fuse NISSAN TIIDA 2009 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 2284 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC-928< SERVICE INFOMATION >

[MR TYPE 1]

DTC P2100, P2103 THROTTLE

CONTROL MOTOR RELAY3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short be NISSAN TIIDA 2009 Service Manual Online EC-928< SERVICE INFOMATION >

[MR TYPE 1]

DTC P2100, P2103 THROTTLE

CONTROL MOTOR RELAY3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short be](/img/5/57398/w960_57398-2283.png)

EC-928< SERVICE INFOMATION >

[MR TYPE 1]

DTC P2100, P2103 THROTTLE

CONTROL MOTOR RELAY3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors. 4.

CHECK FUSE

1. Disconnect 15A fuse.

2. Check 15A fuse for blown.

OK or NG OK >> GO TO 8.

NG >> Replace 15A fuse. 5.

CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-I

Check voltage between ECM terminal 2 and ground under the fol-

lowing conditions with CONSULT-III or tester.

OK or NG OK >> GO TO 8.

NG >> GO TO 6. 6.

CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect IPDM E/R harness connector E43.

4. Check continuity between ECM terminal 2 and IPDM E/R terminal 8.

Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 8.

NG >> GO TO 7. 7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors. 8.

CHECK INTERMITTENT INCIDENT

Refer to EC-626 .

OK or NG OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

NG >> Repair or replace harness or connectors. Ignition switch Voltage

OFF Approximately 0V

ON Battery voltage

(11 - 14V) PBIA9568J

Continuity should exist.

Page 2289 of 4331

![NISSAN TIIDA 2009 Service Manual Online DTC P2101 ELECTRIC THROTTLE CONTROL FUNCTION

EC-933

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O 7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

NISSAN TIIDA 2009 Service Manual Online DTC P2101 ELECTRIC THROTTLE CONTROL FUNCTION

EC-933

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O 7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8](/img/5/57398/w960_57398-2288.png)

DTC P2101 ELECTRIC THROTTLE CONTROL FUNCTION

EC-933

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O 7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors. 8.

CHECK FUSE

1. Disconnect 15A fuse.

2. Check 15A fuse for blown.

OK or NG OK >> GO TO 9.

NG >> Replace 15A fuse. 9.

CHECK INTERMITTENT INCIDENT

Refer to EC-626 .

OK or NG OK >> Replace IPDM E/R. Refer to

PG-27, " Removal and Installation of IPDM E/R " .

NG >> Repair or replace harness or connectors. 10.

CHECK THROTTLE CONTROL MOTOR OUTPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Turn ignition switch OFF.

2. Disconnect electric throttle c ontrol actuator (1) harness connec-

tor.

- : Vehicle front

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 11.

NG >> Repair or replace. 11.

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Remove the intake air duct.

2. Check if foreign matter is c aught between the throttle valve (1)

and the housing.

- : Vehicle front

OK or NG OK >> GO TO 12.

NG >> Remove the foreign matter and clean the electric throttle control actuator inside. 12.

CHECK THROTTLE CONTROL MOTOR

Electric throttle control

actuator terminal ECM terminal Continuity

5 1 Should not exist.

4 Should exist.

6 1 Should exist.

4 Should not exist. PBIB3325E

BBIA0711E

Page 2322 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC-966< SERVICE INFOMATION >

[MR TYPE 1]

DTC P2A00 A/F SENSOR 1

DTC P2A00 A/F SENSOR 1

Component Description INFOID:0000000004537505

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit curren NISSAN TIIDA 2009 Service Manual Online EC-966< SERVICE INFOMATION >

[MR TYPE 1]

DTC P2A00 A/F SENSOR 1

DTC P2A00 A/F SENSOR 1

Component Description INFOID:0000000004537505

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit curren](/img/5/57398/w960_57398-2321.png)

EC-966< SERVICE INFOMATION >

[MR TYPE 1]

DTC P2A00 A/F SENSOR 1

DTC P2A00 A/F SENSOR 1

Component Description INFOID:0000000004537505

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sen-

sor. The sensor element of the A/F sensor 1 is composed an elec-

trode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocar-

bon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800 °C

(1,472 °F).

