PN switch NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 6 of 4331

AT

N

O P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION .. ..........................5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index .................................................... ......5

PRECAUTIONS .............................................. .....7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine ............................................... ......

8

Precaution ........................................................... ......8

Service Notice or Precaution ............................... ......9

PREPARATION .............................................. ....11

Special Service Tool ........................................... ....11

Commercial Service Tool .................................... ....14

A/T FLUID ....................................................... ....17

Checking A/T Fluid .............................................. ....17

Changing A/T Fluid ............................................. ....17

A/T Fluid Cooler Cleaning ................................... ....18

A/T CONTROL SYSTEM ................................ ....21

Cross-Sectional View ... ...........................................21

Shift Mechanism .................................................. ....22

TCM Function ...................................................... ....30

CAN Communication ........................................... ....31

Input/Output Signal of TCM ................................. ....31

Line Pressure Control .. ...........................................32

Shift Control ........................................................ ....33

Lock-up Control ................................................... ....34

Engine Brake Control (Ove rrun Clutch Control) ......35

Control Valve ....................................................... ....37

Centrifugal Cancel Mechanism ........................... ....37

ON BOARD DIAGNOSTIC (OBD) SYSTEM .. ....39

Introduction ......................................................... ....39

OBD-II Function for A/T System .......................... ....39 One or Two Trip Detection Logic of OBD-II .........

....39

OBD-II Diagnostic Trouble Code (DTC) .............. ....39

Malfunction Indicator Lamp (MIL) ............................41

TROUBLE DIAGNOSIS .................................... 42

DTC Inspection Priority Chart .............................. ....42

Fail-Safe .............................................................. ....42

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

43

A/T Electrical Parts Location ............................... ....49

Circuit Diagram .................................................... ....50

Inspections Before Trouble Diagnosis ................. ....51

Road Test ............................................................ ....55

Check Before Engine Is Started .......................... ....56

Check at Idle ........................................................ ....56

Cruise Test - Part 1 ............................................. ....58

Cruise Test - Part 2 ............................................. ....61

Cruise Test - Part 3 ............................................. ....62

Vehicle Speed at Which Gear Shifting Occurs .... ....64

Vehicle Speed at Which Lock-up Occurs/Releas-

es ......................................................................... ....

64

Symptom Chart .................................................... ....65

TCM Terminal and Refere nce Value .......................77

CONSULT-III Function (TRANSMISSION) .......... ....79

Diagnosis Procedure withou t CONSULT-III ............83

DTC U1000 CAN COMMUNICATION LINE ..... 88

Description ........................................................... ....88

On Board Diagnosis Logic ................................... ....88

Possible Cause .................................................... ....88

DTC Confirmation Procedure .............................. ....88

Wiring Diagram - AT - CAN ................................. ....89

Diagnosis Procedure ........................................... ....90

DTC P0705 PARK/NEUTRAL POSITION

(PNP) SWITCH .................................................. 91

Description ........................................................... ....91

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ....

91

On Board Diagnosis Logic ................................... ....91

Possible Cause .................................................... ....91

Page 8 of 4331

AT

N

O

P

N

Wiring Diagram - AT -

SSV/B ................................

145

Diagnosis Procedure ........................................... ..146

Component Inspection ........................................ ..147

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE ............................................................ ..149

Description .......................................................... ..149

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

149

On Board Diagnosis Logic .................................. ..149

Possible Cause ................................................... ..149

DTC Confirmation Procedure .............................. ..149

Wiring Diagram - AT - OVRCSV ......................... ..150

Diagnosis Procedure ........................................... ..151

Component Inspection ........................................ ..152

DTC VEHICLE SPEED SENSOR MTR .......... ..154

Description .......................................................... ..154

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

154

On Board Diagnosis Logic .................................. ..154

Possible Cause ................................................... ..154

DTC Confirmation Procedure .............................. ..154

Wiring Diagram - AT - VSSMTR ...........................155

Diagnosis Procedure ........................................... ..156

DTC BATT/FLUID TEMP SEN (A/T FLUID

TEMP SENSOR CIRCUIT AND TCM POWER

SOURCE) ....................................................... ..

