fuse NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1480 of 4331

YES >> GO TO 13.

NO >> GO TO 12. YES >> GO TO 17.

NO >> Replace 20 A fuse. Ground Inspection " .

Is the inspection result normal? YES >> GO TO 15.

NO >> Repair or replace ground connection. YES >> GO TO 17.

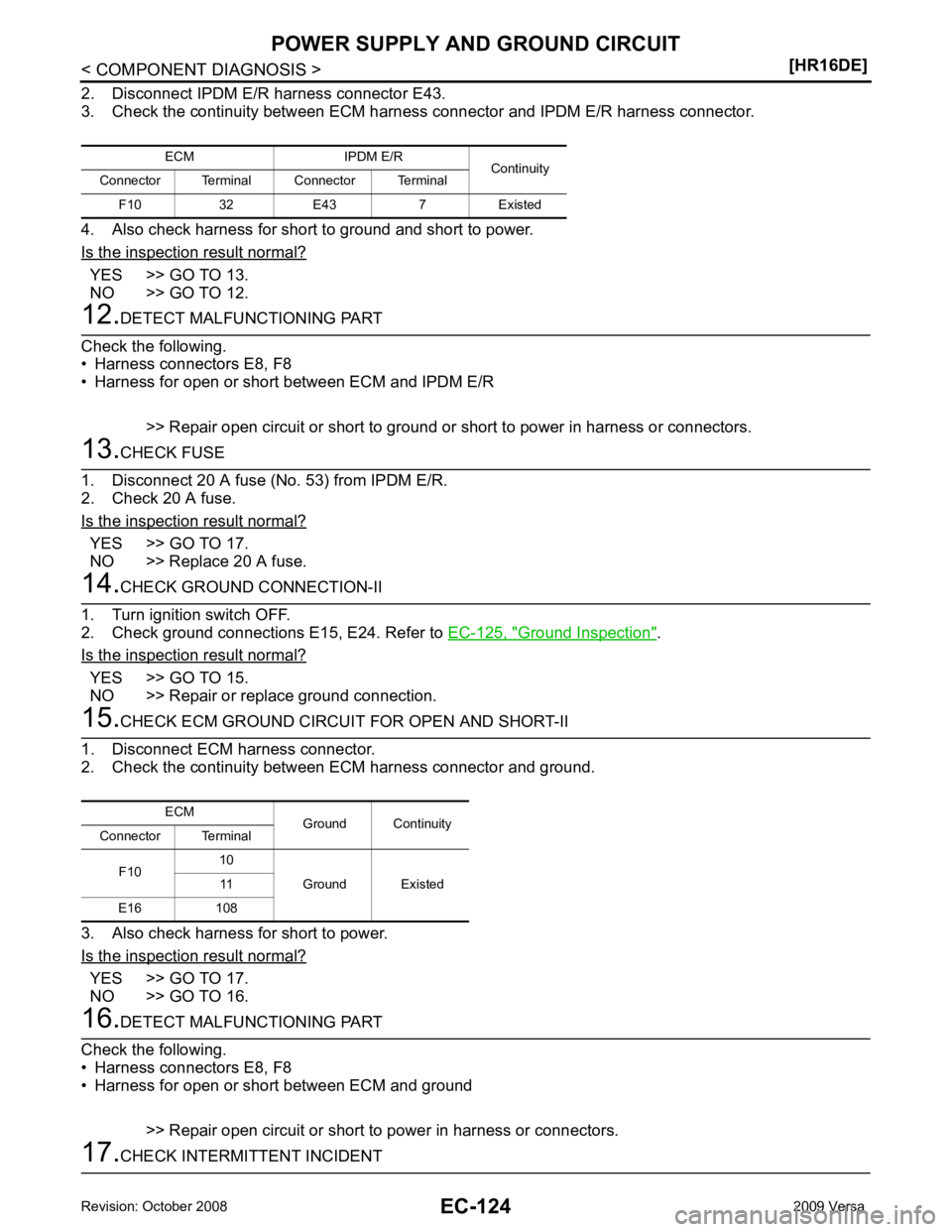

NO >> GO TO 16. ECM

Ground Continuity

Connector Terminal

F10 10

Ground Existed

11

E16 108

Page 1542 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-186< COMPONENT DIAGNOSIS >

[HR16DE]

P0130 A/F SENSOR 1

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F senso NISSAN TIIDA 2009 Service Workshop Manual EC-186< COMPONENT DIAGNOSIS >

[HR16DE]

P0130 A/F SENSOR 1

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F senso](/img/5/57398/w960_57398-1541.png)

EC-186< COMPONENT DIAGNOSIS >

[HR16DE]

P0130 A/F SENSOR 1

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F sensor 1 harness connector.

2. Turn ignition switch ON.

3. Check the voltage between A/F sensor 1 harness connector and

ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3. 3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• IPDM E/R harness connector E45

• 10 A fuse (No. 54)

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors. 4.