CONSULT-III Reference Value in Data Monitor Mode INFOID:0000000004537506

Specification data are reference values.

On Board Diagn osis Logic INFOID:0000000004537507

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor 1 signal is monitored not to be

shifted to LEAN side or RICH side.

DTC Confirmation Procedure INFOID:0000000004537508

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds. PBIB3353E

PBIB3354E

MONITOR ITEM CONDITION SPECIFICATION

A/F SEN1 (B1) • Engine: After warming up Maintaining engine speed at

2,000 rpm Fluctuates around 2.2VDTC No. Trouble diagnosis name DTC detecting condition Possible Cause

P2A00

2A00 Air fuel ratio (A/F) sensor 1

circuit range/performance • The output voltage computed by ECM from the

A/F sensor 1 signal is shifted to the lean side for

a specified period.

• The A/F signal computed by ECM from the A/F

sensor 1 signal is shifted to the rich side for a

specified period. • Air fuel ratio (A/F) sensor 1

• Air fuel ratio (A/F) sensor 1 heater

• Fuel pressure

• Fuel injector

• Intake air leaks

Page 2327 of 4331

EC

NP

O

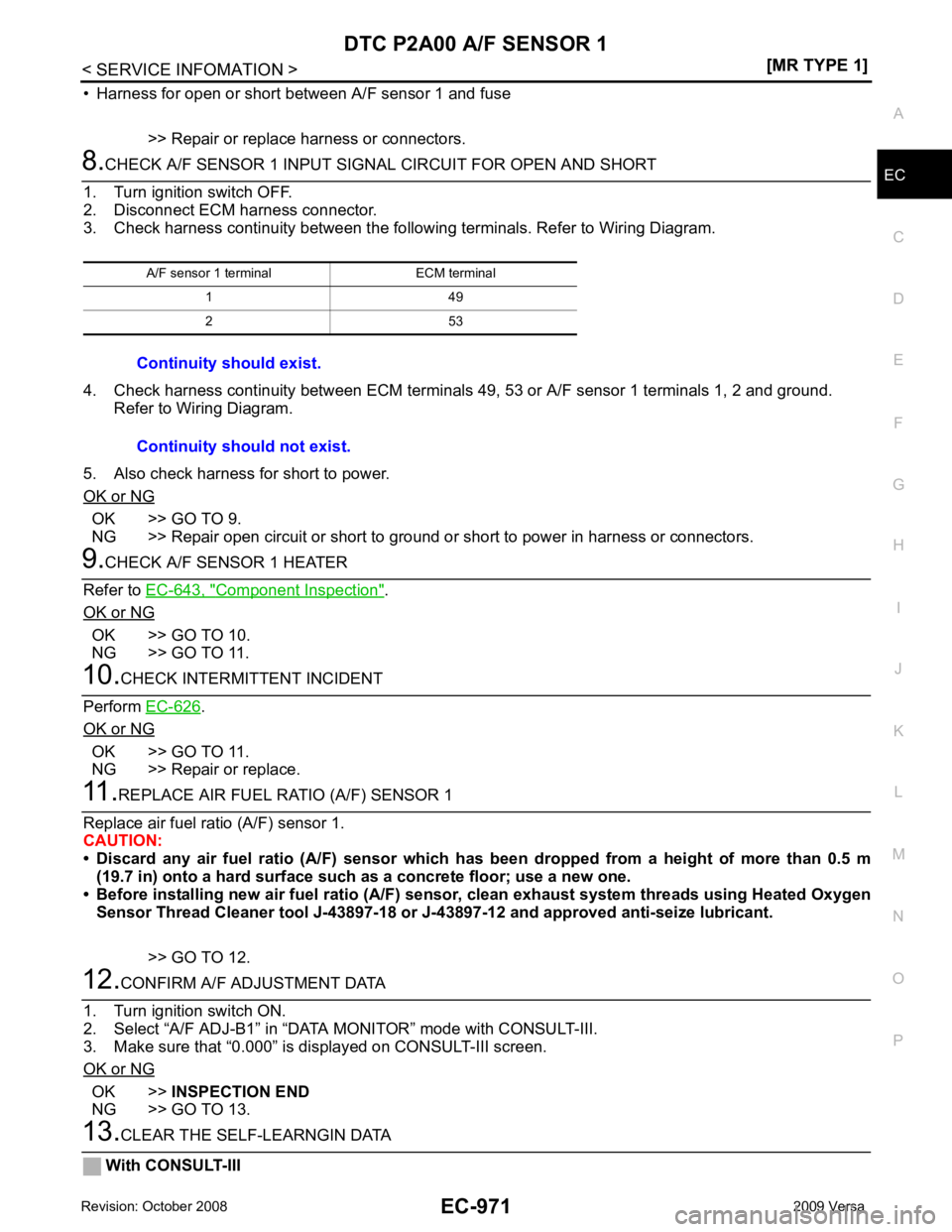

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors. OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. Component Inspection " .

OK or NG OK >> GO TO 10.

NG >> GO TO 11. .

OK or NG OK >> GO TO 11.

NG >> Repair or replace. OK >>

INSPECTION END

NG >> GO TO 13.

Page 2333 of 4331

![NISSAN TIIDA 2009 Service Manual Online ASCD BRAKE SWITCH

EC-977

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Disconnect ASCD brake switch (2) harness connector.

- Stop lamp switch (1)

3. Turn ignition switch ON.

4. NISSAN TIIDA 2009 Service Manual Online ASCD BRAKE SWITCH

EC-977

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Disconnect ASCD brake switch (2) harness connector.

- Stop lamp switch (1)

3. Turn ignition switch ON.

4.](/img/5/57398/w960_57398-2332.png)

ASCD BRAKE SWITCH

EC-977

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O

