oil temperature NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3729 of 4331

Engine Oil Pressure " .

If difference is extreme, check oil passage and oil pump for oil leaks.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

6. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification. Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product

and Sealant " .

c. Check engine oil level.

d. After warming up engine, make sure there are no leaks of engine oil with running engine.

Draining INFOID:0000000004784338

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, park vehicle on a level surface and check for engine oil leakage from engine compo- nents. Refer to LU-7, " Inspection " .

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

Refilling INFOID:0000000004784339

1. Install drain plug with new washer. Refer to EM-39, " Exploded View " .

CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specification and viscosity: Refer to MA-14, " Fluids and Lubricants " .

CAUTION:

• The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

• Always use oil level gauge to determine the pr oper amount of engine oil in the engine.

3. Warm up engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, " Inspection " .

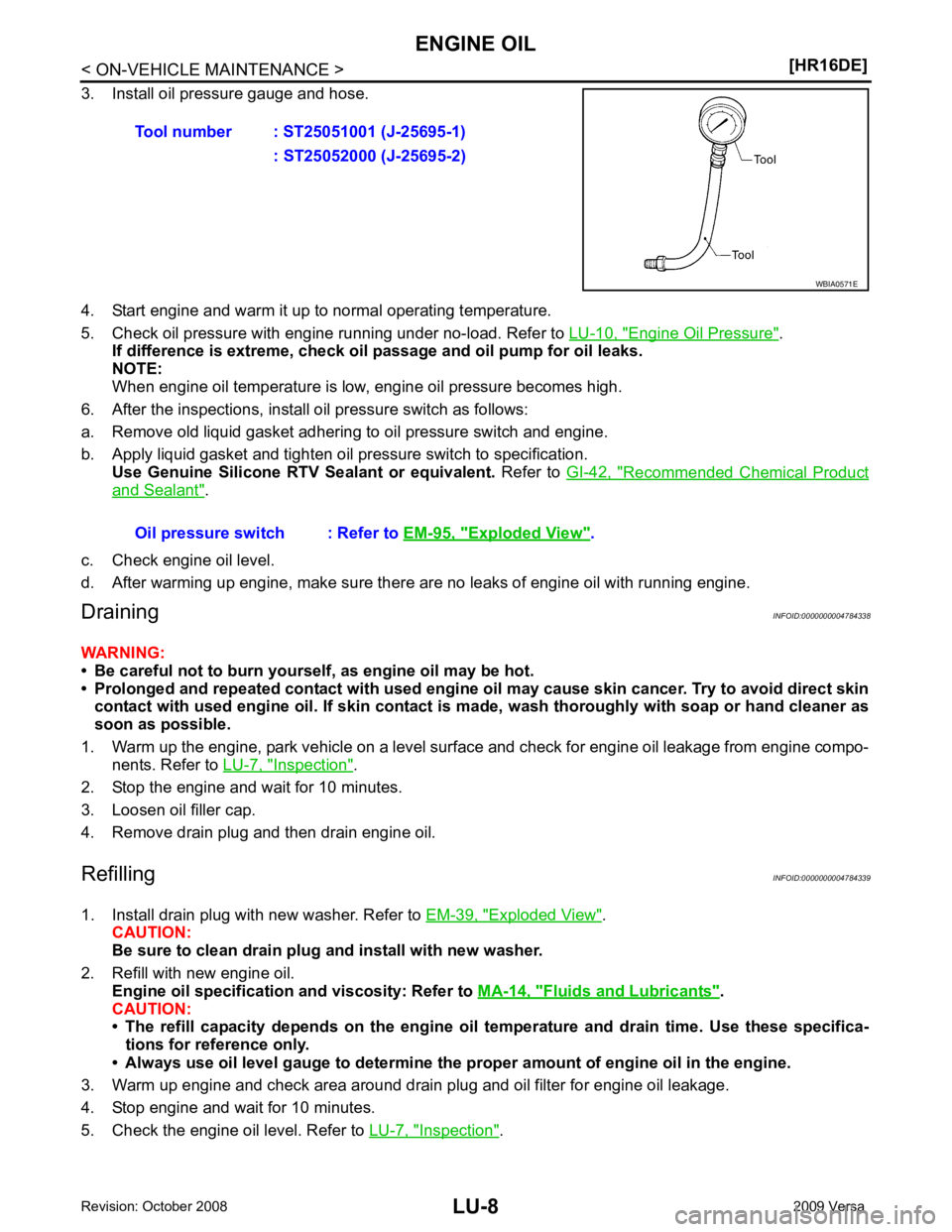

Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2) Exploded View " .

