engine NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3520 of 3745

RSU-6

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000005397077

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are within specifications.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace it if necessary.

Wheel AlignmentInspectionINFOID:0000000005397078

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6

.

3. Wheel bearing axial end play. Refer to RAX-6, "

On-Vehicle Inspection and Service" .

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-13, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER INSPECTION

Revision: January 20102010 Versa

Page 3527 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)RSU-13

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

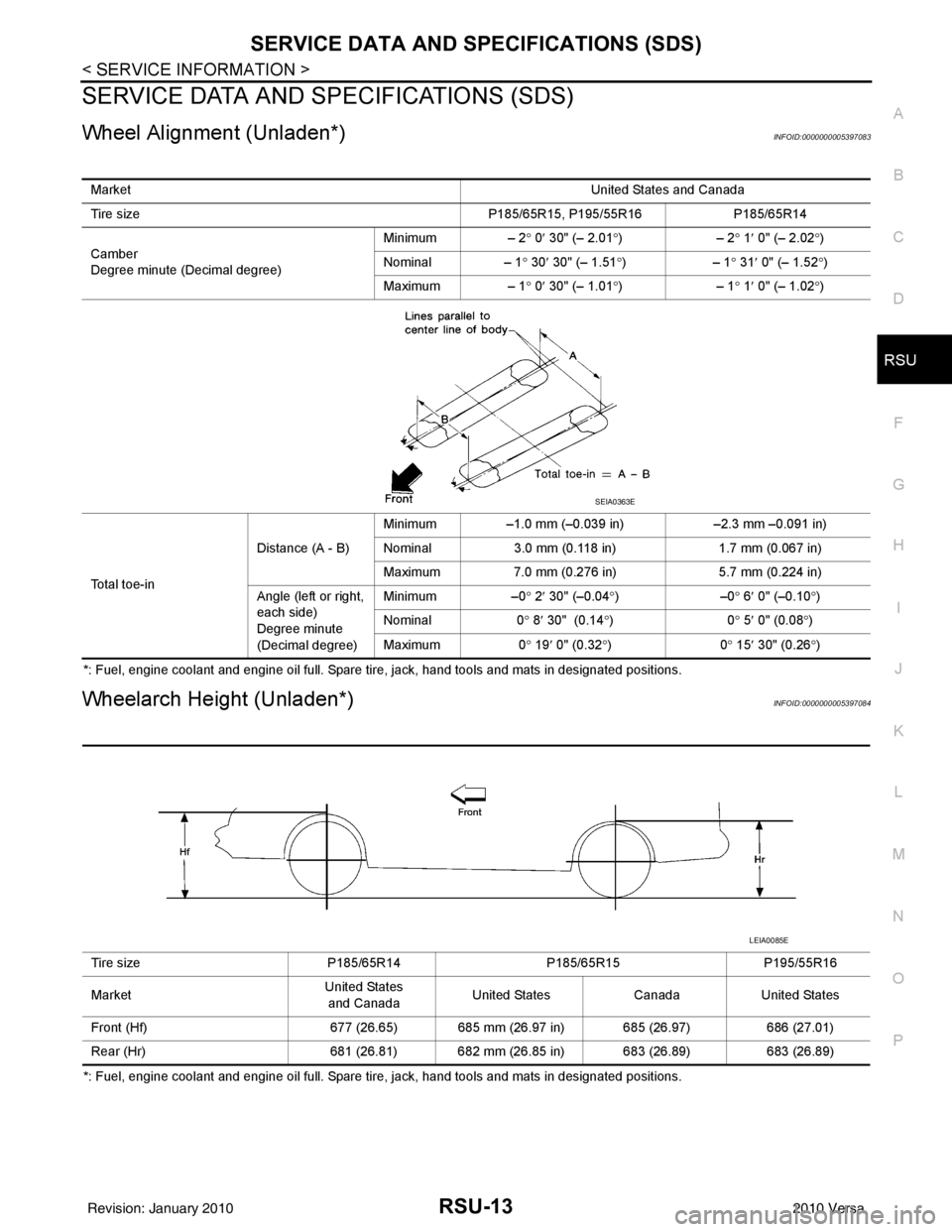

Wheel Alignment (Unladen*)INFOID:0000000005397083

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*)INFOID:0000000005397084

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Market

United States and Canada

Tire size P185/65R15, P195/55R16 P185/65R14

Camber

Degree minute (Decimal degree) Minimum

– 2° 0′ 30" (– 2.01 °)– 2° 1 ′ 0" (– 2.02 °)

