Bcm schematic NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 443 of 4331

BCS

N

O P

CONTENTS

BODY CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

BCM (BODY CONTROL MODULE) ............... .....3

System Description ............................................. ......3

CAN Communication System Description ........... ......7

Schematic ........................................................... ......8 BCM Terminal Arrangement ................................

....10

Terminal and Reference Value for BCM ..................11

BCM Power Supply and Ground Circuit Inspection ....15

CONSULT-III Function (B CM) .................................16

CAN Communication Inspection Using CON-

SULT-III (Self-Diagnosis) ..................................... ....

17

Configuration ....................................................... ....18

Removal and Installation of BCM ........................ ....18

Page 457 of 4331

BCS

N

O P

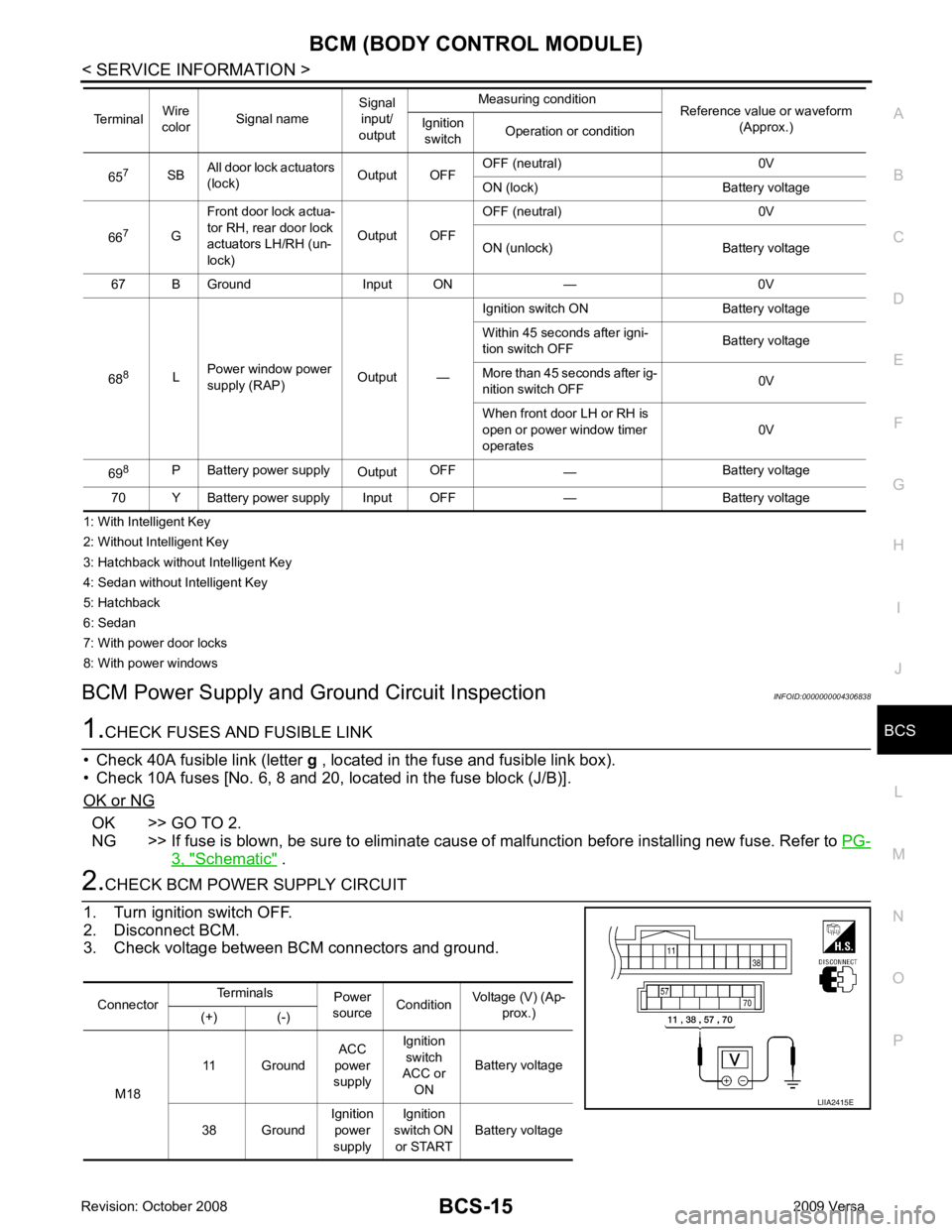

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

BCM Power Supply and Gr ound Circuit Inspection INFOID:0000000004306838OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-3, " Schematic " .