Page 3738 of 4331

![NISSAN TIIDA 2009 Service Manual PDF ENGINE OIL

LU-17

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

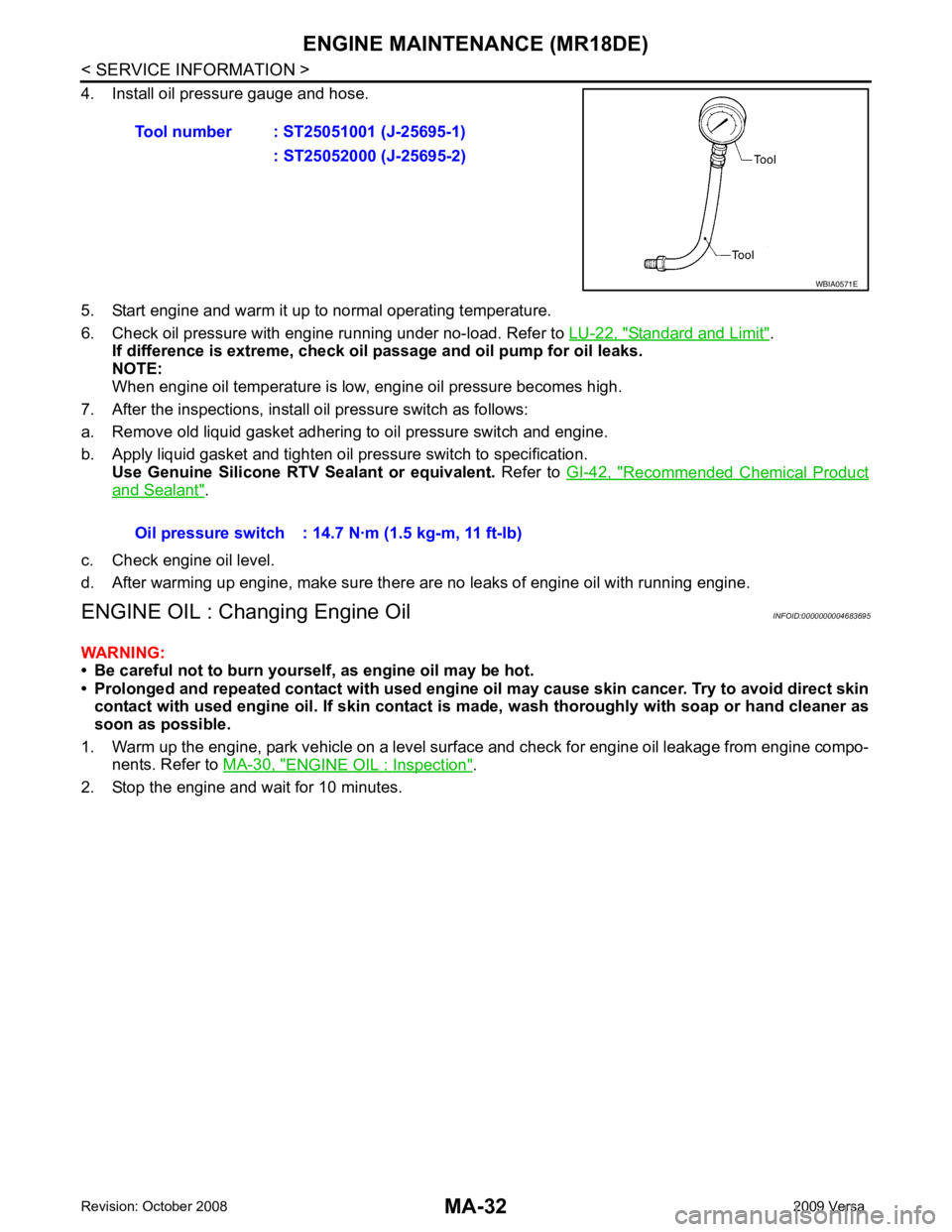

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil p NISSAN TIIDA 2009 Service Manual PDF ENGINE OIL

LU-17

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil p](/img/5/57398/w960_57398-3737.png)

ENGINE OIL

LU-17

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load. Refer to LU-22, " Standard and Limit " .

If difference is extreme, check oi l passage and oil pump for oil leaks.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

7. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification. Use Genuine Silicone RT V Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product

and Sealant " .

c. Check engine oil level.

d. After warming up engine, make sure there are no leaks of engine oil with running engine.

Changing Engine Oil INFOID:0000000004307169

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thorough ly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, park vehicle on a level surf ace and check for engine oil leakage from engine compo-

nents. Refer to LU-16, " Inspection " .

2. Stop the engine and wait for 10 minutes. Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2) WBIA0571E

Oil pressure switch : 14.7 N·

m (1.5 kg-m, 11 ft-lb)

Page 3739 of 4331

Com-

ponent " .

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14 .

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these specifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to LU-16, " Inspection " .

