check engine NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3740 of 4331

![NISSAN TIIDA 2009 Service Repair Manual OIL FILTER

LU-19

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

OIL FILTER

Removal and Installation INFOID:0000000004307170

REMOVAL 1. Remove oil filter using Tool (A). • : Front

W NISSAN TIIDA 2009 Service Repair Manual OIL FILTER

LU-19

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

OIL FILTER

Removal and Installation INFOID:0000000004307170

REMOVAL 1. Remove oil filter using Tool (A). • : Front

W](/img/5/57398/w960_57398-3739.png)

OIL FILTER

LU-19

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

OIL FILTER

Removal and Installation INFOID:0000000004307170

REMOVAL 1. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine

NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION 1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil- ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION 1. Check the engine oil level. Refer to LU-16, " Inspection " .

2. Start engine, and make sure there are no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust as necessary. Refer to LU-16, " Inspection " .

Tool number : KV10115801 (J-38956) PBIC3818E

SMA010

Oil filter: : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Page 3744 of 4331

MA

N

O P

CONTENTS

MAINTENANCE

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool .................................... ......5

GENERAL MAINTE NANCE ........................... .....6

Explanation of General Maintenance .................. ......6

General Maintenance .......................................... ......6

PERIODIC MAINTENANCE ........................... .....9

Introduction of Periodic Maintenance .................. ......9

Schedule 1 .......................................................... ......9

Schedule 2 .......................................................... ....11

RECOMMENDED FLUIDS AND LUBRI-

CANTS ............................................................ ....

14

Fluids and Lubricants .......................................... ....14

SAE Viscosity Number ........................................ ....14

Anti-freeze Coolant Mixture Ratio ....................... ....15

ENGINE MAINTENANCE (HR16DE) ............. ....16

DRIVE BELT .......................................................... ....16

DRIVE BELT : Checking ..................................... ....16

DRIVE BELT : Tension Adjustment .................... ....16

ENGINE COOLANT ............................................... ....17

ENGINE COOLANT : Inspection ......................... ....17

ENGINE COOLANT : Changing Engine Coolant .... 17

FUEL LINES .......................................................... ....19

FUEL LINES : Checking Fuel Line ...................... ....19

AIR CLEANER FILTER ......................................... ....19 AIR CLEANER FILTER : Re

moval and Installation

....20

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection ..................................... ....20

ENGINE OIL : Draining ........................................ ....22

ENGINE OIL : Refilling ........................................ ....22

OIL FILTER ............................................................ ....22

OIL FILTER : Removal and Installation ...................23

SPARK PLUG (HR16DE) ...................................... ....23

SPARK PLUG (HR16DE) : Exploded View ......... ....24

SPARK PLUG (HR16DE) : Removal and Installa-

tion ....................................................................... ....

24

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Checking EVAP Vapor

Line ...................................................................... ....

25

ENGINE MAINTENANCE (MR18DE) ............... 26

DRIVE BELT .......................................................... ....26

DRIVE BELT : Component .................................. ....26

DRIVE BELT : Checking Drive Belts ................... ....26

DRIVE BELT : Tension Adjustment ..................... ....26

ENGINE COOLANT ............................................... ....26

ENGINE COOLANT : Inspection ......................... ....26

ENGINE COOLANT : Changing Engine Coolant .... 27

FUEL LINES ........................................................... ....29

FUEL LINES : Checking Fuel Line ...................... ....29

AIR CLEANER FILTER ......................................... ....29

AIR CLEANER FILTER : Component .................. ....29

AIR CLEANER FILTER : Changing Air Cleaner

Filter ..................................................................... ....