Connector

Terminals

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or

ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

Page 462 of 4331

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ............................................ ......5

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool .................................... ......6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ...... ......9

Diagnostic Worksheet ......................................... ....11

HOOD ............................................................. ....13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspec tion .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ............................................ ....21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description ............................................. ....23

CAN Communication System Description ........... ....25

Schematic ........................................................... ....26

Wiring Diagram - D/LOCK - ................................. ....27

Schematic ........................................................... ....31

Wiring Diagram - D/LOCK - ................................. ....32 Terminal and Reference

Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (B CM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection ....43

Door Switch Check (Hatchback) .......................... ....44

Door Switch Check (Sedan) ................................ ....47

Key Switch (Insert) Check ................................... ....48

Door Lock and Unlock Switch Check .................. ....49

Front Door Lock Assembly LH (Actuator) Check .....52

Door Lock Actuator Check (Front RH and Rear

LH/RH) ................................................................. ....

53

Front Door Key Cylinder S witch LH Check ..............54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

55

REMOTE KEYLESS ENTRY SYSTEM ............. 58

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

58

System Description .............................................. ....58

CAN Communication System Description ........... ....60

Schematic ............................................................ ....61

Wiring Diagram - KEYLES - ................................ ....62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ............................................... ....69

CONSULT-III Function (B CM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ...................... ....71

Keyfob Battery and Function Check .................... ....72

ACC Switch Check .............................................. ....74

Door Switch Check (Hatchback) .......................... ....74

Door Switch Check (Sedan) ................................ ....76

Key Switch (Insert) Check ................................... ....78

Hazard Function Check ....................................... ....78

Horn Function Check ........................................... ....79

Interior Lamp and Ignition Keyhole Illumination

Function Check .................................................... ....

79

Remote Keyless Entry Rece iver Check ...................80

Keyfob Function (Lock) Check ............................ ....82

Page 464 of 4331

BL

N

O P

Check Trunk Lid Opener S

witch Circuit (With Intel-

ligent Key) ........................................................... ..

212

Check Trunk Release Solenoid Circuit ............... ..214

FUEL FILLER LID OPENER .......................... ..217

Removal and Installation of Fuel Filler Lid Opener ..217

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ......................................................... ..

218

Component Parts and Harness Connector Loca-

tion ...................................................................... ..

218

System Description ............................................. ..219

CAN Communication System Description ........... ..221

Schematic ........................................................... ..222

Wiring Diagram - VEHSEC - ............................... ..223

Terminal and Reference Value for BCM ............. ..227

Terminal and Re ference Value for Intelligent Key

Unit ...................................................................... ..

231

CONSULT-III Function (BCM) ............................. ..233

Trouble Diagnosis ............................................... ..235

Preliminary Check ............................................... ..235

Symptom Chart ................................................... ..237

Diagnosis Procedure 1 ........................................ ..238

Diagnosis Procedure 2 ........................................ ..241

Diagnosis Procedure 3 ........................................ ..242

Diagnosis Procedure 4 ........................................ ..242

Diagnosis Procedure 5 ........................................ ..242

Diagnosis Procedure 6 ........................................ ..242

Diagnosis Procedure 7 ........................................ ..242

Diagnosis Procedure 8 ........................................ ..244

Diagnosis Procedure 9 ........................................ ..245 NATS (Nissan Anti-Theft System) ................

248

Component Parts and Harness Connector Loca-

tion ....................................................................... ..

