torque NISSAN TIIDA 2009 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 285 of 4331

AT-280< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

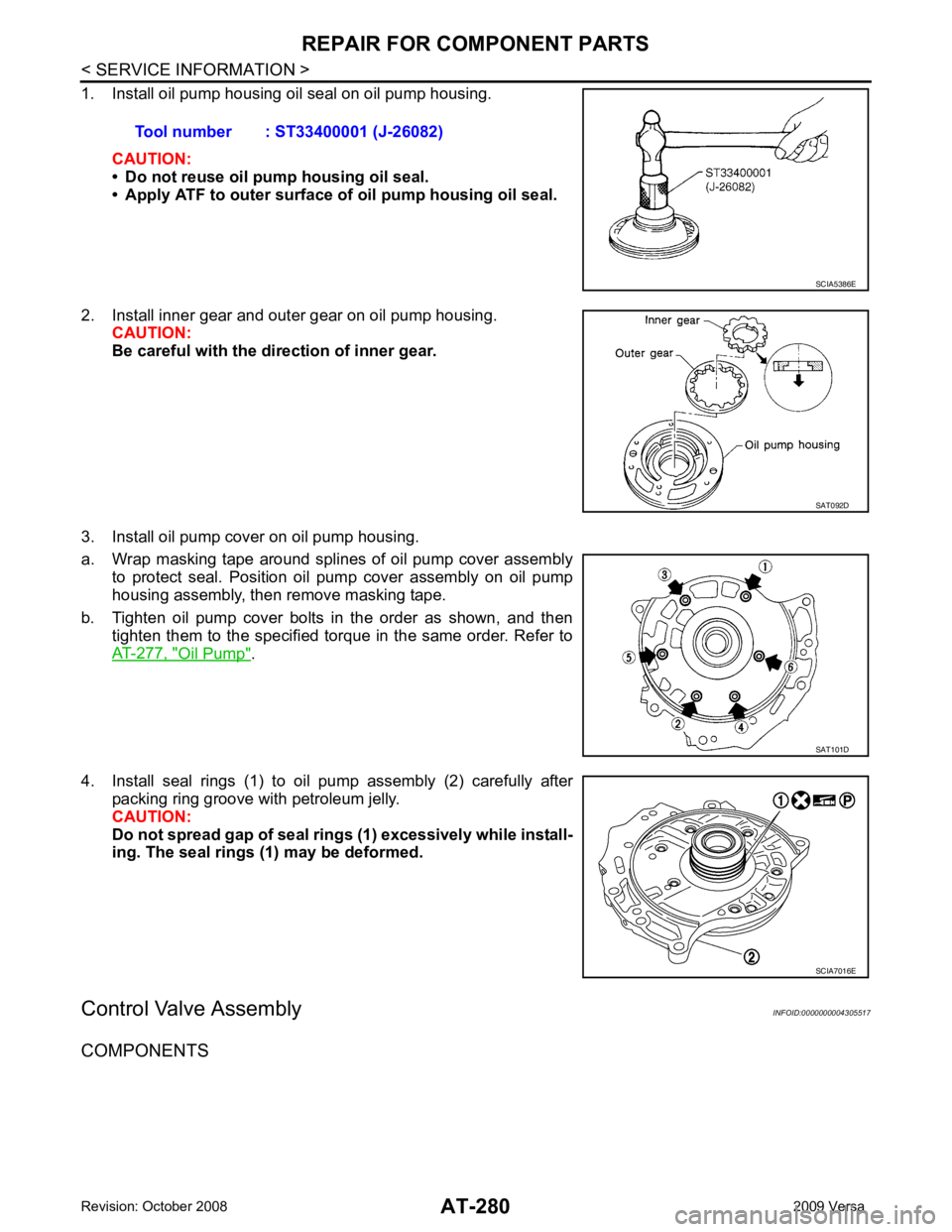

1. Install oil pump housing oil seal on oil pump housing.

CAUTION:

• Do not reuse oil pump housing oil seal.

• Apply ATF to outer surface of oil pump housing oil seal.

2. Install inner gear and outer gear on oil pump housing. CAUTION:

Be careful with the direction of inner gear.

3. Install oil pump cover on oil pump housing.

a. Wrap masking tape around splines of oil pump cover assembly to protect seal. Position oil pump cover assembly on oil pump

housing assembly, then remove masking tape.

b. Tighten oil pump cover bolts in the order as shown, and then tighten them to the specified torque in the same order. Refer to

AT-277, " Oil Pump " .

4. Install seal rings (1) to oil pump assembly (2) carefully after packing ring groove with petroleum jelly.

CAUTION:

Do not spread gap of seal ri ngs (1) excessively while install-

ing. The seal rings (1) may be deformed.