30

ENGINE OIL ........................................................... ....30

ENGINE OIL : Inspection ..................................... ....30

ENGINE OIL : Changing Engine Oil .................... ....32

OIL FILTER ............................................................ ....33

Page 3748 of 4331

PREPARATION

MA-5

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

PREPARATION

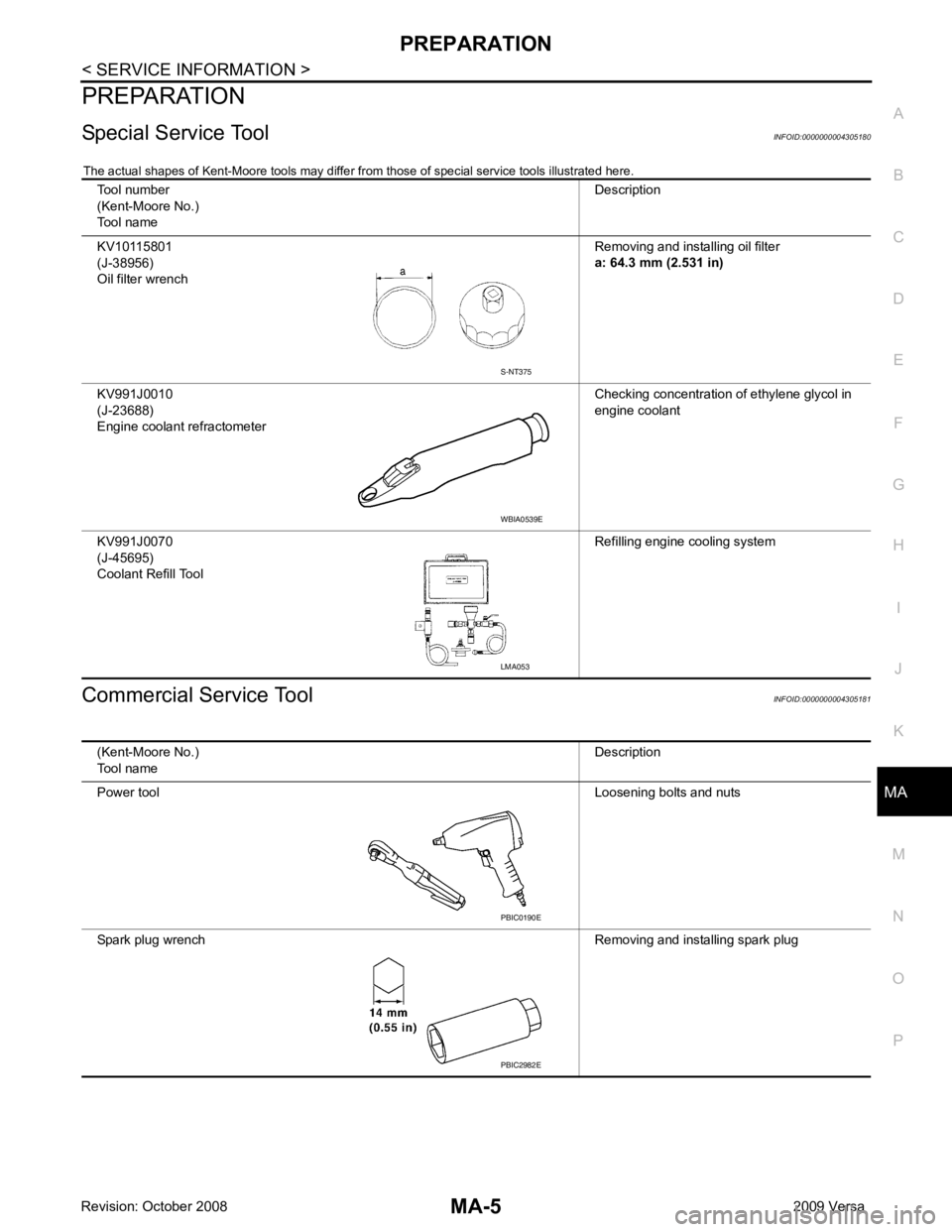

Special Service Tool INFOID:0000000004305180

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004305181

Tool number

(Kent-Moore No.)

Tool name Description

KV10115801

(J-38956)

Oil filter wrench Removing and installing oil filter

a: 64.3 mm (2.531 in)

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system S-NT375

WBIA0539E

LMA053

(Kent-Moore No.)

