instrument panel NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 627 of 3745

![NISSAN TIIDA 2010 Service User Guide BL-118

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

*: Select “SELECTION FROM MENU”.

ACTIVE TEST

* : Sedan

WORK SUPPORT

STOP LAMP SWIndicates [ON/OFF] condition of stop lamp switch.

P RANGE SW I NISSAN TIIDA 2010 Service User Guide BL-118

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

*: Select “SELECTION FROM MENU”.

ACTIVE TEST

* : Sedan

WORK SUPPORT

STOP LAMP SWIndicates [ON/OFF] condition of stop lamp switch.

P RANGE SW I](/img/5/57397/w960_57397-626.png)

BL-118

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

*: Select “SELECTION FROM MENU”.

ACTIVE TEST

* : Sedan

WORK SUPPORT

STOP LAMP SWIndicates [ON/OFF] condition of stop lamp switch.

P RANGE SW Indicates [ON/OFF] condition of shift lever park position.

BD OPEN SW Indicates [ON/OFF] condition of back door open switch.

DOOR LOCK SIG* Indicates [ON/OFF] condition of door lock signal from Intelligent Key button.

DOOR UNLOCK SIG* Indicates [ON/OFF] condition of door unlock signal from Intelligent Key button

KEYLESS PANIC* Indicates [ON/OFF] condition of panic signal from Intelligent Key button

DOOR SW DR* Indicates [OPEN/CLOSE] condition of front door sw

itch driver side from BCM via CAN communica-

tion line.

DOOR SW AS* Indicates [OPEN/CLOSE] condition of front door switch passenger side from BCM via CAN commu-

nication line.

DOOR SW RR* Indicates [OPEN/CLOSE] condition of rear door switch RH from BCM via CAN communication line.

DOOR SW RL* Indicates [OPEN/CLOSE] condition of rear door switch LH from BCM via CAN communication line.

VEHICLE SPEED* Indicates [km/h] condition of vehicle speed.

Monitor item

Content

Te s t i t e mD e s c r i p t i o n

DOOR LOCK/UNLOCK This test is able to check door lock/unlock operation.

• The all door lock actuators are unlocked when “ALL UNLK” on CONSULT-III screen is touched.

• The all door lock actuators are locked when “LOCK” on CONSULT-III screen is touched.

ANTENNA This test is able to check Intelligent Key antenna operation.

When the following conditions are met, hazard warning lamps flash.

• Inside key antenna (front console) detects Intelligent Key, when “ROOM ANT1” on CONSULT-

III screen is touched.

• Inside key antenna (instrument panel and rear floor) detects Intelligent Key, when “ROOM

ANT2” on CONSULT-III screen is touched.

• Outside key antenna (driver side) detects Intelligent Key, when “DR ANT” on CONSULT-III screen is touched.

• Outside key antenna (passenger side) detects Intelligent Key, when “AS ANT” on CONSULT-III screen is touched.

• Outside key antenna (rear bumper) detects Intelligent Key, when “BK DR ANT” on CONSULT-

III screen is touched.

OUTSIDE BUZZER This test is able to check Intelligent Key warning buzzer operation.

Intelligent Key warning buzzer sounds when “ON” on CONSULT-III screen is touched.

INSIDE BUZZER This test is able to check Intelligent Key warning chime (Instrument panel) operation.

• Take away warning chime sounds when “TAKE OUT” on CONSULT-III screen is touched.

• Ignition switch warning chime sounds when “KNOB” on CONSULT-III screen is touched.

• Ignition key warning chime sounds when “KEY” on CONSULT-III screen is touched.

INDICATOR This test is able to check warning lamp operation.

• “KEY” Warning lamp (Green) illuminates when “BLUE ON” on CONSULT-III screen is touched.

• “KEY” Warning lamp (Red) illuminates when

“RED ON” on CONSULT-III screen is touched.

• “LOCK” Warning lamp illuminates when “KNOB ON” on CONSULT-III screen is touched.

• “KEY” Warning lamp (Green) flashes when “BLUE IND” on CONSULT-III screen is touched.

• “KEY” Warning lamp (RED) flashes when “RED IND” on CONSULT-III screen is touched.

• “P-SHIFT” Warning lamp flashes when “KNOB IND” on CONSULT-III screen is touched.

Monitor item Description

CONFIRM KEY FOB ID It can be checked whether Intelligent Key ID code is registered or not in this mode.

TAKE OUT FROM WINDOW

WARN Take away warning chime (from window) mode can be changed to operate (ON) or not operate

(OFF) with this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-

III screen is touched.

Revision: January 20102010 Versa

Page 655 of 3745

BL-146

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

OK or NG

OK >> Replace rear bumper antenna.

NG >> Replace Intelligent Key unit. Refer to BL-158, "

Removal and Installation of Intelligent Key Unit".