CHECK A/F SENSOR 1 INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. 5.

CHECK INTERMITTENT INCIDENT

Perform EC-120, " Diagnosis Procedure " .

A/F sensor 1

Ground Voltage

Connector Terminal

F12 4 Ground Battery voltage PBIB3308E

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

2 53

A/F sensor 1 Ground Continuity

Connector Terminal

F12 1

Ground Not existed

2

ECM Ground Continuity

Connector Terminal

F11 49

Ground Not existed

53

Page 1544 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-188< COMPONENT DIAGNOSIS >

[HR16DE]

P0131 A/F SENSOR 1

P0131 A/F SENSOR 1

Description INFOID:0000000004780111

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se NISSAN TIIDA 2009 Service Workshop Manual EC-188< COMPONENT DIAGNOSIS >

[HR16DE]

P0131 A/F SENSOR 1

P0131 A/F SENSOR 1

Description INFOID:0000000004780111

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se](/img/5/57398/w960_57398-1543.png)

EC-188< COMPONENT DIAGNOSIS >

[HR16DE]

P0131 A/F SENSOR 1

P0131 A/F SENSOR 1

Description INFOID:0000000004780111

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In additi on, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780112

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that t he A/F signal computed by ECM from the A/F sensor 1

signal is not inordinately low.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V at idle.

>> GO TO 2. 2.

CHECK A/F SENSOR FUNCTION

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” in “D ATA MONITOR” mode with CONSULT-III.

3. Check “A/F SEN1 (B1)” indication.

With GST

Follow the procedure “With CONSULT-III” above.

Is the indication constantly approx. 0 V? JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0131 Air fuel ratio (A/F) sensor 1

circuit low voltage • The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly approx. 0 V. • Harness or connectors

(The A/F sensor 1 circuit is open or

shorted.)

• A/F sensor 1

Page 1547 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual P0131 A/F SENSOR 1

EC-191

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPL NISSAN TIIDA 2009 Service Workshop Manual P0131 A/F SENSOR 1

EC-191

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPL](/img/5/57398/w960_57398-1546.png)

P0131 A/F SENSOR 1

EC-191

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F sensor 1 harness connector.

2. Turn ignition switch ON.

3. Check the voltage between A/F sensor 1 harness connector and

ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3. 3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• IPDM E/R harness connector E45

• 10 A fuse (No. 54)

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors. 4.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. 5.

CHECK INTERMITTENT INCIDENT A/F sensor 1

Ground Voltage

Connector Terminal

F12 4 Ground Battery voltage PBIB3308E

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

2 53

A/F sensor 1 Ground Continuity

Connector Terminal

F12 1

Ground Not existed

2

ECM Ground Continuity

Connector Terminal

F11 49

Ground Not existed

53

Page 1549 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual P0132 A/F SENSOR 1

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0132 A/F SENSOR 1

Description INFOID:0000000004780114

The air fuel ratio (A/F) sensor 1 is a planar one-cell NISSAN TIIDA 2009 Service Workshop Manual P0132 A/F SENSOR 1

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0132 A/F SENSOR 1

Description INFOID:0000000004780114

The air fuel ratio (A/F) sensor 1 is a planar one-cell](/img/5/57398/w960_57398-1548.png)

P0132 A/F SENSOR 1

EC-193

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

P0132 A/F SENSOR 1

Description INFOID:0000000004780114

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise m easurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780115

DTC DETECTION LOGIC To judge the malfunction, the diagnosis checks that the A/F signal computed by ECM from the A/F sensor 1

signal is not inordinately high.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V at idle.

>> GO TO 2. 2.

CHECK A/F SENSOR FUNCTION

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “A/F SEN1 (B1)” in “DAT A MONITOR” mode with CONSULT-III.

3. Check “A/F SEN1 (B1)” indication.

With GST

Follow the procedure “With CONSULT-IIII” above.

Is the indication constantly approx. 5 V? JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0132 Air fuel ratio (A/F) sensor 1

circuit high voltage • The A/F signal computed by ECM from the A/F

sensor 1 signal is constantly approx. 5 V. • Harness or connectors

(The A/F sensor 1 circuit is open or

shorted.)

• A/F sensor 1

Page 1552 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-196< COMPONENT DIAGNOSIS >

[HR16DE]

P0132 A/F SENSOR 1

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F senso NISSAN TIIDA 2009 Service Workshop Manual EC-196< COMPONENT DIAGNOSIS >

[HR16DE]

P0132 A/F SENSOR 1

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F senso](/img/5/57398/w960_57398-1551.png)

EC-196< COMPONENT DIAGNOSIS >

[HR16DE]

P0132 A/F SENSOR 1

YES >> GO TO 2.

NO >> Repair or replace ground connection. 2.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect A/F sensor 1 harness connector.

2. Turn ignition switch ON.

3. Check the voltage between A/F sensor 1 harness connector and

ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3. 3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• IPDM E/R harness connector E45

• 10 A fuse (No. 54)

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors. 4.

