torque NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 353 of 4331

Component " .

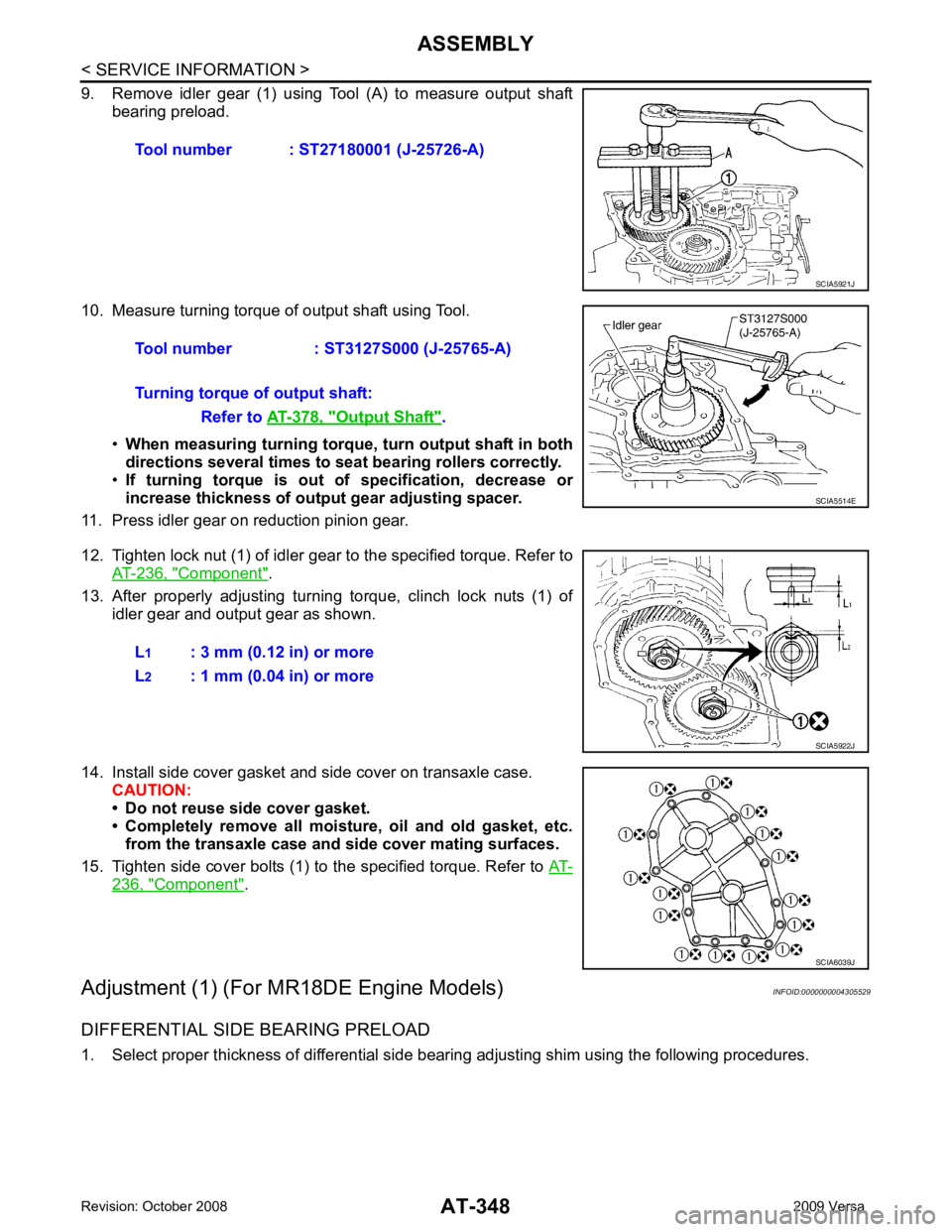

13. After properly adjusting turning torque, clinch lock nuts (1) of idler gear and output gear as shown.

14. Install side cover gasket and side cover on transaxle case. CAUTION:

• Do not reuse side cover gasket.

• Completely remove all moisture, oil and old gasket, etc. from the transaxle case and side cover mating surfaces.

15. Tighten side cover bolts (1) to the specified torque. Refer to AT-236, " Component " .

Adjustment (1) (For MR18DE Engine Models) INFOID:0000000004305529

DIFFERENTIAL SIDE BEARING PRELOAD

1. Select proper thickness of differential side bearing adjusting shim using the following procedures. Tool number : ST27180001 (J-25726-A)

Output Shaft " .

SCIA6039J

Page 354 of 4331

ASSEMBLY

AT-349

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

a. Install differential side bearing outer race without differential side

bearing adjusting shim on transaxle case.

CAUTION:

Apply ATF to differential side bearing outer race.

b. Install differential side bearing outer race on converter housing.

CAUTION:

Apply ATF to differential side bearing outer race.

c. Place final drive assembly on transaxle case.

d. Tighten converter housing bolts (1) and (2) to the specified torque. Refer to AT-336, " Final Drive " .