Control Valve Assembly INFOID:0000000004305517

COMPONENTS Tool number : ST33400001 (J-26082) SCIA5386E

SAT092D

SAT101D

SCIA7016E

Page 286 of 4331

AT

N

O P

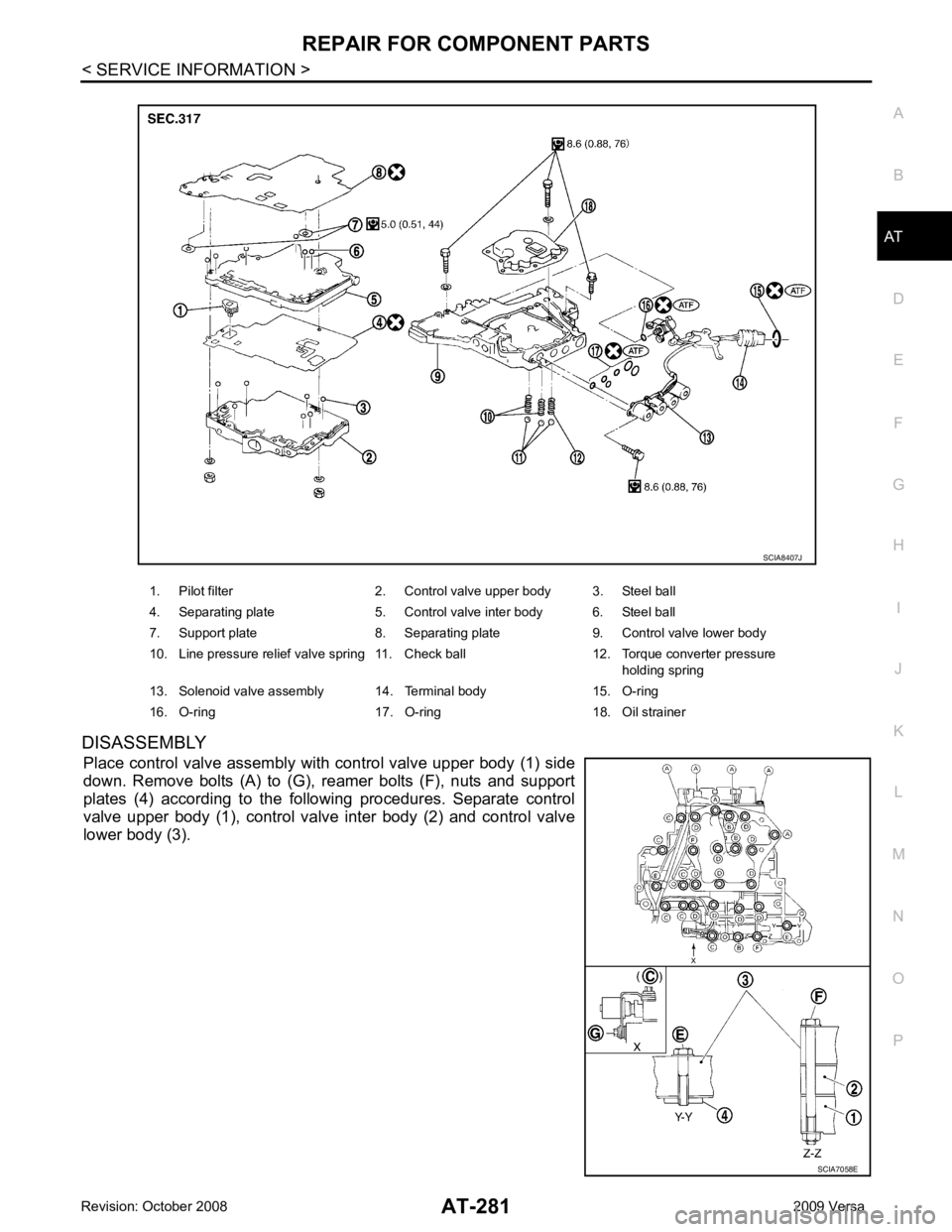

DISASSEMBLY

Place control valve assembly with control valve upper body (1) side

down. Remove bolts (A) to (G), reamer bolts (F), nuts and support

plates (4) according to the following procedures. Separate control

valve upper body (1), control valve inter body (2) and control valve

lower body (3). 1. Pilot filter 2. Control valve upper body 3. Steel ball

4. Separating plate 5. Control valve inter body 6. Steel ball

7. Support plate 8. Separating plate 9. Control valve lower body

10. Line pressure relief valve spring 11. Check ball 12. Torque converter pressure holding spring

13. Solenoid valve assembly 14. Terminal body 15. O-ring

16. O-ring 17. O-ring 18. Oil strainer SCIA7058E

Page 288 of 4331

AT

N

O P

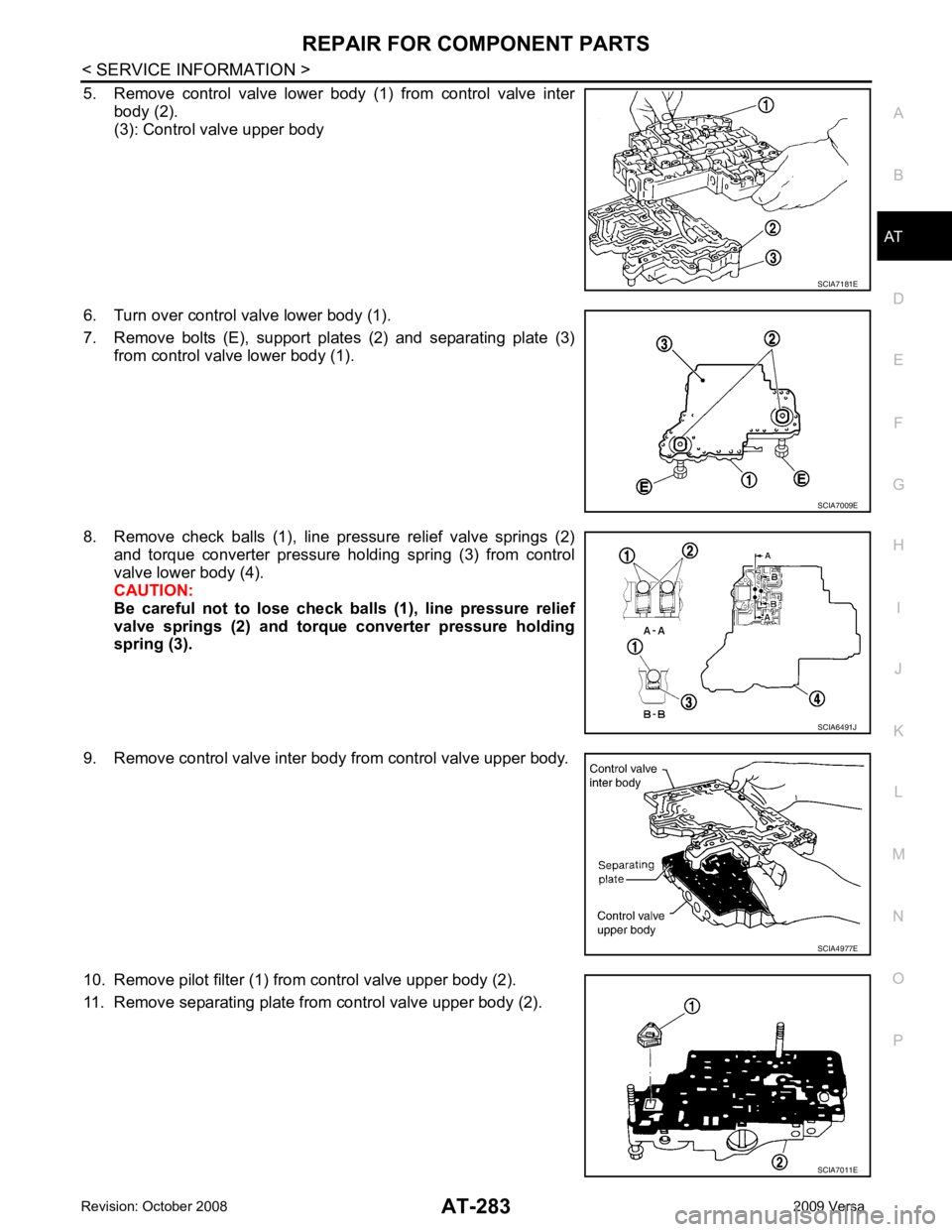

5. Remove control valve lower body (1) from control valve inter

body (2).

(3): Control valve upper body

6. Turn over control valve lower body (1).

7. Remove bolts (E), support plates (2) and separating plate (3) from control valve lower body (1).

