light NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1287 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual SHIFT CONTROL SYSTEM

CVT-343

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock plate (1) NISSAN TIIDA 2009 Service Workshop Manual SHIFT CONTROL SYSTEM

CVT-343

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock plate (1)](/img/5/57398/w960_57398-1286.png)

SHIFT CONTROL SYSTEM

CVT-343

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

7. Remove the plate (1) from the control device assembly.

: Vehicle front

8. Remove the lock plate (1) from the control cable (2). : Vehicle front

9. Remove the control cable (2) from the control device assembly.

10. Insert suitable tool at points (A) and (B) as shown, and press both tabs (E) and (F) at the front (C) and rear (D) slightly toward

the center of the control device assembly to remove the control

device assembly from the underside of the vehicle.

: Vehicle front

INSTALLATION Installation is in the reverse order of removal. SCIA6967E

SCIA6968E

SCIA6970E

Page 1288 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual CVT-344< SERVICE INFORMATION >

[RE0F08B]

SHIFT CONTROL SYSTEM

• When installing the control cable (1) to the control device assembly (2), make sure that the control cable (1) is fully pressed in wit NISSAN TIIDA 2009 Service Workshop Manual CVT-344< SERVICE INFORMATION >

[RE0F08B]

SHIFT CONTROL SYSTEM

• When installing the control cable (1) to the control device assembly (2), make sure that the control cable (1) is fully pressed in wit](/img/5/57398/w960_57398-1287.png)

CVT-344< SERVICE INFORMATION >

[RE0F08B]

SHIFT CONTROL SYSTEM

• When installing the control cable (1) to the control device assembly (2), make sure that the control cable (1) is fully pressed in with the

ribbed surface (A) facing downward from the vehicle.

: Vehicle front

• After installation is completed, adjust and check the CVT position.

Refer to CVT-345, " Adjustment of CVT Position " and

CVT-345, " Checking of CVT Position " .

Control Device Disassembly and Assembly INFOID:0000000004305817

DISASSEMBLY

NOTE:

Refer to CVT-341, " Removal and Installation " to disassemble.

1. Remove selector lever knob from control device assembly. Refer to CVT-344, " Selector Lever Knob

Removal and Installation " .

2. Remove position lamp from position indicator plate (1).

3. Insert a suitable tool to (A) (at 4 locations) as shown, and bend each hook slightly to raise position indicator plate (1) and

remove from control device assembly (2).

4. Remove bracket from control device assembly (2).

5. Remove CVT device harness c onnector from control device

assembly (2).

6. Release tabs (A) on shift lock solenoid and park position switch assembly from hooks (B) on control device assembly to shift

lock solenoid and park position switch assembly.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Selector Lever Knob Re moval and Installation INFOID:0000000004305818

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal/installation. SCIA6253E

SCIA6969E

SCIA6977E

Page 1303 of 4331

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

COMBINATION METERS .............................. .....3

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

3

System Description ............................................. ......3

Arrangement of Combination Meter .................... ......5

Internal Circuit ..................................................... ......6

Wiring Diagram - METER - ................................. ......7

Combination Meter Harness Connector Terminal

Layout ................................................................. ......

9

Terminal and Reference Value for Combination

Meter ................................................................... ......

9

Self-Diagnosis Mode of Combination Meter ........ ....10

CONSULT-III Function (METER/M&A) ............... ....12

Trouble Diagnosis ............................................... ....13

Symptom Chart ................................................... ....14

Power Supply and Ground Circuit Inspection ..... ....14

Vehicle Speed Signal Inspection ......................... ....15

Engine Speed Signal Inspection ......................... ....16

Fuel Level Sensor Signal Inspection ................... ....16

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies .................................................................. ....