Tool name Description

Power tool Loosening bolts and nuts

Spark plug wrench Removing and installing spark plug PBIC0190E

PBIC2982E

Page 3750 of 4331

MA

N

O P

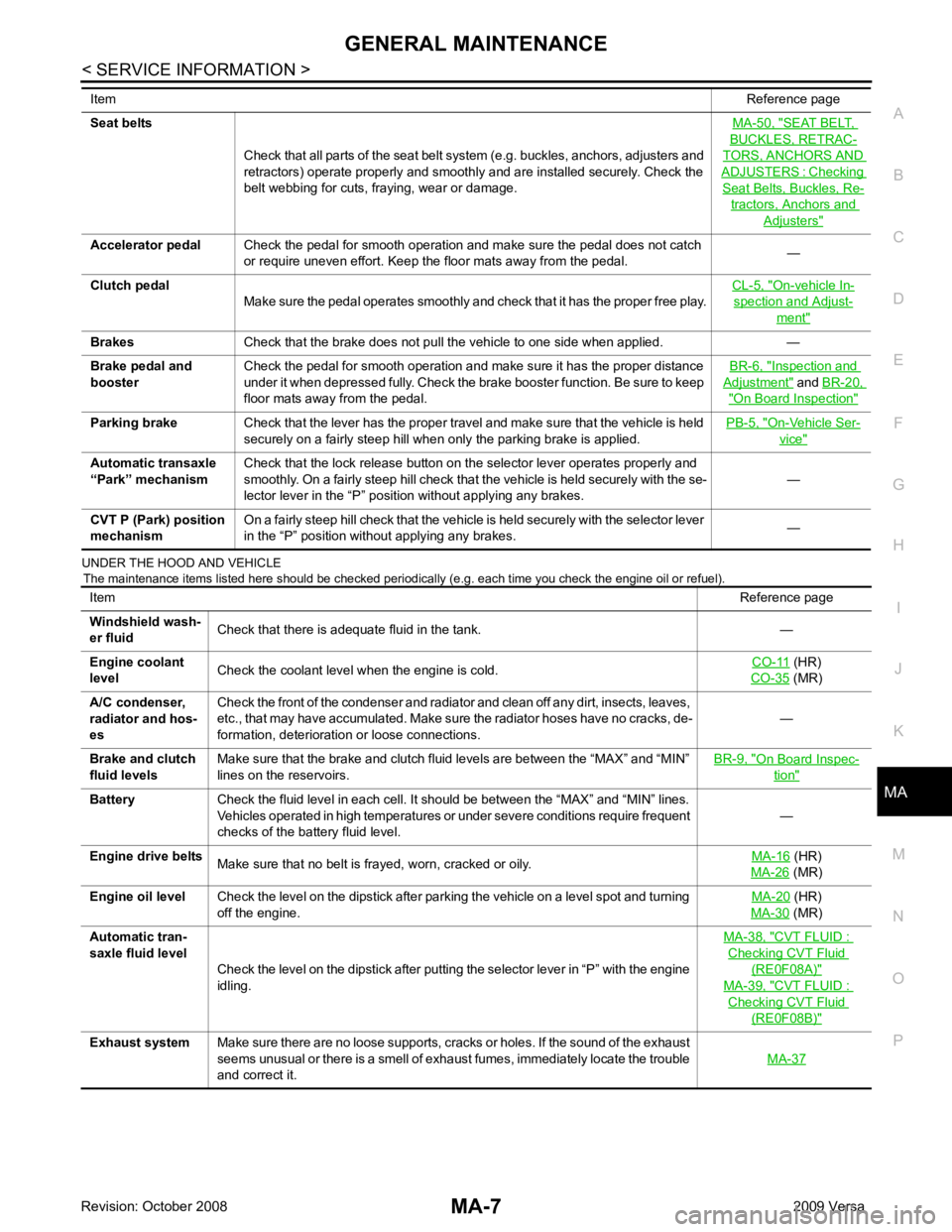

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat belts

Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-50, " SEAT BELT,

BUCKLES, RETRAC-

TORS, ANCHORS AND

ADJUSTERS : Checking

Seat Belts, Buckles, Re-

tractors, Anchors and

Adjusters "

On-vehicle In-

spection and Adjust-

ment "

Inspection and

Adjustment " and

BR-20, " On Board Inspection "

On-Vehicle Ser-

vice "

Item

Reference page

Windshield wash-

er fluid Check that there is adequate fluid in the tank. —

Engine coolant

level Check the coolant level when the engine is cold. CO-11 (HR)

CO-35 (MR)

A/C condenser,

radiator and hos-

es Check the front of the condenser and radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure the radiator hoses have no cracks, de-

formation, deterioration or loose connections. —

Brake and clutch

fluid levels Make sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs. BR-9, " On Board Inspec-

tion "

(HR)

MA-26 (MR)

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turning

off the engine. MA-20 (HR)

MA-30 (MR)

Automatic tran-

saxle fluid level Check the level on the dipstick after putting the selector lever in “P” with the engine

idling. MA-38, " CVT FLUID :

Checking CVT Fluid

(RE0F08A) "

MA-39, " CVT FLUID :

Checking CVT Fluid

(RE0F08B) "