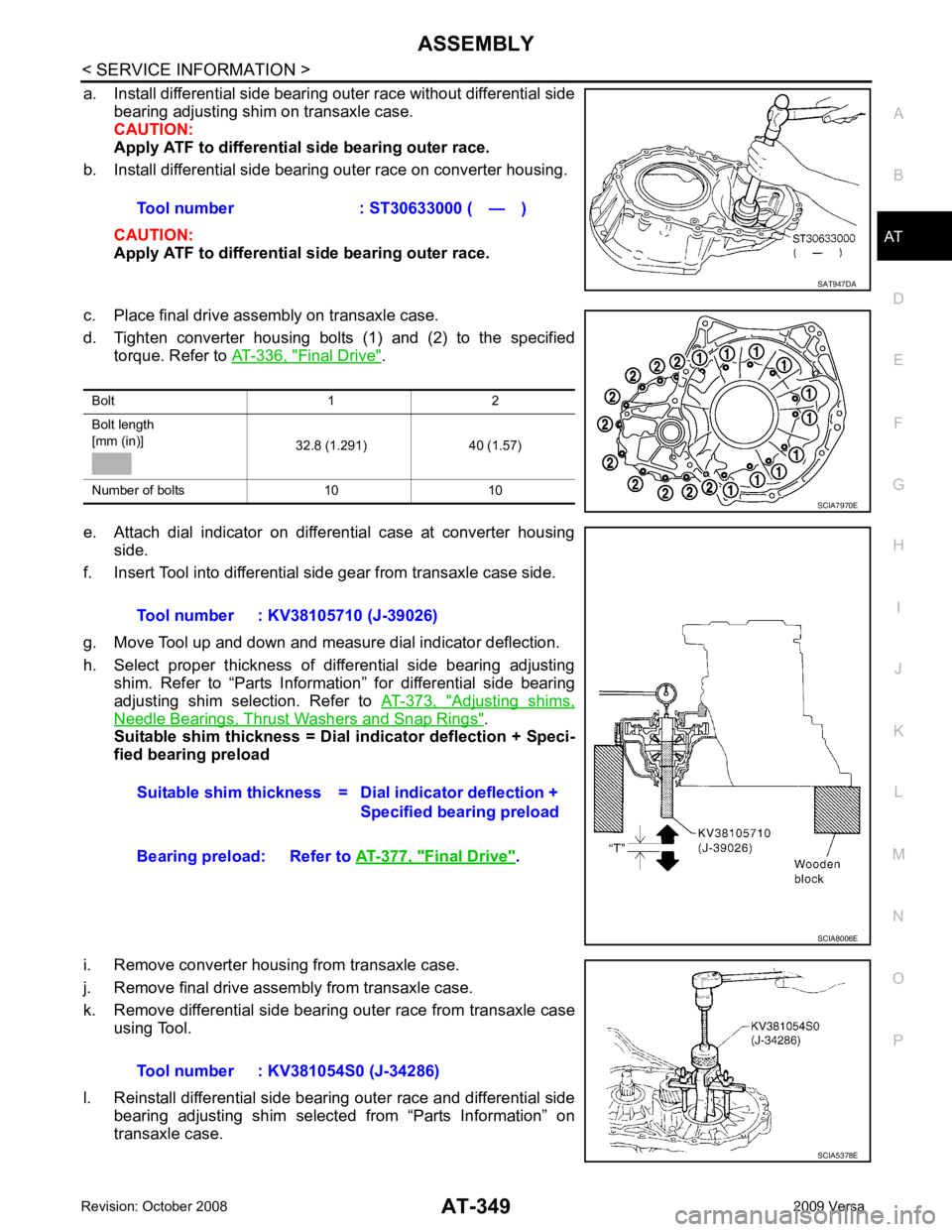

e. Attach dial indicator on differential case at converter housing side.

f. Insert Tool into differential side gear from transaxle case side.

g. Move Tool up and down and measure dial indicator deflection.

h. Select proper thickness of differential side bearing adjusting shim. Refer to “Parts Information” for differential side bearing

adjusting shim selection. Refer to AT-373, " Adjusting shims,

Needle Bearings, Thrust Washers and Snap Rings " .

Suitable shim thickness = Dial indicator deflection + Speci-

fied bearing preload

i. Remove converter housing from transaxle case.

j. Remove final drive assembly from transaxle case.

k. Remove differential side bearing outer race from transaxle case using Tool.

l. Reinstall differential side bearing outer race and differential side bearing adjusting shim selected from “Parts Information” on

transaxle case. Tool number : ST30633000 ( — ) SAT947DA

Bolt 1 2

Bolt length

[mm (in)] 32.8 (1.291) 40 (1.57)

Number of bolts 10 10 SCIA7970E

Tool number : KV38105710 (J-39026)

Suitable shim thickness = D ial indicator deflection +

Specified bearing preload

Bearing preload: Refer to AT-377, " Final Drive " .

SCIA8006E

Tool number : KV381054S0 (J-34286)

SCIA5378E

Page 355 of 4331

AT-350< SERVICE INFORMATION >

ASSEMBLY

m. Reinstall converter housing on transaxle case and ti ghten converter housing bolts to the specified torque.

Refer to AT-236, " Component " .

n. Insert Tool and measure turning torque of final drive assembly.

•Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

• When old bearing is used again, turning torque will be

slightly less than the above.