8. Remove check balls (1), line pressure relief valve springs (2) and torque converter pressure holding spring (3) from control

valve lower body (4).

CAUTION:

Be careful not to lose check ba lls (1), line pressure relief

valve springs (2) and torque converter pressure holding

spring (3).

9. Remove control valve inter body from control valve upper body.

10. Remove pilot filter (1) from control valve upper body (2).

11. Remove separating plate from control valve upper body (2).

Page 290 of 4331

AT

N

O P

Check wire netting of oil strainer for damage. Replace if necessary.

Shift Solenoid Valves “A and B”, Line Pressure Solenoid Valve, Torque Conv erter Clutch Solenoid Valve and Overrun

Clutch Solenoid Valve

Measure resistance.

• For shift solenoid valve A, refer to AT-142, " Component Inspec-

tion " .

• For shift solenoid valve B, refer to AT-147, " Component Inspec-

tion " .

• For line pressure solenoid valve, refer to AT-138, " Component

Inspection " .

• For torque converter clutch solenoid valve, refer to AT-127, " Com-

ponent Inspection " .

• For overrun clutch solenoid valve, refer to AT-152, " Component

Inspection " .

A/T Fluid Temperature Sensor Measure resistance.

• For A/T fluid temperature sensor, refer to AT-161, " Component

Inspection " .