Inside Key Antenna CheckINFOID:0000000005396626

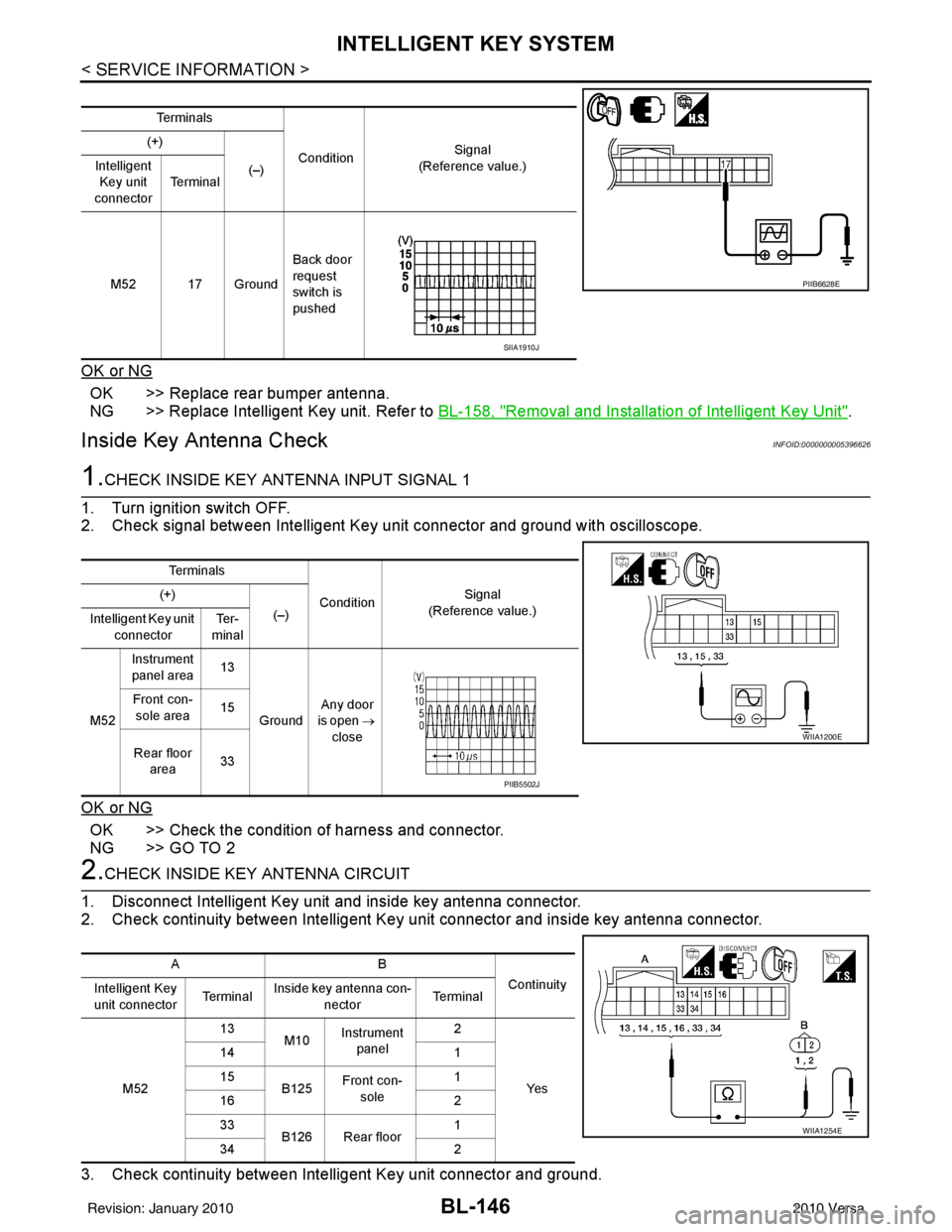

1.CHECK INSIDE KEY ANTENNA INPUT SIGNAL 1

1. Turn ignition switch OFF.

2. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Check the condition of harness and connector.

NG >> GO TO 2

2.CHECK INSIDE KEY ANTENNA CIRCUIT

1. Disconnect Intelligent Key unit and inside key antenna connector.

2. Check continuity between Intelligent Key unit connector and inside key antenna connector.

3. Check continuity between Intelligent Key unit connector and ground.

Te r m i n a l s

Condition Signal

(Reference value.)

(+)

(–)

Intelligent

Key unit

connector Te r m i n a l

M52 17 Ground Back door

request

switch is

pushed

PIIB6628E

SIIA1910J

Te r m i n a l s

ConditionSignal

(Reference value.)