Nominal – 1° 30 ′ 30" (– 1.51 °)– 1° 31 ′ 0" (– 1.52 °)

Maximum – 1° 0′ 30" (– 1.01 °)– 1° 1 ′ 0" (– 1.02 °)

To t a l t o e - i n Distance (A - B)

Minimum

–1.0 mm (–0.039 in) –2.3 mm –0.091 in)

Nominal 3.0 mm (0.118 in) 1.7 mm (0.067 in)

Maximum 7.0 mm (0.276 in) 5.7 mm (0.224 in)

Angle (left or right,

each side)

Degree minute

(Decimal degree) Minimum

–0° 2 ′ 30" (–0.04 °)– 0° 6 ′ 0" (–0.10 °)

Nominal 0° 8 ′ 30" (0.14 °)0 ° 5 ′ 0" (0.08 °)

Maximum 0° 19 ′ 0" (0.32 °)0 ° 15 ′ 30" (0.26 °)

SEIA0363E

Tire size P185/65R14P185/65R15P195/55R16

Market United States

and Canada United States

CanadaUnited States

Front (Hf) 677 (26.65) 685 mm (26.97 in) 685 (26.97) 686 (27.01)

Rear (Hr) 681 (26.81) 682 mm (26.85 in) 683 (26.89) 683 (26.89)

LEIA0085E

Revision: January 20102010 Versa

Page 3529 of 3745

SB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005714399

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005396884

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3541 of 3745

SC-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005715888

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005394854

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3544 of 3745

BATTERYSC-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

BATTERY

How to Handle BatteryINFOID:0000000005394857

CAUTION:

• If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

• Never add distilled water through the hole used to check specific gravity.