248

System Description .............................................. ..248

System Composition ............................................ ..249

ECM Re-communicating Function ....................... ..249

Wiring Diagram - NATS - ..................................... ..251

Terminal and Reference Value for BCM ................252

CONSULT-III Function ........................................ ..256

Trouble Diagnosis Procedure .............................. ..257

Trouble Diagnosis ................................................ ..259

Diagnosis Procedure 1 ........................................ ..260

Diagnosis Procedure 2 ........................................ ..262

Diagnosis Procedure 3 ........................................ ..263

Diagnosis Procedure 4 ........................................ ..264

Diagnosis Procedure 5 ........................................ ..265

Diagnosis Procedure 6 ........................................ ..266

How to Replace NATS Antenna Amp .................. ..266

BODY REPAIR ................................................ 267

Body Exterior Paint Color .................................... ..267

Body Component Parts ....................................... ..269

Corrosion Protection ............................................ ..274

Body Sealing ....................................................... ..278

Body Construction ............................................... ..284

Body Alignment ................................................... ..286

Handling Precaution for Plastics .......................... ..303

Precaution in Repairing High Strength Steel ....... ..307

Foam Repair ........................................................ ..310

Replacement Operation ....................................... ..313

Page 504 of 4331

BL

N

O P

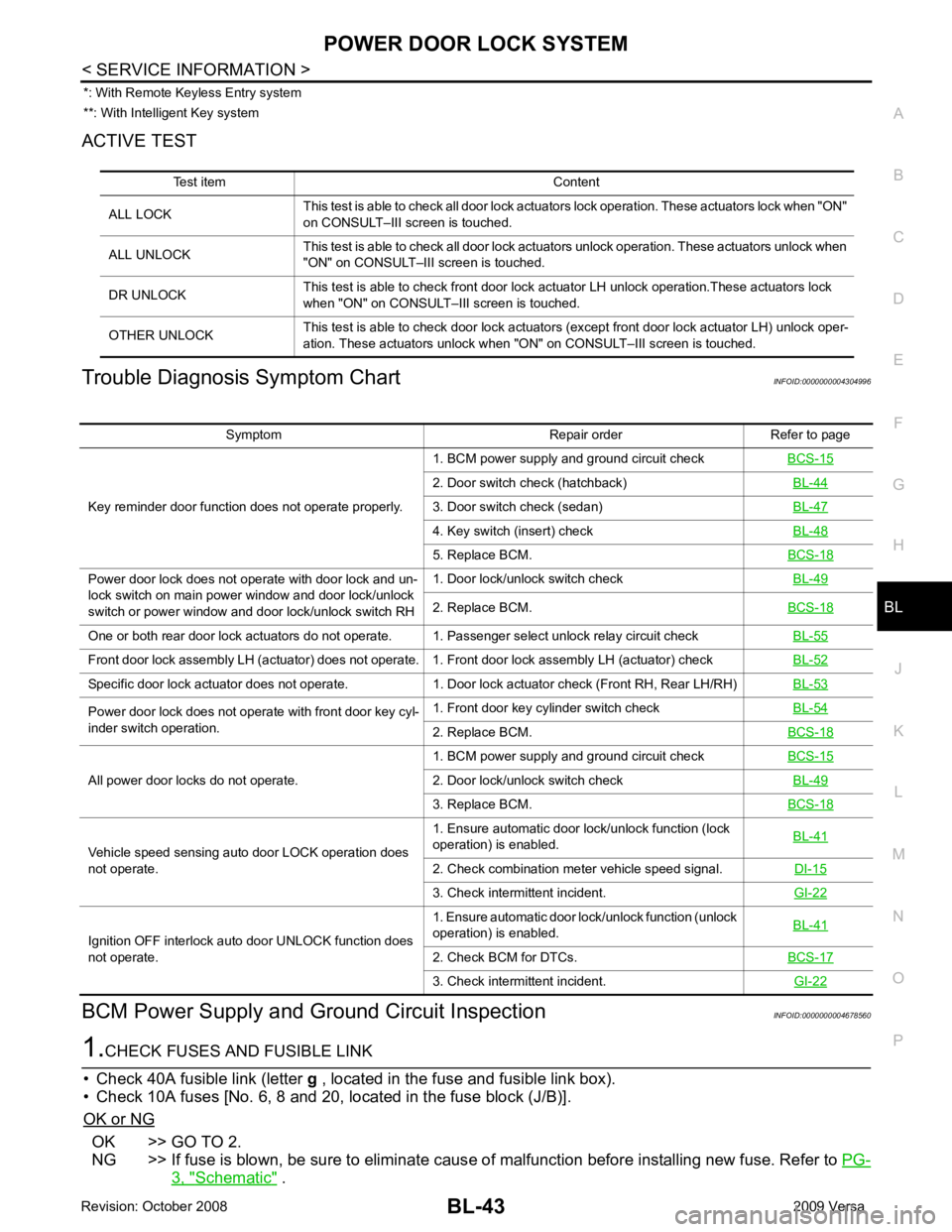

*: With Remote Keyless Entry system

**: With Intelligent Key system

ACTIVE TEST

Trouble Diagnosis Symptom Chart INFOID:0000000004304996

BCM Power Supply and Gr ound Circuit Inspection INFOID:0000000004678560OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-3, " Schematic " .

Test item Content