2. Disconnect ASCD brake switch (2) harness connector.

- Stop lamp switch (1)

3. Turn ignition switch ON.

4. Check voltage between ASCD brake switch terminal 1 and ground with CONSULT-III or tester.

OK or NG OK (M/T models) >>GO TO 6.

OK (A/T and CVT models) >>GO TO 7.

NG >> GO TO 5. 5.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M69, E7

• 10A fuse

• Harness for open or short between ASCD brake switch and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors. 6.

CHECK ASCD BRAKE SWITCH INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ASCD brake switch terminal 2 and ASCD clutch switch terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 7.

CHECK ASCD BRAKE SWITCH INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM term inal 100 and ASCD brake switch terminal 2.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 8.

CHECK ASCD BRAKE SWITCH

Refer to EC-914, " Component Inspection " . BBIA0708E

Voltage: Battery voltage

PBIB0857E

Continuity should exist.

Continuity should exist.

Page 2334 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC-978< SERVICE INFOMATION >

[MR TYPE 1]

ASCD BRAKE SWITCH

OK or NG OK >> GO TO 15.

NG >> Replace ASCD brake switch. 9.

CHECK ASCD CLUTCH SWITCH INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn igniti NISSAN TIIDA 2009 Service Manual Online EC-978< SERVICE INFOMATION >

[MR TYPE 1]

ASCD BRAKE SWITCH

OK or NG OK >> GO TO 15.

NG >> Replace ASCD brake switch. 9.

CHECK ASCD CLUTCH SWITCH INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn igniti](/img/5/57398/w960_57398-2333.png)

EC-978< SERVICE INFOMATION >

[MR TYPE 1]

ASCD BRAKE SWITCH

OK or NG OK >> GO TO 15.

NG >> Replace ASCD brake switch. 9.

CHECK ASCD CLUTCH SWITCH INPUT SIGN AL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 100 and ASCD clutch switch terminal 2.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 10.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 10.

CHECK ASCD CLUTCH SWITCH

Refer to EC-914, " Component Inspection "

OK or NG OK >> GO TO 15.