• Make sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

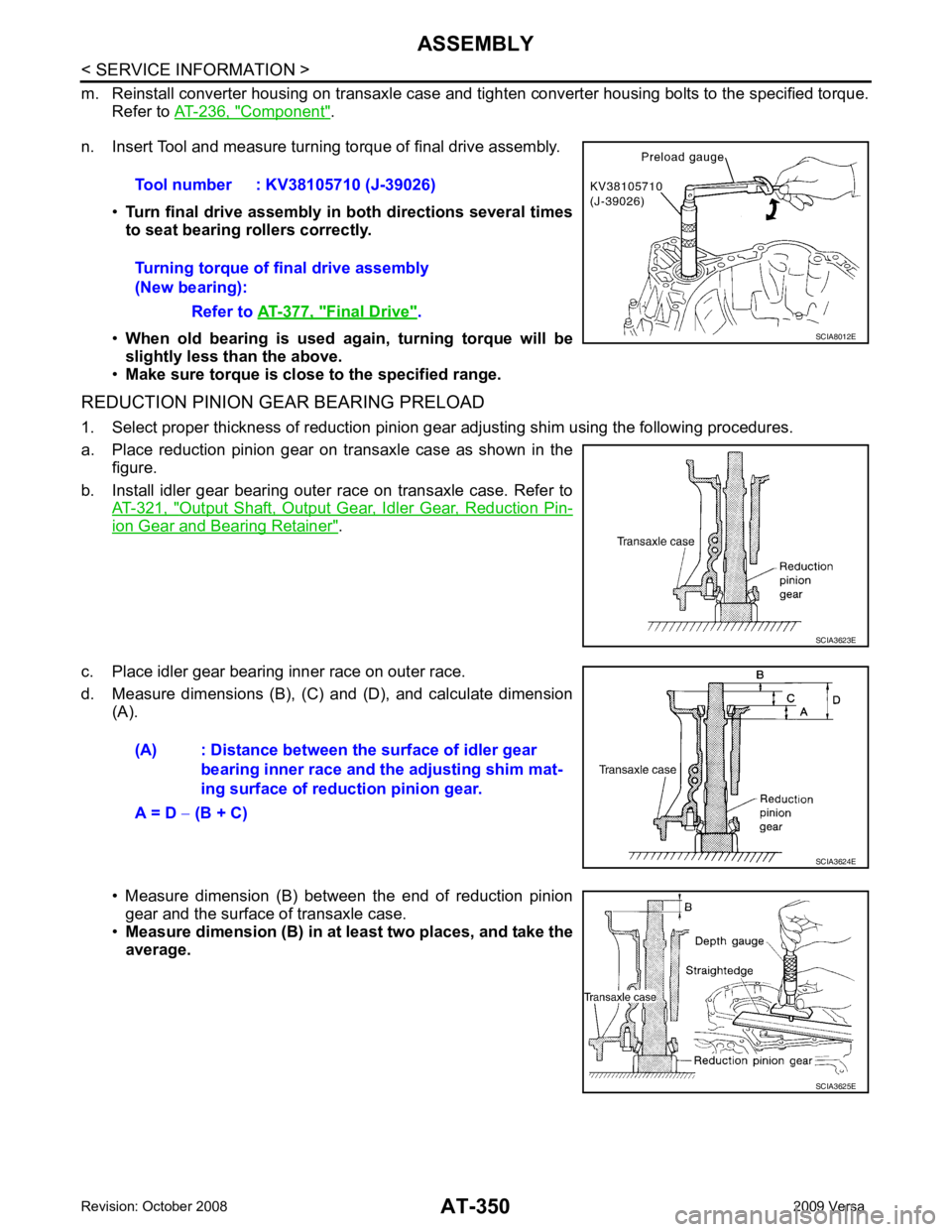

1. Select proper thickness of reduction pinion gear adjusting shim using the following procedures.

a. Place reduction pinion gear on transaxle case as shown in the figure.

b. Install idler gear bearing outer race on transaxle case. Refer to AT-321, " Output Shaft, Output Gear, Idler Gear, Reduction Pin-

ion Gear and Bearing Retainer " .

c. Place idler gear bearing inner race on outer race.

d. Measure dimensions (B), (C) and (D), and calculate dimension (A).

• Measure dimension (B) between the end of reduction pinion gear and the surface of transaxle case.

• Measure dimension (B) in at least two places, and take the

average. Tool number : KV38105710 (J-39026)

Turning torque of final drive assembly

(New bearing):

Refer to AT-377, " Final Drive " .

SCIA8012E

SCIA3623E

(A) : Distance between the surface of idler gear

bearing inner race and the adjusting shim mat-

ing surface of redu ction pinion gear.

A = D − (B + C) SCIA3624E

SCIA3625E

Page 356 of 4331

ASSEMBLY

AT-351

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

• Measure dimension (C) between the surface of idler gear

bearing inner race and the surface of transaxle case.

• Measure dimension (C) in at least two places, and take the

average.

• Remove reduction pinion gear from transaxle case.

• Measure dimension (D) between the end of reduction pinion gear and the adjusting shim mating surface of reduction pinion

gear.

• Measure dimension (D) in at least two places, and take the

average.

• Calculate dimension (A).