(+)

(–)

Intelligent Key unit

connector Te r -

minal

M52 Instrument

panel area 13

Ground Any door

is open →

close

Front con-

sole area 15

Rear floor area 33

WIIA1200E

PIIB5502J

AB

Continuity

Intelligent Key

unit connector Te r m i n a lInside key antenna con-

nector Te r m i n a l

M52 13

M10Instrument

panel 2

Ye s

14

1

15 B125Front con-

sole 1

16 2

33 B126 Rear floor 1

34 2

WIIA1254E

Revision: January 20102010 Versa

Page 656 of 3745

INTELLIGENT KEY SYSTEMBL-147

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

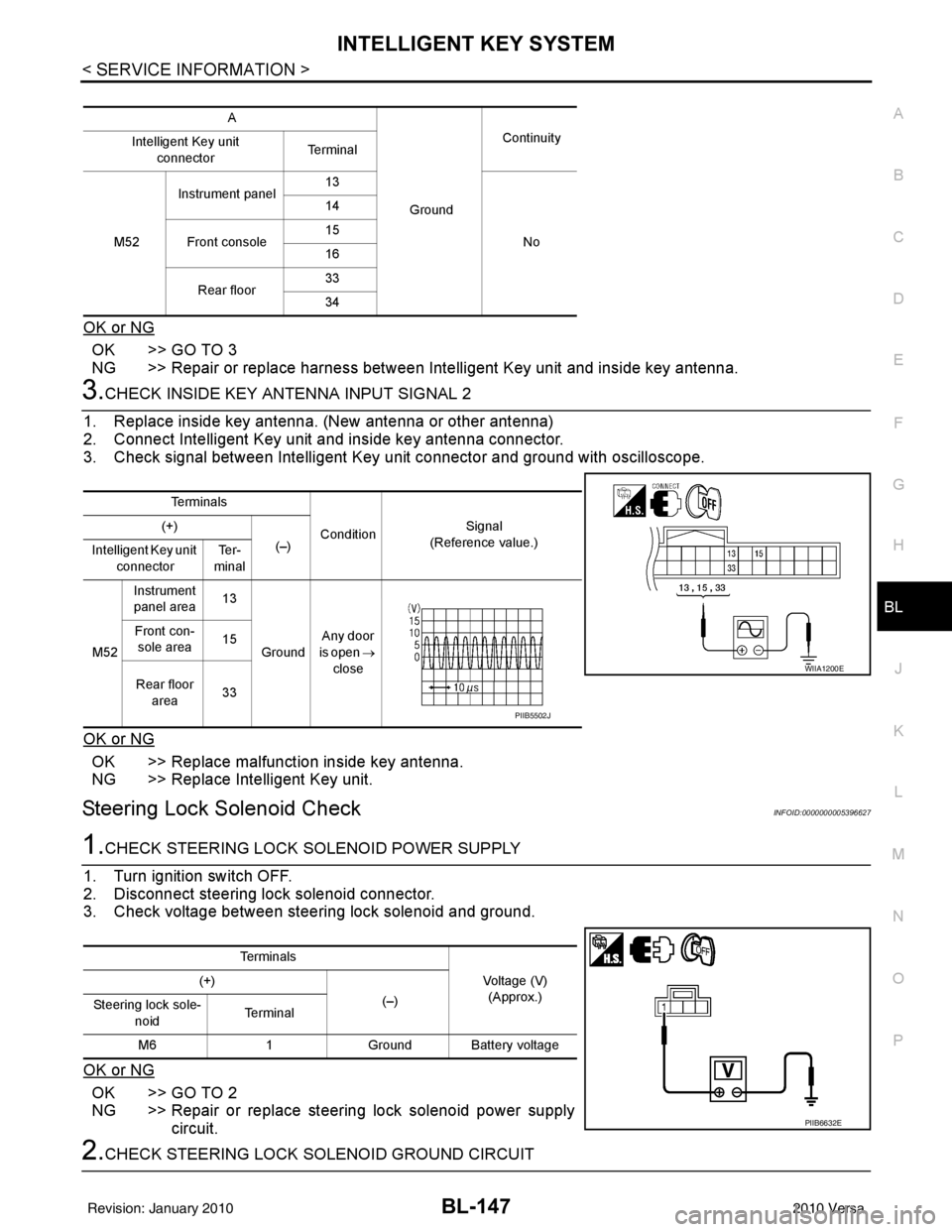

OK or NG

OK >> GO TO 3

NG >> Repair or replace harness between Intelligent Key unit and inside key antenna.

3.CHECK INSIDE KEY ANTENNA INPUT SIGNAL 2

1. Replace inside key antenna. (New antenna or other antenna)

2. Connect Intelligent Key unit and inside key antenna connector.

3. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Replace malfunction inside key antenna.

NG >> Replace Intelligent Key unit.

Steering Lock Solenoid CheckINFOID:0000000005396627

1.CHECK STEERING LOCK SOLENOID POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect steering lock solenoid connector.

3. Check voltage between steering lock solenoid and ground.

OK or NG

OK >> GO TO 2

NG >> Repair or replace steering lock solenoid power supply circuit.