NG >> Replace ASCD clutch switch. 11.

CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch (1) harness connector.

- ASCD brake switch (2)

3. Check voltage between stop lamp switch terminal 1 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 13.

NG >> GO TO 12. 12.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M69, E7

• 10A fuse Continuity should exist.

BBIA0708E

Voltage: Battery voltage PBIB3317E

Page 2345 of 4331

![NISSAN TIIDA 2009 Service Manual Online FUEL INJECTOR

EC-989

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O 3.

CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuel injector (1) harness NISSAN TIIDA 2009 Service Manual Online FUEL INJECTOR

EC-989

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O 3.

CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuel injector (1) harness](/img/5/57398/w960_57398-2344.png)

FUEL INJECTOR

EC-989

< SERVICE INFOMATION >

[MR TYPE 1] C

D E

F

G H

I

J

K L

M A EC

NP

O 3.

CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuel injector (1) harness connector.

3. Turn ignition switch ON.

4. Check voltage between fuel injector terminal 1 and ground with CONSULT-III or tester.

OK or NG OK >> GO TO 5.

NG >> GO TO 4. 4.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• IPDM E/R harness connector E45

• 10A fuse

• Harness for open or short between fuel injector and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors. 5.

CHECK FUEL INJECTOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between fuel injector terminal 2 and ECM terminals 25, 29, 30, 31. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. 6.

CHECK FUEL INJECTOR

Refer to EC-990, " Component Inspection " .

OK or NG OK >> GO TO 7.

NG >> Replace fuel injector. 7.

CHECK INTERMITTENT INCIDENT

Refer to EC-626 . PBIA9870J

Voltage: Battery voltage

PBIB0582E

Continuity should exist.

