clock NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3826 of 4331

Rec-

ommended Chemical Product and Sealant " .

CAUTION:

• Never allow old liquid gasket, moisture, oil, or foreign matter to remain on mounting surface.

• Check that mounting surface is not damaged.

• Apply a continuous bead of liqu id gasket to the mounting surface.

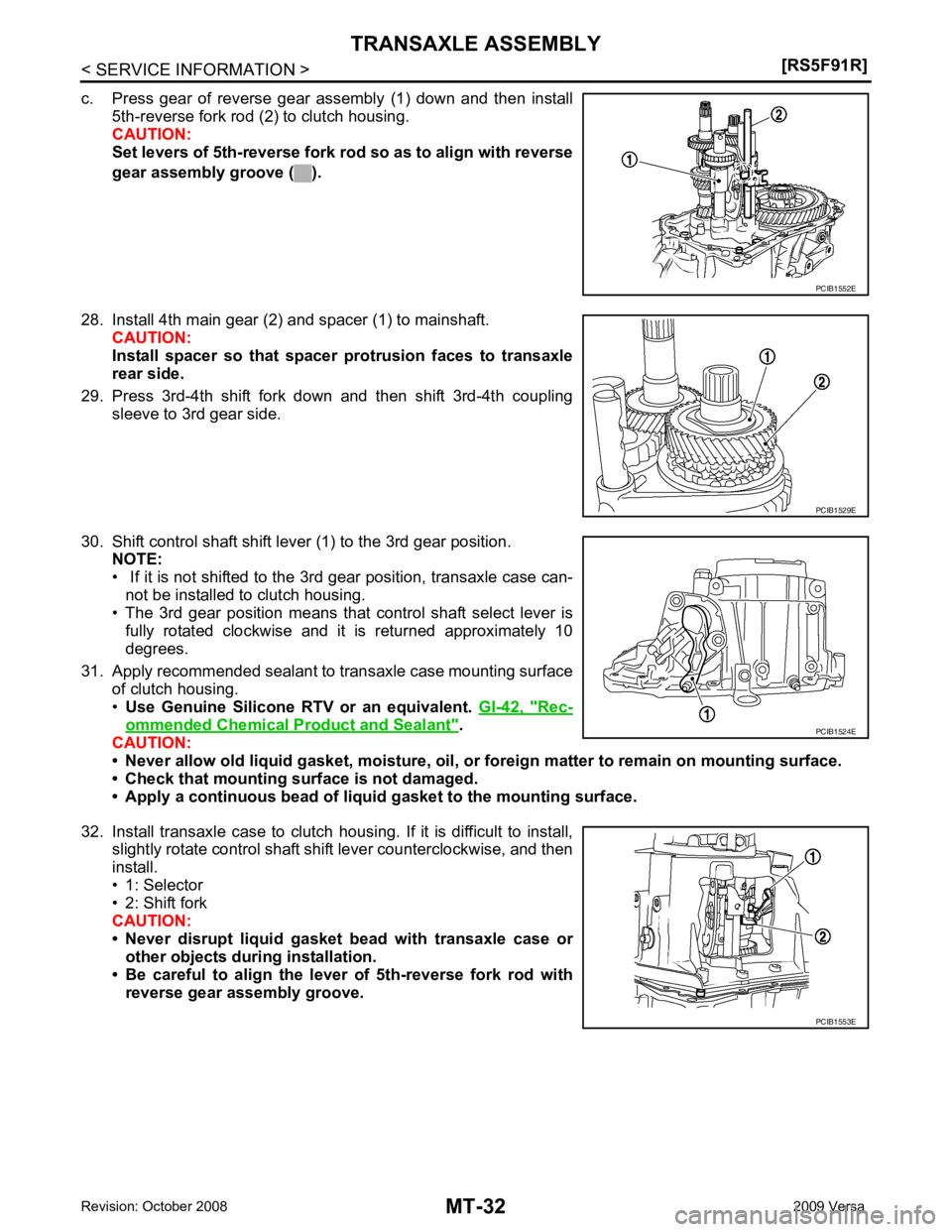

32. Install transaxle case to clutch housing. If it is difficult to install, slightly rotate control shaft shift lever counterclockwise, and then

install.