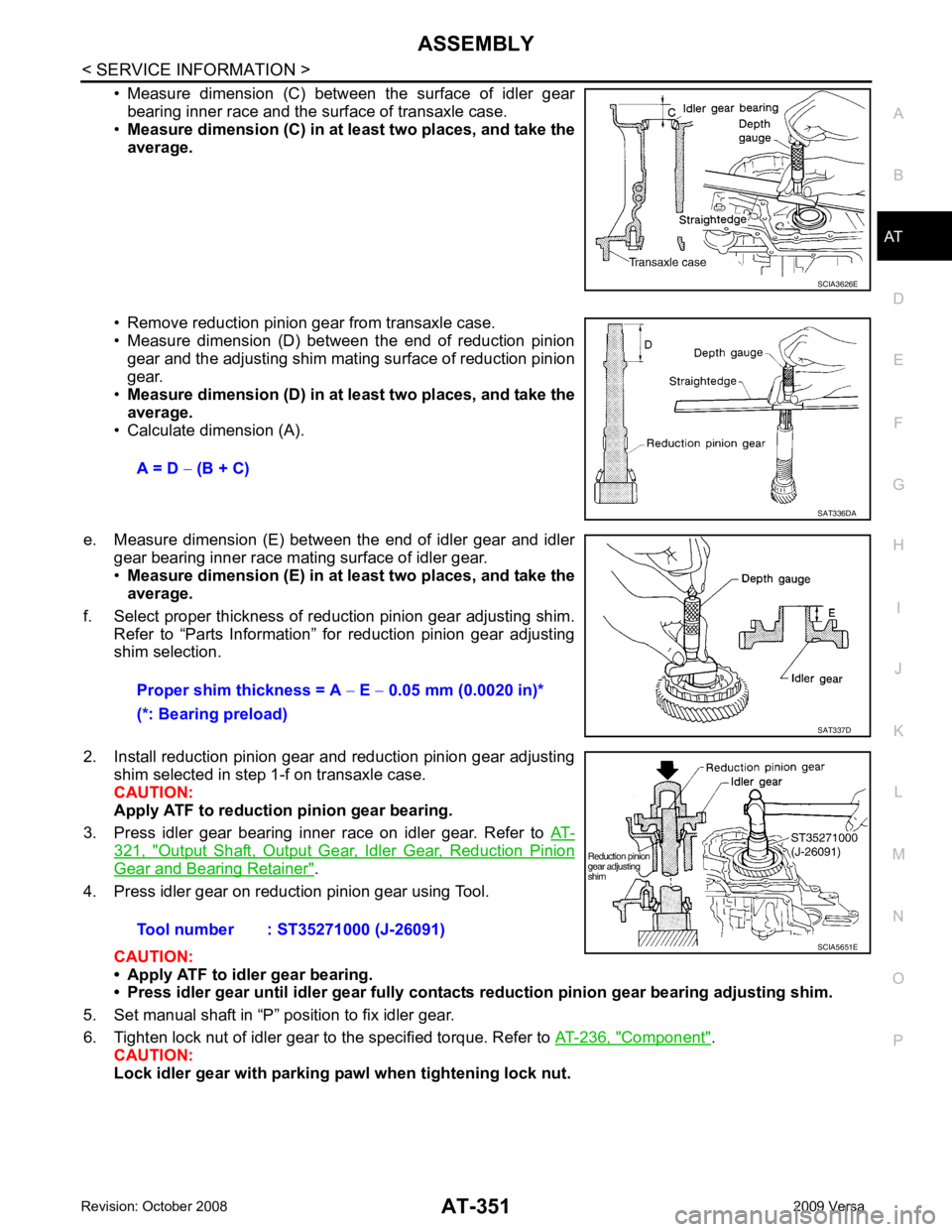

e. Measure dimension (E) between the end of idler gear and idler gear bearing inner race mating surface of idler gear.

• Measure dimension (E) in at least two places, and take the

average.

f. Select proper thickness of reduction pinion gear adjusting shim. Refer to “Parts Information” for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear. Refer to AT-321, " Output Shaft, Output Gear, Idler Gear, Reduction Pinion

Gear and Bearing Retainer " .

4. Press idler gear on reduction pinion gear using Tool.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction pinion gear bearing adjusting shim.

5. Set manual shaft in “P” position to fix idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-236, " Component " .

CAUTION:

Lock idler gear with parking pa wl when tightening lock nut. SCIA3626E

A = D

− (B + C) SAT336DA

Proper shim thickness = A

− E − 0.05 mm (0.0020 in)*

(*: Bearing preload) SAT337D

Tool number : ST35271000 (J-26091)

SCIA5651E

Page 357 of 4331

AT-352< SERVICE INFORMATION >

ASSEMBLY

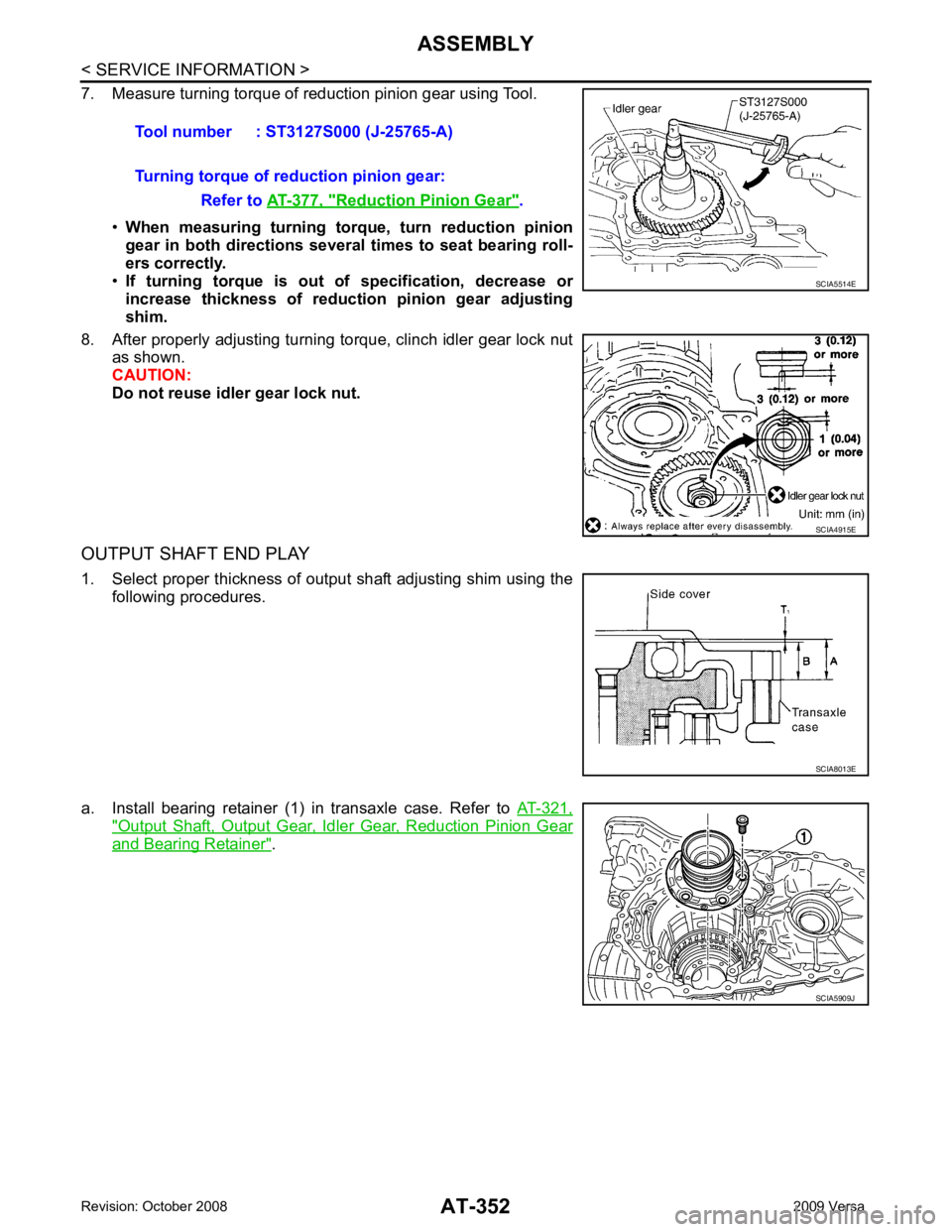

7. Measure turning torque of reduction pinion gear using Tool.

•When measuring turning torq ue, turn reduction pinion

gear in both directions several times to seat bearing roll-

ers correctly.