157

Description .......................................................... ..157

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

157

On Board Diagnosis Logic .................................. ..157

Possible Cause ................................................... ..157

DTC Confirmation Procedure .............................. ..157

Wiring Diagram - AT - BA/FTS ............................ ..158

Diagnosis Procedure ........................................... ..159

Component Inspection ........................................ ..161

DTC TURBINE REVOLUTION SENSOR ....... ..163

Description .......................................................... ..163

CONSULT-III Refe rence Value in Data Monitor

Mode ................................................................... ..

163

On Board Diagnosis Logic .................................. ..163

Possible Cause ................................................... ..163

DTC Confirmation Procedure .............................. ..163

Wiring Diagram - AT - PT/SEN ........................... ..164

Diagnosis Procedure ........................................... ..165

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ............................................................. ..

168

Description .......................................................... ..168

On Board Diagnosis Logic .................................. ..168

Possible Cause ................................................... ..168

DTC Confirmation Procedure .............................. ..168

Diagnosis Procedure ........................................... ..168

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ................................................................ ..169

Wiring Diagram - AT - MAIN ............................... ..169 Diagnosis Procedure ...........................................

..170

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUI T ............................................ 172

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

172

TCM Terminal and Refere nce Value .....................172

Diagnosis Procedure ........................................... ..172

Component Inspection ......................................... ..176

SHIFT POSITION INDICATOR CIRCUIT ........ 177

Description ........................................................... ..177

CONSULT-III Reference Va lue in Data Monitor

Mode .................................................................... ..

177

Diagnosis Procedure ........................................... ..177

TROUBLE DIAGNOSIS FOR SYMPTOMS .... 178

Wiring Diagram - AT - NONDTC ......................... ..178

OD OFF Indicator Lamp Does Not Come On ...... ..181

Engine Cannot Be Started in "P" and "N" Position ..183

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ............................................. ..

184

In "N" Position, Vehicle Moves ............................ ..184

Large Shock "N" → "R" Position .......................... ..185

Vehicle Does Not Creep Backward in "R" Position ..186

Vehicle Does Not Creep Forw ard in "D", "2" or "1"

Position ................................................................ ..

187

Vehicle Cannot Be Started from D 1 ..................... ..188

A/T Does Not Shift: D 1→ D 2or Does Not Kick-

down: D 4→ D 2 ..................................................... ..190

A/T Does Not Shift: D 2→ D 3 ................................ ..192

A/T Does Not Shift: D 3→ D 4 ................................ ..193

A/T Does Not Perform Lock-up ........................... ..194

A/T Does Not Hold Lock-up Condition ................. ..195

Lock-up Is Not Released ..................................... ..196

Engine Speed Does Not Return to Idle (Light

Braking D 4→ D 3) ................................................. ..197

A/T Does Not Shift: D 4→ D 3, When OD OFF ...... ..198

A/T Does Not Shift: D 3→ 22, When Selector Lever

"D" → "2" Position ............................................... ..

199

A/T Does Not Shift: 2 2→ 11, When Selector Lever

"2" → "1" Position ................................................ ..

200

Vehicle Does Not Decelerate by Engine Brake ... ..202

TCM Self-Diagnosis Does Not Activate ............... ..205

A/T SHIFT LOCK SYSTEM ............................. 207

Description ........................................................... ..207

Shift Lock System Parts Location ........................ ..207

Wiring Diagram - AT - SHIFT .............................. ..208

Diagnosis Procedure ........................................... ..208

TRANSMISSION CONTROL MODULE .......... 211

Removal and Installation ..................................... ..211

SHIFT CONTROL SYSTEM ............................ 212

Control Device Removal an d Installation ...............212

Control Device Disassembly and Assembly ..........215

Selector Lever Knob Remo val and Installation ......215

Adjustment of A/T Position .................................. ..216

Page 12 of 4331

AT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004803451

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004305289

NOTE:

• This Procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 14 of 4331

AT

N

O P

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in pl ace during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-18, " A/T Fluid Cooler Cleaning " .

• After overhaul, refill the A/T with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-17, " Changing A/T Fluid " ,

AT-17, " Checking A/T Fluid " .

Service Notice or Precaution INFOID:0000000004305292

ATF COOLER SERVICE If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T oil cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. Check Serv ice Bulletins for latest A/T oil cooler cleaning pro-

cedure. For radiator replacement, refer to CO-16, " Removal and Installation " (HR16DE engine models),

CO-38, " Removal and Installation " (MR18DE engine models).