• 1: Selector

• 2: Shift fork

CAUTION:

• Never disrupt liquid gasket bead with transaxle case or

other objects during installation.

• Be careful to align the lever of 5th-reverse fork rod with

reverse gear assembly groove. PCIB1529E

PCIB1524E

PCIB1553E

Page 3916 of 4331

MTC

N

O P

1. Turn blower control dial clockwise to "1" position. Blower should operate on low speed.

2. Turn blower control dial clockwise to "2" position, and continue checking blower speed until all speeds are

checked.

3. Leave blower on Maximum speed.

If NG, go to trouble diagnosis procedure for MTC-33, " Front Blower Motor Circuit " .

If OK, continue the check.

CHECKING DISCHARGE AIR 1. Turn mode door control dial to each position.

2. Confirm that discharge air comes out accord ing to the air distribution table. Refer to MTC-20, " Discharge

Air Flow " .

If NG, go to trouble diagnosis procedure for MTC-31, " Mode Door " .

If OK, continue the check.

CHECKING RECIRCULATION 1. Set intake door lever to REC position.

2. Operate intake door lever to FRE position.

3. Listen for intake door position change (you should hear blower sound change slightly).

If NG, go to trouble diagnosis procedure for MTC-33, " Intake Door " .

If OK, continue the check.

CHECKING TEMPERATURE DECREASE 1. Turn temperature control dial counterclockwise to full cold position.

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for MTC-45, " Insufficient Cooling " .

If OK, continue the check.

CHECKING TEMPERATURE INCREASE 1. Turn temperature control dial clockwise to full hot position.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for MTC-52, " Insufficient Heating " .

If OK, continue the check.

CHECKING A/C SWITCH (IF EQUIPPED) 1. Turn fan control dial to the desired (1 to 4 speed) position.

2. Press A/C switch.

3. A/C switch indicator will turn ON. • Confirm that the compressor clutch engages (sound or visual inspection).

If NG, go to trouble diagnosis procedure for MTC-37, " Magnet Clutch Circuit (If Equipped) " .

If OK, continue the check.

CHECKING DEFROST A/C SWITCH (IF EQUIPPED) 1. Turn fan control dial to the desired (1 to 4 speed) position.

2. Turn mode dial to ( ) DEF.

3. Confirm that the compressor clutch engages (sound or vi sual inspection) and the A/C switch indicator illu-

minates.

If NG, go to trouble diagnosis procedure for MTC-37, " Magnet Clutch Circuit (If Equipped) " .

If all operational checks are OK (symptom cannot be duplicated), go to MTC-22, " How to Perform Trouble

Diagnosis for Quick and Accurate Repair " and perform tests as outlined. If symptom appears, refer to

MTC-22," How to Perform Trouble Diagnosis for Quick and Accurate Repair " and perform applicable trouble diagnosis

procedures.

Mode Door INFOID:0000000004307068

SYMPTOM: Air outlet does not change.

INSPECTION FLOW

Page 3947 of 4331

Component Parts " .

2. Remove side ventilator duct (right). Refer to MTC-69, " Removal and Installation " .

3. Disconnect blower motor connector (1).

4. Push the flange holding hook (A) toward the blower motor (2), then rotate the blower motor (2) clockwise and remove it from

the A/C unit assembly.

CAUTION:

When blower fan and blower motor are assembled, the bal-

ance is adjusted, do not di sassemble to replace the individ-

ual parts.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Rotate the blower motor until the blower motor fl ange holding hook locks securely into the A/C unit

assembly.