ALL LOCK This test is able to check all door lock actuators lock operation. These actuators lock when "ON"

on CONSULT–III screen is touched.

ALL UNLOCK This test is able to check all door lock actuators unlock operation. These actuators unlock when

"ON" on CONSULT–III screen is touched.

DR UNLOCK This test is able to check front door lock actuator LH unlock operation.These actuators lock

when "ON" on CONSULT– III screen is touched.

OTHER UNLOCK This test is able to check door lock actuators (except front door lock actuator LH) unlock oper-

ation. These actuators unlock when "ON" on CONSULT–III screen is touched. Symptom Repair order Refer to page

Key reminder door function does not operate properly. 1. BCM power supply and ground circuit check

BCS-15 2. Door switch check (hatchback)

BL-44 3. Door switch check (sedan)

BL-47 4. Key switch (insert) check

BL-48 5. Replace BCM.

BCS-18Power door lock does not operate with door lock and un-

lock switch on main power window and door lock/unlock

switch or power window and door lock/unlock switch RH 1. Door lock/unlock switch check

BL-49 2. Replace BCM.

BCS-18One or both rear door lock actuators do not operate. 1. Passenger select unlock relay circuit check

BL-55Front door lock assembly LH (actuator) does not operate. 1. Front door lock assembly LH (actuator) check

BL-52Specific door lock actuator does not operate. 1. Door lock actuator check (Front RH, Rear LH/RH)

BL-53Power door lock does not operate with front door key cyl-

inder switch operation. 1. Front door key cylinder switch check

BL-54 2. Replace BCM.

BCS-18All power door locks do not operate.

1. BCM power supply and ground circuit check

BCS-15 2. Door lock/unlock switch check

BL-49 3. Replace BCM.

BCS-18Vehicle speed sensing auto door LOCK operation does

not operate. 1. Ensure automatic door lock/unlock function (lock

operation) is enabled. BL-41 2. Check combination meter vehicle speed signal.

DI-15 3. Check intermittent incident.

GI-22Ignition OFF interlock auto door UNLOCK function does

not operate. 1. Ensure automatic door lock/unlock function (unlock

operation) is enabled. BL-41 2. Check BCM for DTCs.

BCS-17 3. Check intermittent incident.