TORQUE CONVERTER SERVICE The torque converter should be replaced under any of the following conditions:

• External leaks in the hub weld area.

• Converter hub is scored or damaged.

• Converter pilot is broken, damaged or fits poorly into crankshaft.

• Steel particles are found after flushing the cooler and cooler lines.

• Pump is damaged or steel particles are found in the converter.

• Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

• Converter is contaminated with engi ne coolant containing antifreeze.

• Internal malfunction of stator roller clutch.

• Heavy clutch debris due to overheating (blue converter).

• Steel particles or clutch lining material found in flui d filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

• The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

• The threads in one or more of the converter bolt holes are damaged.

• A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

• Vehicle has been exposed to high mileage (only). The e xception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD-II SELF-DIAGNOSIS • A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on AT-83, " Diagnosis Procedure without CONSULT-III " for the indicator used to display each self-diagnostic

result.

• The self-diagnostic results indicated by the MIL ar e automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-39, " OBD-II Diagnostic Trouble Code

(DTC) " to complete the repair and avo

id unnecessary blinking of the MIL.

• The following self-diagnostic items can be detected us ing ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

- PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD-II, refer to AT-39 .

Page 38 of 4331

AT

N

O P

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE • A/T fluid viscosity and frictional characteristics of t he clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

• The line pressure is reduced below 60 °C (140 °F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

• Line pressure is increased to a maximum irrespective of the throt- tle opening when A/T fluid temperature drops to −10 °C (14 °F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift Control INFOID:0000000004305304

The shift is regulated entirely by electronic cont rol to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals trans mitted by the revolution sensor and the ECM (accelerator

pedal position sensor). This results in improved acceleration performance and fuel economy.

CONTROL OF SHIFT SOLENOID VALVES A AND B The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and revolution sen-

sor to select the optimum gear pos ition on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS SAT008J

Page 42 of 4331

AT

N

O P

Control Valve

INFOID:0000000004305307

FUNCTION OF CONTROL VALVES

Centrifugal Cancel Mechanism INFOID:0000000004305308

FUNCTION The centrifugal cancel mechanism is a mechanism to c ancel the centrifugal hydraulic pressure instead of the

conventional check balls. It cancels the centrifugal hy draulic pressure which is generated as high clutch drum

rotates, and it allows for preventing high clutch from dragging and for providing stable high clutch piston press-

ing force in all revolution speeds.

STRUCTURE/OPERATION Valve name Function

Pressure regulator valve, plug and sleeve

plug Regulates oil discharged from the oil pump to provide optimum line pressure for all driving

conditions.

Pressure modifier valve and sleeve Used as a signal supplementary valve to the pressure regulator valve. Regulates pres- sure-modifier pressure (signal pressure) which controls optimum line pressure for all driv-

ing conditions.

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls lock-up mechanism, overrun clutch, shift timing.

Accumulator control valve Regulates accumulator back-pressure to pressure suited to driving conditions.

Manual valve Directs line pressure to oil circuits corresponding to select positions. Hydraulic pressure drains when the shift lever is in Neutral.

Shift valve A Simultaneously switches three oil circuits using output pressure of shift solenoid valve A to meet driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and upshifting (1st → 2nd → 3rd → 4th gears/4th → 3rd

→ 2nd → 1st gears) in combination with shift valve B.

Shift valve B Simultaneously switches two oil circuits using output pressure of shift solenoid valve B in relation to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and upshifting (1st → 2nd → 3rd → 4th gears/4th → 3rd

→ 2nd → 1st gears) in combination with shift valve A.

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simultaneously with application of the brake band in D4. (Interlocking occurs if the overrun clutch engages

during D 4.)

1st reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when downshift- ing from the 1st position 12 to 1 1.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock. In the 1st and 2nd positions, line pressure acts on the overrun clutch reducing valve to

increase the pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control valve, plug

and sleeve Activates or inactivates the lock-up function.

Also provides smooth lock-up through transient application and release of the lock-up

system.

1-2 accumulator valve and piston Lessens the shock find when the 2nd gear band servo contracts, and provides smooth shifting.

3-2 timing valve Switches the pace that oil pressure is released depending on vehicle speed; maximizes the high clutch release timing, and allows for soft downshifting.