Page 4086 of 4331

SQUEAK AND RATTLE TROUBLE DIAGNOSES

RF-5

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

J

K L

M A

B RF

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

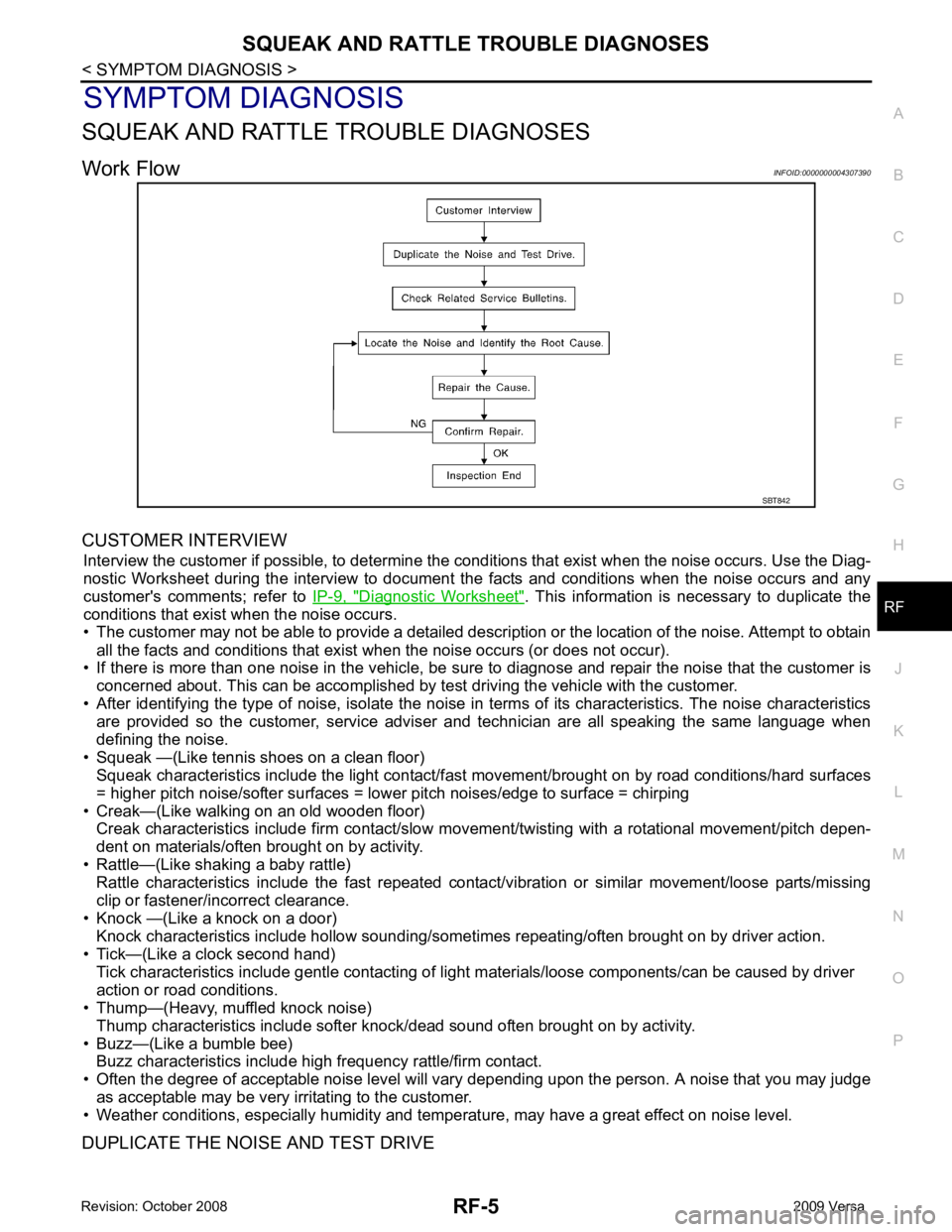

Work Flow INFOID:0000000004307390

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to IP-9, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE SBT842