GI-22

Page 644 of 4331

BACK DOOR LOCK

BL-183

< SERVICE INFORMATION >

C

D E

F

G H

J

K L

M A

B BL

N

O P

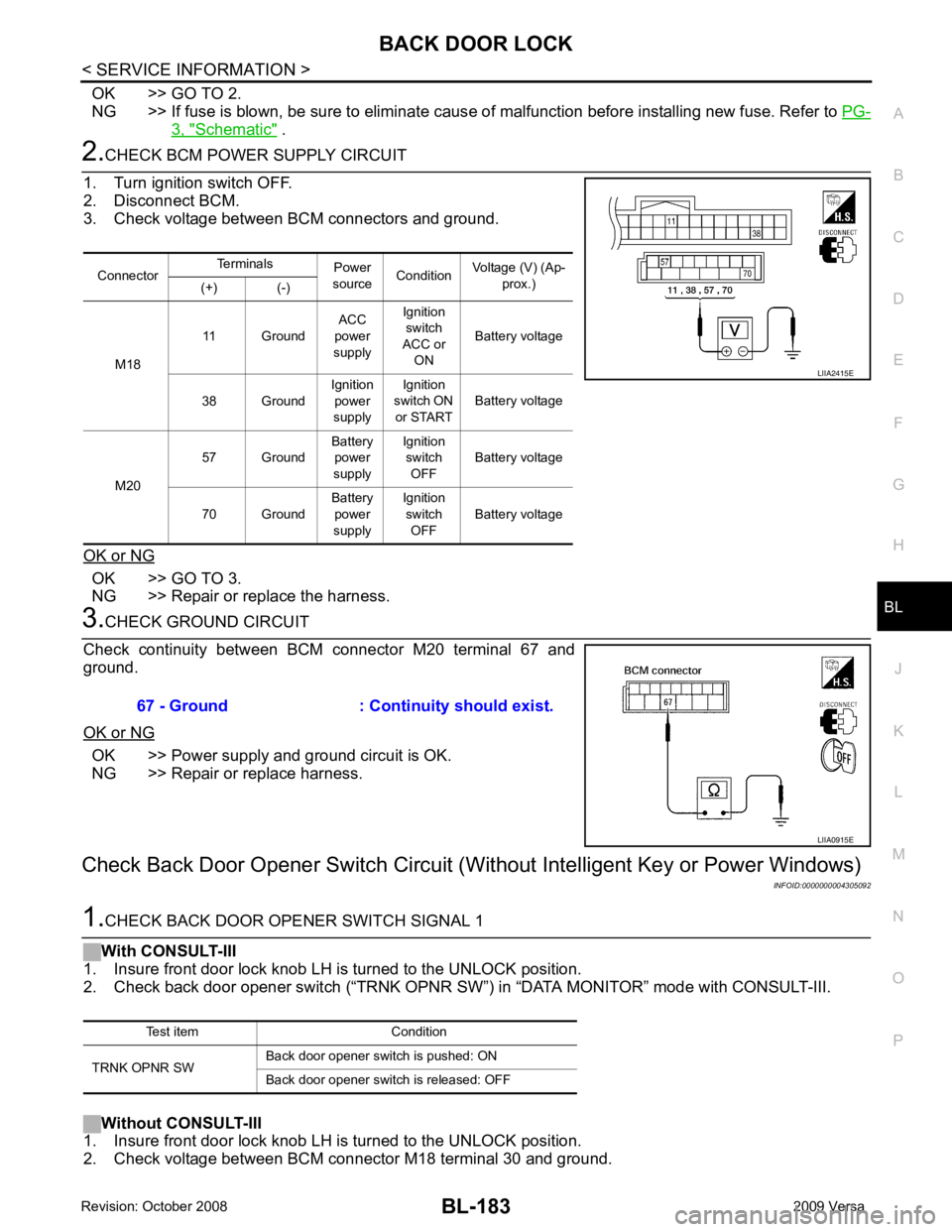

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-3, " Schematic " .

2.

CHECK BCM POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM connectors and ground.

OK or NG OK >> GO TO 3.

NG >> Repair or replace the harness. 3.

CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 terminal 67 and

ground.

OK or NG OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

Check Back Door Opener S witch Circuit (Without Intellig ent Key or Power Windows)

INFOID:00000000043050921.

CHECK BACK DOOR OPENER SWITCH SIGNAL 1

With CONSULT-III

1. Insure front door lock knob LH is turned to the UNLOCK position.

2. Check back door opener switch (“TRNK OPNR SW ”) in “DATA MONITOR” mode with CONSULT-III.

Without CONSULT-III

1. Insure front door lock knob LH is turned to the UNLOCK position.

2. Check voltage between BCM connector M18 terminal 30 and ground. Connector

Terminals

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage LIIA2415E

67 - Ground : Continuity should exist.