18

Fuel Gauge Does Not Move to Full-position ...........18

DTC [U1000] CAN Communication Circuit ......... ....18

Electrical Component Inspection ......................... ....19

Removal and Installation .........................................19

WARNING LAMPS ......................................... ....20

Schematic ........................................................... ....20

Wiring Diagram - WARN - ................................... ....21 Oil Pressure Wa

rning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

29

Oil Pressure Wa rning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

31

Component Inspection ......................................... ....31

A/T INDICATOR ................................................ 33

System Description .............................................. ....33

Wiring Diagram - AT/IND - ................................... ....34

A/T Indicator Does Not Illuminate ........................ ....35

CVT INDICATOR ............................................... 37

System Description .............................................. ....37

Schematic ............................................................ ....37

Wiring Diagram - CVTIND - ................................. ....38

CVT Indicator Does Not Illuminate ...................... ....40

WARNING CHIME ............................................. 42

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

42

System Description .............................................. ....42

Wiring Diagram - CHIME - ................................... ....45

Terminal and Reference Value for BCM ..................46

CONSULT-III Function (B CM) .................................46

Trouble Diagnosis ................................................ ....47

Combination Meter Buzzer Cir cuit Inspection .........48

Front Door Switch LH Signal Inspection .............. ....49

Key Switch Signal Inspec tion (Without Intelligent

Key) ..................................................................... ....

50

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

51

Lighting Switch Signal Inspection ........................ ....53

Parking Brake Switch Signal Inspection .............. ....53

Electrical Component Inspection ......................... ....54

Page 1345 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual DI

N

O P

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

Wit NISSAN TIIDA 2009 Service Workshop Manual DI

N

O P

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

Wit](/img/5/57398/w960_57398-1344.png)

DI

N

O P

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38,

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

IGNITION KEY WARNING CHIME (WITHOUT INTELLIGENT KEY) With the key inserted into the key switch, and the igni tion switch in the OFF or ACC position, when driver's

door is opened, the warning chime will sound.

• BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter with CAN communication line.

• When combination meter receives key warning signal, it sounds warning chime.

IGNITION KEY WARNING CHIME (WITH INTELLIGENT KEY)

When Mechanical Key Is Used With the key inserted into the key switch, and the igniti on switch in the LOCK or ACC position, when driver's

door is opened, the warning chime will sound.

• BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter with CAN communication line.

• When combination meter receives key warning signal, it sounds warning chime.

When Intelligent Key Is Carried With The Driver

Refer to BL-88, " System Description " .

LIGHT WARNING CHIME The warning chime sounds, when driver's door is opened (door switch ON) with lighting switch ON and the

ignition switch is in any position other than ON or START.

NOTE:

BCM detected lighting switch in the 1st or 2nd position, refer to LT-62, " Combination Switch Reading Func-

tion " .

• BCM detects headlamps are illuminated, and sends li ght warning signal to combination meter with CAN

communication lines. WKIA5464E

Page 1349 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual DI

N

O P

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, after prin ting the monitor i NISSAN TIIDA 2009 Service Workshop Manual DI

N

O P

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, after prin ting the monitor i](/img/5/57398/w960_57398-1348.png)

DI

N

O P

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAG RESULTS

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, after prin ting the monitor item, go to “LAN system”. Refer to

LAN-17, " Trouble Diagnosis Flow Chart " .

Trouble Diagnosis INFOID:0000000004307032

HOW TO PERFORM TROUBLE DIAGNOSIS 1. Confirm the symptom and customer complaint.

2. Understand the outline of system. Refer to DI-42, " System Description " .

3. Perform the preliminary inspection. Refer to "PRELIMINARY INSPECTION".

4. According to symptom c hart, repair or replace the cause of the malfunction. Refer to "SYMPTOM

CHART".

5. Does warning chime system operate normally? If it operates normally, GO TO 6. If not, GO TO 4.

6. Inspection End.

PRELIMINARY INSPECTION BCM diagnostic

test item Diagnostic mode Description

Inspection by part WORK SUPPORT

Supports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU PART NUMBER BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions. Monitored item ALL SIGNALS

SELECTION

FROM MENU Contents

IGN ON SW X X Indicates [ON/OFF] condition of ignition switch.