Page 4168 of 4331

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-5

< SERVICE INFORMATION >

C

D E

F

G H

J

K L

M A

B SE

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

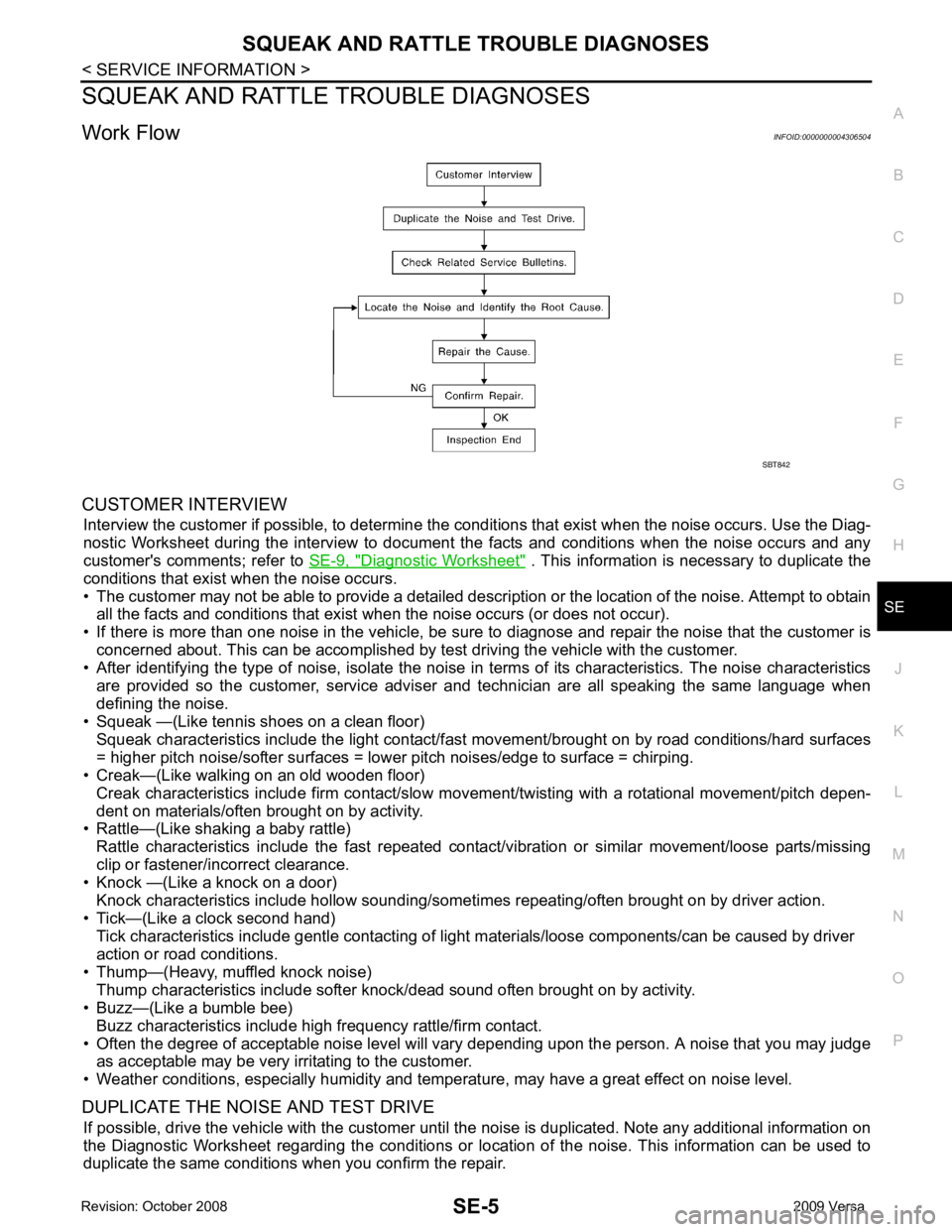

Work Flow INFOID:0000000004306504

CUSTOMER INTERVIEW Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to SE-9, " Diagnostic Worksheet " . This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair. SBT842