Page 3752 of 4331

MA

N

O P

PERIODIC MAINTENANCE

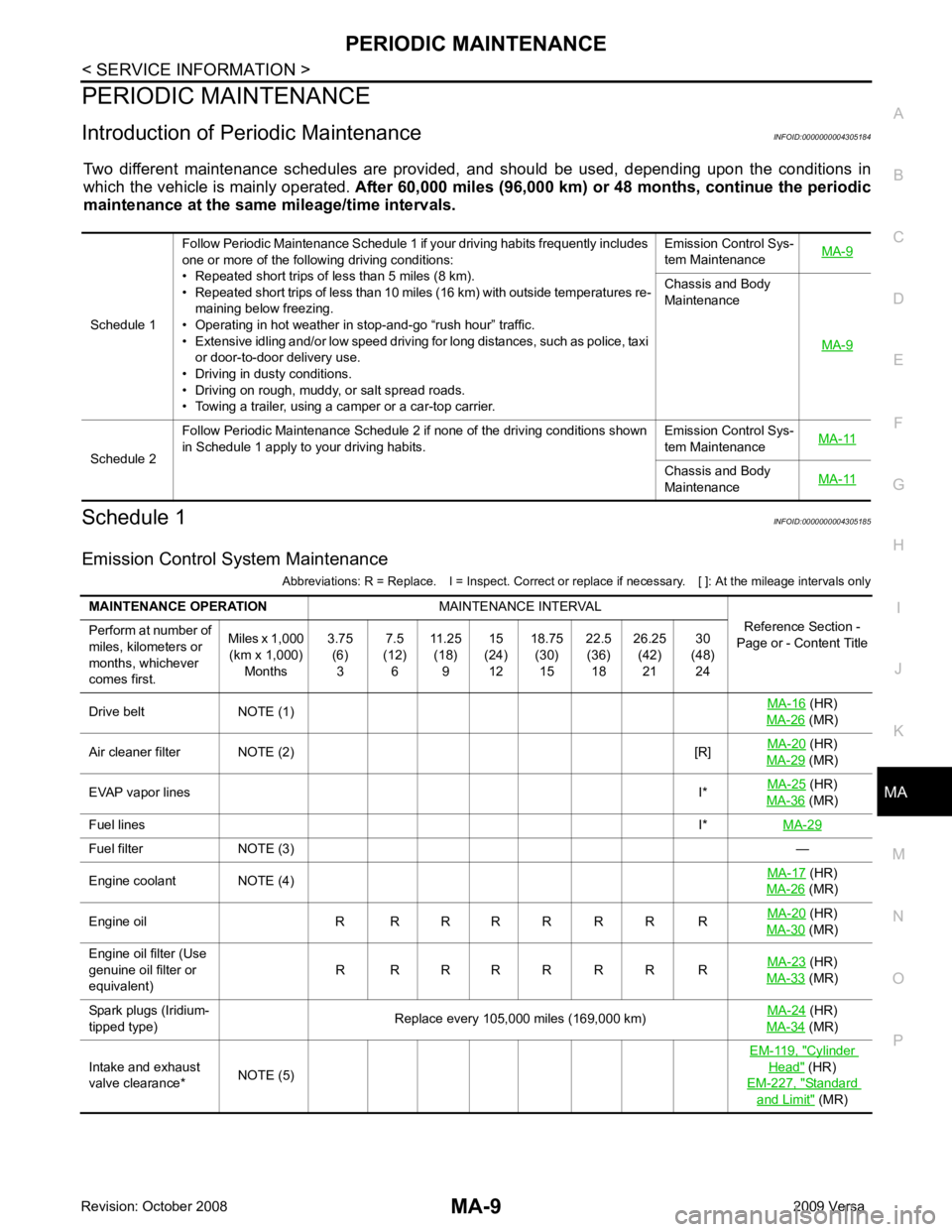

Introduction of Periodic Maintenance INFOID:0000000004305184

Two different maintenance schedules are provi ded, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1 INFOID:0000000004305185

Emission Control System Maintenance Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Schedule 1

Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re- maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance MA-9 Chassis and Body

Maintenance

MA-9Schedule 2

Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to your driving habits. Emission Control Sys-

tem Maintenance MA-11 Chassis and Body

Maintenance MA-11 (HR)

MA-26 (MR)

Air cleaner filter NOTE (2) [R]MA-20 (HR)

MA-29 (MR)

EVAP vapor lines I*MA-25 (HR)

MA-36 (MR)

Fuel lines I*MA-29 Fuel filter NOTE (3)

—

Engine coolant NOTE (4) MA-17 (HR)

MA-26 (MR)

Engine oil R R R R R R R R MA-20 (HR)

MA-30 (MR)

Engine oil filter (Use

genuine oil filter or

equivalent) R R R R R R R R

MA-23 (HR)

MA-33 (MR)

Spark plugs (Iridium-

tipped type) Replace every 105,000 miles (169,000 km)

MA-24 (HR)

MA-34 (MR)

Intake and exhaust

valve clearance* NOTE (5) EM-119, " Cylinder

Head " (HR)

EM-227, " Standard

and Limit " (MR)

Page 3765 of 4331

MA-22< SERVICE INFORMATION >

ENGINE MAINTENANCE (HR16DE)