LIIA0915E

Test item Condition

TRNK OPNR SW Back door opener switch is pushed: ON

Back door opener switch is released: OFF

Page 668 of 4331

TRUNK LID OPENER

BL-207

< SERVICE INFORMATION >

C

D E

F

G H

J

K L

M A

B BL

N

O P

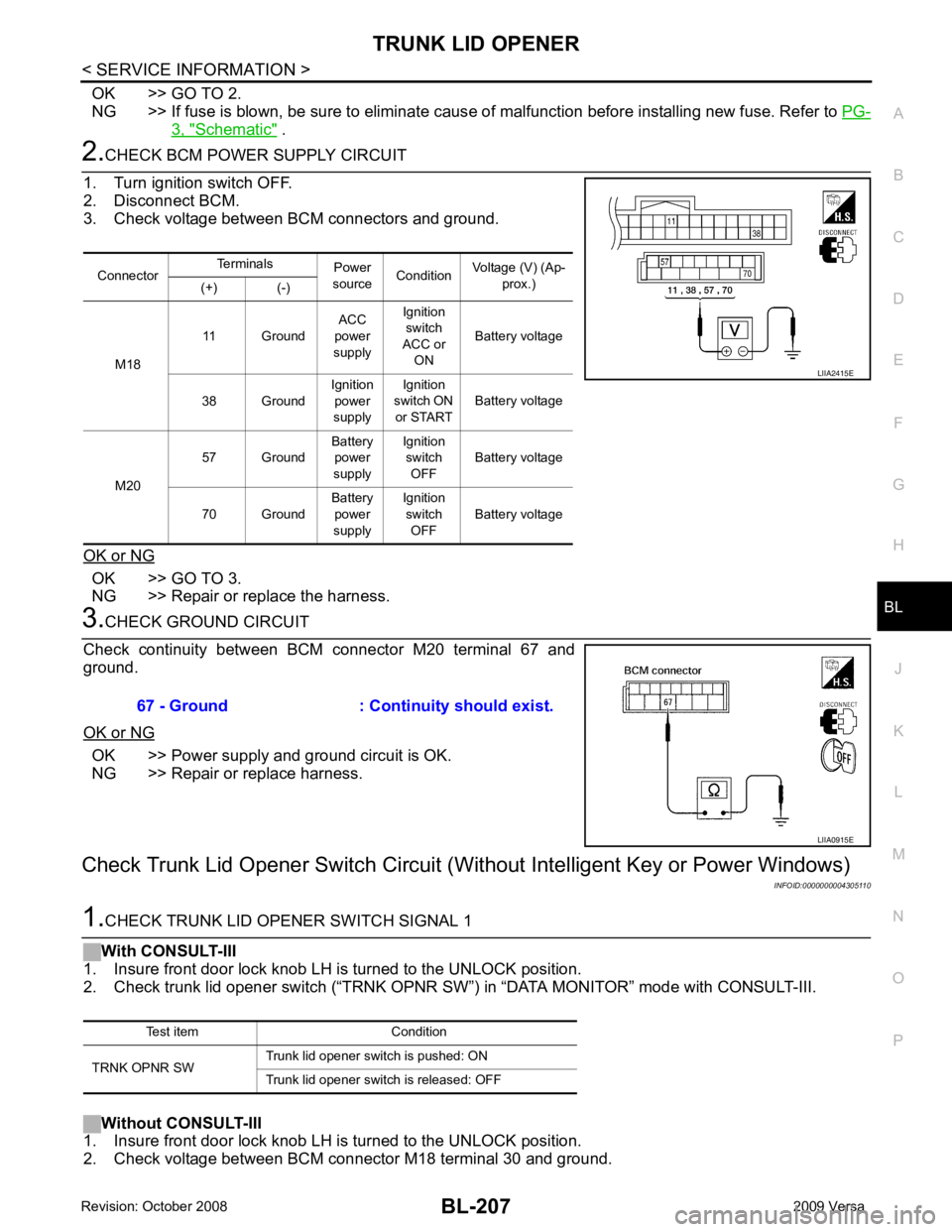

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-3, " Schematic " .

2.

CHECK BCM POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM connectors and ground.

OK or NG OK >> GO TO 3.

NG >> Repair or replace the harness. 3.

CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 terminal 67 and

ground.

OK or NG OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

Check Trunk Lid Opener Switch Circuit (Wit hout Intelligent Key or Power Windows)

INFOID:00000000043051101.

CHECK TRUNK LID OPENER SWITCH SIGNAL 1

With CONSULT-III

1. Insure front door lock knob LH is turned to the UNLOCK position.

2. Check trunk lid opener switch (“TRNK OPNR SW”) in “DATA MONITOR” mode with CONSULT-III.

Without CONSULT-III

1. Insure front door lock knob LH is turned to the UNLOCK position.

2. Check voltage between BCM connector M18 terminal 30 and ground. Connector

Terminals

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage LIIA2415E

67 - Ground : Continuity should exist.