Shuttle valve Determines if the overrun clutch solenoid valve should control the 3-2 timing valve or the overrun clutch control valve and switches between the two.

Cooler check valve At low speeds and with a small load when a little heat is generated, saves the volume of cooler flow, and stores the oil pressure for lock-up.

Page 44 of 4331

AT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Introduction INFOID:0000000004305309

A/T system has two self-diagnostic systems.

The first is emission-related on boar d diagnostic system (OBD-II) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malf unction indicator lamp) and is stored as a DTC in the

ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are ov erlapped with OBD-II self-diagnostic items. For detail,

refer to AT-79, " CONSULT-III Function (TRANSMISSION) " .

OBD-II Function for A/T System INFOID:0000000004305310

The ECM provides emission-related on board diagnostic (O BD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-rela ted parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indica tor lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-II INFOID:0000000004305311

ONE TRIP DETECTION LOGIC If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC) INFOID:0000000004305312

HOW TO READ DTC AND 1ST TRIP DTC DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic troubl e code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONS ULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected curr ently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data The ECM has a memory function, which stores the driv ing condition such as fuel system status, calculated

load value, engine coolant temperature, short term f uel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Page 45 of 4331

CONSULT-III Function " (HR16DE),

EC-604, " CONSULT-III Function (ENGINE) " (MR

Type 1) or EC-1116, " CONSULT-III F

unction (ENGINE) " (MR Type 2).

Only one set of freeze frame data (either 1st trip freez e frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM me mory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame dat a (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT- III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

• If the battery cable is disconnected, the diagnosti c trouble code will be cleared within 24 hours.

• When you erase the DTC, using CONSULT-III or GS T is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-90, " Diagnosis Description " (HR16DE),

EC-542, " Emission-related

Diagnostic Information " (MR Type 1) or

EC-1052, " Emission-related Diagnostic Information " (MR Type 2).

• Diagnostic trouble codes (DTC)

• 1st trip diagnostic trou ble codes (1st trip DTC)

• Freeze frame data

• 1st trip freeze frame data

• System readiness test (SRT) codes

• Test values

HOW TO ERASE DTC (WITH CONSULT-III)

• If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-III “ON” and touch “TRANSMISSION”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-83, " Diagnosis Procedure

without CONSULT-III " . (The engine warm-up step can be skipped when performing the diagnosis only to

erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to EC-110, " Diagnosis Tool Function "

(HR16DE),

EC-612, " Generic Scan Tool (GST) Function " (MR Type 1) or

EC-1124, " Generic Scan Tool

(GST) Function " (MR Type 2).

HOW TO ERASE DTC (NO TOOLS)