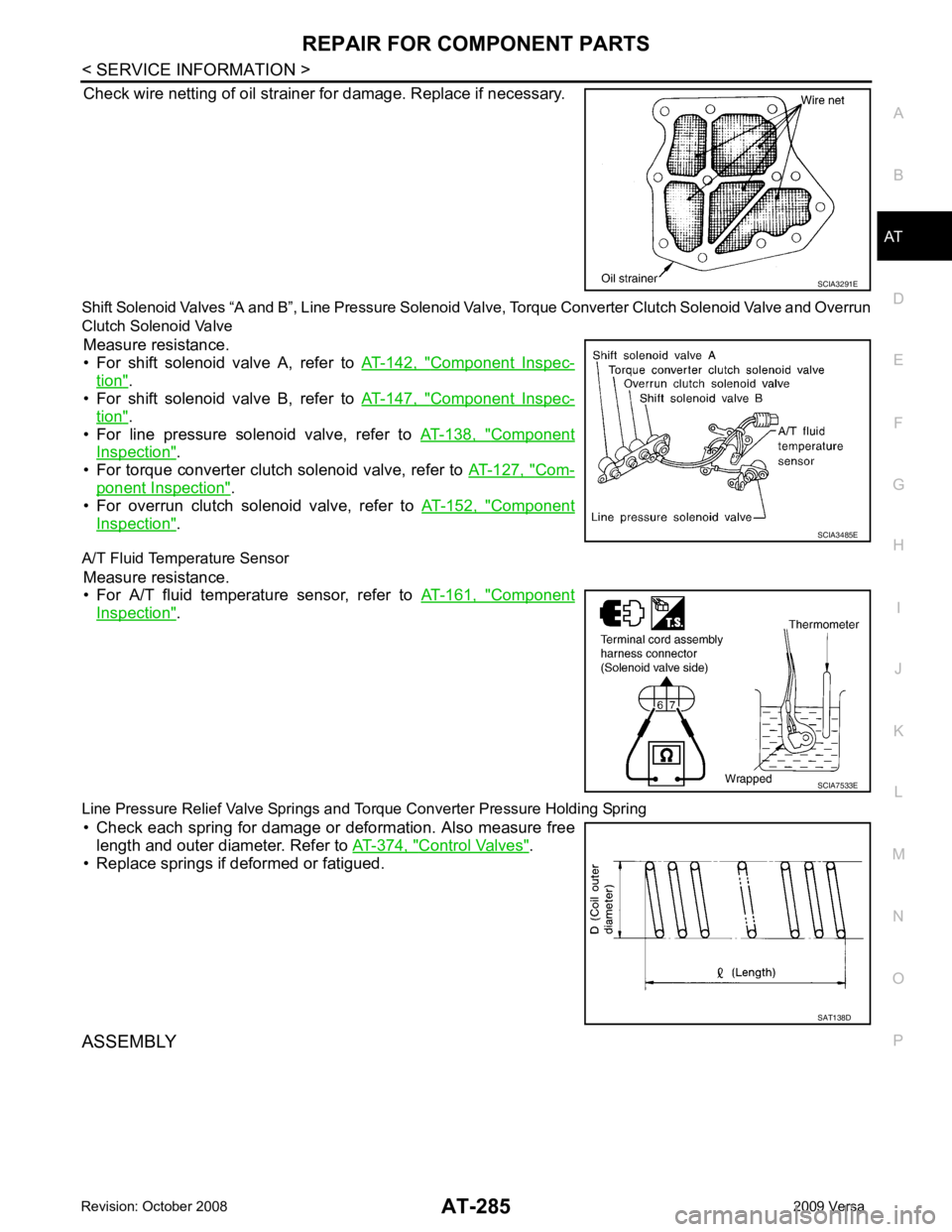

Line Pressure Relief Valve Springs and To rque Converter Pressure Holding Spring

• Check each spring for damage or deformation. Also measure free length and outer diameter. Refer to AT-374, " Control Valves " .

• Replace springs if deformed or fatigued.

ASSEMBLY SCIA3485E

SAT138D

Page 292 of 4331

AT

N

O P

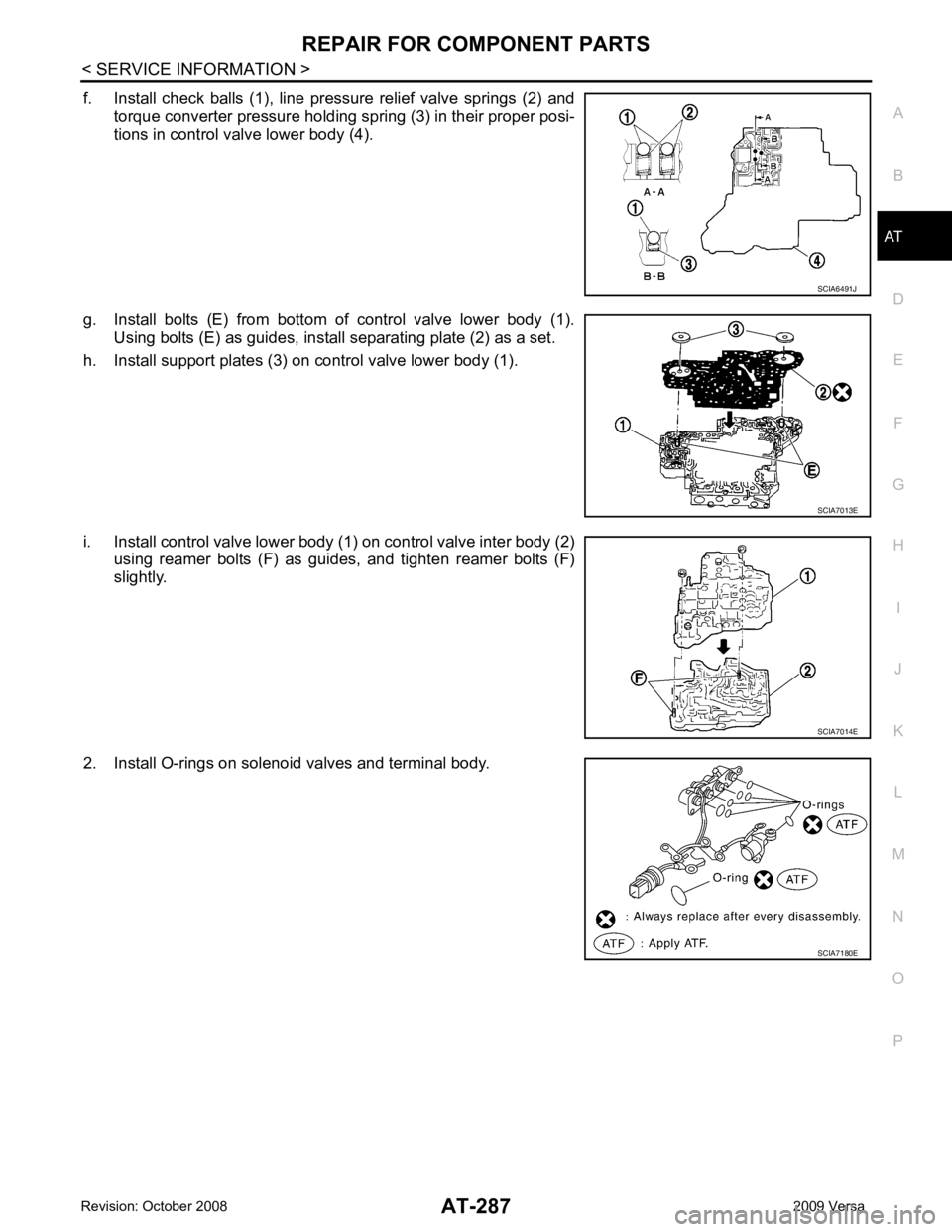

f. Install check balls (1), line pressure relief valve springs (2) and

torque converter pressure holding spring (3) in their proper posi-

tions in control valve lower body (4).

g. Install bolts (E) from bottom of control valve lower body (1). Using bolts (E) as guides, install separating plate (2) as a set.

h. Install support plates (3) on control valve lower body (1).

i. Install control valve lower body (1) on control valve inter body (2) using reamer bolts (F) as guides, and tighten reamer bolts (F)

slightly.

