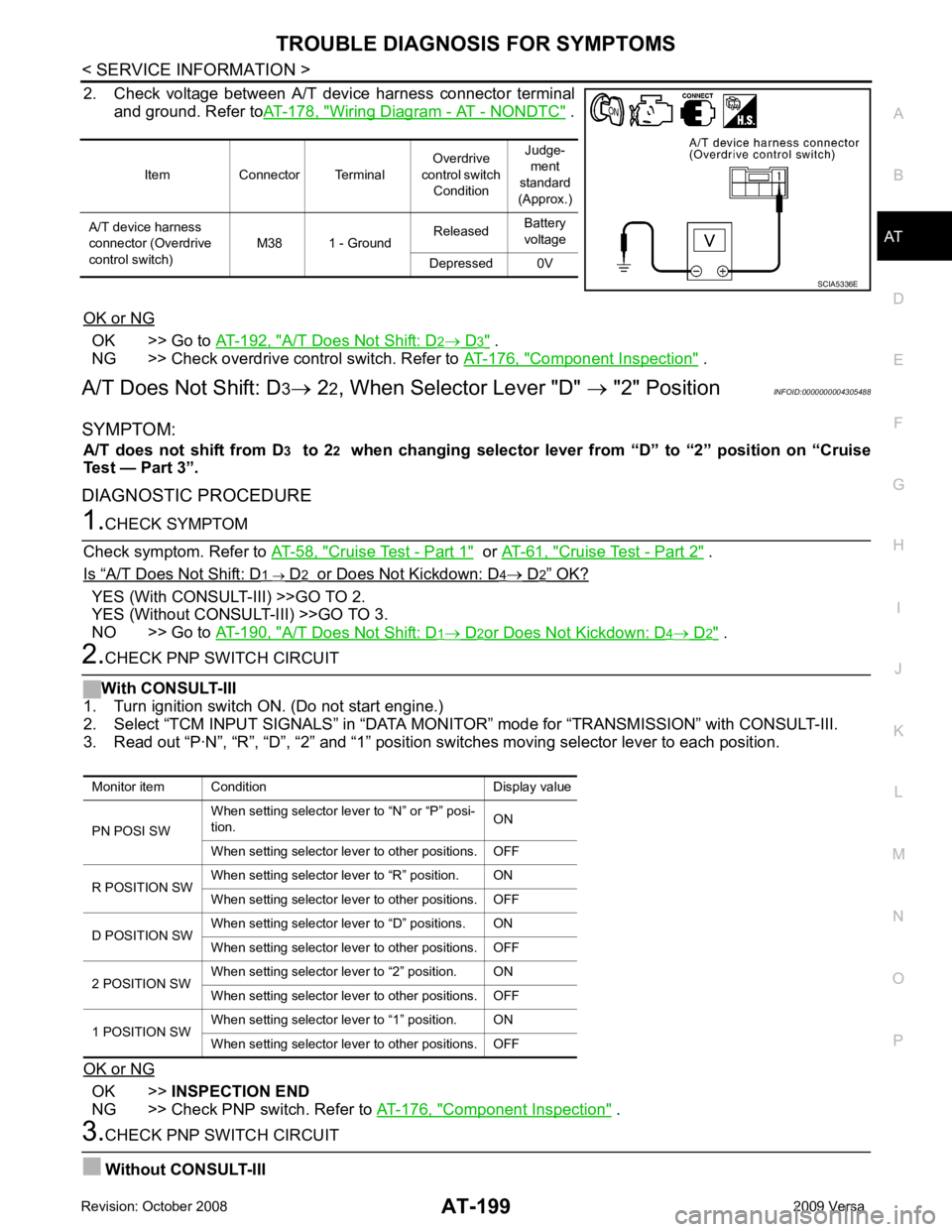

2. Check voltage between A/T device harness connector terminal

and ground. Refer to AT-178, " Wiring Diagram - AT - NONDTC " .

OK or NG OK >> Go to

AT-192, " A/T Does Not Shift: D 2 → D 3 " .

NG >> Check overdrive control switch. Refer to AT-176, " Component Inspection " .

A/T Does Not Shift: D 3→ 22, When Selector Lever "D" → "2" Position INFOID:0000000004305488

SYMPTOM: A/T does not shift from D 3 to 2 2 when changing selector lever from “D” to “2” position on “Cruise

Test — Part 3”.