• If turning torque is out of specification, decrease or

increase thickness of reducti on pinion gear adjusting

shim.

8. After properly adjusting turning torque, clinch idler gear lock nut as shown.

CAUTION:

Do not reuse idler gear lock nut.

OUTPUT SHAFT END PLAY

1. Select proper thickness of output shaft adjusting shim using the following procedures.

a. Install bearing retainer (1) in transaxle case. Refer to AT-321," Output Shaft, Output Gear, Idler Gear, Reduction Pinion Gear

and Bearing Retainer " .

Tool number : ST3127S000 (J-25765-A)

Turning torque of reduction pinion gear: Refer to AT-377, " Reduction Pinion Gear " .

SCIA5514E

SCIA4915E

SCIA8013E

SCIA5909J

Page 368 of 4331

ASSEMBLY

AT-363

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

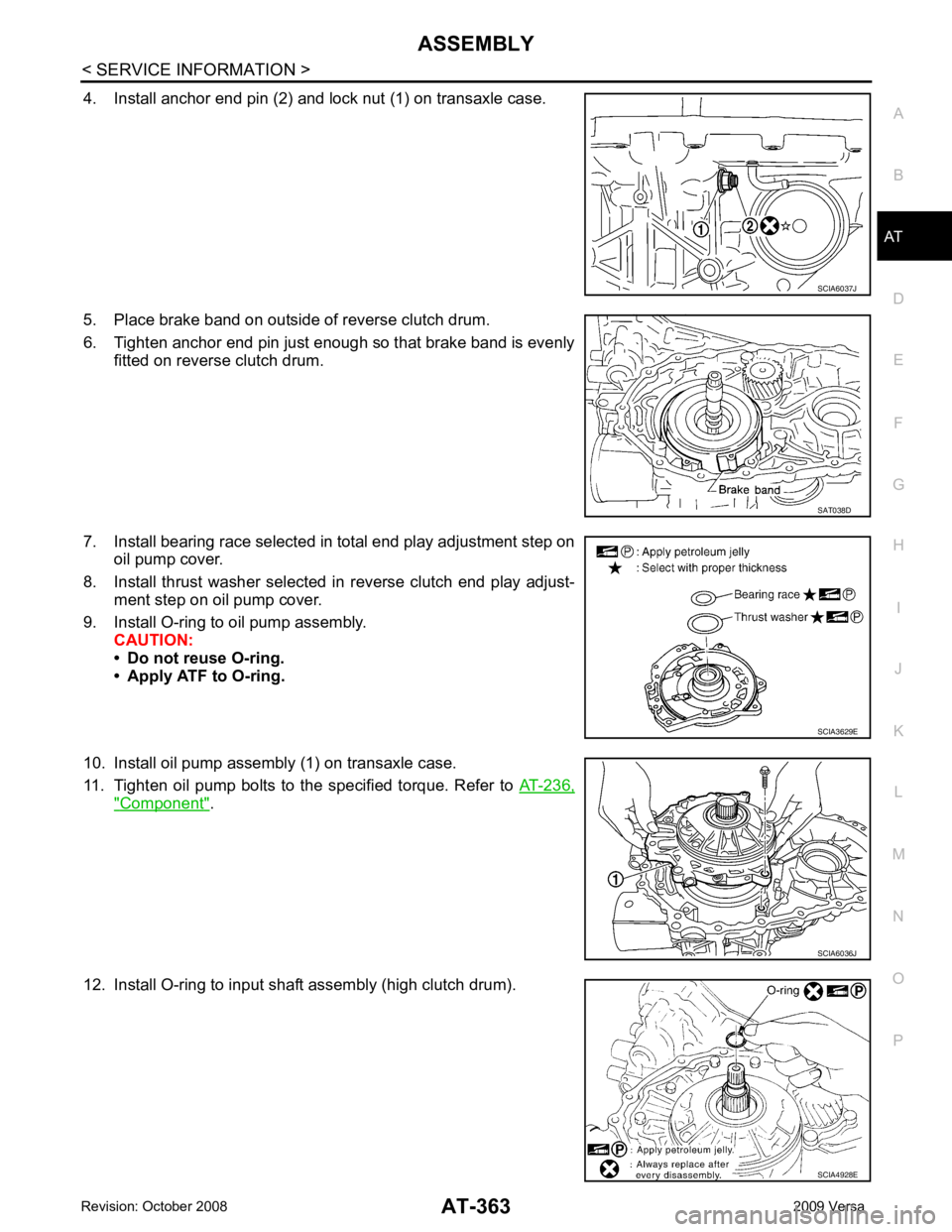

4. Install anchor end pin (2) and lock nut (1) on transaxle case.

5. Place brake band on outside of reverse clutch drum.

6. Tighten anchor end pin just enough so that brake band is evenly fitted on reverse clutch drum.

7. Install bearing race selected in total end play adjustment step on oil pump cover.