LIIA0915E

Test item Condition

TRNK OPNR SW Trunk lid opener switch is pushed: ON

Trunk lid opener switch is released: OFF

Page 1303 of 4331

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

COMBINATION METERS .............................. .....3

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

3

System Description ............................................. ......3

Arrangement of Combination Meter .................... ......5

Internal Circuit ..................................................... ......6

Wiring Diagram - METER - ................................. ......7

Combination Meter Harness Connector Terminal

Layout ................................................................. ......

9

Terminal and Reference Value for Combination

Meter ................................................................... ......

9

Self-Diagnosis Mode of Combination Meter ........ ....10

CONSULT-III Function (METER/M&A) ............... ....12

Trouble Diagnosis ............................................... ....13

Symptom Chart ................................................... ....14

Power Supply and Ground Circuit Inspection ..... ....14

Vehicle Speed Signal Inspection ......................... ....15

Engine Speed Signal Inspection ......................... ....16

Fuel Level Sensor Signal Inspection ................... ....16

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies .................................................................. ....

18

Fuel Gauge Does Not Move to Full-position ...........18

DTC [U1000] CAN Communication Circuit ......... ....18

Electrical Component Inspection ......................... ....19

Removal and Installation .........................................19

WARNING LAMPS ......................................... ....20

Schematic ........................................................... ....20

Wiring Diagram - WARN - ................................... ....21 Oil Pressure Wa

rning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

29

Oil Pressure Wa rning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

31

Component Inspection ......................................... ....31

A/T INDICATOR ................................................ 33

System Description .............................................. ....33

Wiring Diagram - AT/IND - ................................... ....34

A/T Indicator Does Not Illuminate ........................ ....35

CVT INDICATOR ............................................... 37

System Description .............................................. ....37

Schematic ............................................................ ....37

Wiring Diagram - CVTIND - ................................. ....38

CVT Indicator Does Not Illuminate ...................... ....40

WARNING CHIME ............................................. 42

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

42

System Description .............................................. ....42

Wiring Diagram - CHIME - ................................... ....45

Terminal and Reference Value for BCM ..................46

CONSULT-III Function (B CM) .................................46

Trouble Diagnosis ................................................ ....47

Combination Meter Buzzer Cir cuit Inspection .........48

Front Door Switch LH Signal Inspection .............. ....49

Key Switch Signal Inspec tion (Without Intelligent

Key) ..................................................................... ....

50

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

51

Lighting Switch Signal Inspection ........................ ....53

Parking Brake Switch Signal Inspection .............. ....53

Electrical Component Inspection ......................... ....54

Page 3304 of 4331

GW

N

O P

CONTENTS

GLASSES, WINDOW SYSTEM & MIRRORS

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Handling for Adhesive and Primer ...................... ......4

PREPARATION .............................................. .....5

Commercial Service Tool .................................... ......5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................6

Work Flow ........................................................... ......6

Generic Squeak and Rattle Troubleshooting ...... ......8

Diagnostic Worksheet ......................................... ....10

WINDSHIELD GLASS .................................... ....12

Removal and Installation .........................................12

OPERA WINDOW GLASS ............................. ....14

Removal and Installation .........................................14

REAR WINDOW GLASS AND MOLDING ..... ....16

Removal and Installation .........................................16

POWER WINDOW SYST EM ..............................19

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

19

System Description ............................................. ....19

CAN Communication System Description ........... ....23

Schematic ........................................................... ....24

Wiring Diagram - WINDOW- ............................... ....25

Main Power Window and Door Lock/Unlock

Switch Harness Connector Terminal Layout ....... ....

29

Terminal and Reference Value for Main Power

Window and Door Lock/Unlock Switch ............... ....

29

Terminal and Reference Value for BCM ............. ....30

Work Flow ........................................................... ....30 CONSULT-III Function (B

CM) .................................30

Power Window Auto Operat ion Initialization ............31

Trouble Diagnosis Symptom Chart ...................... ....31

BCM Power Supply and Ground Circuit Inspection ....32

Main Power Window and Door Lock/Unlock

Switch Power Supply and Ground Circuit Inspec-

tion ....................................................................... ....