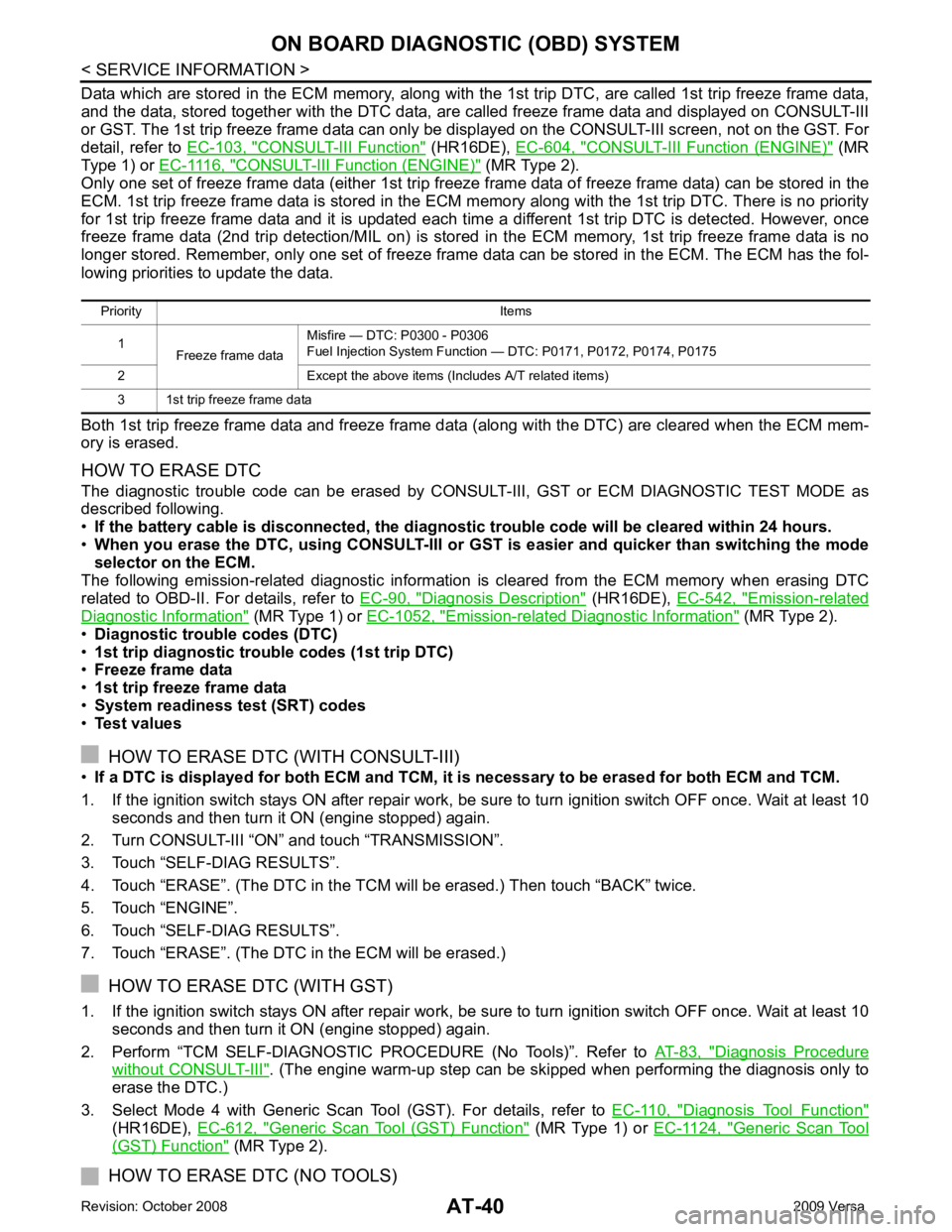

Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 46 of 4331

AT

N

O P

The OD OFF indicator lamp is located on the combination meter.

1. If the ignition switch stays ON after repair work, be su re to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PR OCEDURE (No Tools)”. Refer to AT-83, " Diagnosis Procedure

without CONSULT-III " . (The engine warm-up step can be ski

pped when performing the diagnosis only to

erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-90, " Diagnosis Description "

(HR16DE),

EC-542, " Emission-related Diagnostic Information " (MR Type 1) or

EC-1052, " Emission-

related Diagnostic Information " (MR Type 2).