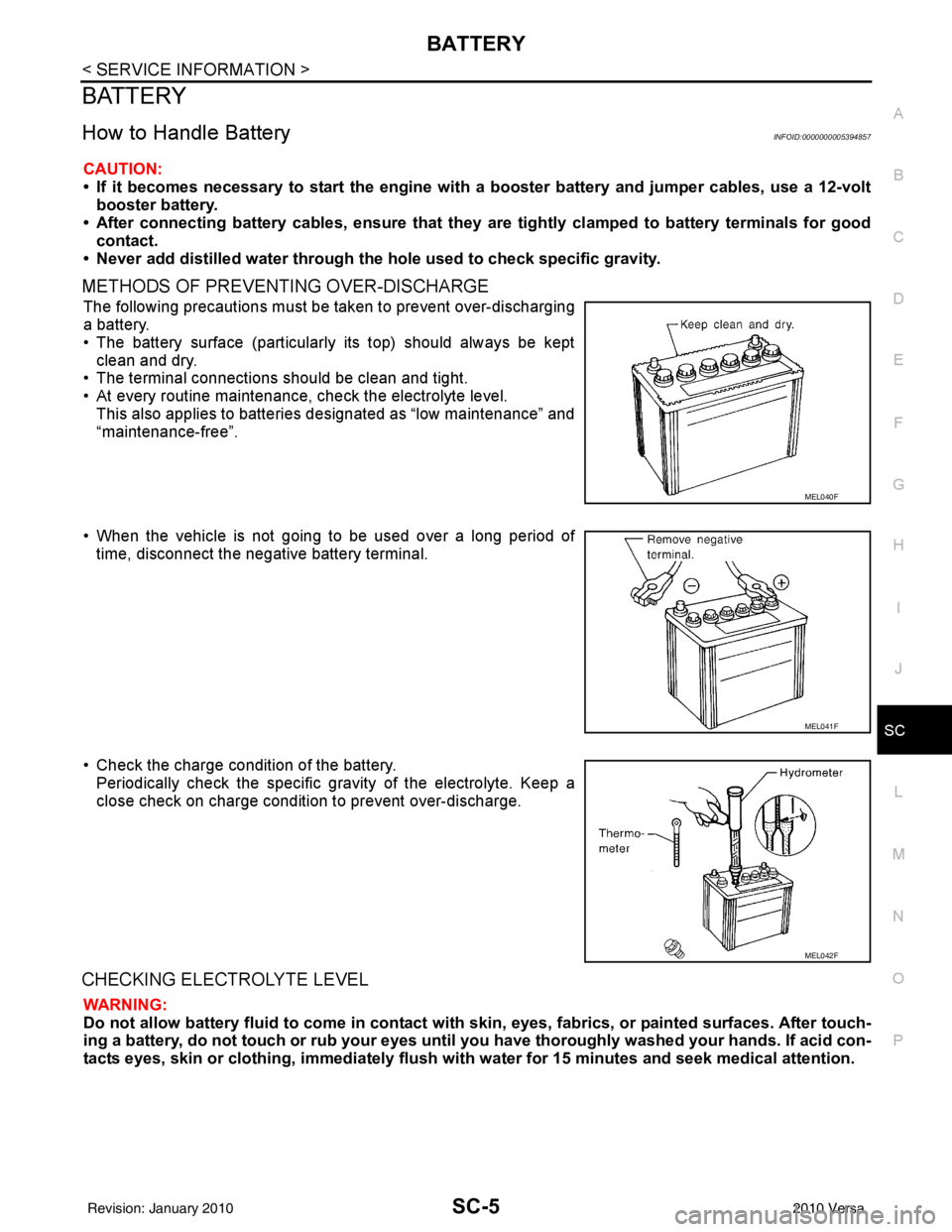

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging

a battery.

• The battery surface (particularly its top) should always be kept

clean and dry.

• The terminal connections should be clean and tight.

• At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance” and

“maintenance-free”.

• When the vehicle is not going to be used over a long period of time, disconnect the negative battery terminal.

• Check the charge condition of the battery. Periodically check the specific gr avity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until yo u have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, imme diately flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

Revision: January 20102010 Versa

Page 3547 of 3745

SC-8

< SERVICE INFORMATION >

BATTERY

CAUTION:

When disconnecting, disconnect the battery negative terminal first.