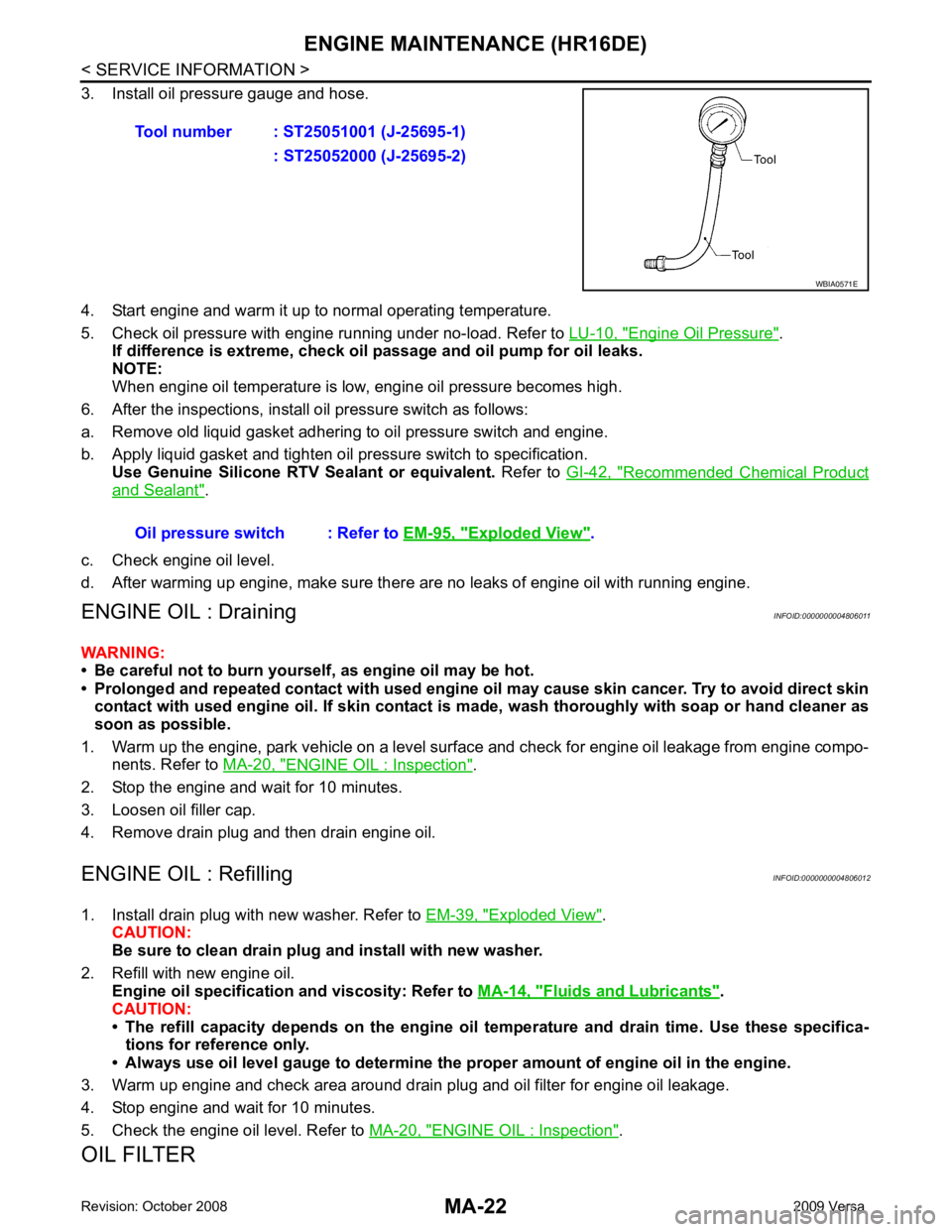

3. Install oil pressure gauge and hose.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load. Refer to LU-10, " Engine Oil Pressure " .

If difference is extreme, check oil passage and oil pump for oil leaks.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

6. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification. Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product

and Sealant " .

c. Check engine oil level.

d. After warming up engine, make sure there are no leaks of engine oil with running engine.

ENGINE OIL : Draining INFOID:0000000004806011

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, park vehicle on a level surface and check for engine oil leakage from engine compo- nents. Refer to MA-20, " ENGINE OIL : Inspection " .

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

ENGINE OIL : Refilling INFOID:0000000004806012

1. Install drain plug with new washer. Refer to EM-39, " Exploded View " .

CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specification and viscosity: Refer to MA-14, " Fluids and Lubricants " .

CAUTION:

• The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

• Always use oil level gauge to determine the pr oper amount of engine oil in the engine.

3. Warm up engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to MA-20, " ENGINE OIL : Inspection " .

OIL FILTER Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2) WBIA0571E

Oil pressure switch : Refer to

EM-95, " Exploded View " .

Page 3775 of 4331

MA-32< SERVICE INFORMATION >

ENGINE MAINTENANCE (MR18DE)

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load. Refer to LU-22, " Standard and Limit " .

If difference is extreme, check oil passage and oil pump for oil leaks.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

7. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification. Use Genuine Silicone RTV Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product

and Sealant " .

c. Check engine oil level.

d. After warming up engine, make sure there are no leaks of engine oil with running engine.

ENGINE OIL : Changing Engine Oil INFOID:0000000004683695

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause ski n cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, park vehicle on a level surface and check for engine oil leakage from engine compo- nents. Refer to MA-30, " ENGINE OIL : Inspection " .

2. Stop the engine and wait for 10 minutes. Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2) WBIA0571E

Oil pressure switch : 14.7 N·m (1.5 kg-m, 11 ft-lb)

Page 3776 of 4331

ENGINE MAINTENANCE (MR18DE)