2.CHECK STEERING LOCK SOLENOID GROUND CIRCUIT

A

GroundContinuity

Intelligent Key unit

connector Te r m i n a l

M52 Instrument panel

13

No

14

Front console 15

16

Rear floor 33

34

Te r m i n a l s

ConditionSignal

(Reference value.)

(+)

(–)

Intelligent Key unit

connector Te r -

minal

M52 Instrument

panel area 13

Ground Any door

is open →

close

Front con-

sole area 15

Rear floor area 33

WIIA1200E

PIIB5502J

Te r m i n a l s

Voltage (V)(Approx.)

(+)

(–)

Steering lock sole-

noid Te r m i n a l

M6 1Ground Battery voltage

PIIB6632E

Revision: January 20102010 Versa

Page 689 of 3745

BL-180

< SERVICE INFORMATION >

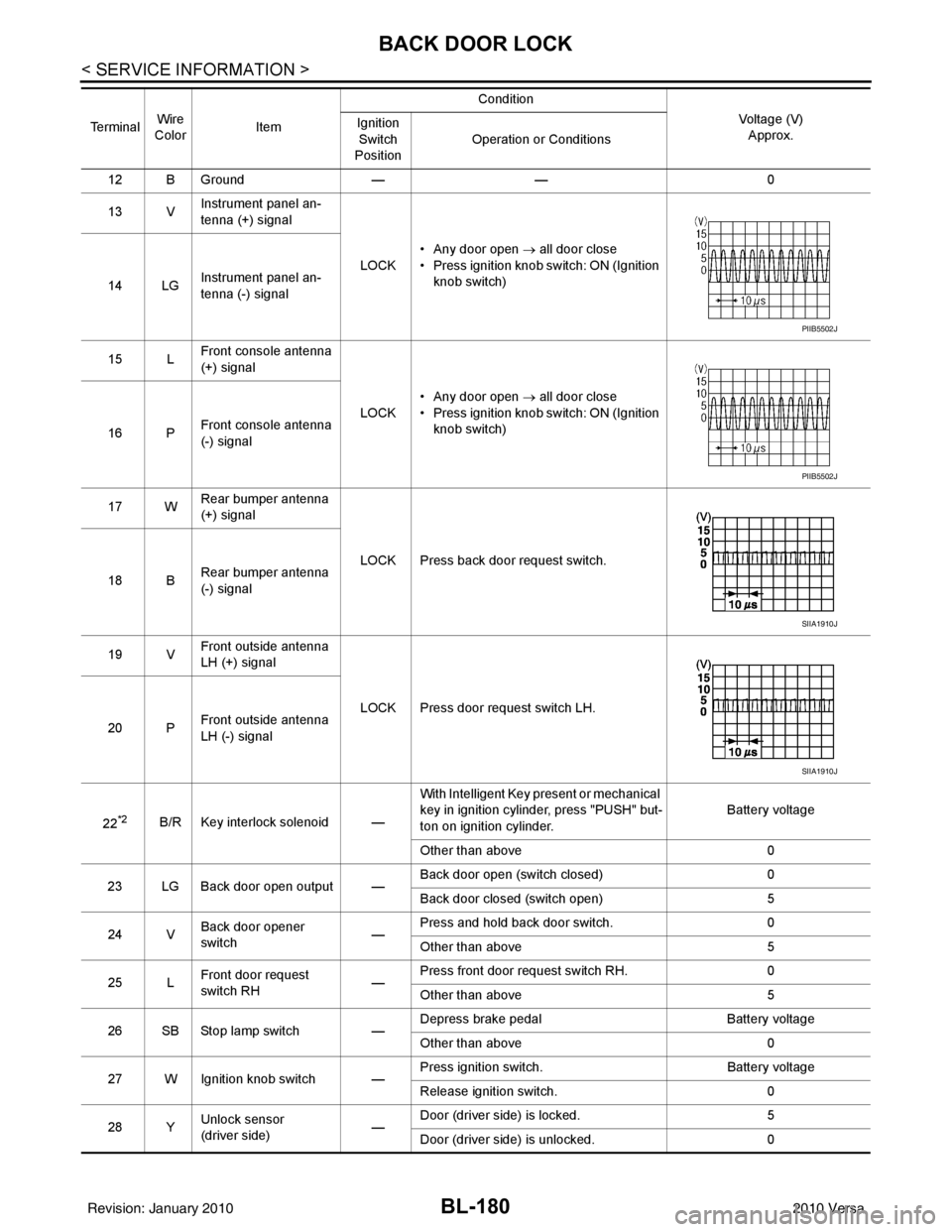

BACK DOOR LOCK

12 B Ground—— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2B/R Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH —Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

28 Y Unlock sensor

(driver side) —Door (driver si

de) is locked. 5

Door (driver side ) is unlocked. 0

Te r m i n a l

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Revision: January 20102010 Versa