2. Remove battery hold-down wedge bolt (A) and remove battery hold-down wedge bracket (3).

3. Remove battery cover.

4. Remove battery.

INSTALLATION (All except MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

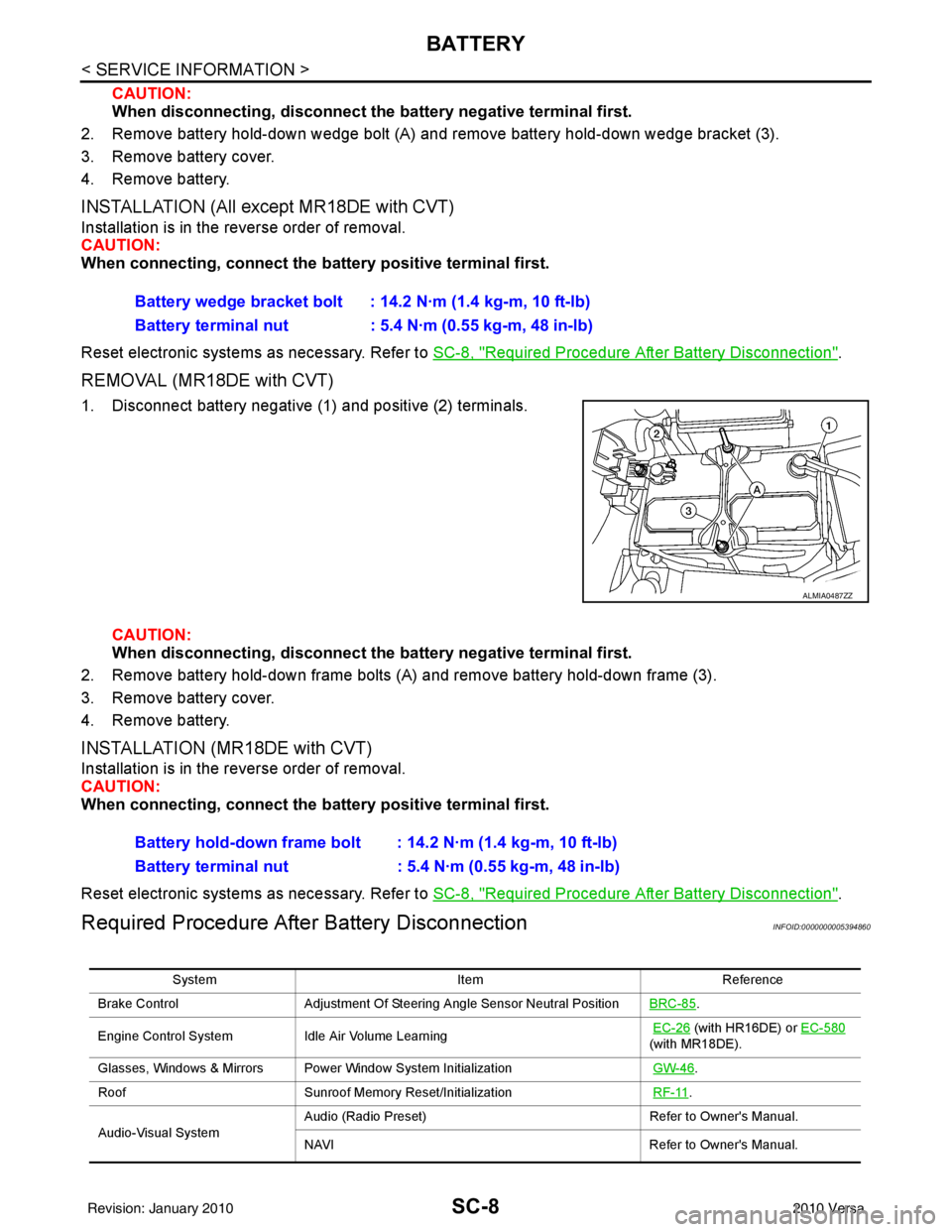

REMOVAL (MR18DE with CVT)

1. Disconnect battery negative (1) and positive (2) terminals.

CAUTION:

When disconnecting, disconnect th e battery negative terminal first.

2. Remove battery hold-down frame bolts (A) and remove battery hold-down frame (3).

3. Remove battery cover.

4. Remove battery.

INSTALLATION (MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

Required Procedure After Battery DisconnectionINFOID:0000000005394860

Battery wedge bracket bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

ALMIA0487ZZ

Battery hold-down frame bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

System ItemReference

Brake Control Adjustment Of Steering Angle Sensor Neutral Position BRC-85

.

Engine Control System Idle Air Volume Learning

EC-26

(with HR16DE) or EC-580

(with MR18DE).

Glasses, Windows & Mirrors Power Window System Initialization GW-46

.

Roof Sunroof Memory Reset/Initialization RF-11

.

Audio-Visual System Audio (Radio Preset)

Refer to Owner's Manual.

NAVI Refer to Owner's Manual.