32

Front Power Window Motor LH Circuit Inspection ....33

Front Power Window RH Circuit Inspection (Pow-

er Window and Door Lock/Unlock Switch RH Op-

eration) ................................................................ ....

34

Front Power Window Motor RH Circuit Inspection ....34

Encoder Circuit Inspection ................................... ....36

Door Switch Check .............................................. ....38

Rear Power Window LH Circuit Inspection (Rear

Power Window Switch LH Operation) ................. ....

39

Rear Power Window RH Circu it Inspection (Rear

Power Window Switch RH Operation) ................. ....

40

Rear Power Window Motor LH Circuit Inspection ....40

Rear Power Window Motor RH Circuit Inspection ....42

FRONT DOOR GLASS AND REGULATOR ..... 44

Removal and Installation ..................................... ....44

Disassembly and Assembly ................................. ....46

Inspection after Installati on ......................................46

REAR DOOR GLASS AND REGULATOR ....... 48

Removal and Installation ..................................... ....48

Disassembly and Assembly ................................. ....50

Inspection after Installati on ......................................50

REAR WINDOW DEFOGGER .......................... 51

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

51

System Description .............................................. ....51

CAN Communication System Description ........... ....52

Wiring Diagram - DEF - ....................................... ....53

Terminal and Reference Value for BCM ..................55

Terminal and Reference Va lue for IPDM E/R ..........55

Work Flow ............................................................ ....55

Page 3396 of 4331

LAN

N

O P

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

PRECAUTION ....... ........................................

7

PRECAUTIONS .............................................. .....7

Precautions for Trouble Diagnosis ...................... ......7

Precautions for Harness Repair ................................7

FUNCTION DIAGNOSIS .. .............................8

CAN COMMUNICATION SYSTEM ................ .....8

System Description ............................................. ......8

System Diagram .................................................. ......8

CAN Communication Control Circuit ................... ......9

DIAG ON CAN ................................................ ....10

Description .......................................................... ....10

System Diagram .................................................. ....10

TROUBLE DIAGNOSIS ................................. ....11

Condition of Error Detection ................................ ....11

Symptom When Error Oc curs in CAN Communi-

cation System ...................................................... ....

11

CAN Diagnosis with CONSULT-III ...................... ....14

Self-Diagnosis ..................................................... ....14

CAN Diagnostic Support Monitor ........................ ....14

How to Use CAN Communication Signal Chart .. ....16

BASIC INSPECTION ....... ............................17

DIAGNOSIS AND REPAIR WORKFLOW ..... ....17

Trouble Diagnosis Flow Chart ............................. ....17

Trouble Diagnosis Procedure .............................. ....17

CAN

HOW TO USE THIS MANU AL .....................22

HOW TO USE THIS SECTION ....................... ....22

Caution ................................................................ ....22

Abbreviation List .................................................. ....22

PRECAUTION ....... .......................................23 PRECAUTIONS .................................................

23

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

23

Precautions for Trouble Diagnosis ...................... ....23

Precautions for Harness Repair .......................... ....23

BASIC INSPECTION ....... ............................25

DIAGNOSIS AND REPAIR WORKFLOW ........ 25

Interview Sheet .................................................... ....25

FUNCTION DIAGNOSIS .. ............................26

CAN COMMUNICATION SYSTEM ................... 26

CAN System Specification Chart ......................... ....26

CAN Communication Signal Chart ...................... ....26

COMPONENT DIAGNOSIS .........................29

CAN COMMUNICATION SYSTEM ................... 29

Component Parts Location .................................. ....29

Schematic ............................................................ ....30

Wiring Diagram - CAN - ....................................... ....31

MALFUNCTION AREA CHART ........................ 33

Main Line ............................................................. ....33

Branch Line ......................................................... ....33

Short Circuit ......................................................... ....33

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT .................................................................. 34

Diagnosis Procedure ........................................... ....34

MAIN LINE BETWEEN DLC AND TCM CIR-

CUIT .................................................................. 35

Diagnosis Procedure ........................................... ....35

ECM BRANCH LINE CIRCUIT ......................... 36

Diagnosis Procedure ........................................... ....36

BCM BRANCH LINE CIRCUIT ......................... 37

Diagnosis Procedure ........................................... ....37