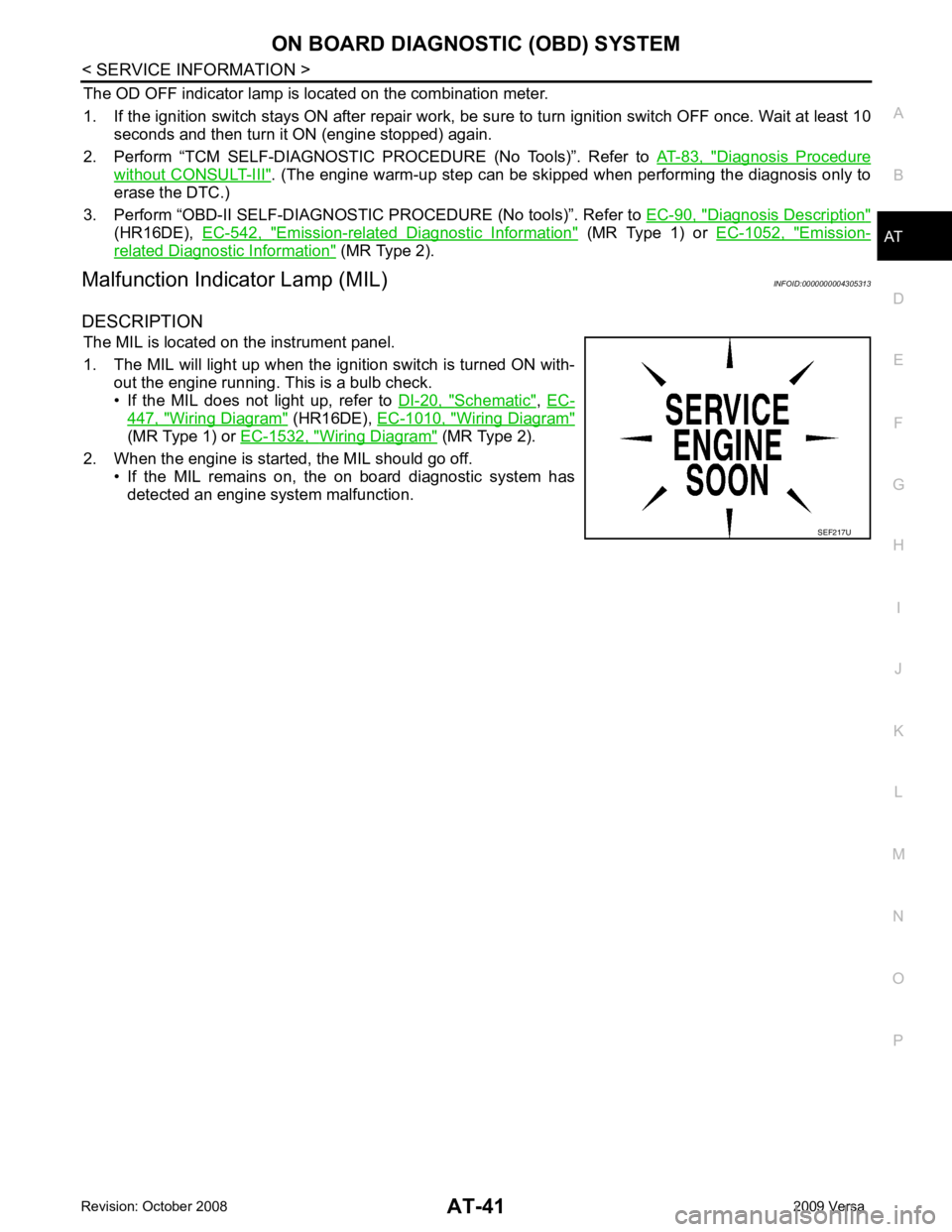

Malfunction Indicator Lamp (MIL) INFOID:0000000004305313

DESCRIPTION The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-20, " Schematic " ,

EC- 447, " Wiring Diagram " (HR16DE),

EC-1010, " Wiring Diagram "

(MR Type 1) or

EC-1532, " Wiring Diagram " (MR Type 2).

2. When the engine is start ed, the MIL should go off.

• If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

Page 47 of 4331

.

Fail-Safe INFOID:0000000004305315

The TCM has an electronic Fail-safe mode. This allows t he vehicle to be driven even if a major electrical input/

output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

Always follow the “ AT-43, " How to Perform Trouble Diagnosis for Quick and Accurate Repair " ”.

The SELF-DIAGNOSIS results will be as follows:

• The first SELF-DIAGNOSIS will indicate damage to t he vehicle speed sensor or the revolution sensor.

• During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

FAIL-SAFE FUNCTION

The following fail-safe functions allow vehicles to be driven even when sensor, switch or solenoid malfunction

occurs.

Vehicle Speed Sensor·A/T (Revolution Sensor)

Vehicle speed sensor·MTR signal is input from combination meter.

Accelerator Pedal Position Signal and Throttle Position Signal

TCM controls the throttle opening angle to a predetermi ned fixed position to enable driving if a malfunctioning

signal is input to TCM.