DIAGNOSTIC PROCEDURE 1.

CHECK SYMPTOM

Check symptom. Refer to AT-58, " Cruise Test - Part 1 " or

AT-61, " Cruise Test - Part 2 " .

Is “ A/T Does Not Shift: D 1 → D 2 or Does Not Kickdown: D 4 → D 2 ” OK?

YES (With CONSULT-III) >>GO TO 2.

YES (Without CONSULT-III) >>GO TO 3.

NO >> Go to AT-190, " A/T Does Not Shift: D 1 → D 2 or Does Not Kickdown: D 4 → D 2 " .

2.

CHECK PNP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG OK >>

INSPECTION END

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

3.

CHECK PNP SWITCH CIRCUIT

Without CONSULT-III Item Connector Terminal

Overdrive

control switch Condition Judge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0V SCIA5336E

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 205 of 4331

AT-200< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

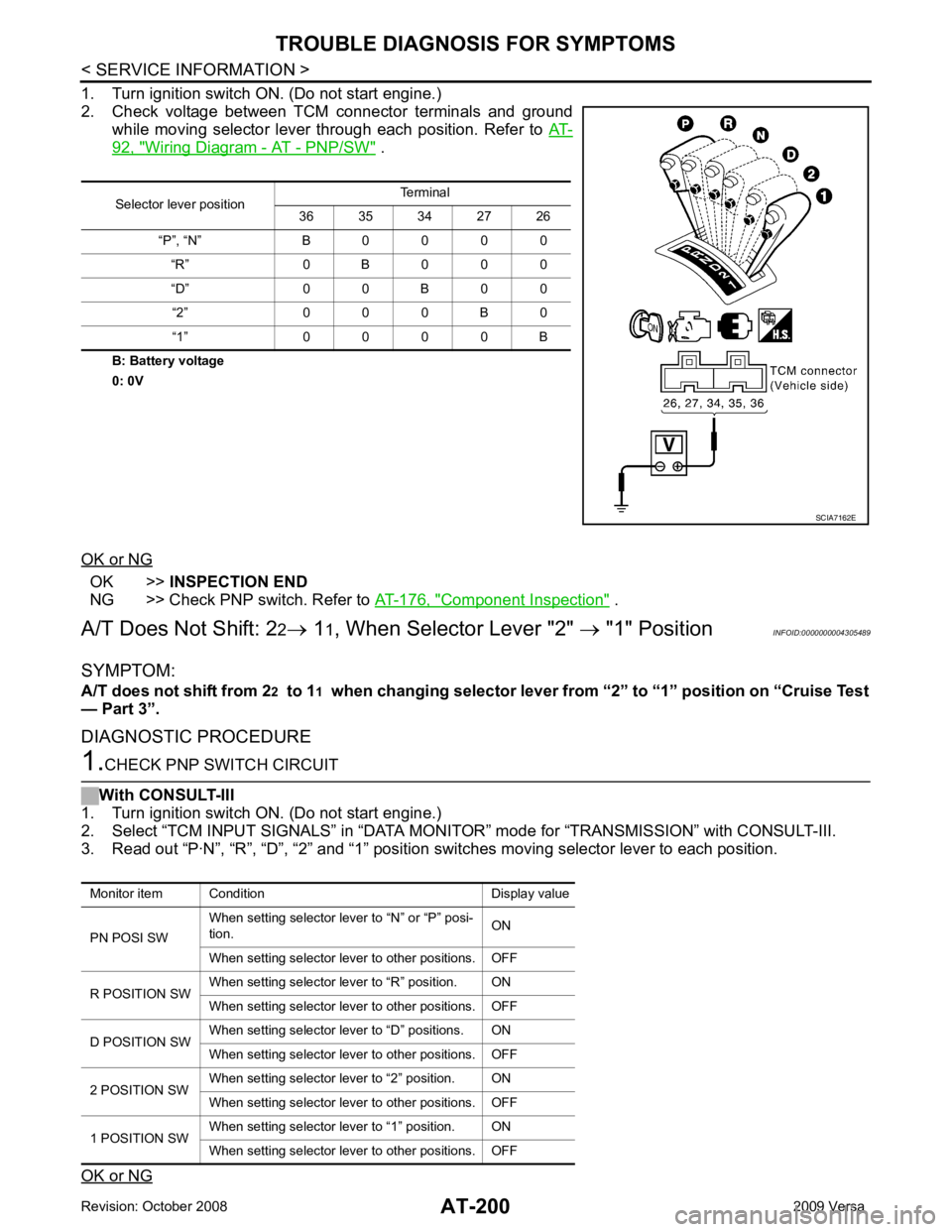

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-92, " Wiring Diagram - AT - PNP/SW " .