Page 713 of 3745

BL-204

< SERVICE INFORMATION >

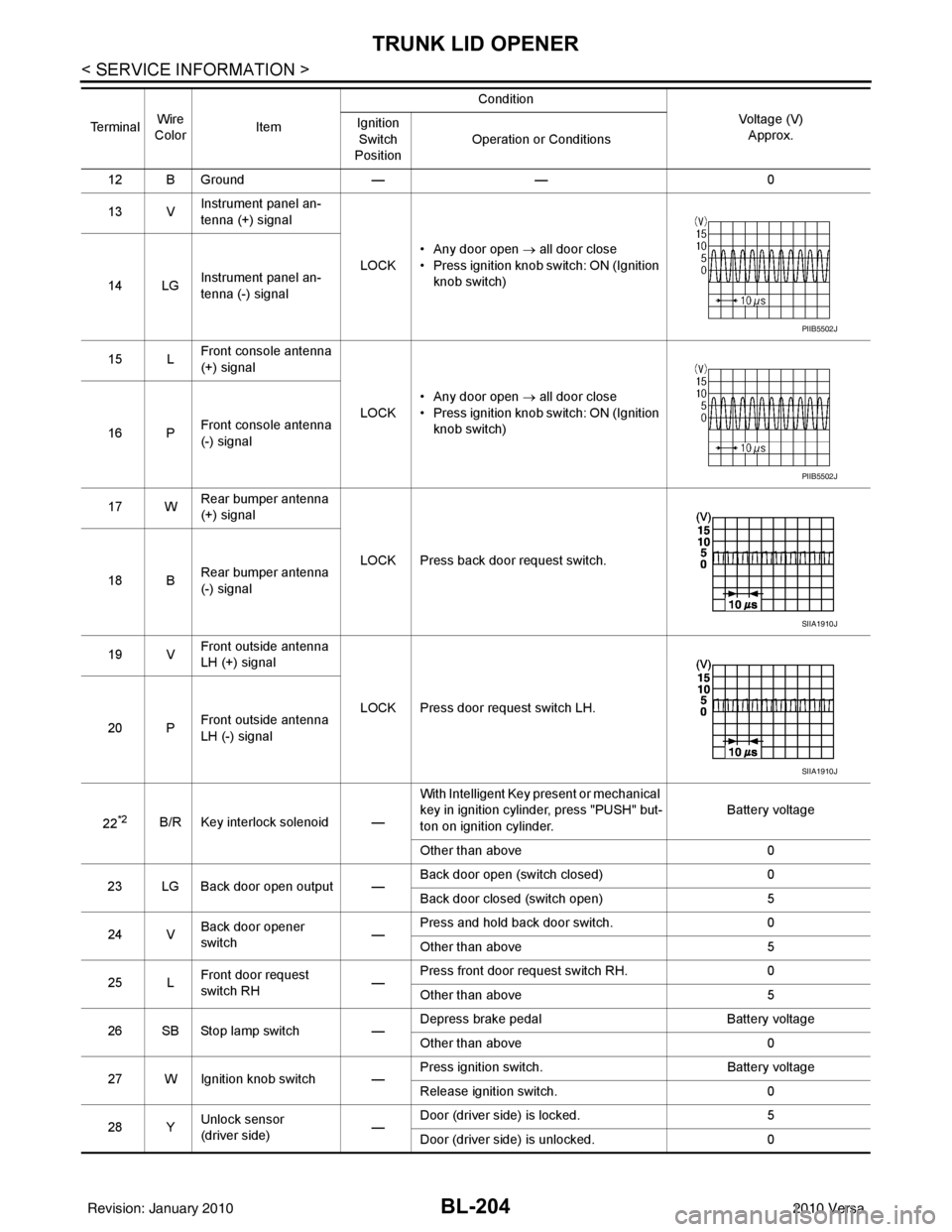

TRUNK LID OPENER

12 B Ground—— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2B/R Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH —Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

28 Y Unlock sensor

(driver side) —Door (driver si

de) is locked. 5

Door (driver side ) is unlocked. 0

Te r m i n a l

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Revision: January 20102010 Versa