8. Install thrust washer selected in reverse clutch end play adjust- ment step on oil pump cover.

9. Install O-ring to oil pump assembly. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

10. Install oil pump assembly (1) on transaxle case.

11. Tighten oil pump bolts to the specified torque. Refer to AT-236," Component " .

12. Install O-ring to input shaft assembly (high clutch drum). SCIA6037J

SAT038D

SCIA3629E

SCIA6036J

SCIA4928E

Page 370 of 4331

AT

N

O P

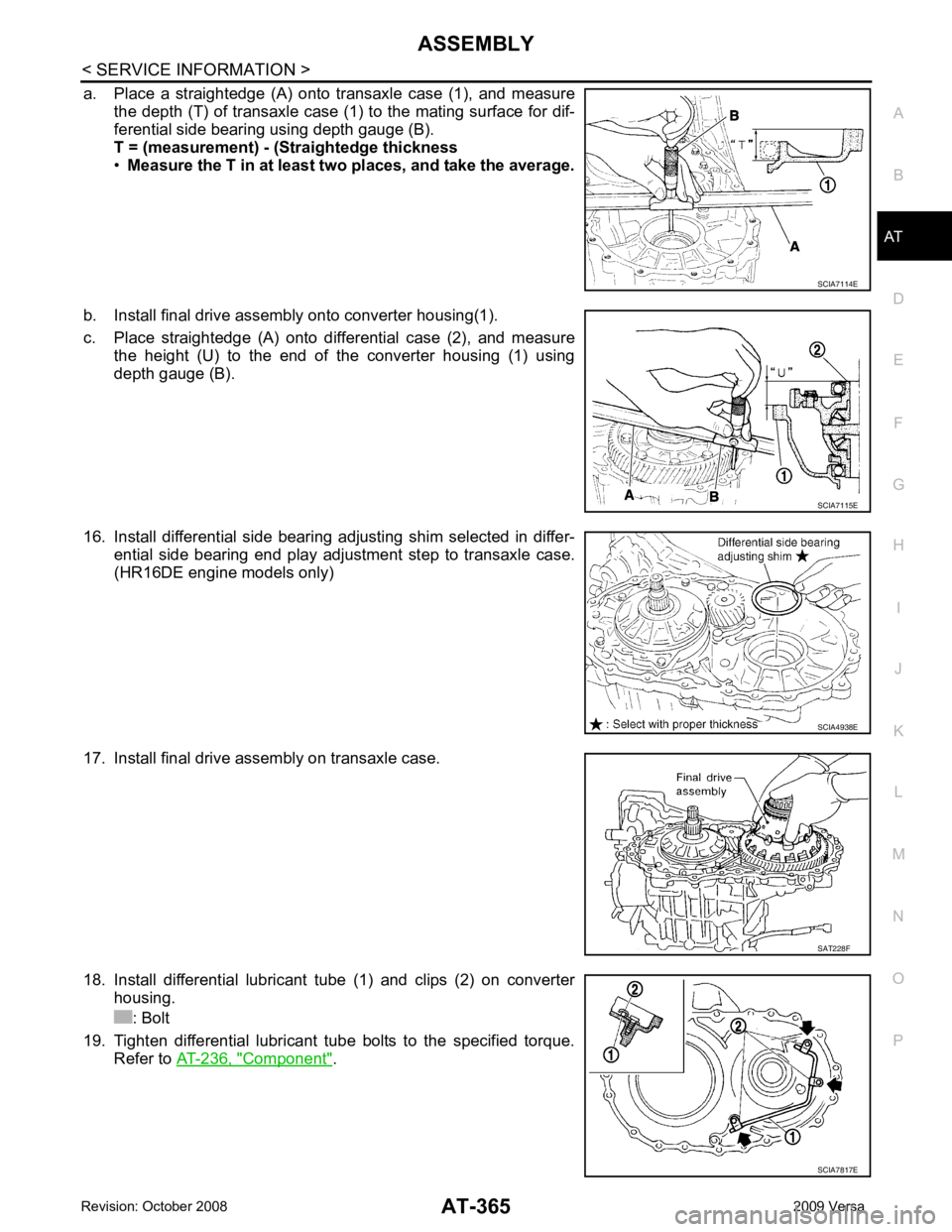

a. Place a straightedge (A) onto tr

ansaxle case (1), and measure

the depth (T) of transaxle case (1) to the mating surface for dif-

ferential side bearing using depth gauge (B).

T = (measurement) - (Straightedge thickness

• Measure the T in at least two places, and take the average.

b. Install final drive assembly onto converter housing(1).

c. Place straightedge (A) onto differential case (2), and measure the height (U) to the end of the converter housing (1) using

depth gauge (B).

16. Install differential side bearing adjusting shim selected in differ- ential side bearing end play adjustment step to transaxle case.

(HR16DE engine models only)