KEY ON SW X X Indicates [ON/OFF] condition of key switch.

DOOR SW-DR X X Indicates [ON/OFF] condition of front door switch LH.

LIGHT SW 1ST X X Indicates [ON/OFF] condition of lighting switch.

BUCKLE SW X X Indicates [ON/OFF] condition of seat belt buckle switch LH. Test item Malfunction is detected when···

IGN KEY WARN ALM This test is able to check key warning chime operation.

LIGHT WARN ALM This test is able to check light warning chime operation.

SEAT BELT WARN TEST This test is able to check seat belt warning chime operation. Display item [Code] Malfunction is detected when...

CAN communication [U1000] Malfunction is detected in CAN communication.

Page 1350 of 4331

CONSULT-III Function (BCM) " .

Self - diagnostic results content

No malfunction detected>>GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts. CONSULT-III Function (METER/M&A) " .

Self - diagnostic results content

No malfunction detected>> Inspection End.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

SYMPTOM CHART

Combination Meter Buzzer Circuit Inspection INFOID:0000000004307033YES >> Combination meter buzzer circuit is OK. Return to

DI-47, " Trouble Diagnosis " .

NO >> GO TO 2. Combination Meter Buzzer Circuit Inspection "

•

DI-49, " Front Door Switch LH Signal Inspection "

If above check is OK, replace BCM. Refer to

BCS-18, " Removal

and Installation of BCM " .

Key warning chime

does not activate. Without Intelligent Key.

Perform

DI-50, " Key Switch Signal Inspection (Without Intelligent

Key) " .

If above check is OK, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

With Intelligent Key, when mechanical key

is used. Perform

DI-51, " Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical Key Is Used) " .

If above check is OK, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

With Intelligent Key, when Intelligent Key

is carried with the driver. Refer to

BL-119, " Trouble Diagnosis Symptom Chart " .

Light warning chime does not activate. Perform

DI-53, " Lighting Switch Signal Inspection " .

If above check is OK, replace BCM. Refer to BCS-18, " Removal

and Installation of BCM " .

Parking brake warning chime does not activate Perform the following inspections

• DI-53, " Parking Brake Switch Signal Inspection "

•

DI-15, " Vehicle Speed Signal Inspection "

Page 1355 of 4331

DI

N

O P

Check voltage between key switch and ignition knob switch harness

connector and ground.

OK or NG OK >> Replace BCM. Refer to

BCS-18, " Removal and Installa-

tion of BCM " .

NG >> Repair harness or connector.

Lighting Switch Signal Inspection INFOID:0000000004307037OK >> Lighting switch signal is OK. Return to

DI-47, " Trouble Diagnosis " .

NG >> Check the lighting switch. Refer to LT-63, " Combination Switch Inspection " .

Parking Brake Switch Signal Inspection INFOID:0000000004307038OK >> Replace combination meter. Refer to

DI-19, " Removal and Installation " .

NG >> GO TO 2. B

Page 1446 of 4331

" Fail Safe " .)

TWO TRIP DETECTION LOGIC

When a malfunction is detected for the first time, 1st tr ip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MIL will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MIL lights up. The MIL lights up at the same time when the DTC is stored. <2nd

trip> The “trip” in the “Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic item s will cause the ECM to light up or blink the MIL,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

×: Applicable —: Not applicable

DTC AND FREEZE FRAME DATA

DTC and 1st Trip DTC Emission-related diagnostic information Diagnostic service

Diagnostic Trouble Code (DTC) Service $03 of SAE J1979

Freeze Frame data Service $02 of SAE J1979

System Readiness Test (SRT) code Service $01 of SAE J1979

1st Trip Diagnostic Trouble Code (1st Trip DTC) Service $07 of SAE J1979

1st Trip Freeze Frame data

Test values and Test limits Service $06 of SAE J1979

Calibration ID Service $09 of SAE J1979 DTC 1st trip DTC

Freeze

Frame data 1st trip Freeze

Frame data SRT code SRT status Test value

CONSULT-III × × × × × × —

GST × × × —× × ×

ECM × ×* — — — ×— Items

MIL DTC 1st trip DTC

1st trip 2nd trip 1st trip

displaying 2nd trip

displaying 1st trip

displaying 2nd trip

displaying

Blinking Lighting

up Blinking

Lighting

up

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected ×

— — — — — ×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0304 is

being detected — —

×— — ×— —

One trip detection diagnoses

(Refer to EC-475, " DTC Index " .)