MA-33

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

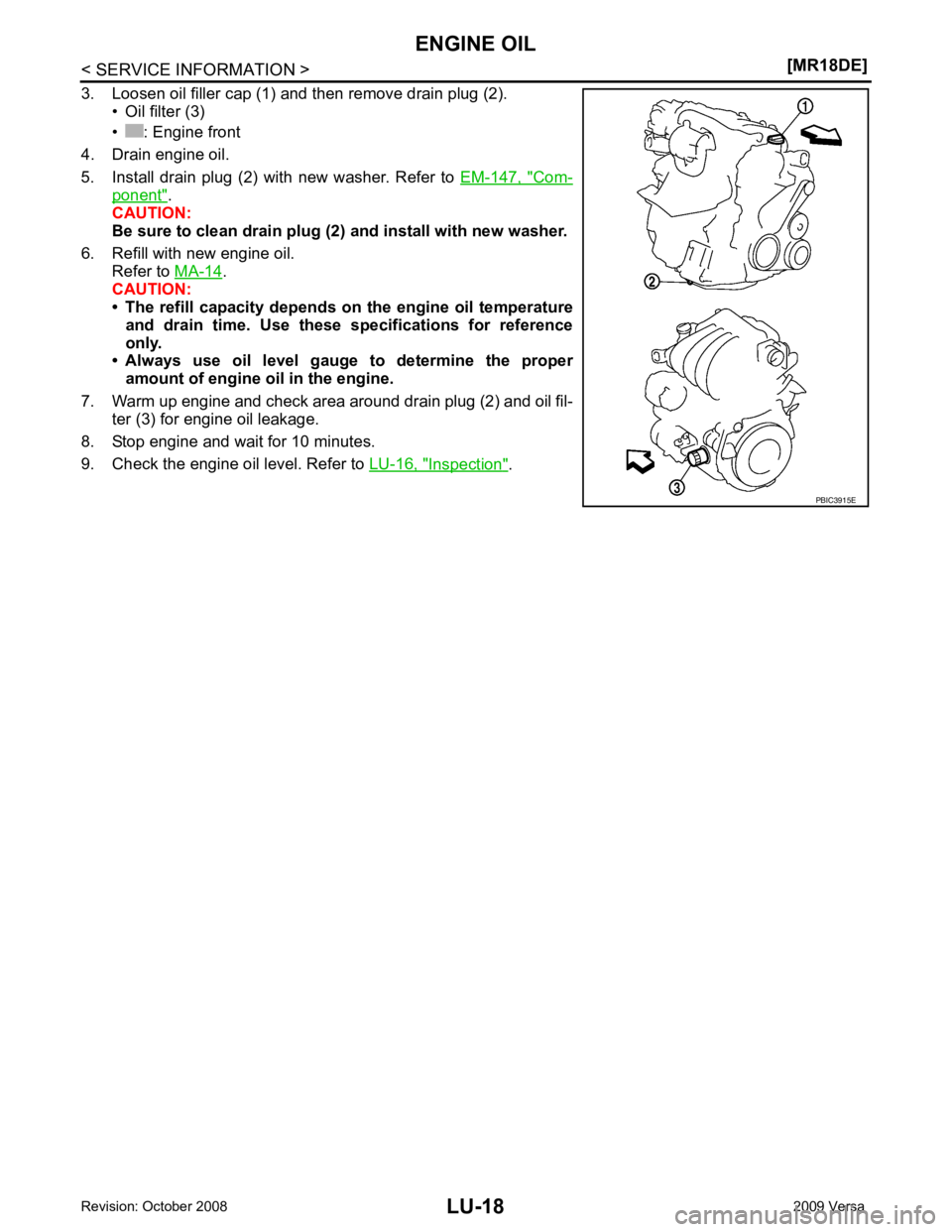

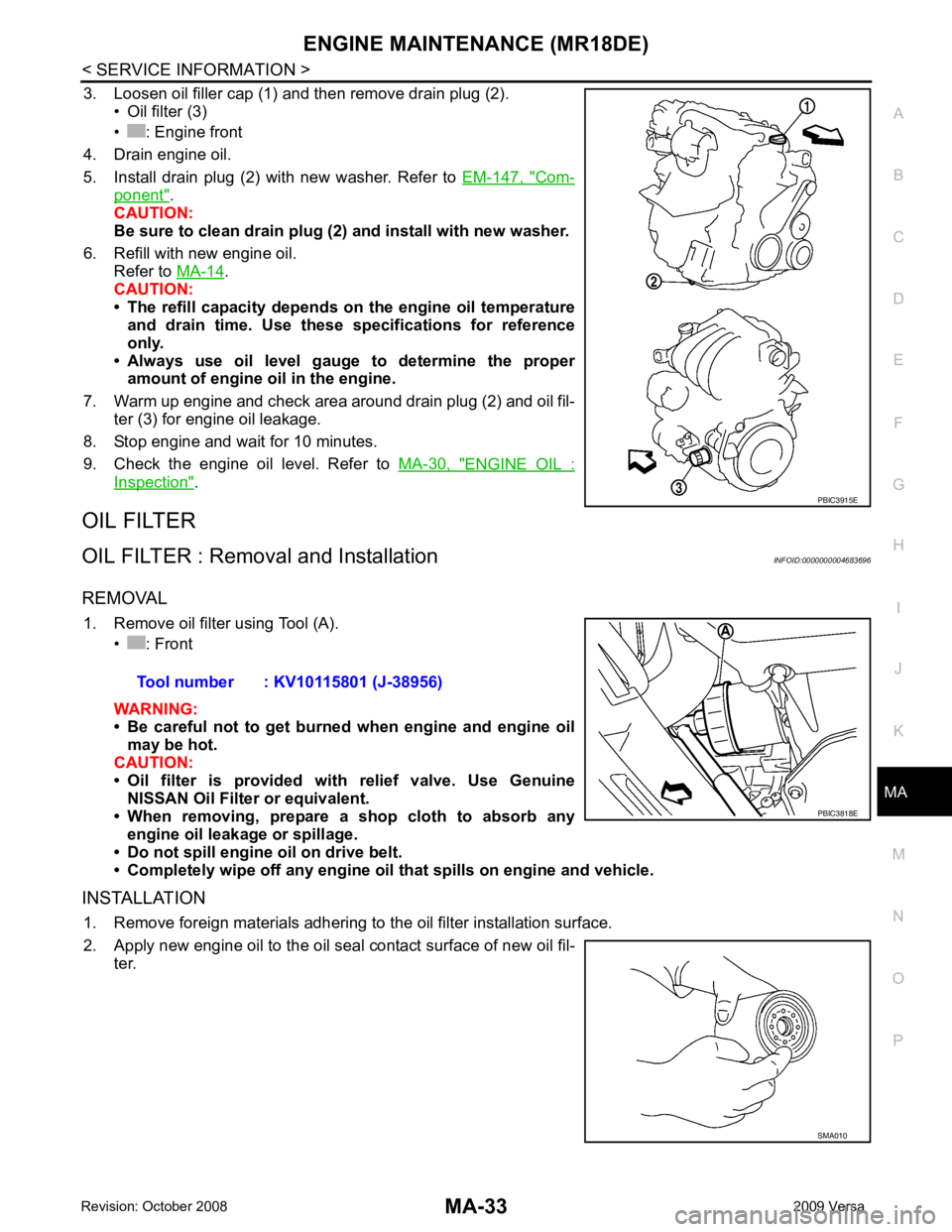

3. Loosen oil filler cap (1) and then remove drain plug (2).

• Oil filter (3)

• : Engine front

4. Drain engine oil.

5. Install drain plug (2) with new washer. Refer to EM-147, " Com-

ponent " .

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14 .