17. Install final drive assembly on transaxle case.

18. Install differential lubricant tube (1) and clips (2) on converter housing.

: Bolt

19. Tighten differential lubricant tube bolts to the specified torque. Refer to AT-236, " Component " .

SCIA7817E

Page 371 of 4331

AT-366< SERVICE INFORMATION >

ASSEMBLY

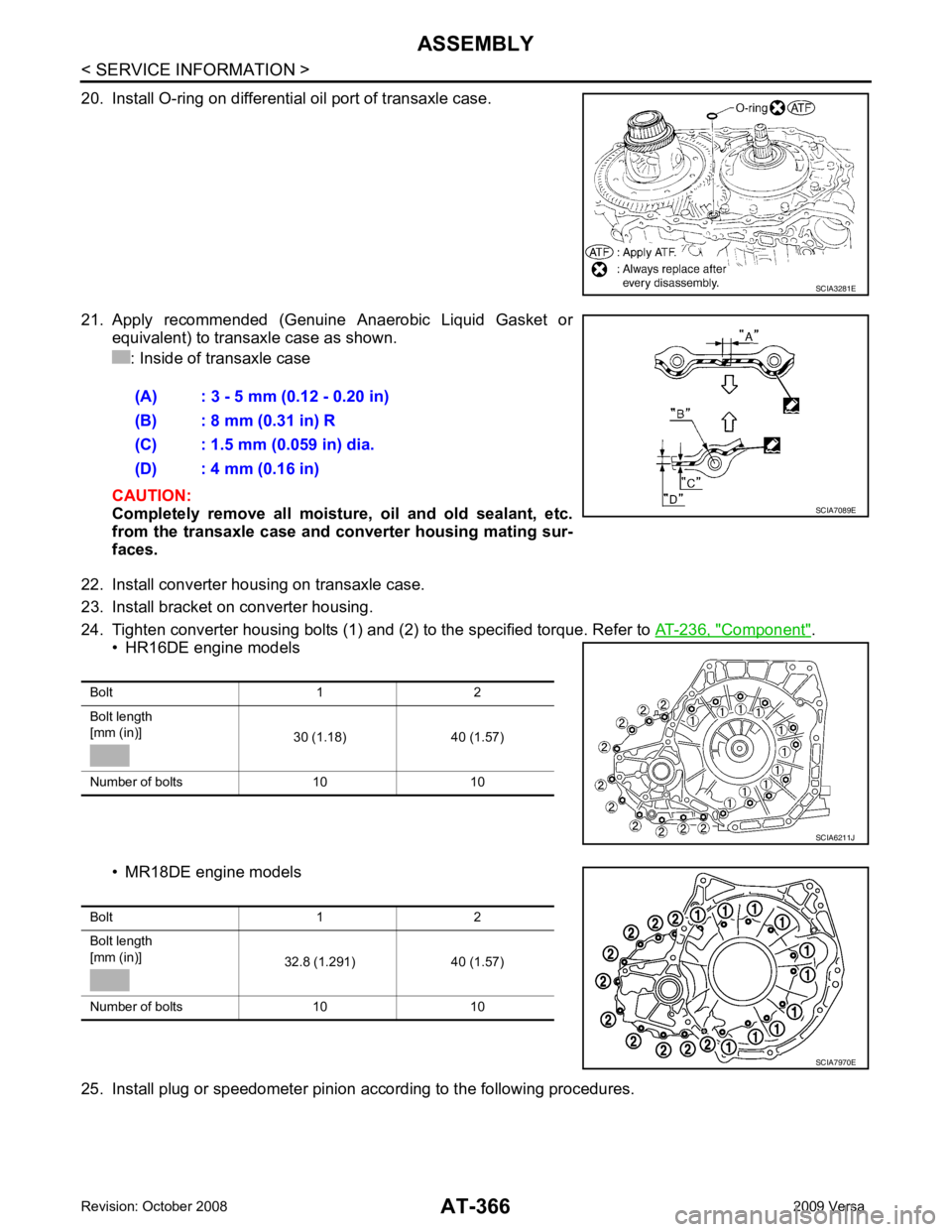

20. Install O-ring on differential oil port of transaxle case.

21. Apply recommended (Genuine Anaerobic Liquid Gasket or equivalent) to transaxle case as shown.

: Inside of transaxle case

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transaxle case and converter housing mating sur-

faces.

22. Install converter housing on transaxle case.

23. Install bracket on converter housing.

24. Tighten converter housing bolts (1) and (2) to the specified torque. Refer to AT-236, " Component " .

• HR16DE engine models

• MR18DE engine models

25. Install plug or speedometer pinion according to the following procedures. SCIA3281E

(A) : 3 - 5 mm (0.12 - 0.20 in)

(B) : 8 mm (0.31 in) R

(C) : 1.5 mm (0.059 in) dia.

(D) : 4 mm (0.16 in) SCIA7089E

Bolt 1 2

Bolt length

[mm (in)] 30 (1.18) 40 (1.57)

Number of bolts 10 10 SCIA6211J

Bolt 1 2

Bolt length

[mm (in)] 32.8 (1.291) 40 (1.57)

Number of bolts 10 10 SCIA7970E

Page 372 of 4331

ASSEMBLY

AT-367

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

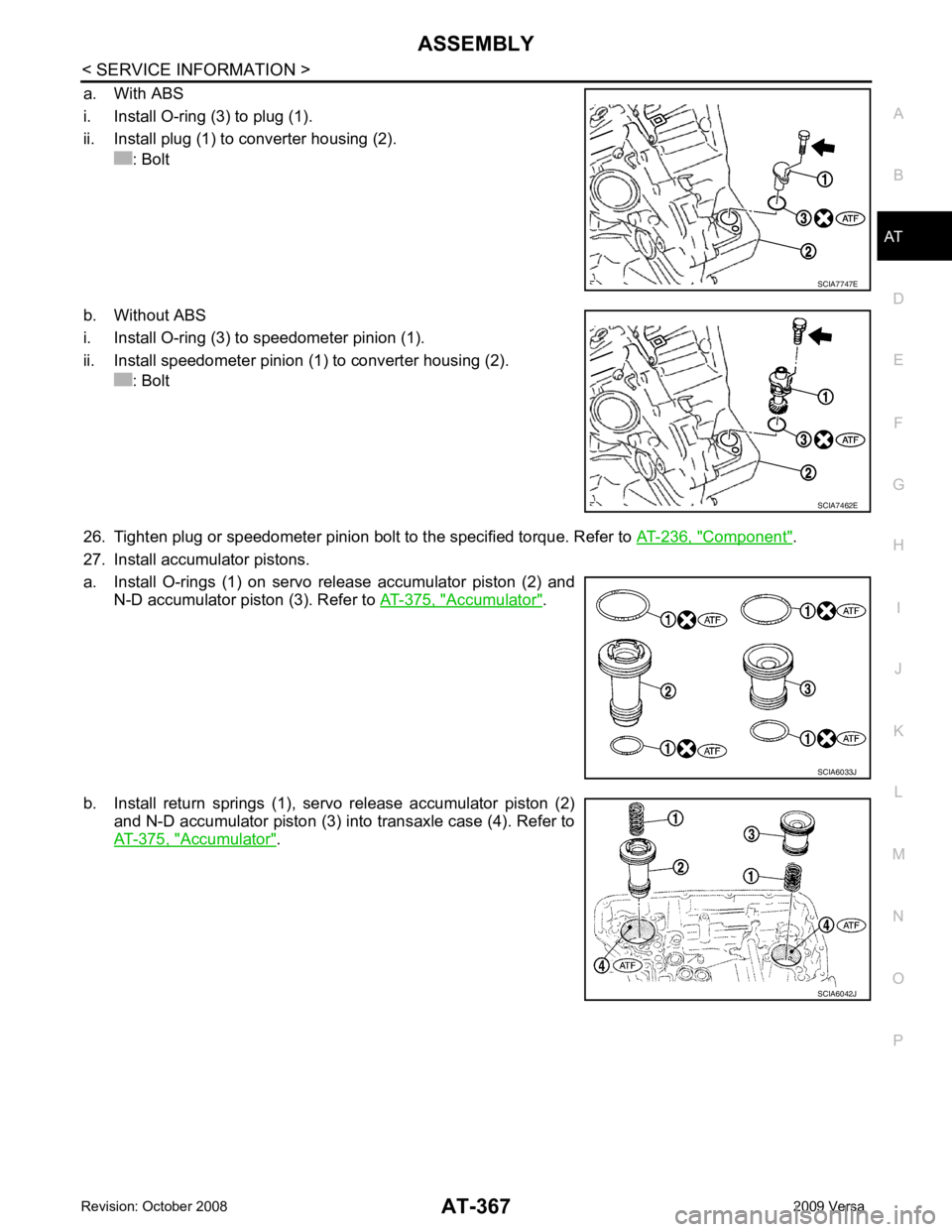

a. With ABS

i. Install O-ring (3) to plug (1).