Page 741 of 3745

BL-232

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

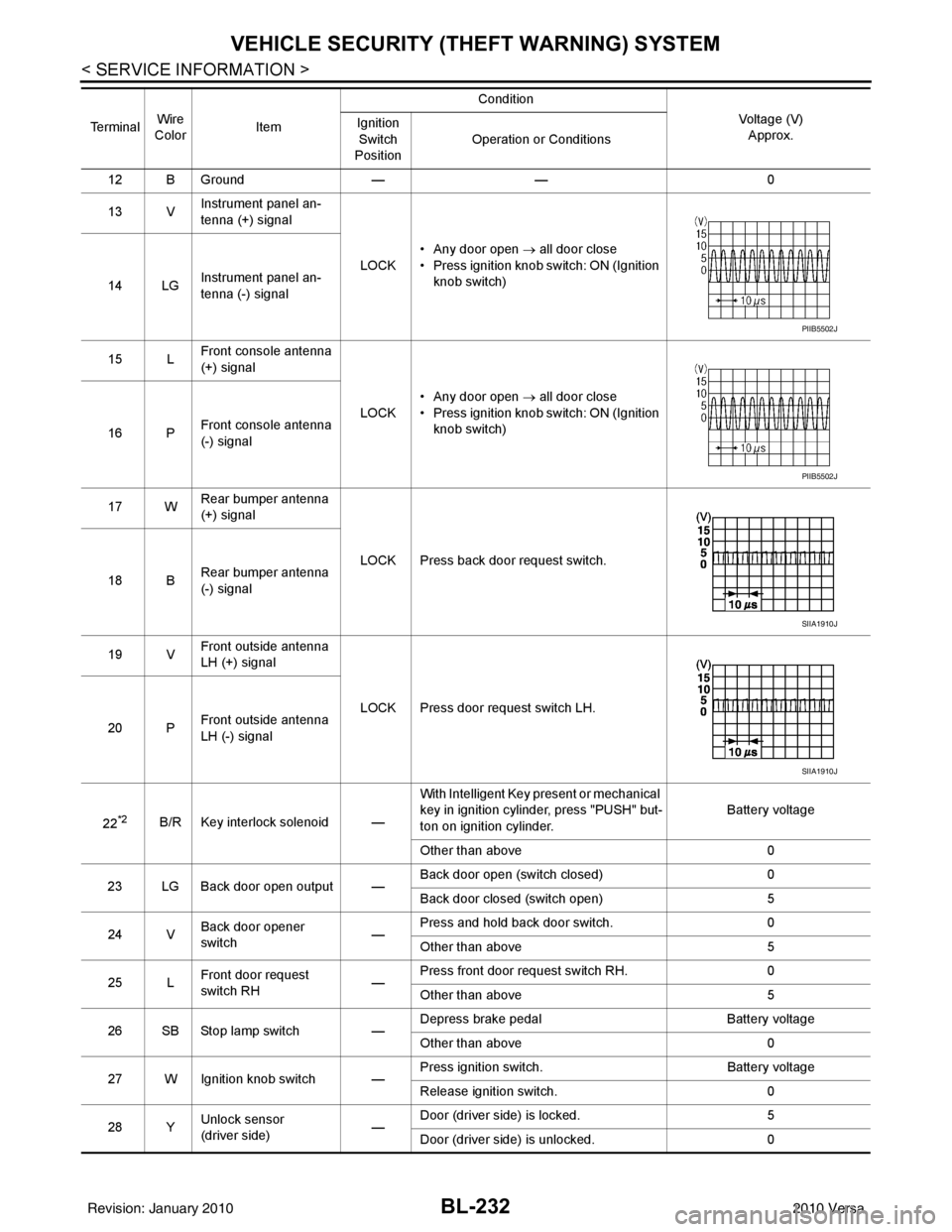

12 B Ground —— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2B/R Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH —Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

28 Y Unlock sensor

(driver side) —Door (driver si

de) is locked. 5

Door (driver side ) is unlocked. 0

Te r m i n a l

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Revision: January 20102010 Versa