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these sp ecifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to MA-30, " ENGINE OIL :

Inspection " .

OIL FILTER

OIL FILTER : Remova l and Installation INFOID:0000000004683696

REMOVAL 1. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION 1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil- ter. PBIC3915E

Tool number : KV10115801 (J-38956)

PBIC3818E

SMA010

Page 3892 of 4331

MTC

N

O P

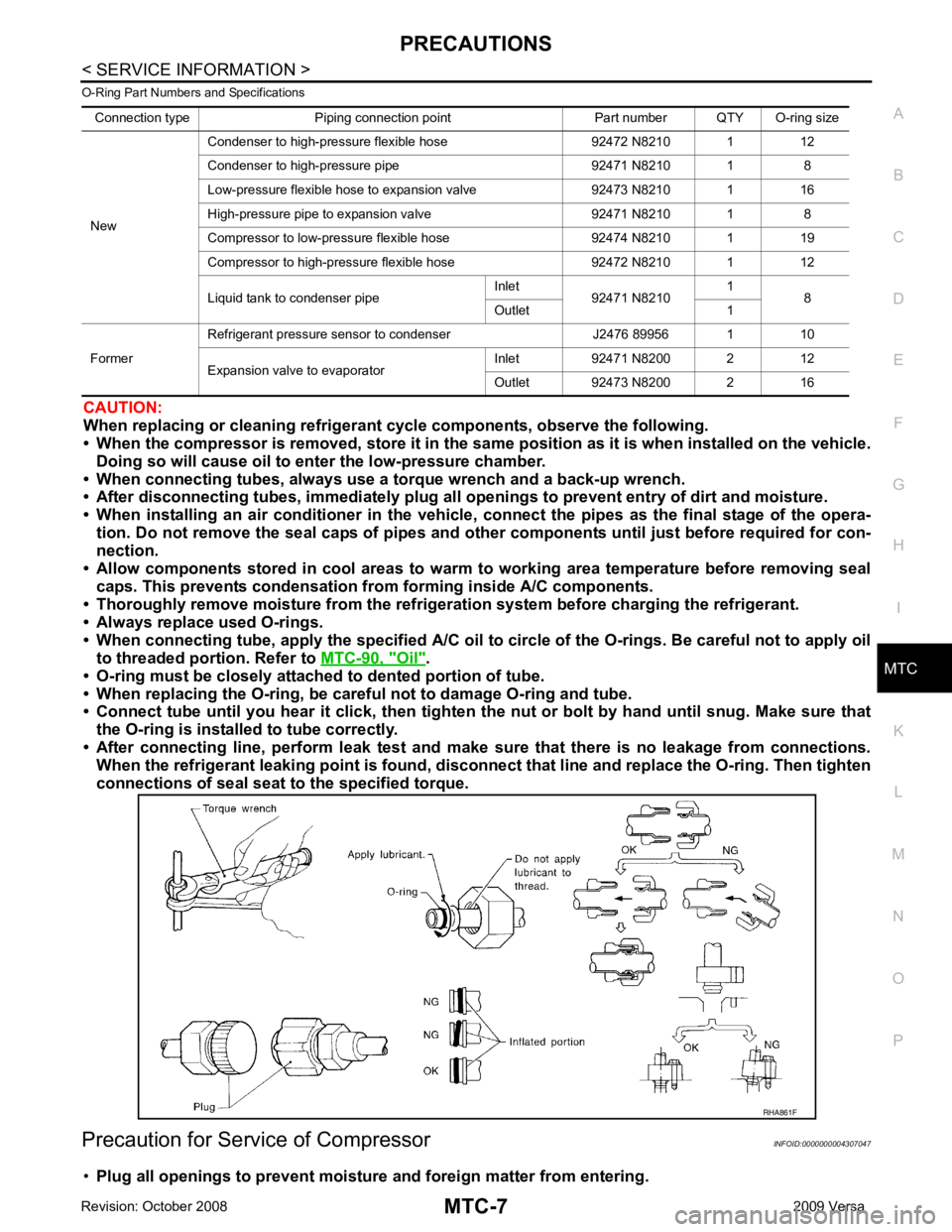

O-Ring Part Numbers and Specifications

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

• When the compressor is removed, store it in the sam e position as it is when installed on the vehicle.

Doing so will cause oil to en ter the low-pressure chamber.

• When connecting tubes, always use a to rque wrench and a back-up wrench.

• After disconnecting tubes, immediately plug all op enings to prevent entry of dirt and moisture.

• When installing an air conditione r in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refriger ation system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply the speci fied A/C oil to circle of the O-rings. Be careful not to apply oil

to threaded portion. Refer to MTC-90, " Oil " .

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, perform leak test and make sure that there is no leakage from connections.

When the refrigerant leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

Precaution for Service of Compressor INFOID:0000000004307047

• Plug all openings to prevent moisture and foreign matter from entering.