Revision: January 20102010 Versa

Page 3556 of 3745

STARTING SYSTEMSC-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

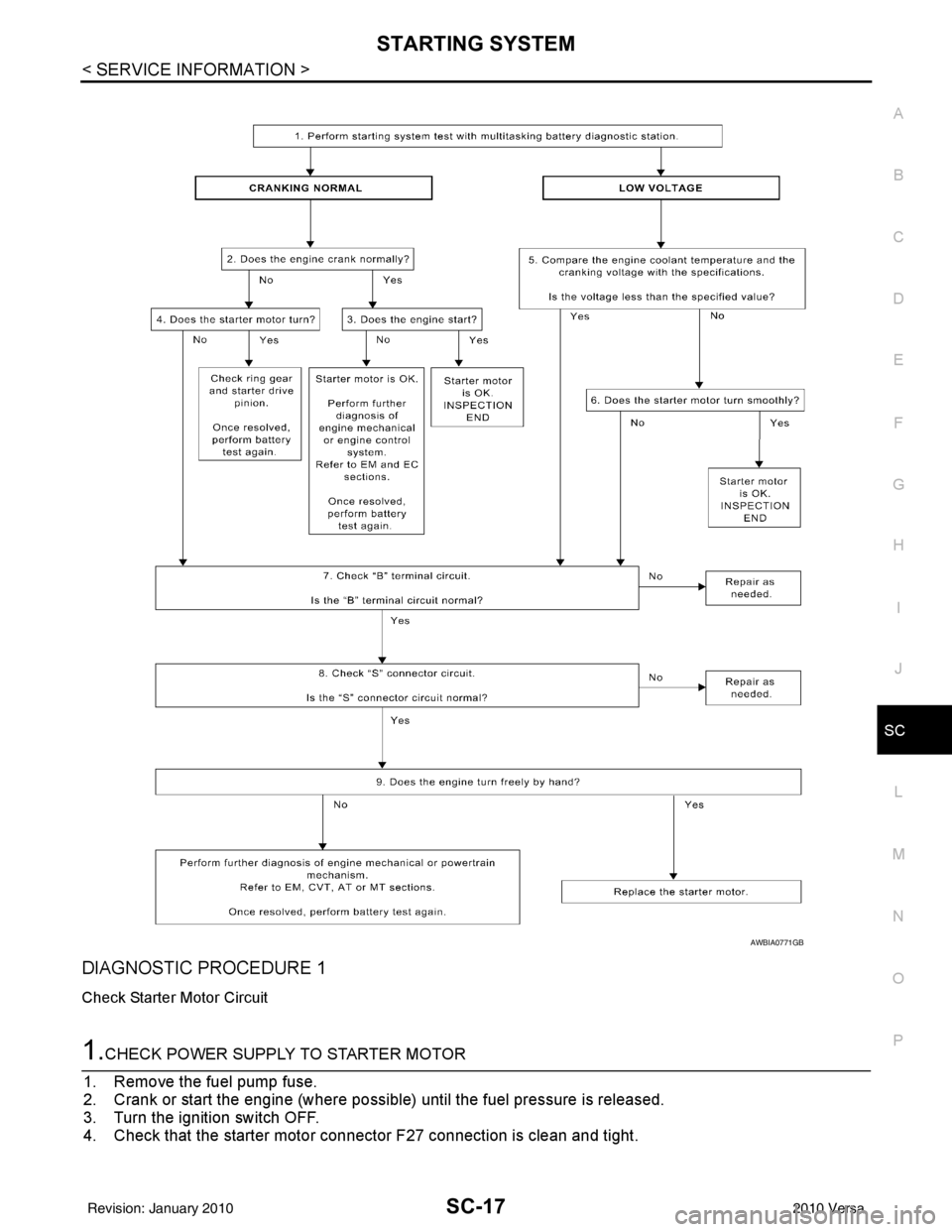

DIAGNOSTIC PROCEDURE 1

Check Starter Motor Circuit

1.CHECK POWER SUPPLY TO STARTER MOTOR

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Check that the starter motor connector F27 connection is clean and tight.