Page 3759 of 4331

MA-16< SERVICE INFORMATION >

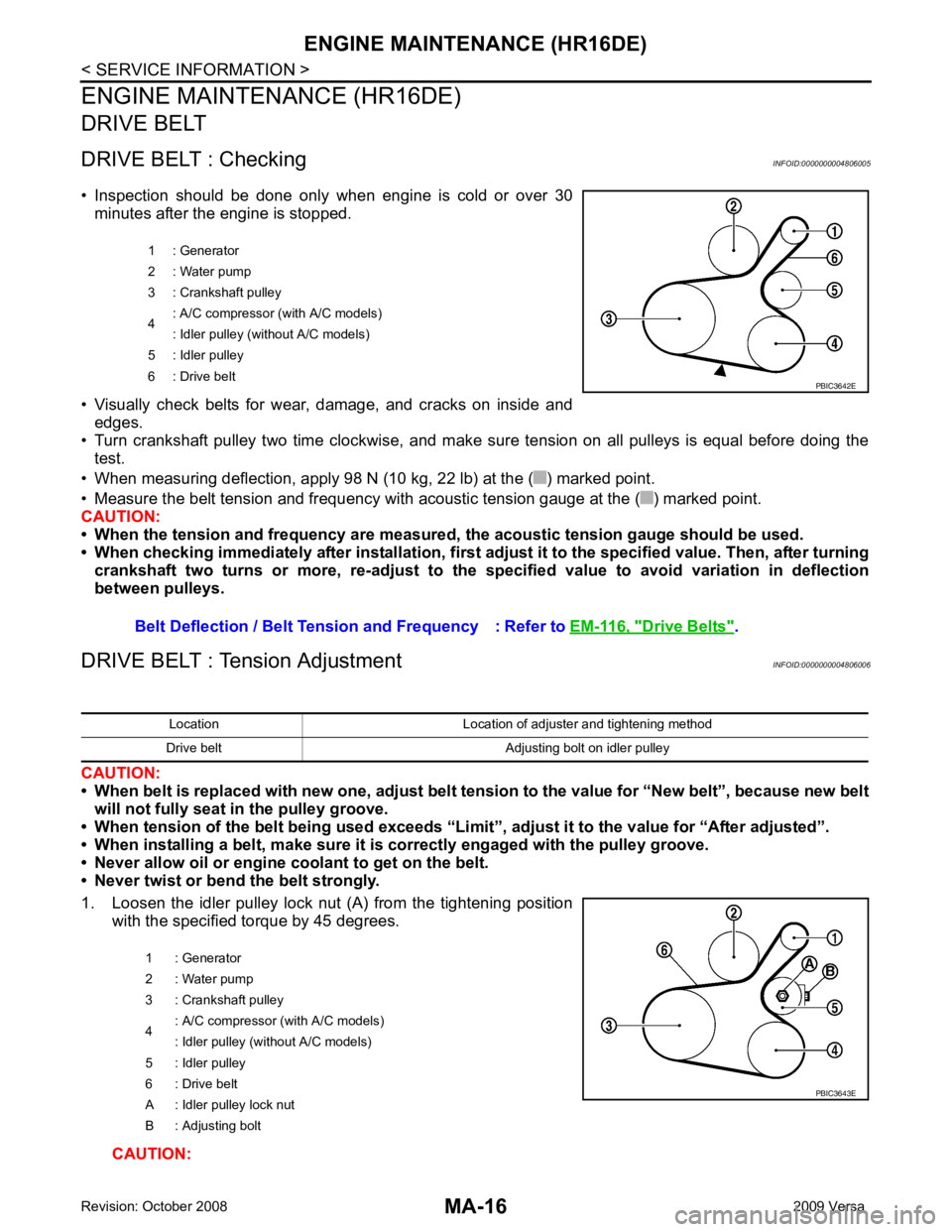

ENGINE MAINTENANCE (HR16DE)

ENGINE MAINTENANCE (HR16DE)

DRIVE BELT

DRIVE BELT : Checking INFOID:0000000004806005

• Inspection should be done only when engine is cold or over 30 minutes after the engine is stopped.

• Visually check belts for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley two time clockwise, and make sure tension on all pulleys is equal before doing the test.

• When measuring deflection, apply 98 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency with acous tic tension gauge at the ( ) marked point.

CAUTION:

• When the tension and frequency are measured, the acoustic tension gauge should be used.

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, re-adjust to the sp ecified value to avoid variation in deflection

between pulleys.

DRIVE BELT : Tension Adjustment INFOID:0000000004806006

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New belt”, because new belt

will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

• When installing a belt, make sure it is correctly engaged with the pulley groove.

• Never allow oil or engine coolant to get on the belt.

• Never twist or bend the belt strongly.

1. Loosen the idler pulley lock nut (A) from the tightening position with the specified torque by 45 degrees.

CAUTION: 1 : Generator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt

Belt Deflection / Belt Tension and Frequency : Refer to EM-116, " Drive Belts " . PBIC3642E

Location Location of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

1 : Generator

2 : Water pump

3 : Crankshaft pulley

4 : A/C compressor

(with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt

A : Idler pulley lock nut

B : Adjusting bolt PBIC3643E

Page 3760 of 4331

ENGINE MAINTENANCE (HR16DE)

MA-17

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

• When the lock nut is loosened excessively, the idle

r pulley tilts and the correct tension adjust-

ment cannot be performed. Never loo sen it excessively (more than 45 degrees).

• Put a matching mark on the lock nut, and check turning angle with a protractor. Never visually

check the tightening angle.

2. Adjust the belt tension by turning the adjusting bolt. CAUTION:

• When checking immediately after in stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflec-

tion between pulleys.

• When the tension adjustment is performed, the lo ck nut should be in the condition at step“2”. If

the tension adjustment is performed when the lo ck nut is loosened more than the standard, the

idler pulley tilts and the correct tens ion adjustment cannot be performed.