Connection type Piping connection point Part number QTY O-ring size

New Condenser to high-pressure flexible hose 92472 N8210 1 12

Condenser to high-pressure pipe 92471 N8210 1 8

Low-pressure flexible hose to expansion valve 92473 N8210 1 16

High-pressure pipe to expansion valve 92471 N8210 1 8

Compressor to low-pressure flexible hose 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser pipe Inlet

92471 N8210 1

8

Outlet 1

Former Refrigerant pressure sensor to condenser J2476 89956 1 10

Expansion valve to evaporator Inlet 92471 N8200 2 12

Outlet 92473 N8200 2 16

Page 3936 of 4331

MTC

N

O P

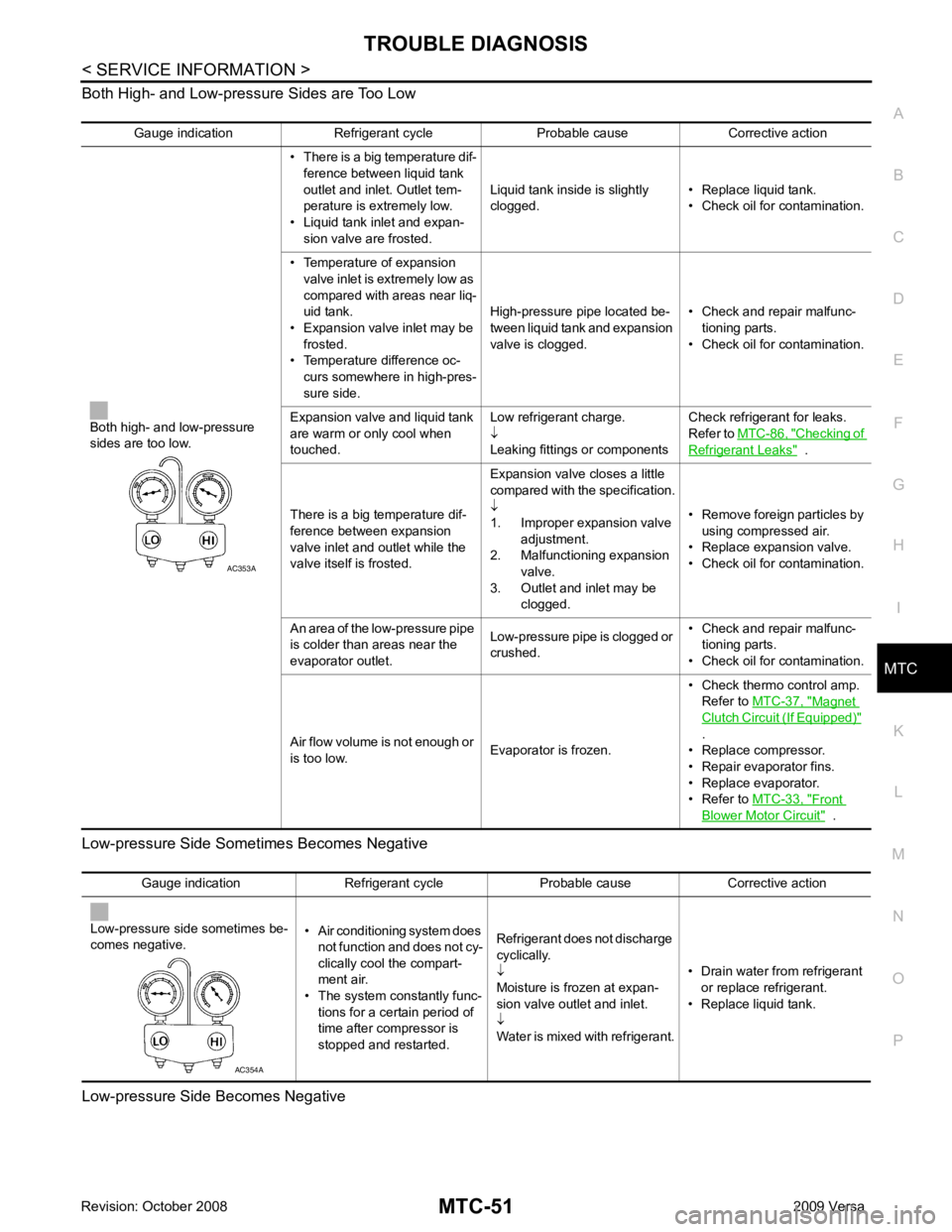

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Some times Becomes Negative

Low-pressure Side Becomes Negative Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low. • There is a big temperature dif-

ference between liquid tank

outlet and inlet. Outlet tem-

perature is extremely low.

• Liquid tank inlet and expan- sion valve are frosted. Liquid tank inside is slightly

clogged. • Replace liquid tank.

• Check oil for contamination.

• Temperature of expansion valve inlet is extremely low as

compared with areas near liq-

uid tank.

• Expansion valve inlet may be

frosted.

• Temperature difference oc- curs somewhere in high-pres-

sure side. High-pressure pipe located be-

tween liquid tank and expansion

valve is clogged. • Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Expansion valve and liquid tank

are warm or only cool when

touched. Low refrigerant charge.

↓

Leaking fittings or components Check refrigerant for leaks.

Refer to MTC-86, " Checking of

Refrigerant Leaks " .

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted. Expansion valve closes a little

compared with the specification.

↓

1. Improper expansion valve

adjustment.

2. Malfunctioning expansion valve.

3. Outlet and inlet may be clogged. • Remove foreign particles by

using compressed air.

• Replace expansion valve.

• Check oil for contamination.

An area of the low-pressure pipe

is colder than areas near the

evaporator outlet. Low-pressure pipe is clogged or

crushed. • Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Air flow volume is not enough or

is too low. Evaporator is frozen.• Check thermo control amp.

Refer to MTC-37, " Magnet

Clutch Circuit (If Equipped) "

.

• Replace compressor.

• Repair evaporator fins.

• Replace evaporator.

• Refer to MTC-33, " Front

Blower Motor Circuit " .