AWBIA0771GB

Revision: January 20102010 Versa

Page 3557 of 3745

SC-18

< SERVICE INFORMATION >

STARTING SYSTEM

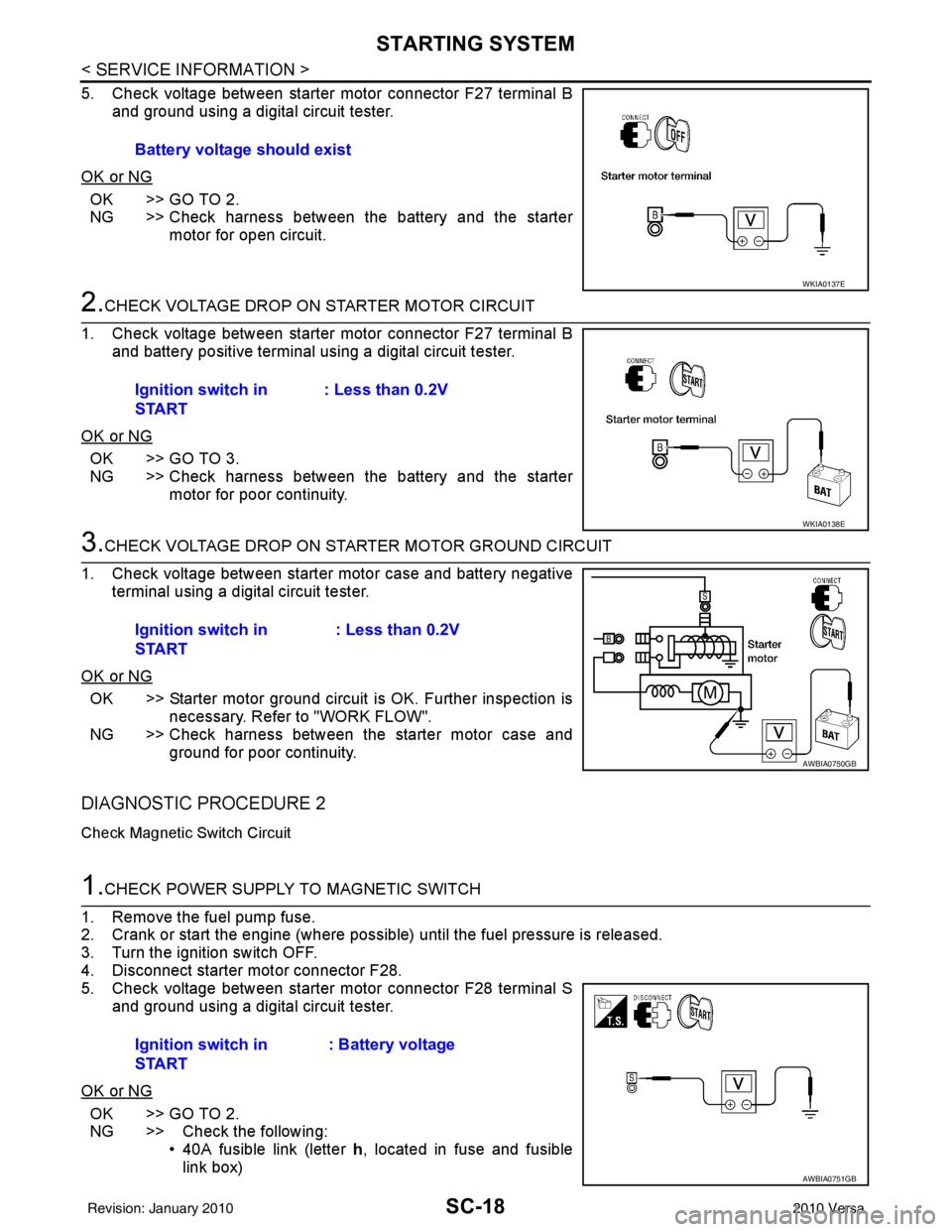

5. Check voltage between starter motor connector F27 terminal Band ground using a digital circuit tester.

OK or NG

OK >> GO TO 2.