3. Tighten the idler pulley lock nut.

ENGINE COOLANT

ENGINE COOLANT : Inspection INFOID:0000000004806014

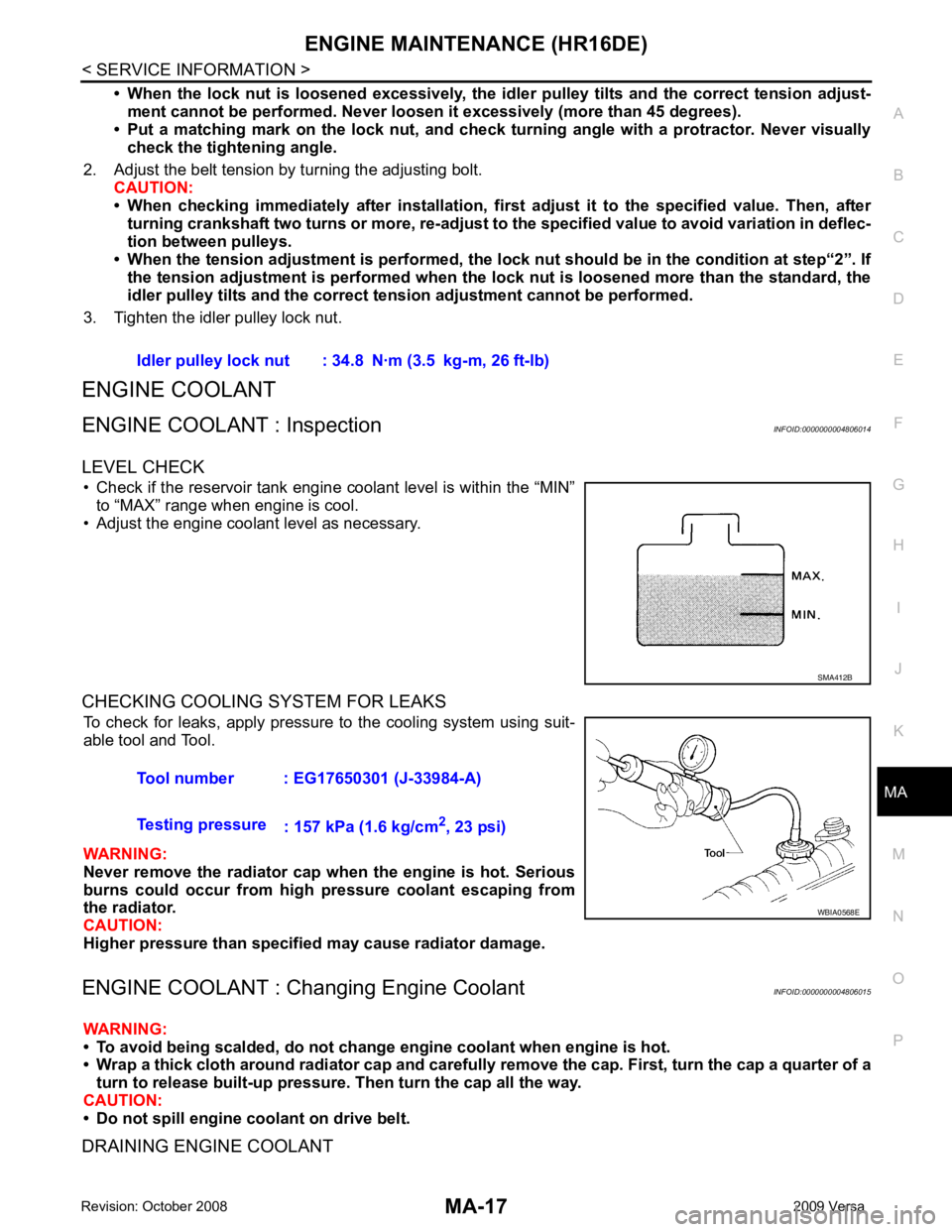

LEVEL CHECK • Check if the reservoir tank engine coolant level is within the “MIN” to “MAX” range when engine is cool.

• Adjust the engine coolant level as necessary.