Page 4028 of 4331

PG

N

O P

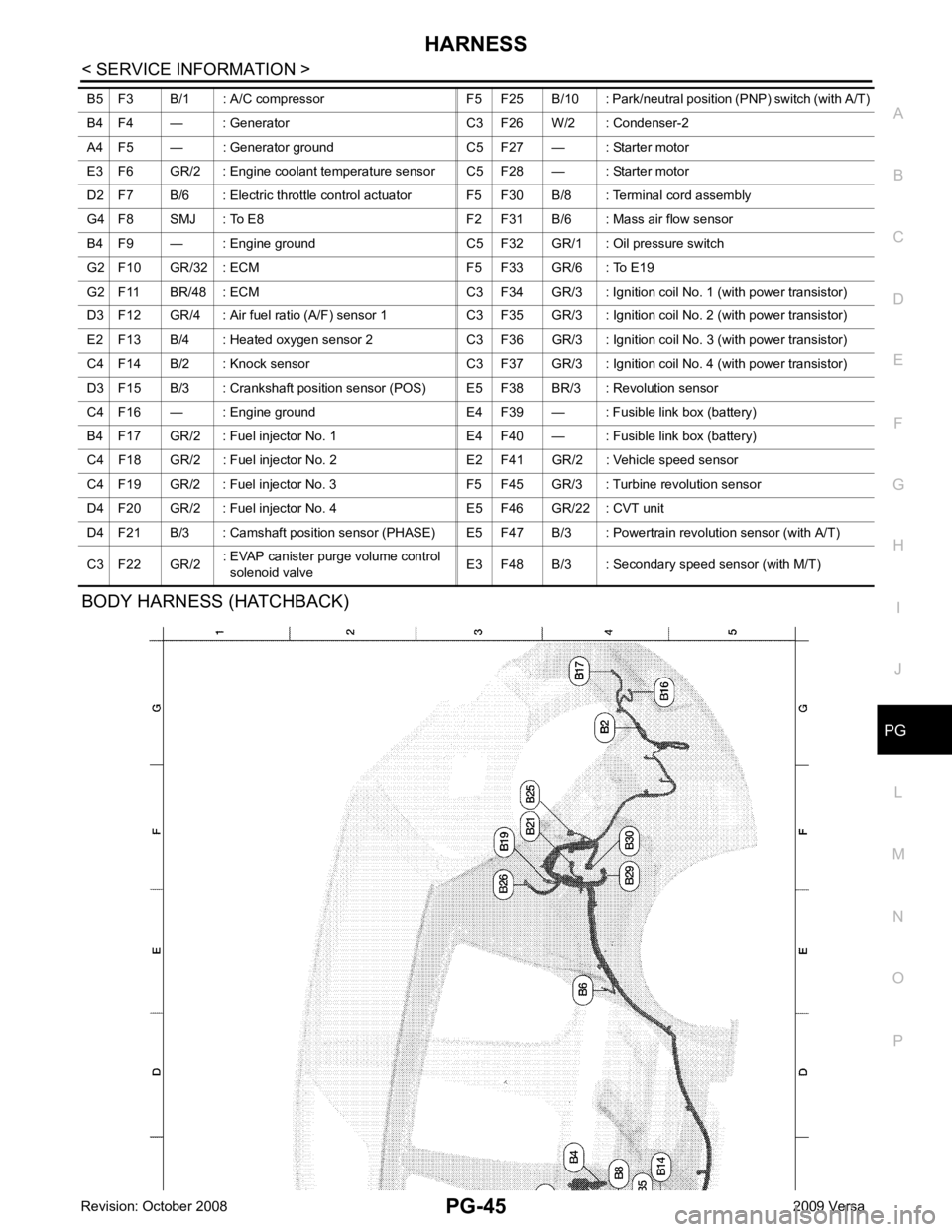

BODY HARNESS (HATCHBACK) B5 F3 B/1 : A/C compressor F5 F25 B/10 : Park/n

eutral position (PNP) switch (with A/T)

B4 F4 — : Generator C3 F26 W/2 : Condenser-2

A4 F5 — : Generator ground C5 F27 — : Starter motor

E3 F6 GR/2 : Engine coolant temperature sensor C5 F28 — : Starter motor

D2 F7 B/6 : Electric throttle control actuator F5 F30 B/8 : Terminal cord assembly

G4 F8 SMJ : To E8 F2 F31 B/6 : Mass air flow sensor

B4 F9 — : Engine ground C5 F32 GR/1 : Oil pressure switch

G2 F10 GR/32 : ECM F5 F33 GR/6 : To E19

G2 F11 BR/48 : ECM C3 F34 GR/3 : Ignition coil No. 1 (with power transistor)

D3 F12 GR/4 : Air fuel ratio (A/F) sensor 1 C3 F35 GR/3 : Ignition coil No. 2 (with power transistor)

E2 F13 B/4 : Heated oxygen sensor 2 C3 F36 GR/3 : Ignition coil No. 3 (with power transistor)

C4 F14 B/2 : Knock sensor C3 F37 GR/3 : Ignition coil No. 4 (with power transistor)

D3 F15 B/3 : Crankshaft position sensor (POS) E5 F38 BR/3 : Revolution sensor

C4 F16 — : Engine ground E4 F39 — : Fusible link box (battery)

B4 F17 GR/2 : Fuel injector No. 1 E4 F40 — : Fusible link box (battery)

C4 F18 GR/2 : Fuel injector No. 2 E2 F41 GR/2 : Vehicle speed sensor

C4 F19 GR/2 : Fuel injector No. 3 F5 F45 GR/3 : Turbine revolution sensor

D4 F20 GR/2 : Fuel injector No. 4 E5 F46 GR/22 : CVT unit

D4 F21 B/3 : Camshaft position sensor (PHASE) E5 F4 7 B/3 : Powertrain revolution sensor (with A/T)

C3 F22 GR/2 : EVAP canister purge volume control

solenoid valve E3 F48 B/3 : Secondary speed sensor (with M/T)