Page 4227 of 4331

SRS

N

O P

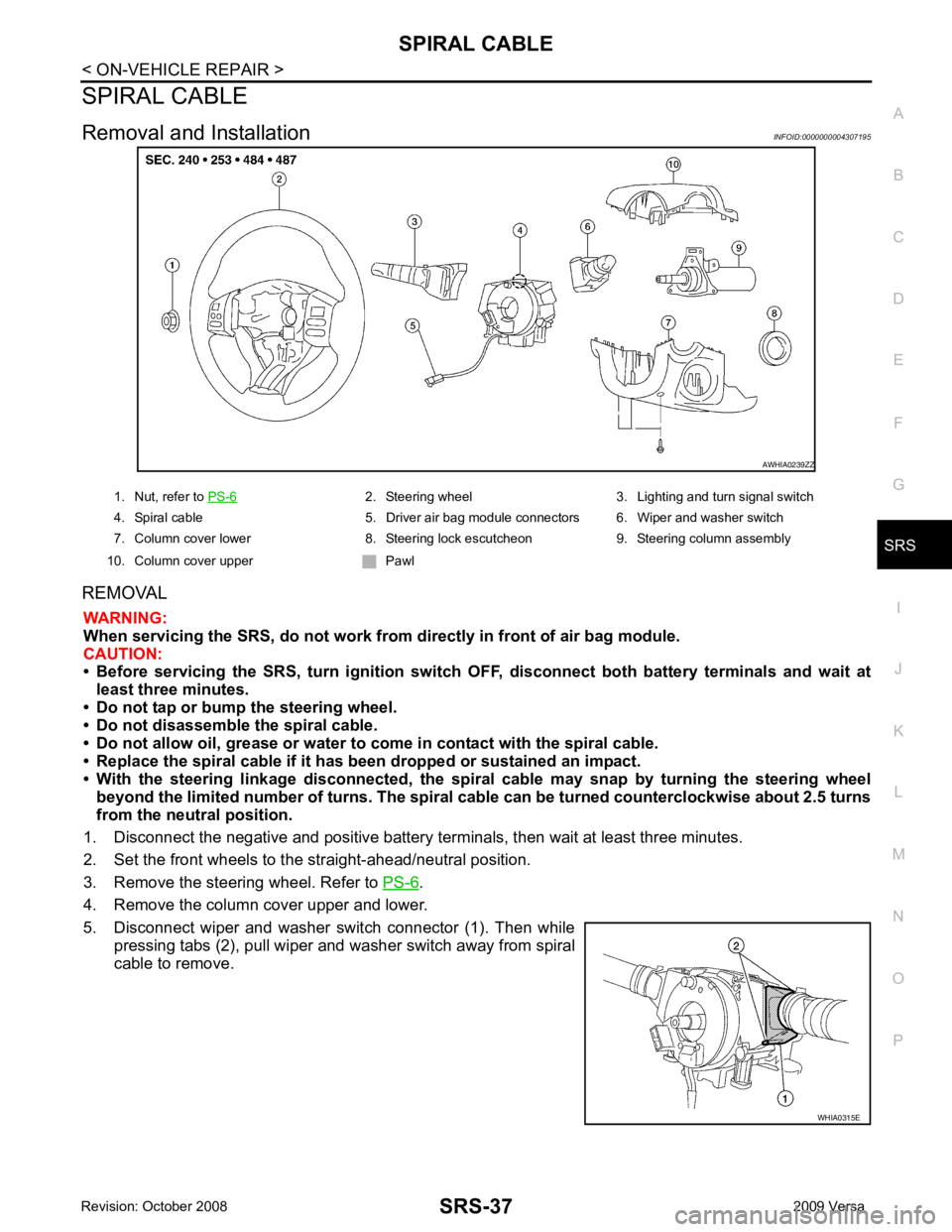

SPIRAL CABLE

Removal and Installation INFOID:0000000004307195

REMOVAL WARNING:

When servicing the SRS, do not work from directly in front of air bag module.

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery terminals and wait at

least three minutes.

• Do not tap or bump the steering wheel.

• Do not disassemble the spiral cable.

• Do not allow oil, grease or water to co me in contact with the spiral cable.

• Replace the spiral cable if it has b een dropped or sustained an impact.

• With the steering linkage disconn ected, the spiral cable may snap by turning the steering wheel

beyond the limited number of turns. The spiral cable can be turned counterclockwise about 2.5 turns

from the neutral position.

1. Disconnect the negative and positive battery term inals, then wait at least three minutes.

2. Set the front wheels to the straight-ahead/neutral position.

3. Remove the steering wheel. Refer to PS-6 .

4. Remove the column cover upper and lower.

5. Disconnect wiper and washer switch connector (1). Then while pressing tabs (2), pull wiper and washer switch away from spiral

cable to remove. 2. Steering wheel 3. Lighting and turn signal switch

4. Spiral cable 5. Driver air bag module connectors 6. Wiper and washer switch

7. Column cover lower 8. Steering lock escutcheon 9. Steering column assembly

10. Column cover upper Pawl