ii. Install plug (1) to converter housing (2). : Bolt

b. Without ABS

i. Install O-ring (3) to speedometer pinion (1).

ii. Install speedometer pinion (1) to converter housing (2). : Bolt

26. Tighten plug or speedometer pinion bolt to the specified torque. Refer to AT-236, " Component " .

27. Install accumulator pistons.

a. Install O-rings (1) on servo release accumulator piston (2) and N-D accumulator piston (3). Refer to AT-375, " Accumulator " .

b. Install return springs (1), servo release accumulator piston (2) and N-D accumulator piston (3) into transaxle case (4). Refer to

AT-375, " Accumulator " . SCIA7747E

SCIA7462E

SCIA6033J

SCIA6042J

Page 373 of 4331

AT-368< SERVICE INFORMATION >

ASSEMBLY

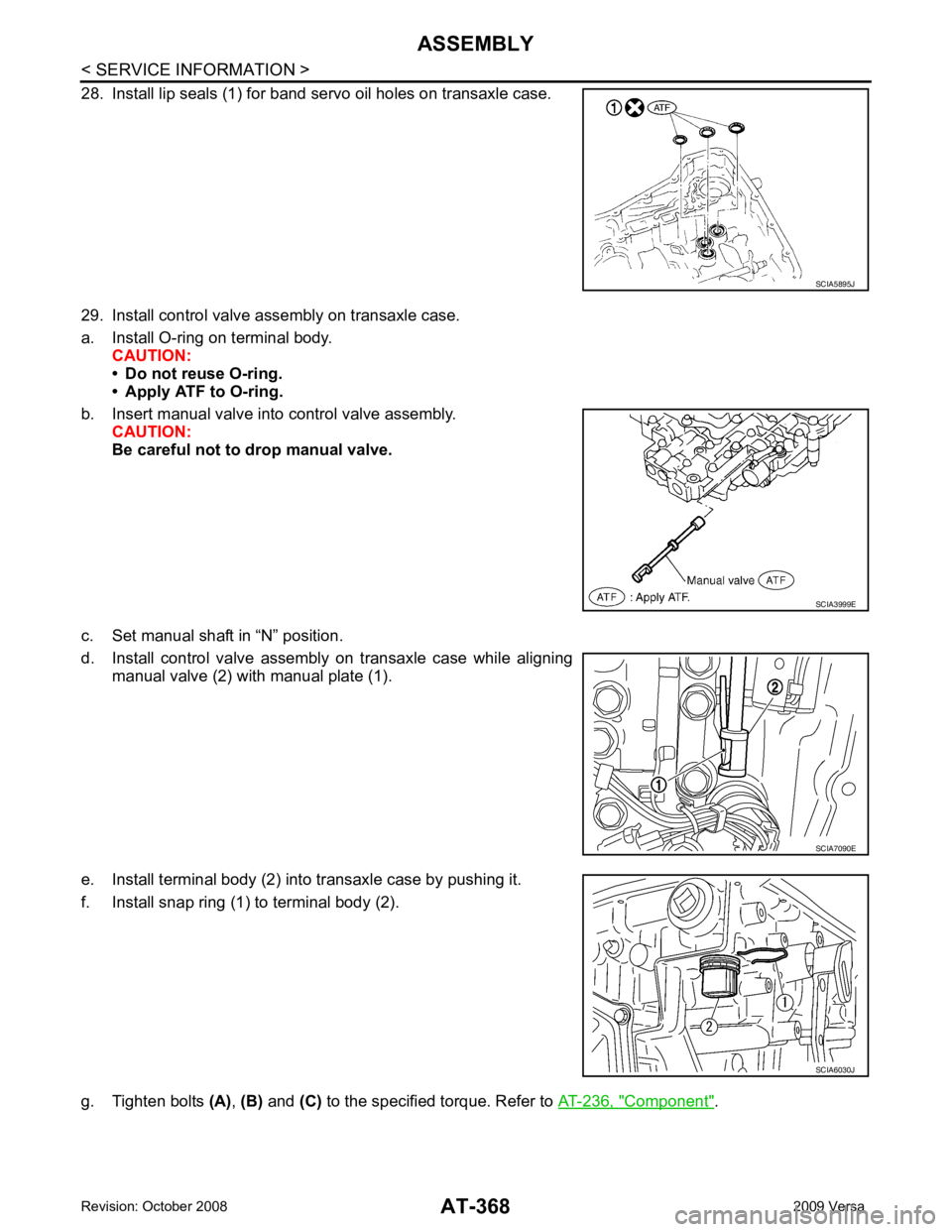

28. Install lip seals (1) for band servo oil holes on transaxle case.

29. Install control valve assembly on transaxle case.

a. Install O-ring on terminal body. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

b. Insert manual valve into control valve assembly. CAUTION:

Be careful not to drop manual valve.

c. Set manual shaft in “N” position.

d. Install control valve assembly on transaxle case while aligning manual valve (2) with manual plate (1).

e. Install terminal body (2) into transaxle case by pushing it.

f. Install snap ring (1) to terminal body (2).

g. Tighten bolts (A), (B) and (C) to the specified torque. Refer to AT-236, " Component " . SCIA5895J

SCIA3999E

SCIA7090E

SCIA6030J