B: Battery voltage

0: 0V

OK or NG OK >>

INSPECTION END

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

A/T Does Not Shift: 2 2→ 11, When Selector Lever "2" → "1" Position INFOID:0000000004305489

SYMPTOM:

A/T does not shift from 2 2 to 1 1 when changing selector lever from “2” to “1” position on “Cruise Test

— Part 3”.

DIAGNOSTIC PROCEDURE 1.

CHECK PNP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG Selector lever position

Terminal

36 35 34 27 26

“P”, “N” B 0 0 0 0 “R” 0 B 0 0 0

“D” 0 0 B 0 0 “2” 0 0 0 B 0

“1” 0 0 0 0 B SCIA7162E

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 206 of 4331

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-201

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

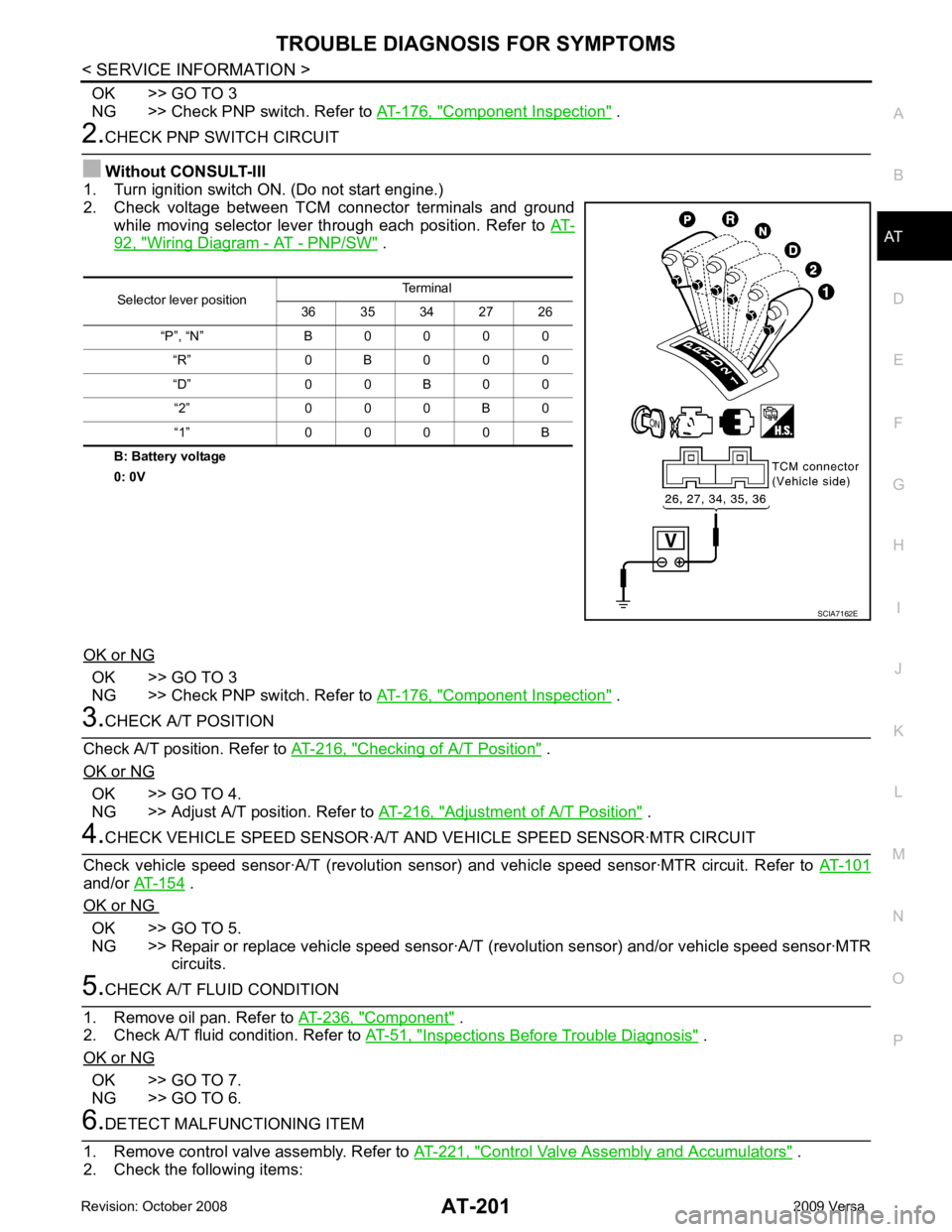

OK >> GO TO 3

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

2.

CHECK PNP SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground

while moving selector lever through each position. Refer to AT-92, " Wiring Diagram - AT - PNP/SW " .

B: Battery voltage

0: 0V

OK or NG OK >> GO TO 3

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

3.

CHECK A/T POSITION

Check A/T position. Refer to AT-216, " Checking of A/T Position " .

OK or NG OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-216, " Adjustment of A/T Position " .

4.

CHECK VEHICLE SPEED SENS OR·A/T AND VEHICLE SPEED SENSOR·MTR CIRCUIT

Check vehicle speed sensor·A/T (re volution sensor) and vehicle speed sensor·MTR circuit. Refer to AT-101and/or

AT-154 .

OK or NG OK >> GO TO 5.

NG >> Repair or replace vehicle speed sensor·A/T (revolution sensor) and/or vehicle speed sensor·MTR

circuits. 5.

CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-236, " Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 7.

NG >> GO TO 6. 6.

DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

2. Check the following items: Selector lever position

Terminal

36 35 34 27 26

“P”, “N” B 0 0 0 0 “R” 0 B 0 0 0

“D” 0 0 B 0 0 “2” 0 0 0 B 0

“1” 0 0 0 0 B SCIA7162E

Page 208 of 4331

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-203

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

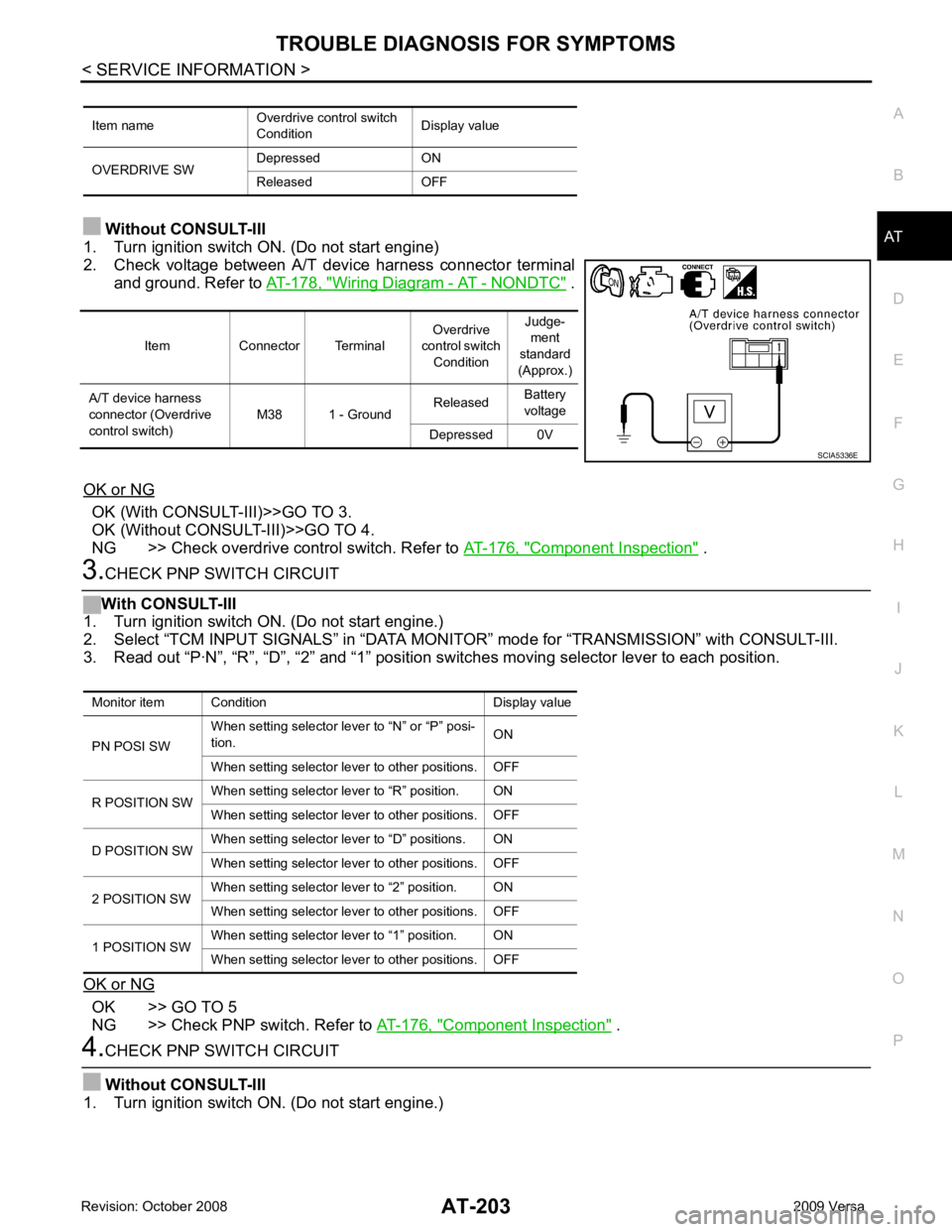

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T device harness connector terminal and ground. Refer to AT-178, " Wiring Diagram - AT - NONDTC " .

OK or NG OK (With CONSULT-III)>>GO TO 3.

OK (Without CONSULT-III)>>GO TO 4.

NG >> Check overdrive control switch. Refer to AT-176, " Component Inspection " .

3.

CHECK PNP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG OK >> GO TO 5

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

4.

CHECK PNP SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.) Item name

Overdrive control switch

Condition Display value

OVERDRIVE SW Depressed ON

Released OFF Item Connector Terminal

Overdrive

control switch Condition Judge-

ment

standard

(Approx.)