NG >> Check harness between the battery and the starter motor for open circuit.

2.CHECK VOLTAGE DROP ON STARTER MOTOR CIRCUIT

1. Check voltage between starter motor connector F27 terminal B and battery positive terminal using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

3.CHECK VOLTAGE DROP ON STARTER MOTOR GROUND CIRCUIT

1. Check voltage between starter motor case and battery negative terminal using a digital circuit tester.

OK or NG

OK >> Starter motor ground circuit is OK. Further inspection is necessary. Refer to "WORK FLOW".

NG >> Check harness between the starter motor case and

ground for poor continuity.

DIAGNOSTIC PROCEDURE 2

Check Magnetic Switch Circuit

1.CHECK POWER SUPPLY TO MAGNETIC SWITCH

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Disconnect starter motor connector F28.

5. Check voltage between starter motor connector F28 terminal S and ground using a digital circuit tester.

OK or NG

OK >> GO TO 2.

NG >> Check the following: • 40A fusible link (letter h, located in fuse and fusible

link box)

Battery voltage should exist

WKIA0137E

Ignition switch in

START

: Less than 0.2V

WKIA0138E

Ignition switch in

START : Less than 0.2V

AWBIA0750GB

Ignition switch in

START: Battery voltage

AWBIA0751GB

Revision: January 20102010 Versa

Page 3558 of 3745

STARTING SYSTEMSC-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

• 10A fuse (No. 49, M/T model s, located in the IPDM E/R)

• 15A fuse (No. 52, located in the IPDM E/R)

• 20A fuse (No. 53, located in the IPDM E/R)

• Transmission range switch, clutch interlock switch or TCM depending on equipment