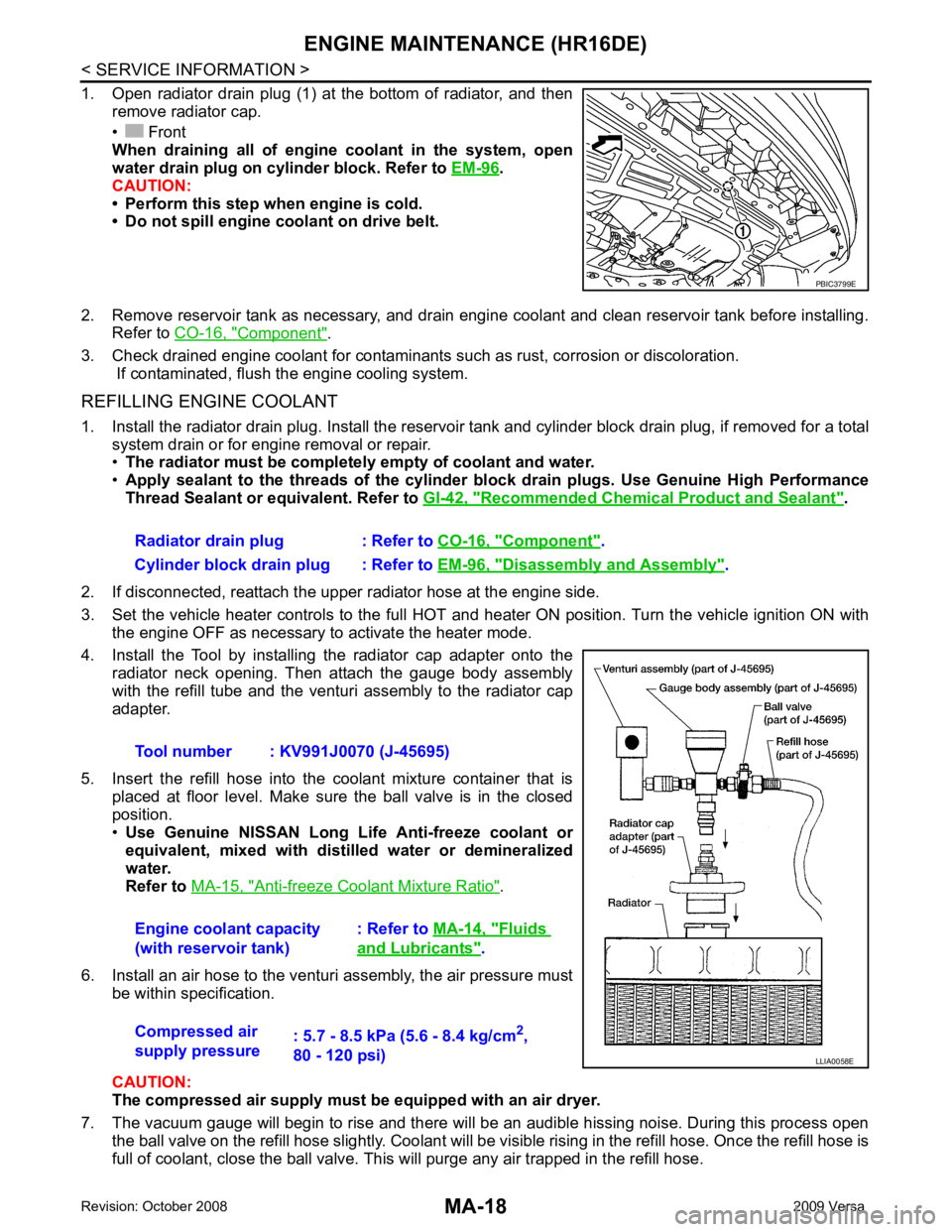

CHECKING COOLING SYSTEM FOR LEAKS To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine Coolant INFOID:0000000004806015

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT Idler pulley lock nut : 34.8 N·m (3.5 kg-m, 26 ft-lb)

SMA412B

Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm 2

, 23 psi) WBIA0568E

Page 3761 of 4331

MA-18< SERVICE INFORMATION >

ENGINE MAINTENANCE (HR16DE)

1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-96 .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-16, " Component " .

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose. PBIC3799E

Radiator drain plug : Refer to

CO-16, " Component " .

Cylinder block drain plug : Refer to EM-96, " Disassembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi) LLIA0058E

Page 3762 of 4331

ENGINE MAINTENANCE (HR16DE)

MA-19

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

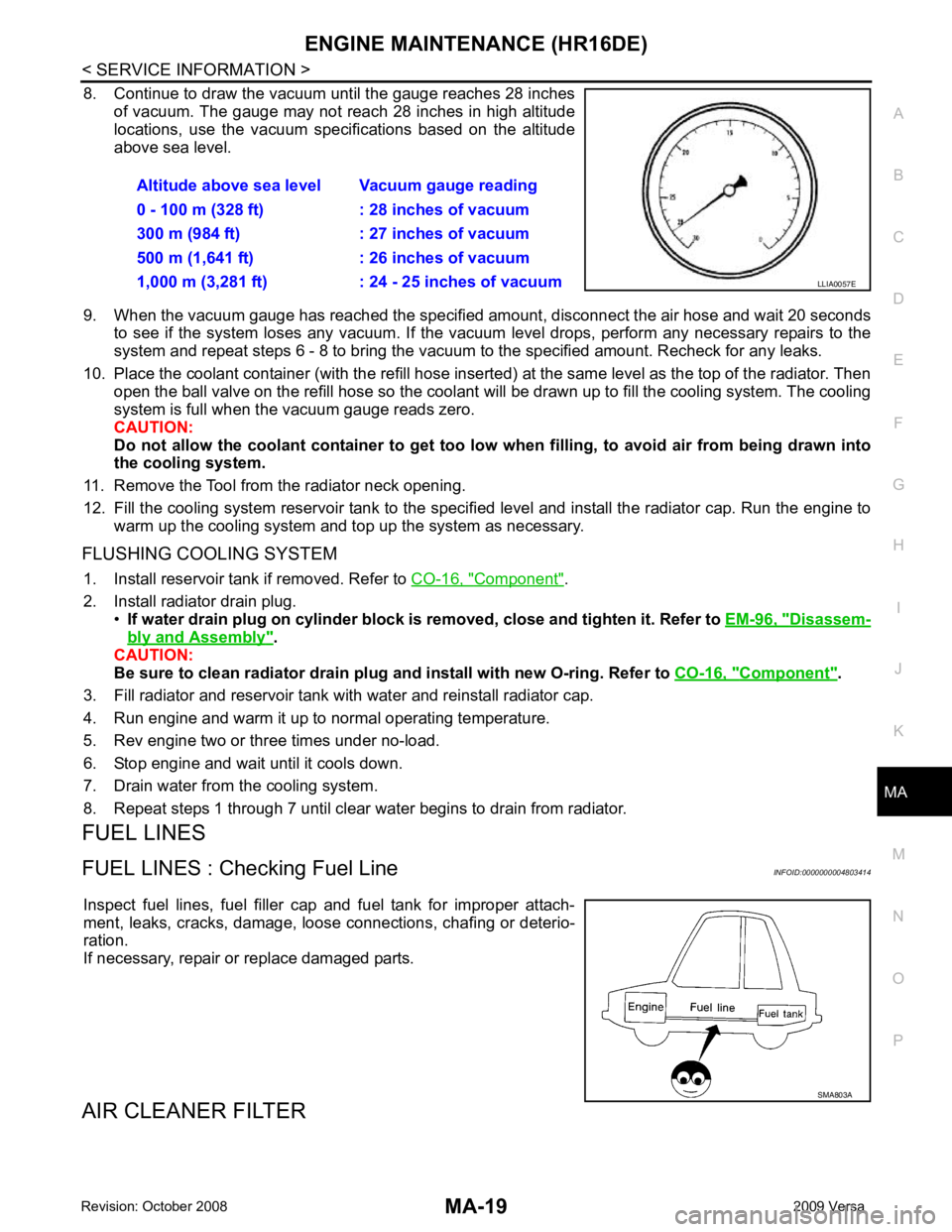

8. Continue to draw the vacuum until the gauge reaches 28 inches

of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

FLUSHING COOLING SYSTEM 1. Install reservoir tank if removed. Refer to CO-16, " Component " .