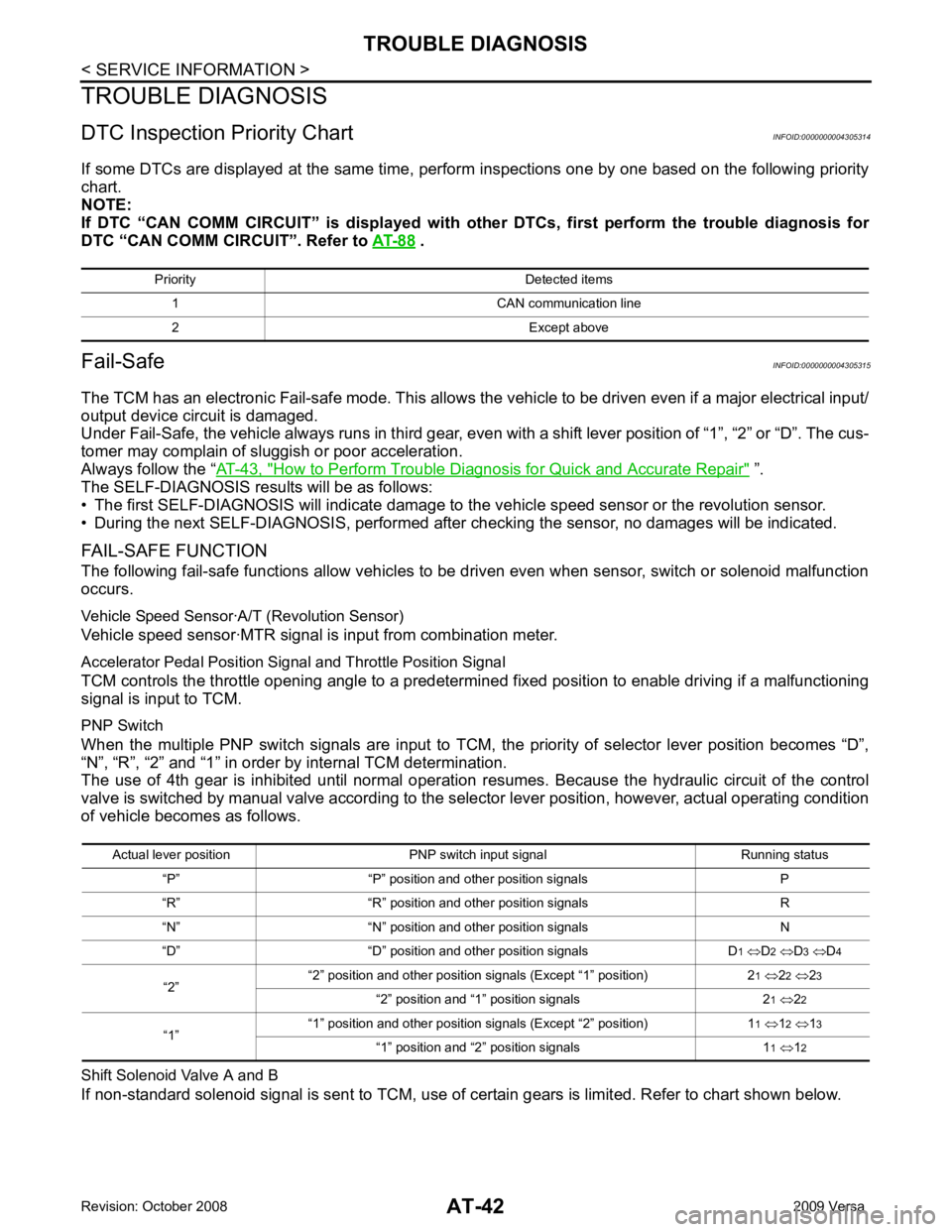

PNP Switch

When the multiple PNP switch signals are input to TCM, the priority of selector lever position becomes “D”,

“N”, “R”, “2” and “1” in order by internal TCM determination.

The use of 4th gear is inhibited unt il normal operation resumes. Because t he hydraulic circuit of the control

valve is switched by manual valve according to the sele ctor lever position, however, actual operating condition

of vehicle becomes as follows.

Shift Solenoid Valve A and B

If non-standard solenoid signal is sent to TCM, use of certain gears is limited. Refer to chart shown below.

Priority Detected items

1 CAN communication line

2 Except above Actual lever position PNP switch input signal Running status

“P” “P” position and other position signals P

“R” “R” position and other position signals R

“N” “N” position and other position signals N

“D” “D” position and other position signals D 1

⇔ D2 ⇔ D3 ⇔ D4

“2” “2” position and other position signals (Except “1” position) 2

1 ⇔ 22 ⇔ 23

“2” position and “1” position signals 2 1 ⇔ 22

“1” “1” position and other position signals (Except “2” position) 1

1

⇔ 12 ⇔ 13

“1” position and “2” position signals 1 1 ⇔ 12