—

×— — ×— — —

Except above — — — ×— × × —

Page 1447 of 4331

EC

NP

O

The 1st trip DTC (whose number is the same as the DT

C number) is displayed for the latest self-diagnostic

result obtained. If the ECM memory was cleared previously , and the 1st trip DTC did not recur, the 1st trip DTC

will not be displayed.

If a malfunction is detected during the 1st trip, the 1st trip DTC is stored in the ECM memory. The MIL will not

light up (two trip detection logic). If the same malfunc tion is not detected in the 2nd trip (meeting the required

driving pattern), the 1st trip DTC is cleared from the ECM memory. If the same malfunction is detected in the

2nd trip, both the 1st trip DTC and DTC are stored in t he ECM memory and the MIL lights up. In other words,

the DTC is stored in the ECM memory and the MIL light s up when the same malfunction occurs in two consec-

utive trips. If a 1st trip DTC is stored and a non-diagnostic operation is performed between the 1st and 2nd

trips, only the 1st trip DTC will continue to be stored. Fo r malfunctions that blink or light up the MIL during the

1st trip, the DTC and 1st trip DTC are stored in the ECM memory.

Procedures for clearing the DTC and the 1st trip DTC fr om the ECM memory are described in “How to Erase

DTC and 1st Trip DTC”.

For malfunctions in which 1st trip DTCs are displayed, refer to EC-475, " DTC Index " . These items are

required by legal regulations to c ontinuously monitor the system/component . In addition, the items monitored

non-continuously are also displayed on CONSULT-III.

1st trip DTC is specified in Service $07 of SAE J1979. 1st trip DTC detection occurs without lighting up the MIL

and therefore does not warn the driver of a malfunction. However, 1st trip DTC detection will not prevent the

vehicle from being tested, for example during Inspection/Maintenance (I/M) tests.

When a 1st trip DTC is detected, check, print out or write down and erase (1st trip) DTC and Freeze Frame

data as specified in Work Flow procedure Step 2, refer to EC-22, " Work Flow " . Then perform DTC CONFIR-

MATION PROCEDURE or Component Function Check to tr y to duplicate the malfunction. If the malfunction is

duplicated, the item requires repair.