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-96, " Disassem-

bly and Assembly " .

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, " Component " .

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : Checking Fuel Line INFOID:0000000004803414

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum LLIA0057E

SMA803A

Page 3763 of 4331

MA-20< SERVICE INFORMATION >

ENGINE MAINTENANCE (HR16DE)

AIR CLEANER FILTER : Removal and Installation INFOID:0000000004806007

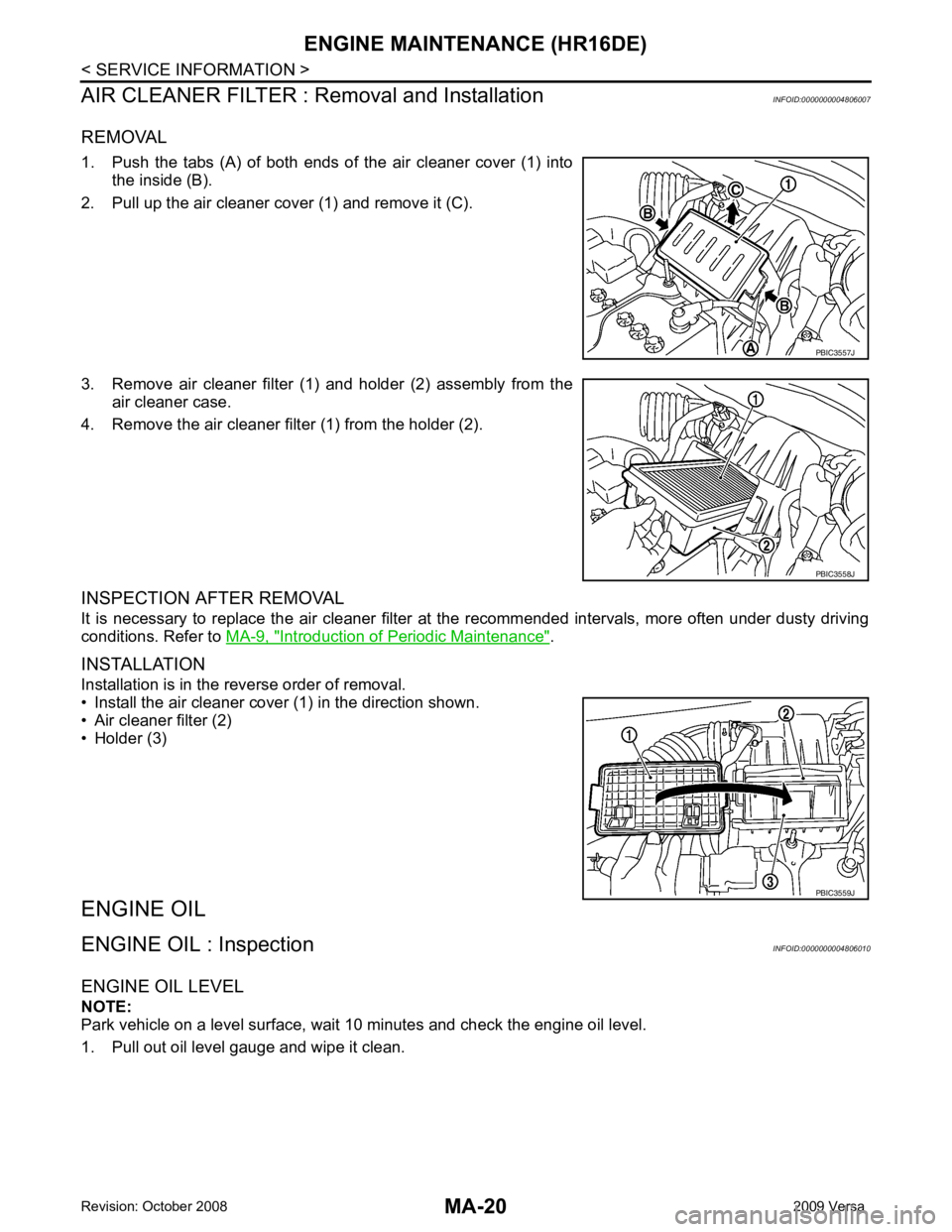

REMOVAL

1. Push the tabs (A) of both ends of the air cleaner cover (1) into the inside (B).

2. Pull up the air cleaner cover (1) and remove it (C).

3. Remove air cleaner filter (1) and holder (2) assembly from the air cleaner case.

4. Remove the air cleaner filter (1) from the holder (2).

INSPECTION AFTER REMOVAL

It is necessary to replace the air cleaner filter at the recommended intervals, more often under dusty driving

conditions. Refer to MA-9, " Introduction of Periodic Maintenance " .