• Ignition switch

• Ignition relay IPDM E/R

• Starter relay IPDM E/R

• Starter relay request ON signal from BCM

• Harness for open or short circuit

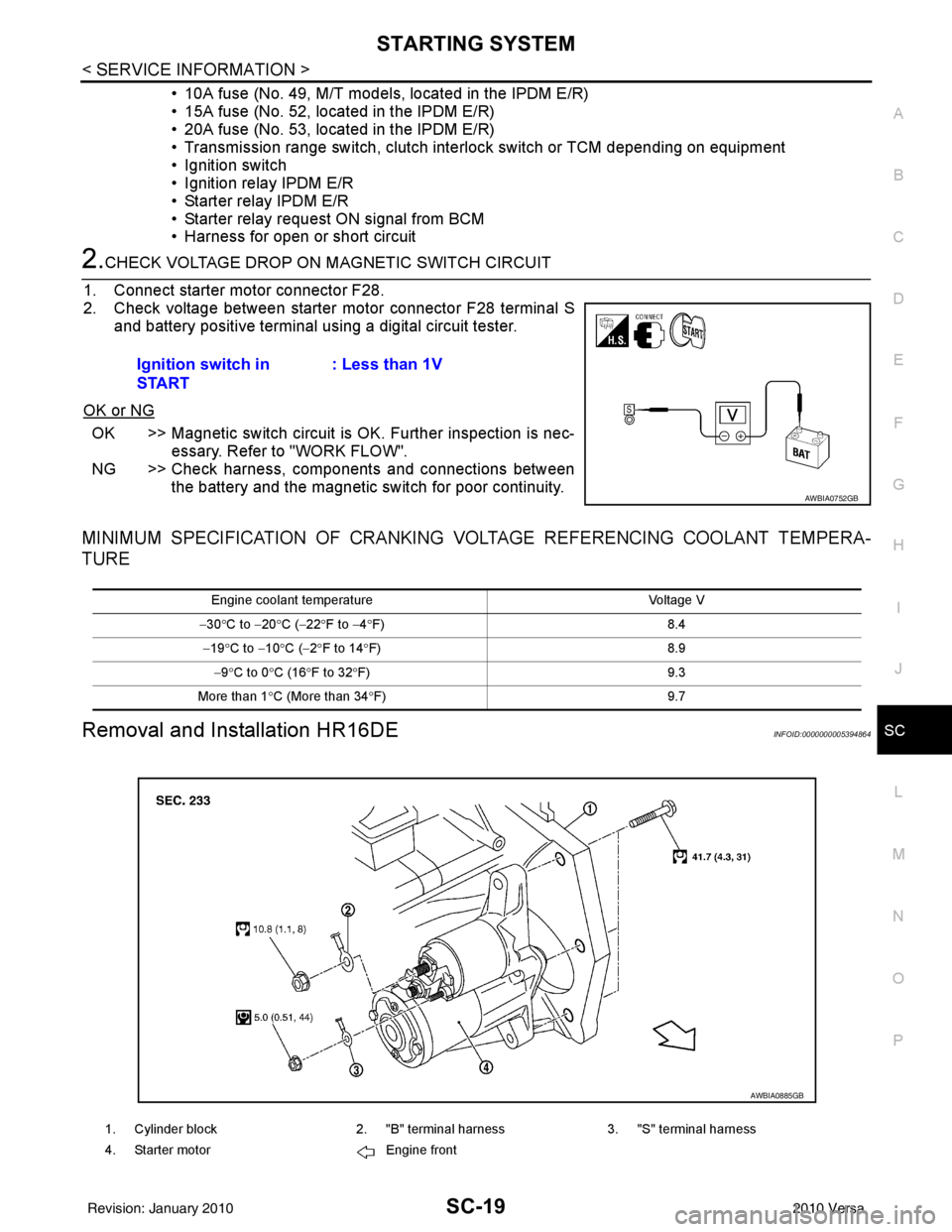

2.CHECK VOLTAGE DROP ON MAGNETIC SWITCH CIRCUIT

1. Connect starter motor connector F28.

2. Check voltage between starter motor connector F28 terminal S and battery positive terminal using a digital circuit tester.

OK or NG

OK >> Magnetic switch circuit is OK. Further inspection is nec-

essary. Refer to "WORK FLOW".

NG >> Check harness, components and connections between the battery and the magnetic switch for poor continuity.

MINIMUM SPECIFICATION OF CRANKING VO LTAGE REFERENCING COOLANT TEMPERA-

TURE

Removal and Installation HR16DEINFOID:0000000005394864

Ignition switch in

START : Less than 1V

AWBIA0752GB

Engine coolant temperature

Voltage V

− 30 °C to − 20°C ( −22 °F to −4 °F) 8.4

− 19 °C to − 10°C ( −2°F to 14 °F) 8.9

− 9 °C to 0 °C (16 °F to 32 °F) 9.3

More than 1 °C (More than 34 °F) 9.7

1. Cylinder block2. "B" terminal harness3. "S" terminal harness

4. Starter motor Engine front

AWBIA0885GB

Revision: January 20102010 Versa

Page 3560 of 3745

CHARGING SYSTEMSC-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

SC

N

O P

CHARGING SYSTEM

System DescriptionINFOID:0000000005394866

The generator provides DC voltage to operate the vehicl e's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal 3 through

• 10A fuse (No. 29, located in the fuse and fusible link box).

Power is supplied through terminal 1 to charge the batte ry and operate the vehicle's electrical system. Output

voltage is monitored at terminal 3 by the IC regulator. The charging circuit is protected by the 120A fusible link

[letter a , located in the fusible link box (battery)].

Ground is supplied

• to generator terminal 5

• through body ground F5, and

• through the generator case to the cylinder block

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28 for the charge warning lamp.

The IC regulator controls ground to terminal 38 of the combination meter through terminal 2 of the generator.

When the ignition is turned on and power becomes availabl e at terminal 2, this "wakes up" the regulator. The

regulator monitors charge output and grounds terminal 2 or leaves it open depending on charge output. With

power and ground supplied, the charge warning lamp will il luminate. When the generator is providing sufficient

voltage, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Revision: January 20102010 Versa