2. Install O-rings on solenoid valves and terminal body.

Page 294 of 4331

AT

N

O P

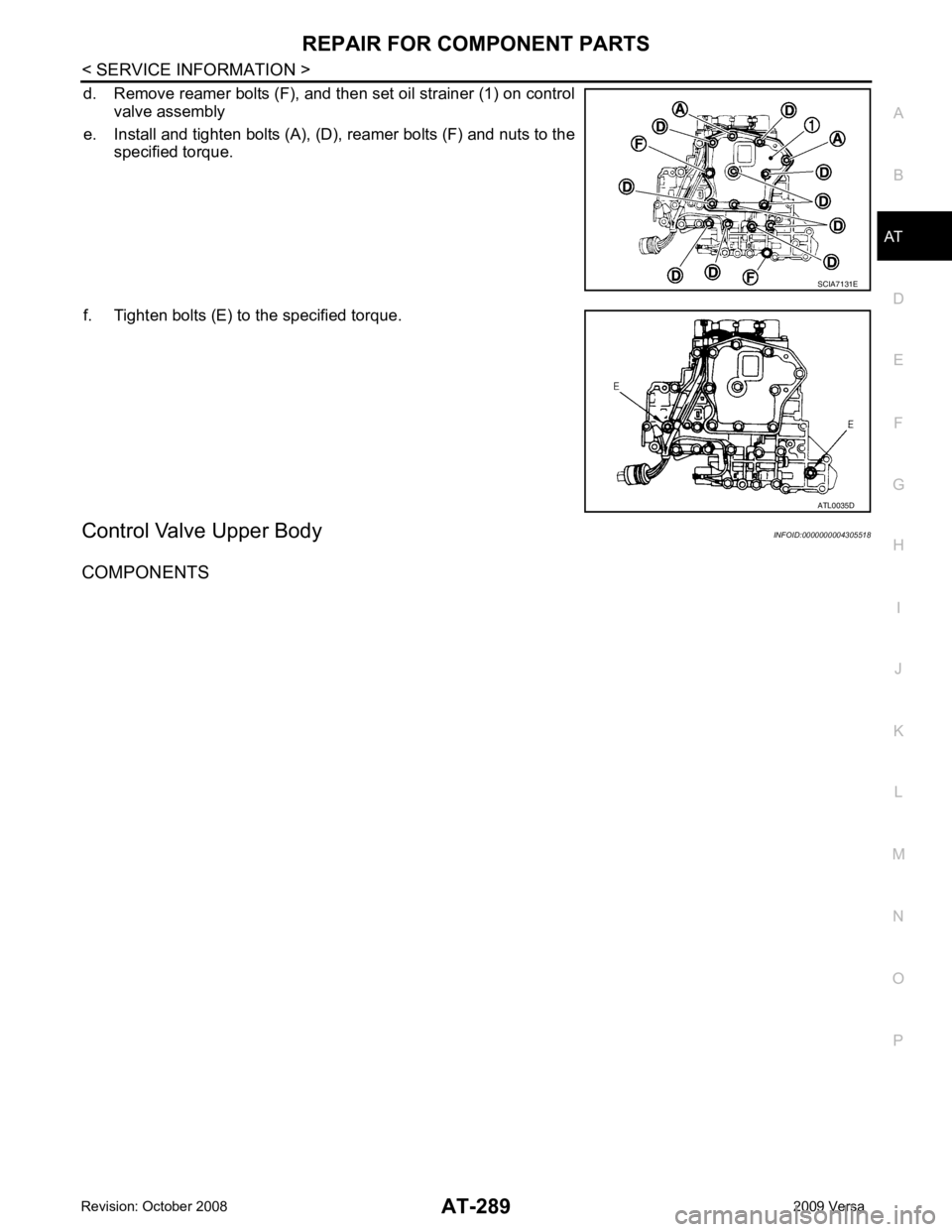

d. Remove reamer bolts (F), and then set oil strainer (1) on control

valve assembly

e. Install and tighten bolts (A), (D), reamer bolts (F) and nuts to the specified torque.

f. Tighten bolts (E) to the specified torque.