INSTALLATION

Installation is in the reverse order of removal.

• Install the air cleaner cover (1) in the direction shown.

• Air cleaner filter (2)

• Holder (3)

ENGINE OIL

ENGINE OIL : Inspection INFOID:0000000004806010

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level surface, wait 10 minutes and check the engine oil level.

1. Pull out oil level gauge and wipe it clean. PBIC3557J

PBIC3558J

PBIC3559J

Page 3764 of 4331

ENGINE MAINTENANCE (HR16DE)

MA-21

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

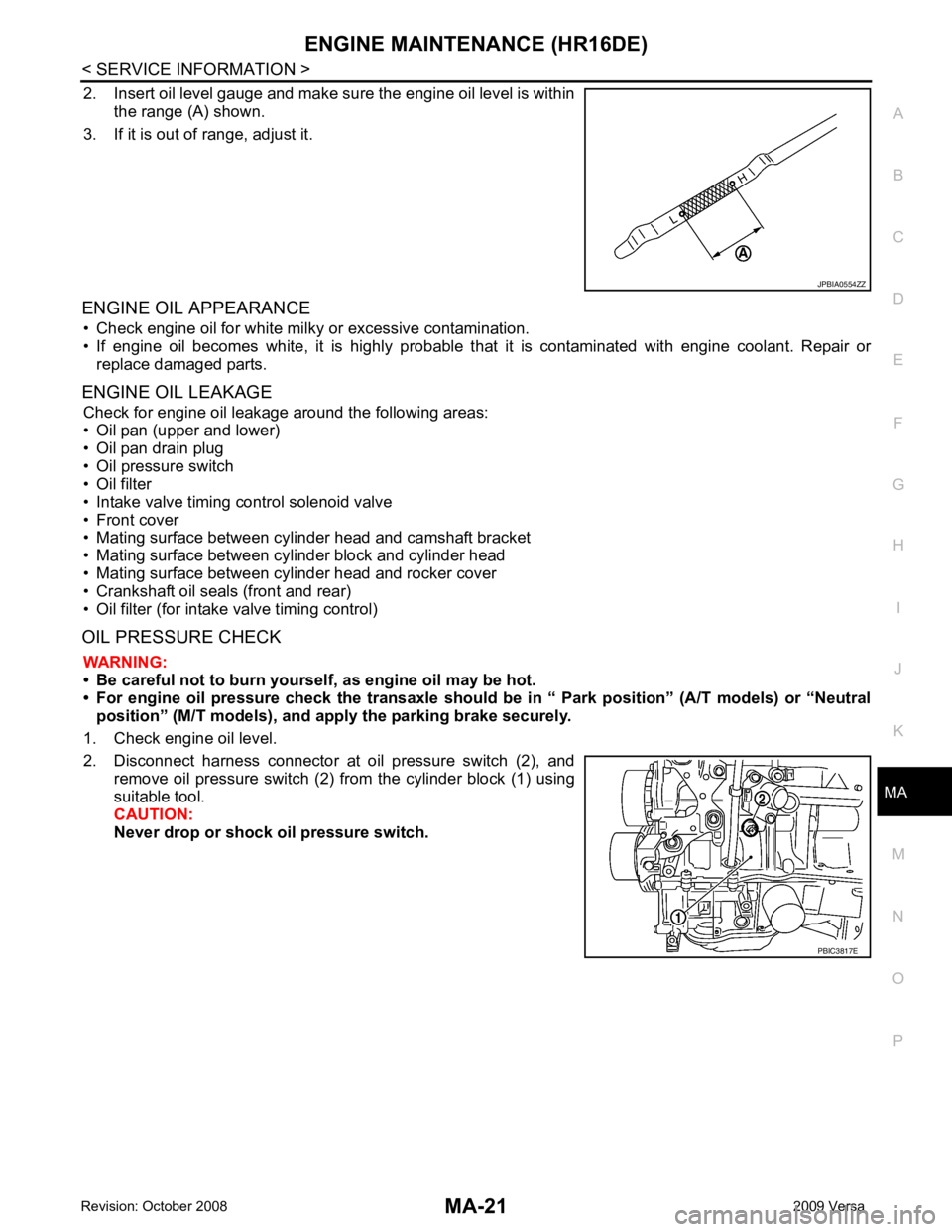

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE • Check engine oil for white milky or excessive contamination.

• If engine oil becomes white, it is highly probable t hat it is contaminated with engine coolant. Repair or

replace damaged parts.

ENGINE OIL LEAKAGE Check for engine oil leakage around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder head and camshaft bracket

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

OIL PRESSURE CHECK WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• For engine oil pressure check the transaxle should be in “ Park position” (A/T models) or “Neutral

position” (M/T models), and apply the parking brake securely.

1. Check engine oil level.

2. Disconnect harness connector at oil pressure switch (2), and remove oil pressure switch (2) from the cylinder block (1) using

suitable tool.

CAUTION:

Never drop or shock oil pressure switch. JPBIA0554ZZ

PBIC3817E