A/T device harness

connector (Overdrive

control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0V SCIA5336E

Monitor item Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 209 of 4331

AT-204< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

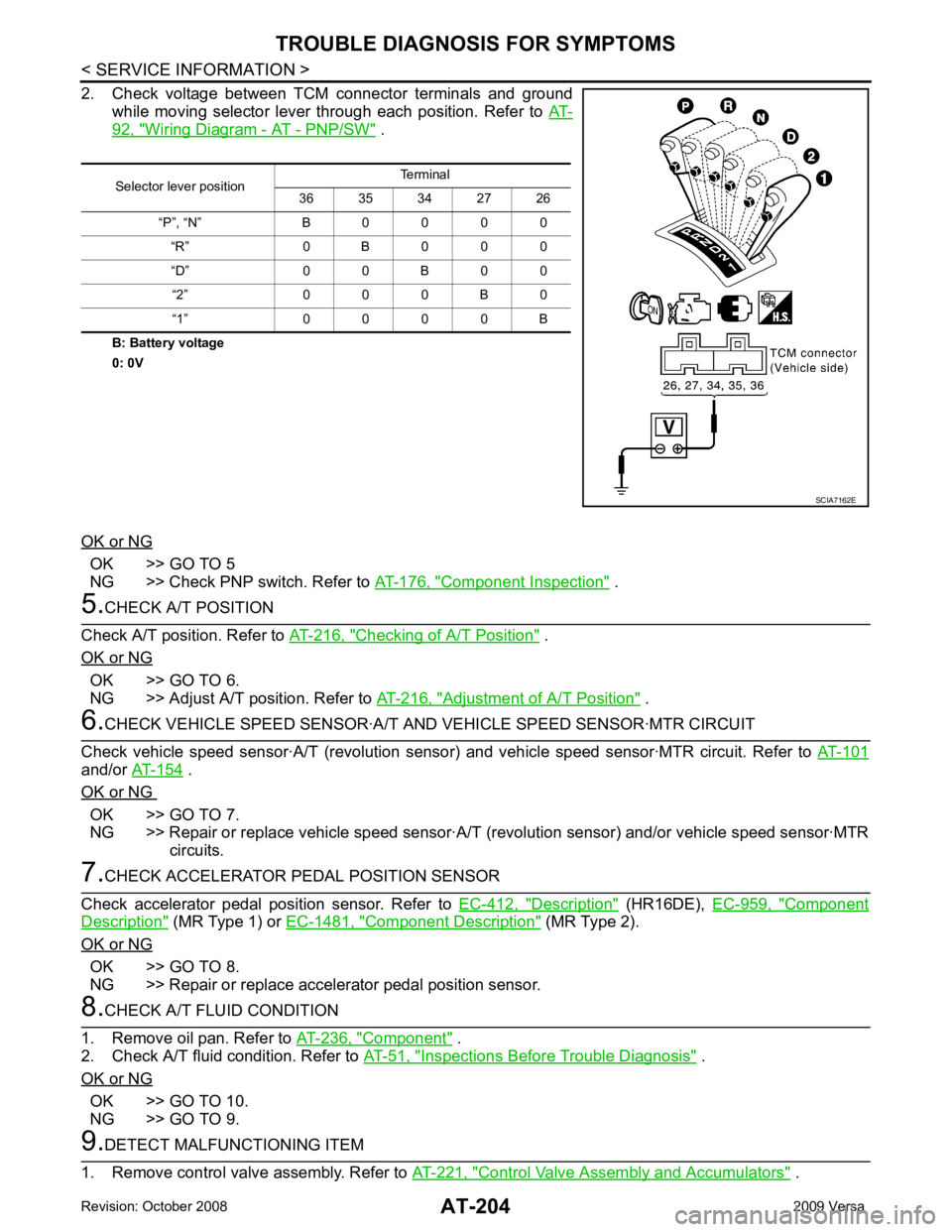

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-92, " Wiring Diagram - AT - PNP/SW " .

B: Battery voltage

0: 0V

OK or NG OK >> GO TO 5

NG >> Check PNP switch. Refer to AT-176, " Component Inspection " .

5.

CHECK A/T POSITION

Check A/T position. Refer to AT-216, " Checking of A/T Position " .

OK or NG OK >> GO TO 6.

NG >> Adjust A/T position. Refer to AT-216, " Adjustment of A/T Position " .

6.

CHECK VEHICLE SPEED SENSOR·A/T A ND VEHICLE SPEED SENSOR·MTR CIRCUIT

Check vehicle speed sensor·A/T (revolution senso r) and vehicle speed sensor·MTR circuit. Refer to AT-101and/or

AT-154 .

OK or NG OK >> GO TO 7.

NG >> Repair or replace vehicle speed sensor·A/T (revolution sensor) and/or vehicle speed sensor·MTR

circuits. 7.

CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-412, " Description " (HR16DE),

EC-959, " Component

Description " (MR Type 1) or

EC-1481, " Component Description " (MR Type 2).

OK or NG OK >> GO TO 8.

NG >> Repair or replace accelerator pedal position sensor. 8.

CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-236, " Component " .

2. Check A/T fluid condition. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 10.

NG >> GO TO 9. 9.

DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

Selector lever position

Terminal

36 35 34 27 26

“P”, “N” B 0 0 0 0 “R” 0 B 0 0 0

“D” 0 0 B 0 0 “2” 0 0 0 B 0

“1” 0 0 0 0 B SCIA7162E

Page 385 of 4331

AV

N

O P

CONTENTS

AUDIO, VISUAL, NAVIGATION & TELEPHONE SYS-

TEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

PREPARATION .............................................. .....3

Commercial Service Tool .................................... ......3

AUDIO ............................................................ .....4

Component Parts Location .................................. ......4

System Description ............................................. ......4

Schematic ........................................................... ......6

Wiring Diagram - AUDIO - ................................... ......8

Audio Unit (Base System) Harness Connector

Terminal Layout .................................................. ....

16

Terminal and Reference Value for Audio Unit

(Base System) ..................................................... ....

16

Audio Unit (Mid Level and Premium System) Har-

ness Connector Terminal Layout ........................ ....