Control Valve Upper Body INFOID:0000000004305518

COMPONENTS

Page 296 of 4331

AT

N

O P

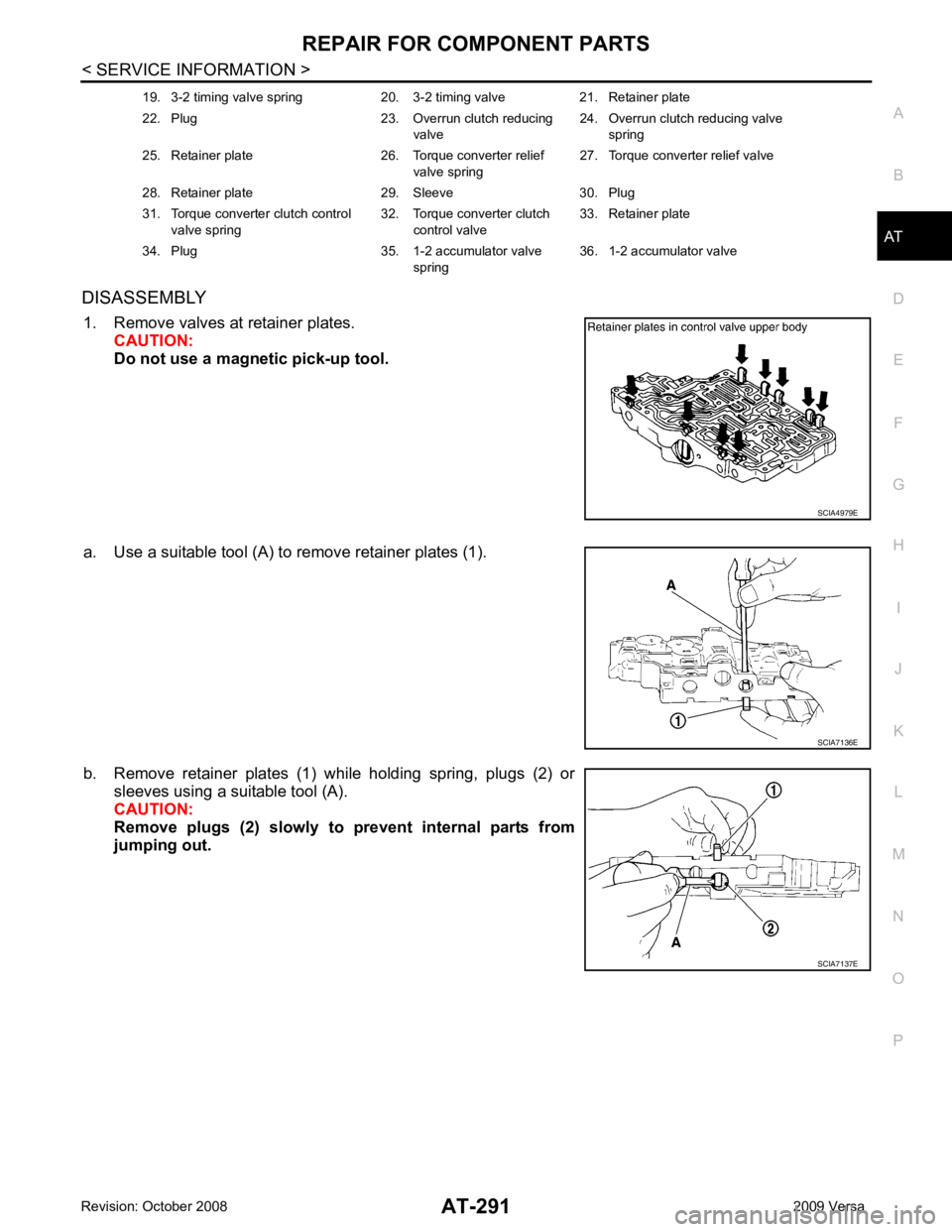

DISASSEMBLY

1. Remove valves at retainer plates. CAUTION:

Do not use a magnetic pick-up tool.

a. Use a suitable tool (A) to remove retainer plates (1).

b. Remove retainer plates (1) while holding spring, plugs (2) or sleeves using a suitable tool (A).

CAUTION:

Remove plugs (2) slowly to prevent internal parts from

jumping out. 19. 3-2 timing valve spring 20. 3-2 timing valve 21. Retainer plate

22. Plug 23. Overrun clutch reducing valve24. Overrun clutch reducing valve

spring

25. Retainer plate 26. Torque converter relief valve spring27. Torque converter relief valve

28. Retainer plate 29. Sleeve 30. Plug

31. Torque converter clutch control valve spring 32. Torque converter clutch

control valve 33. Retainer plate

34. Plug 35. 1-2 accumulator valve spring36. 1-2 accumulator valve

Page 348 of 4331

AT

N

O P

ASSEMBLY

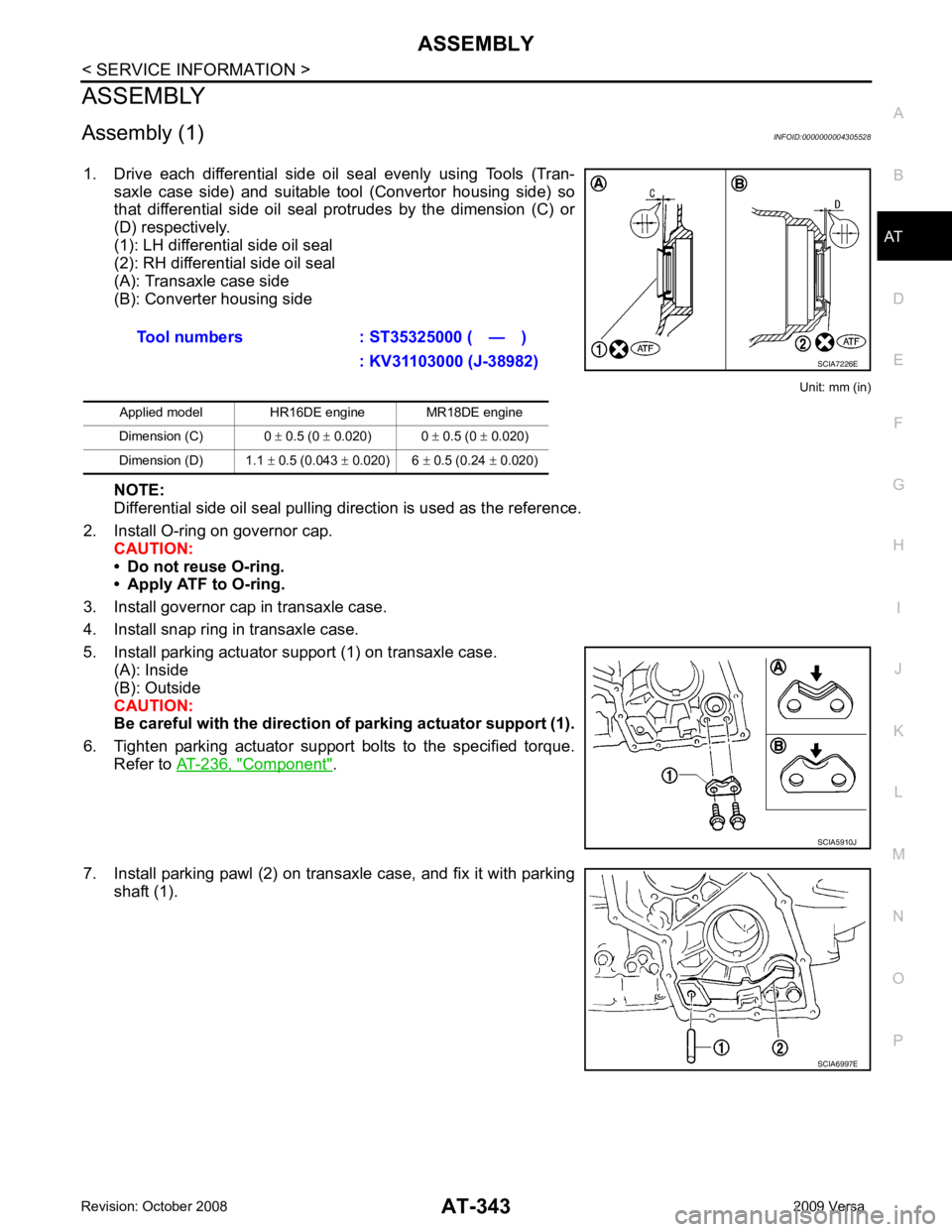

Assembly (1) INFOID:0000000004305528

1. Drive each differential side oil seal evenly using Tools (Tran- saxle case side) and suitable tool (Convertor housing side) so

that differential side oil seal protrudes by the dimension (C) or

(D) respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

Differential side oil seal pulling direction is used as the reference.