CHECK A/F SENSOR 1 INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. 5.

CHECK INTERMITTENT INCIDENT A/F sensor 1

Ground Voltage

Connector Terminal

F12 4 Ground Battery voltage PBIB3308E

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

2 53

A/F sensor 1 Ground Continuity

Connector Terminal

F12 1

Ground Not existed

2

ECM Ground Continuity

Connector Terminal

F11 49

Ground Not existed

53

Page 1554 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-198< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

P0133 A/F SENSOR 1

Description INFOID:0000000004780117

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se NISSAN TIIDA 2009 Service Workshop Manual EC-198< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

P0133 A/F SENSOR 1

Description INFOID:0000000004780117

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The se](/img/5/57398/w960_57398-1553.png)

EC-198< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

P0133 A/F SENSOR 1

Description INFOID:0000000004780117

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In additi on, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

DTC Logic INFOID:0000000004780118

DTC DETECTION LOGIC

To judge the malfunction of A/F sensor 1, this diagnosis measures response time of the A/F signal computed

by ECM from the A/F sensor 1 signal. The time is compensated by engine operating (speed and load), fuel

feedback control constant, and the A/F sensor 1 temper ature index. Judgment is based on whether the com-

pensated time (the A/F signal cycling time index) is inordinately long or not.

DTC CONFIRMATION PROCEDURE 1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

Do you have CONSULT-III? YES >> GO TO 2.

NO >> GO TO 5. 2.

PERFORM DTC CONFIRMATION PROCEDURE-I JMBIA0112GB

PBIB3354E

DTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P0133 Air fuel ratio (A/F) sensor

1 circuit slow response • The response of the A/F signal computed

by ECM from A/F sensor 1 signal takes

more than the specified time. • Harness or connectors

(The A/F sensor 1 circuit is open or shorted.)

• A/F sensor 1

• A/F sensor 1 heater

• Fuel pressure

• Fuel injector

• Intake air leaks

• Exhaust gas leaks

• PCV

• Mass air flow sensor

Page 1558 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-202< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

3. Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

DET NISSAN TIIDA 2009 Service Workshop Manual EC-202< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

3. Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

DET](/img/5/57398/w960_57398-1557.png)

EC-202< COMPONENT DIAGNOSIS >

[HR16DE]

P0133 A/F SENSOR 1

3. Check the voltage between A/F sensor 1 harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7. 7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• IPDM E/R harness connector E45

• 10 A fuse (No. 54)

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors. 8.

CHECK A/F SENSOR 1 INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

5. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair open circuit or short to ground or short to power in harness or connectors. 9.

CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Refer to EC-139, " Component Inspection " .

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 13. 10.

CHECK MASS AIR FLOW SENSORA/F sensor 1

Ground Voltage

Connector Terminal

F12 4 Ground Battery voltage PBIB3308E

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

2 53

A/F sensor 1 Ground Continuity

Connector Terminal

F12 1

Ground Not existed

2

ECM Ground Continuity

Connector Terminal

F11 49

Ground Not existed

53

Page 1611 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES NISSAN TIIDA 2009 Service Workshop Manual P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES](/img/5/57398/w960_57398-1610.png)

P0300, P0301, P0302,

P0303, P0304 MISFIRE

EC-255

< COMPONENT DIAGNOSIS >

[HR16DE] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Listen to each fuel injector operating sound.

Is the inspection result normal? YES >> GO TO 5.

NO >> Perform trouble diagnosis for FUEL INJECTOR, refer to EC-432, " Component Inspection " .

5.

CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure. NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• During the operation, alw ays stay 0.5 m (19.7 in) away

from the spark plug and the ig nition coil within. Be careful

not to get an electrical sh ock while checking, because the

electrical discharge voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 6. 6.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Is the inspection result normal? YES >> GO TO 7.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-439, " Component Function

Check " .

Clicking noise should be heard.

PBIB3332E

Spark should be generated.

JMBIA0066GB

Spark should be generated.

Page 1632 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual EC-276< COMPONENT DIAGNOSIS >

[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Rem NISSAN TIIDA 2009 Service Workshop Manual EC-276< COMPONENT DIAGNOSIS >

[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Rem](/img/5/57398/w960_57398-1631.png)

EC-276< COMPONENT DIAGNOSIS >

[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoi d the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• During the operation, always stay 0.5 m (19.7 in) away from the spark plug and the ig nition coil. Be careful not to

get an electrical shock wh ile checking, because the elec-

trical discharge voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 7. 7.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded metal portion.

Is the inspection result normal? YES >> GO TO 8.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-441, " Diagnosis Procedure " .

8.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal? YES >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-117, " Spark Plug " .

NO >> Repair or clean spark plug. Then GO TO 9. 9.

CHECK FUNCTION OF IGNITION COIL-III Spark should be generated. JMBIA0066GB

Spark should be generated.

SEF156I