Page 869 of 3745

BRAKE BOOSTERBR-21

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

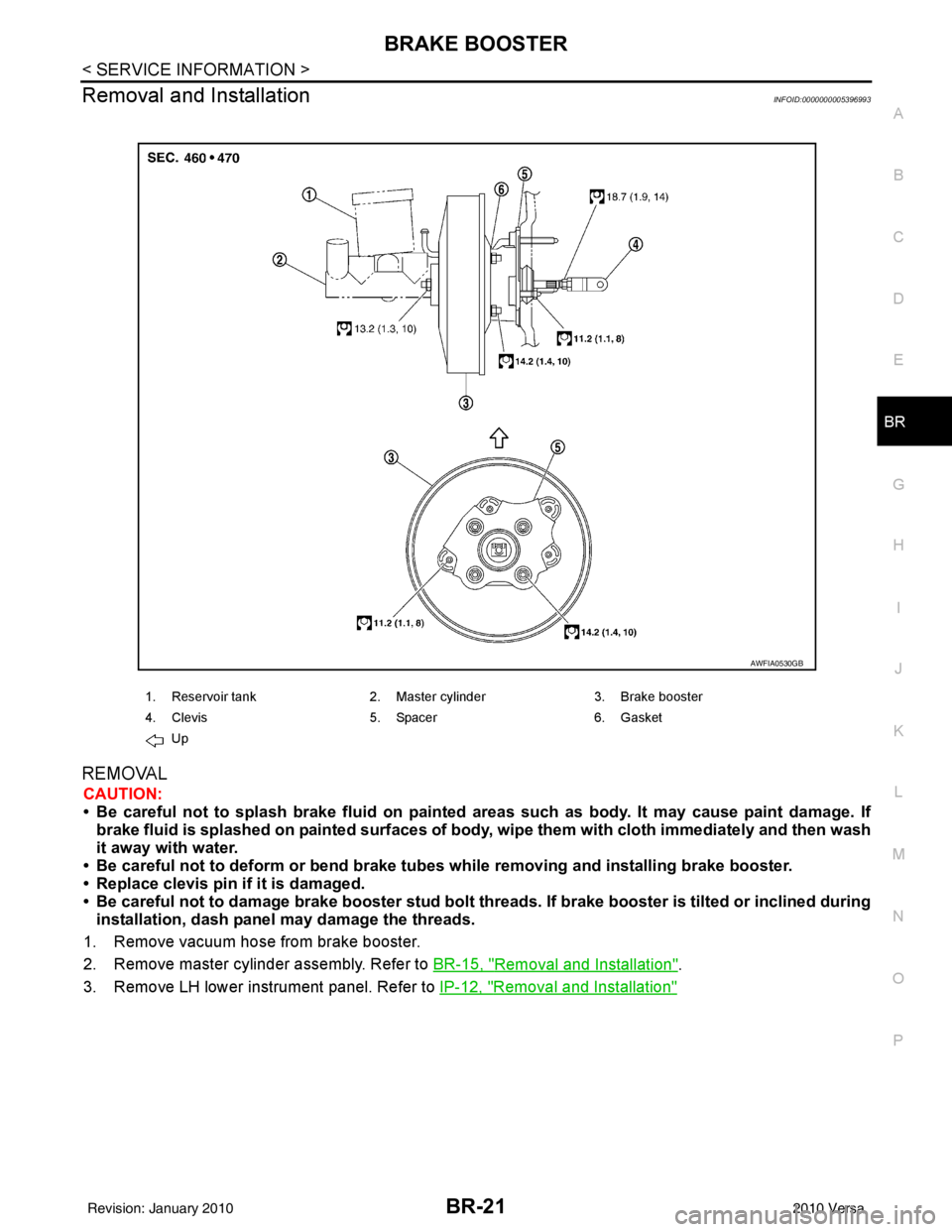

Removal and InstallationINFOID:0000000005396993

REMOVAL

CAUTION:

• Be careful not to splash brake fluid on painted areas such as body. It may cause paint damage. If brake fluid is splashed on painte d surfaces of body, wipe them with cloth immediately and then wash

it away with water.

• Be careful not to deform or bend brake tub es while removing and installing brake booster.

• Replace clevis pin if it is damaged.

• Be careful not to damage brake booster stud bolt thr eads. If brake booster is tilted or inclined during

installation, dash panel may damage the threads.

1. Remove vacuum hose from brake booster.

2. Remove master cylinder assembly. Refer to BR-15, "

Removal and Installation".

3. Remove LH lower instrument panel. Refer to IP-12, "

Removal and Installation"