17

Terminal and Reference Value for Audio Unit (Mid

Level and Premium System) ............................... ....

17

Subwoofer Harness Connector Terminal Layout

(Premium Audio System) .................................... ....

20

Terminal and Reference Value for Subwoofer

(Premium Audio System) .................................... ....

20

Satellite Radio Tuner Ha rness Connector Termi-

nal Layout ............................................................ ....

20

Terminal and Reference Value for Satellite Radio

Tuner ................................................................... ....

21

Trouble Diagnosis ............................................... ....21

Noise Inspection .................................................. ....22

Power Supply Circuit Inspection ......................... ....23

Satellite Radio Tuner (Fac tory Installed) Power

and Ground Supply Circuit Inspection ................. ....

24

Satellite Radio Tuner (Fac tory Installed) Commu-

nication Circuit Inspection ................................... ....

25

Satellite Radio Tuner (Fac tory Installed) Left

Channel Audio Signal Circuit Inspection ............. ....

27 Satellite Radio Tuner (Fac

tory Installed) Right

Channel Audio Signal Circuit Inspection ............. ....

27

Steering Switch Check (With Bluetooth) .............. ....28

Sound Is Not Heard from Front Door Speaker

(Base System) ..................................................... ....

30

Sound Is Not Heard from Rear Door Speaker

(Base System) ..................................................... ....

31

Sound Is Not Heard from Front Door Speaker or

Tweeter (Mid Level and Premium System) .............

32

Sound Is Not Heard from Rear Door Speaker (Mid

Level and Premium System) ............................... ....

33

Sound Is Not Heard from Subwoofer (Premium

System) ............................................................... ....

35

Removal and Installation ..................................... ....37

AUDIO ANTENNA ............................................. 42

Location of Antenna ............................................. ....42

Removal and Installation of Roof Antenna ..............42

TELEPHONE ..................................................... 44

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

44

System Description .............................................. ....44

Wiring Diagram - H/PHON - ................................ ....46

Bluetooth Control Unit Harness Connector Termi-

nal Layout ............................................................ ....

48

Terminal and Reference Value for Bluetooth Con-

trol Unit ................................................................ ....

48

Bluetooth Control Unit Se lf-Diagnosis Function ......49

Workflow .............................................................. ....50

Power Supply and Ground Circuit Inspection for

Bluetooth Control Unit .. ...........................................

50

Basic Inspection of Hands-Free Phone ............... ....51

Steering Wheel Audio Co ntrol Switch Does Not

Operate ................................................................ ....

52

Voice Activated Control Fu nction Does Not Oper-

ate ........................................................................ ....

53

Removal and Installation ..................................... ....55

Page 462 of 4331

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ............................................ ......5

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool .................................... ......6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ...... ......9

Diagnostic Worksheet ......................................... ....11

HOOD ............................................................. ....13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspec tion .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ............................................ ....21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description ............................................. ....23

CAN Communication System Description ........... ....25

Schematic ........................................................... ....26

Wiring Diagram - D/LOCK - ................................. ....27

Schematic ........................................................... ....31

Wiring Diagram - D/LOCK - ................................. ....32 Terminal and Reference

Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (B CM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection ....43

Door Switch Check (Hatchback) .......................... ....44

Door Switch Check (Sedan) ................................ ....47

Key Switch (Insert) Check ................................... ....48

Door Lock and Unlock Switch Check .................. ....49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder S witch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM ............. 58

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

58

System Description .............................................. ....58

CAN Communication System Description ........... ....60

Schematic ............................................................ ....61

Wiring Diagram - KEYLES - ................................ ....62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ............................................... ....69

CONSULT-III Function (B CM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ...................... ....71

Keyfob Battery and Function Check .................... ....72

ACC Switch Check .............................................. ....74

Door Switch Check (Hatchback) .......................... ....74

Door Switch Check (Sedan) ................................ ....76

Key Switch (Insert) Check ................................... ....78

Hazard Function Check ....................................... ....78

Horn Function Check ........................................... ....79

Interior Lamp and Ignition Keyhole Illumination

Function Check .................................................... ....

79

Remote Keyless Entry Rece iver Check ...................80

Keyfob Function (Lock) Check ............................ ....82