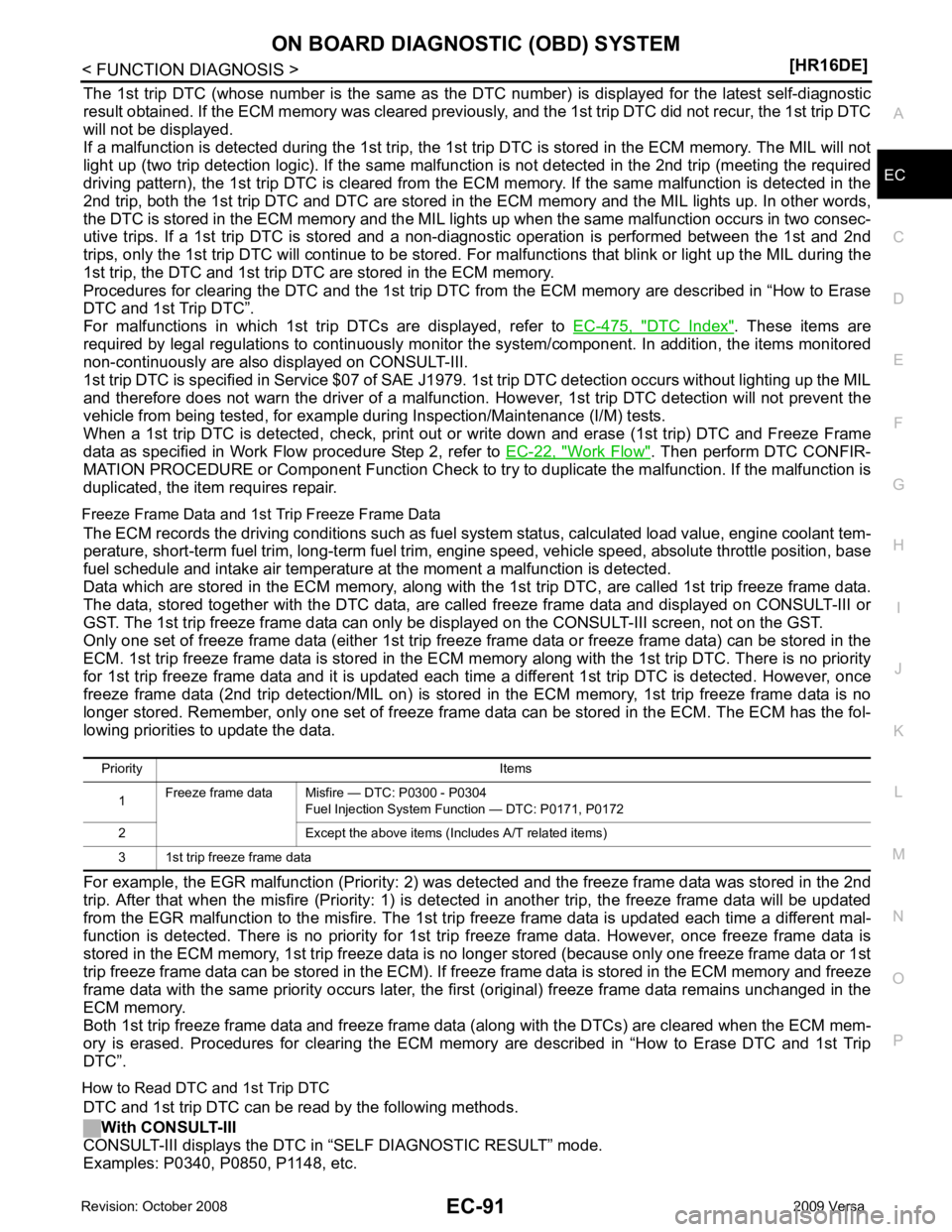

Freeze Frame Data and 1st Trip Freeze Frame Data The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant tem-

perature, short-term fuel trim, long-term fuel trim, engi ne speed, vehicle speed, absolute throttle position, base

fuel schedule and intake air temperature at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are ca lled freeze frame data and displayed on CONSULT-III or

GST. The 1st trip freeze frame data can only be di splayed on the CONSULT-III screen, not on the GST.

Only one set of freeze frame data (either 1st trip freez e frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM me mory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (P riority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st tr ip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If fr eeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame dat a (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described in “How to Erase DTC and 1st Trip

DTC”.

How to Read DTC and 1st Trip DTC DTC and 1st trip DTC can be read by the following methods.

With CONSULT-III

CONSULT-III displays the DTC in “SELF DIAGNOSTIC RESULT” mode.

Examples: P0340, P0850, P1148, etc. Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0304