2. Install O-ring on governor cap. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case. (A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support bolts to the specified torque. Refer to AT-236, " Component " .

7. Install parking pawl (2) on transaxle case, and fix it with parking shaft (1).Tool numbers : ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DE engine MR18DE engine

Dimension (C) 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension (D) 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

Page 350 of 4331

AT

N

O P

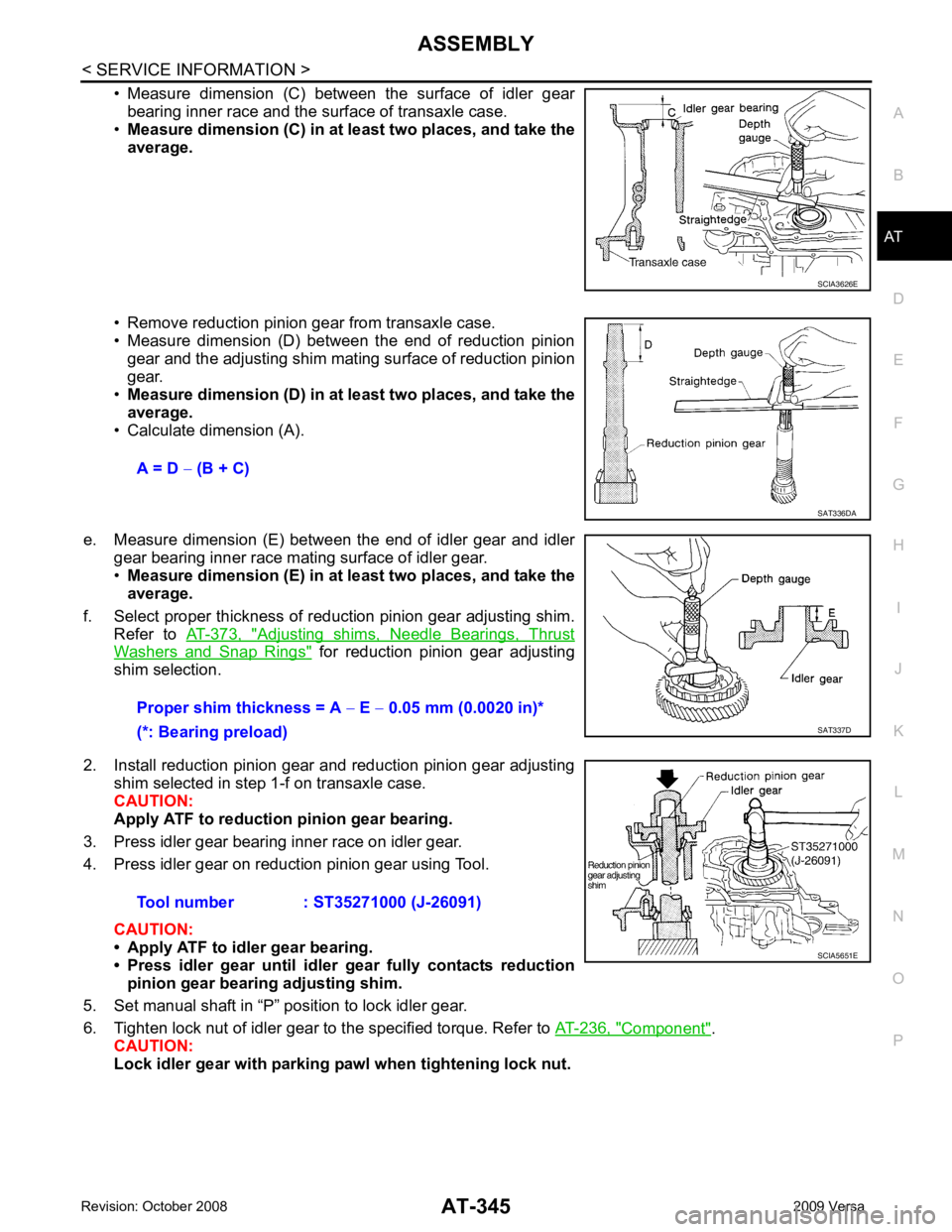

• Measure dimension (C) between the surface of idler gear

bearing inner race and the surface of transaxle case.

• Measure dimension (C) in at least two places, and take the

average.

• Remove reduction pinion gear from transaxle case.

• Measure dimension (D) between the end of reduction pinion gear and the adjusting shim mating surface of reduction pinion

gear.

• Measure dimension (D) in at least two places, and take the

average.

• Calculate dimension (A).

e. Measure dimension (E) between the end of idler gear and idler gear bearing inner race mating surface of idler gear.

• Measure dimension (E) in at least two places, and take the

average.

f. Select proper thickness of reduction pinion gear adjusting shim. Refer to AT-373, " Adjusting shims, Needle Bearings, Thrust

Washers and Snap Rings " for reduction pinion gear adjusting

shim selection.

2. Install reduction pinion gear and reduction pinion gear adjusting shim selected in step 1-f on transaxle case.

CAUTION:

Apply ATF to reduction pinion gear bearing.

3. Press idler gear bearing inner race on idler gear.

4. Press idler gear on reduction pinion gear using Tool.

CAUTION:

• Apply ATF to idler gear bearing.