1. Reservoir tank2. Master cylinder 3. Brake booster

4. Clevis 5. Spacer 6. Gasket

Up

AWFIA0530GB

Revision: January 20102010 Versa

Page 870 of 3745

BR-22

< SERVICE INFORMATION >

BRAKE BOOSTER

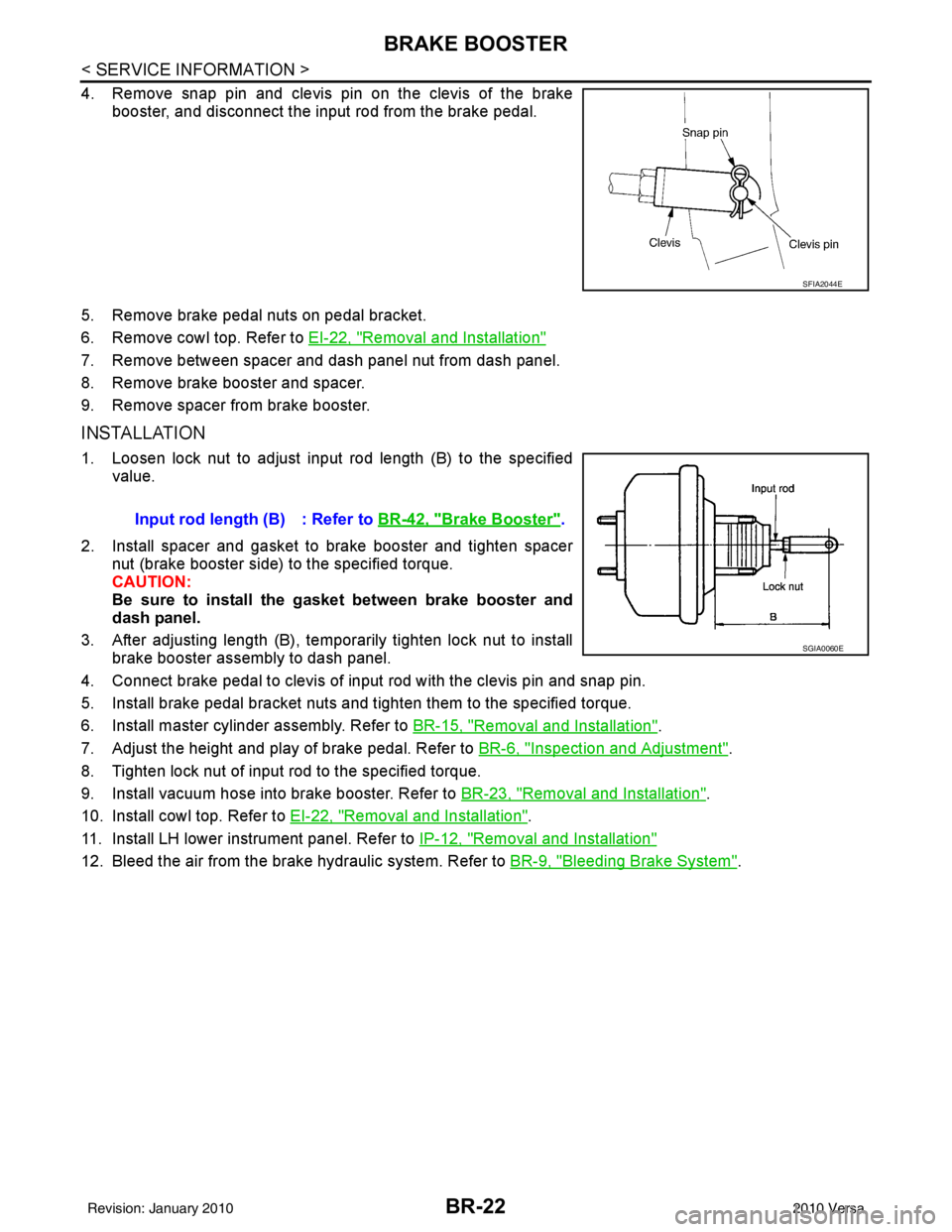

4. Remove snap pin and clevis pin on the clevis of the brakebooster, and disconnect the input rod from the brake pedal.

5. Remove brake pedal nuts on pedal bracket.

6. Remove cowl top. Refer to EI-22, "

Removal and Installation"

7. Remove between spacer and dash panel nut from dash panel.

8. Remove brake booster and spacer.

9. Remove spacer from brake booster.

INSTALLATION

1. Loosen lock nut to adjust input rod length (B) to the specified

value.

2. Install spacer and gasket to brake booster and tighten spacer nut (brake booster side) to the specified torque.

CAUTION:

Be sure to install the gasket between brake booster and

dash panel.

3. After adjusting length (B), temporarily tighten lock nut to install brake booster assembly to dash panel.

4. Connect brake pedal to clevis of input rod with the clevis pin and snap pin.

5. Install brake pedal bracket nuts and tighten them to the specified torque.

6. Install master cylinder assembly. Refer to BR-15, "

Removal and Installation".

7. Adjust the height and play of brake pedal. Refer to BR-6, "

Inspection and Adjustment".

8. Tighten lock nut of input rod to the specified torque.

9. Install vacuum hose into brake booster. Refer to BR-23, "

Removal and Installation".

10. Install cowl top. Refer to EI-22, "

Removal and Installation".

11. Install LH lower instrument panel. Refer to IP-12, "

Removal and Installation"

12. Bleed the air from the brake hydraulic system. Refer to BR-9, "Bleeding Brake System".

SFIA2044E

Input rod length (B) : Refer to BR-42, "Brake Booster".

SGIA0060E

Revision: January 20102010 Versa

Page 1060 of 3745

![NISSAN TIIDA 2010 Service User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-27

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005397780

The CVT system has two s NISSAN TIIDA 2010 Service User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-27

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005397780

The CVT system has two s](/img/5/57397/w960_57397-1059.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-27

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000005397780

The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic syst em (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MI L (malfunction indicator lamp) and is stored as a DTC in

the ECM memory, and the TCM memory.

The second is the TCM original self-diagnosis perform ed by the TCM. The malfunction is stored in the TCM

memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail, refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

OBD-II Function for CVT SystemINFOID:0000000005397781

The ECM provides emission-related on board diagnostic (OBD-II) functions for the CVT system. One function

is to receive a signal from the TCM used with OBD-relat ed parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indica tor lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to CVT system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000005397782

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” m eans a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000005397783

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONS ULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected curr ently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

Revision: January 20102010 Versa

Page 1062 of 3745

![NISSAN TIIDA 2010 Service User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-29

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch NISSAN TIIDA 2010 Service User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-29

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch](/img/5/57397/w960_57397-1061.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMCVT-29

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with- out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-21, "

Schematic", or see

EC-1033, "

Wiring Diagram".

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U

Revision: January 20102010 Versa