Page 2350 of 4331

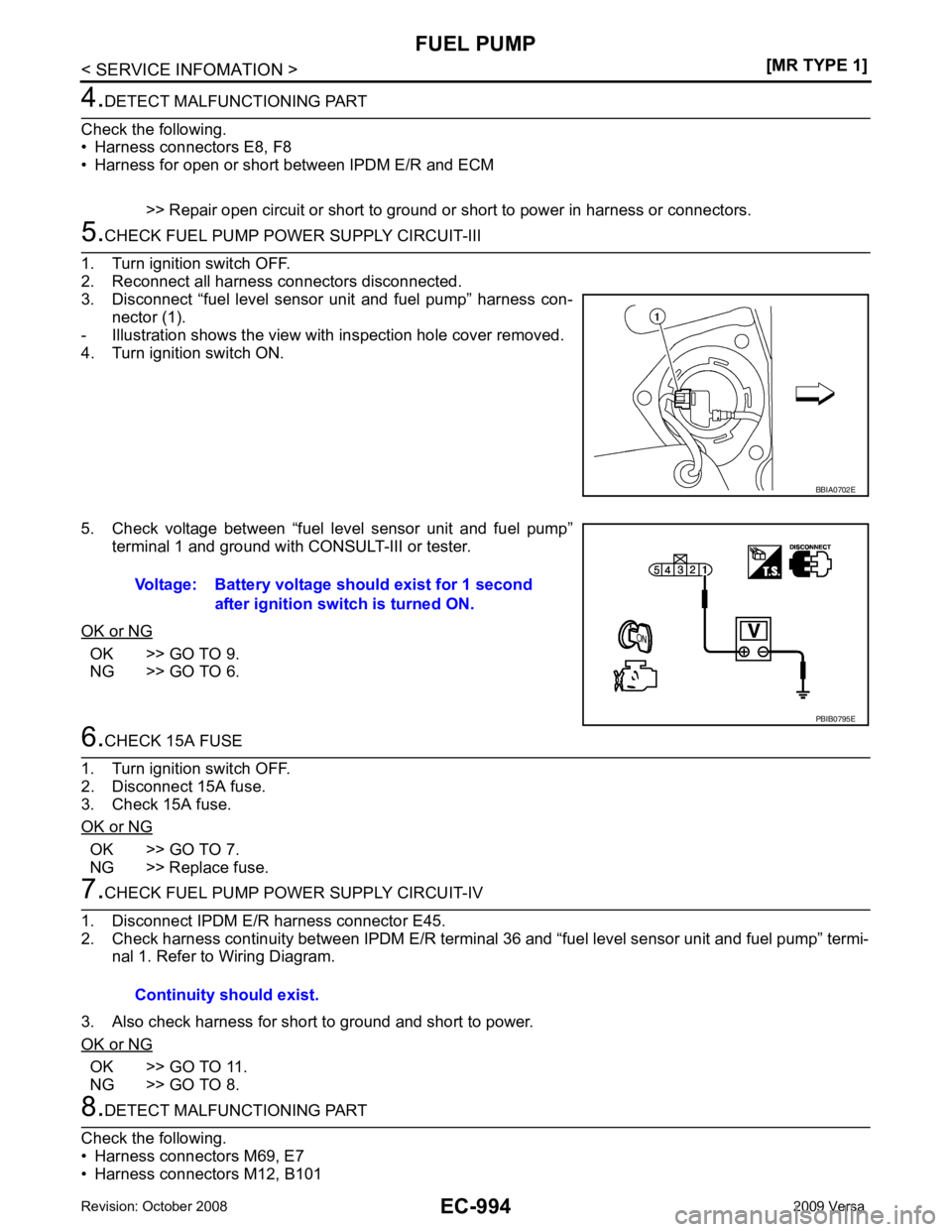

OK >> GO TO 9.

NG >> GO TO 6. OK >> GO TO 7.

NG >> Replace fuse. OK >> GO TO 11.

NG >> GO TO 8.

Page 2360 of 4331

![NISSAN TIIDA 2009 Service Manual Online EC-1004< SERVICE INFOMATION >

[MR TYPE 1]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or f NISSAN TIIDA 2009 Service Manual Online EC-1004< SERVICE INFOMATION >

[MR TYPE 1]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or f](/img/5/57398/w960_57398-2359.png)

EC-1004< SERVICE INFOMATION >

[MR TYPE 1]

IGNITION SIGNAL

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to releas e fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel

pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm between the edge of the spark plug and grounded metal portion

as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spar k plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20kV or more.

• It might cause to damage the ignition coil if the gap of more than 17 mm is taken.

NOTE:

When the gap is less than 13 mm, the spark might be generated even if the coil is malfunctioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

3. Check resistance between condenser-2 terminals 1 and 2.

4. If NG, replace condenser-2.

Removal and Installation INFOID:0000000004537539

IGNITION COIL WITH POWER TRANSISTOR

Refer to EM-153 .

Spark should be generated. PBIB2958E

PBIB2325E

Resistance: Above 1 M

Ω [at 25 °C (77 °F)] PBIB0794E

Page 2443 of 4331

![NISSAN TIIDA 2009 Service Manual Online BASIC SERVICE PROCEDURE

EC-1087

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After e NISSAN TIIDA 2009 Service Manual Online BASIC SERVICE PROCEDURE

EC-1087

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After e](/img/5/57398/w960_57398-2442.png)

BASIC SERVICE PROCEDURE

EC-1087

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

• Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

• The fuel hose connection method u sed when taking fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains seal abil ity with O-rings inside.

• Do not perform fuel pressure check with electrical syst ems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder- ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam- age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-156, " Removal and Installation " .

• Do not twist or kink fuel hose because it is plastic hose.

4. Connect fuel hose for fuel pressure check (1) to fuel tube (engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moist-

ened with gasoline.

• Apply proper amount of gasoline between top of the fuel tube (3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710

or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the positi on within 1 - 2 mm (0.04 - 0.08 in).

• Make sure that clamp screw does not contact adjacent parts. PBIB2958E

Tightening torque: 1 - 1.5 N·m

(0.1 - 0.15 kg-m, 9 - 13 in-lb) PBIB2982E

PBIB2983E