• Press idler gear until idler gear fully contacts reduction

pinion gear bearin g adjusting shim.

5. Set manual shaft in “P” position to lock idler gear.

6. Tighten lock nut of idler gear to the specified torque. Refer to AT-236, " Component " .

CAUTION:

Lock idler gear with parking pa wl when tightening lock nut.

Page 352 of 4331

ASSEMBLY

AT-347

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

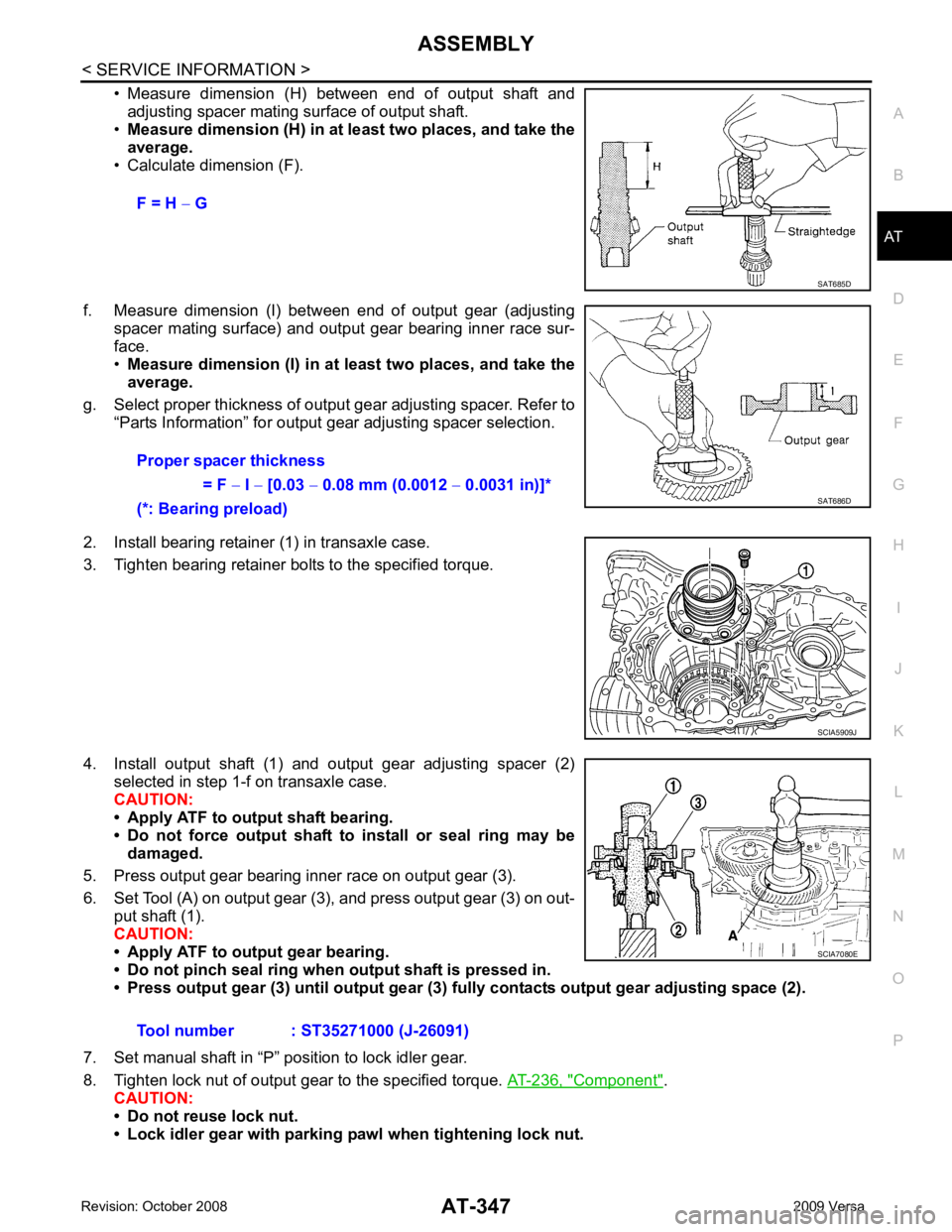

• Measure dimension (H) between end of output shaft and

adjusting spacer mating surface of output shaft.

• Measure dimension (H) in at least two places, and take the

average.

• Calculate dimension (F).

f. Measure dimension (I) betw een end of output gear (adjusting

spacer mating surface) and output gear bearing inner race sur-

face.

• Measure dimension (I) in at least two places, and take the

average.

g. Select proper thickness of output gear adjusting spacer. Refer to “Parts Information” for output gear adjusting spacer selection.

2. Install bearing retainer (1) in transaxle case.

3. Tighten bearing retainer bolts to the specified torque.

4. Install output shaft (1) and output gear adjusting spacer (2) selected in step 1-f on transaxle case.

CAUTION:

• Apply ATF to output shaft bearing.

• Do not force output shaft to install or seal ring may be

damaged.

5. Press output gear bearing inner race on output gear (3).

6. Set Tool (A) on output gear (3), and press output gear (3) on out- put shaft (1).

CAUTION:

• Apply ATF to output gear bearing.

• Do not pinch seal ring when output shaft is pressed in.

• Press output gear (3) until output gear (3 ) fully contacts output gear adjusting space (2).

7. Set manual shaft in “P” position to lock idler gear.

8. Tighten lock nut of output gear to the specified torque. AT-236, " Component " .

CAUTION:

• Do not reuse lock nut.

• Lock idler gear with parking pawl when tightening lock nut. F = H

− G SAT685D

Proper spacer thickness

= F − I − [0.03 − 0.08 mm (0.0012 − 0.0031 in)]*

(*: Bearing preload) SAT686D

SCIA5909J

Tool number : ST35271000 (J-26091) SCIA7080E