Fuel Injection System Function — DTC: P0171, P0172

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 1451 of 4331

EC

NP

O

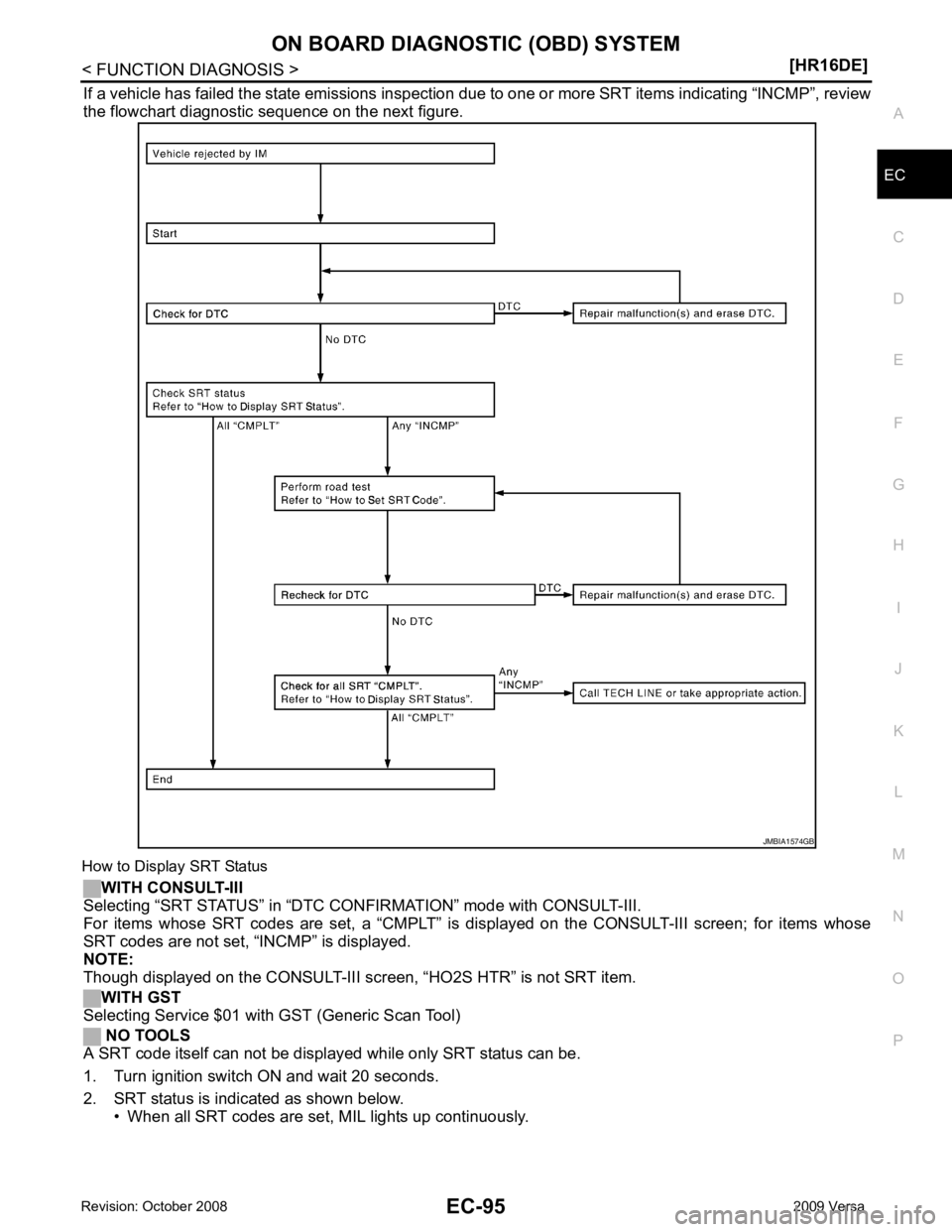

If a vehicle has failed the state emissions inspection

due to one or more SRT items indicating “INCMP”, review

the flowchart diagnostic sequence on the next figure.

How to Display SRT Status WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMATION” mode with CONSULT-III.

For items whose SRT codes are set, a “CMPLT” is di splayed on the CONSULT-III screen; for items whose

SRT codes are not set, “INCMP” is displayed.

NOTE:

Though displayed on the CONSULT-III scr een, “HO2S HTR” is not SRT item.

WITH GST

Selecting Service $01 with GST (Generic Scan Tool)

NO TOOLS

A SRT code itself can not be displayed while only SRT status can be.

1. Turn ignition switch ON and wait 20 seconds.

2. SRT status is indicated as shown below. • When all SRT codes are set, MIL lights up continuously.