stop start NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 136 of 3745

P0734 4GR INCORRECT RATIOAT-119

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the vo ltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “4TH GR FNCTN P0734” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

5. Accelerate vehicle to 55 to 65 km/h (34 to 40 MPH) under the following conditions and release the accel-

erator pedal completely.

THROTTLE POSI: Less th an 5.5/8 (at all times during step 4)

SLCT LVR POSI: “D” position

- Make sure that “GEAR” shows “3” after releasing pedal.

6. Depress accelerator pedal steadily with 1.0/8 - 2.0/ 8 of “THROTTLE POSI” from a speed of 55 to 65 km/h

(34 to 40 MPH) until “TESTING” has turned to “STO P VEHICLE” or “COMPLETED”. (It will take approxi-

mately 3 seconds.)

If the check result NG appears on CONSULT-III screen, go to AT-119, "

Diagnosis Procedure".

If “STOP VEHICLE” appears on CONSULT-III screen, go to following step.

- Make sure that “GEAR” shows “4” when depressing accelerator pedal with 1.0/8 - 2.0/8 of

“THROTTLE POSI”.

- If “TESTING” does not appear on CONSULT-III fo r a long time, select “SELF-DIAG RESULTS” for

“TRANSMISSION”. In case a DTC other than “P0734 4GR INCORRECT RATIO” is shown, refer to

AT-77, "

CONSULT-III Function (TRANSMISSION)".

7. Stop vehicle.

8. Follow the instruction displayed. (Check for normal shifting referring to the table below.)

9. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “Diagnostic Procedure”.)

Refer to AT-119, "

Diagnosis Procedure".

Refer to AT-64, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005397309

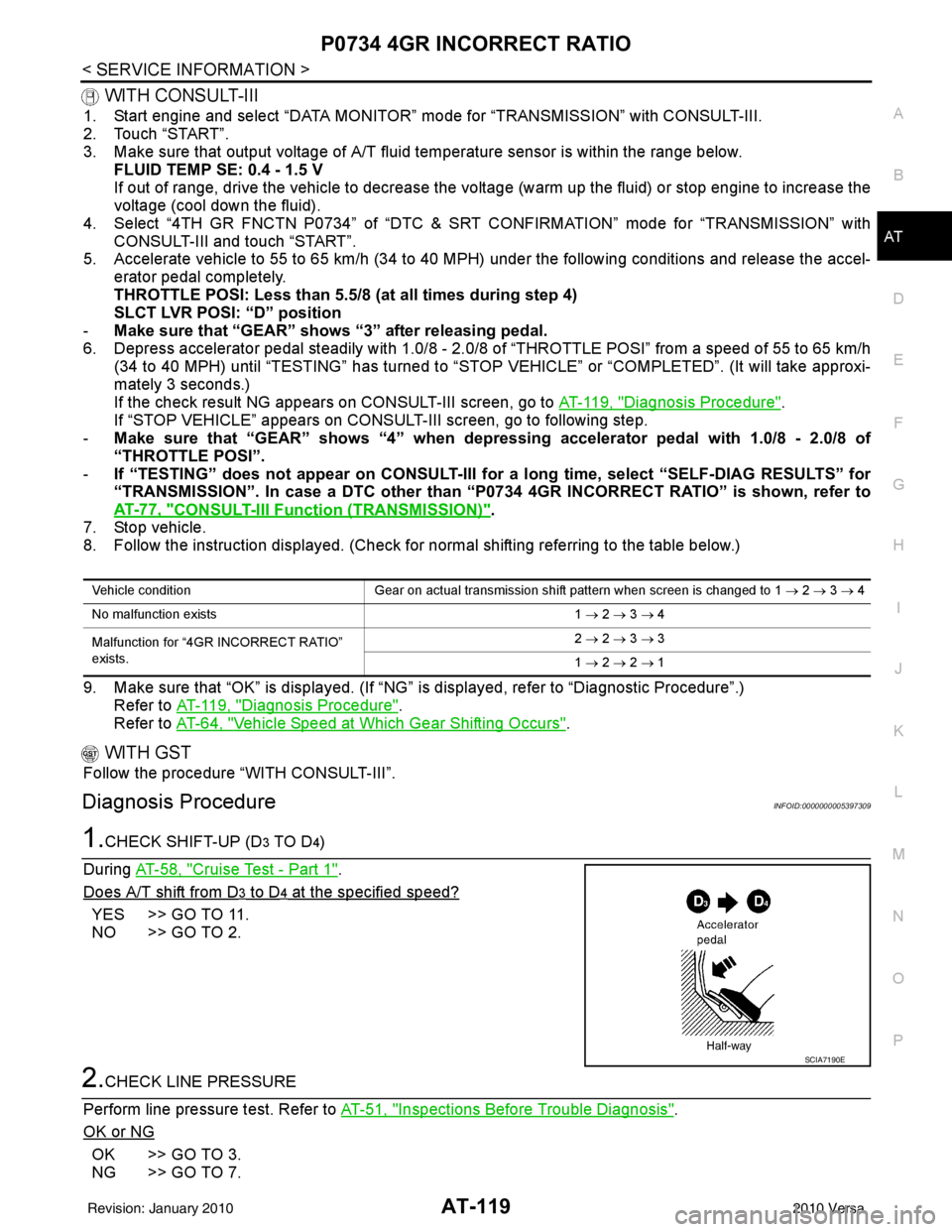

1.CHECK SHIFT-UP (D3 TO D4)

During AT-58, "

Cruise Test - Part 1".

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 11.

NO >> GO TO 2.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-51, "

Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 3.

NG >> GO TO 7.

Vehicle condition Gear on actual transmission shift pattern when screen is changed to 1 → 2 → 3 → 4

No malfunction exists 1 → 2 → 3 → 4

Malfunction for “4GR INCORRECT RATIO”

exists. 2

→ 2 → 3 → 3

1 → 2 → 2 → 1

SCIA7190E

Revision: January 20102010 Versa

Page 145 of 3745

AT-128

< SERVICE INFORMATION >

P0744 TORQUE CONVERTER

P0744 TORQUE CONVERTER

DescriptionINFOID:0000000005397318

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosismalfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397319

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005397320

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 T/C CLUTCH FNCTN” wit h CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stuc k closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 T/C CLUTCH FNCTN” is detected.

Possible CauseINFOID:0000000005397321

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005397322

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Revision: January 20102010 Versa

Page 234 of 3745

SHIFT CONTROL SYSTEMAT-217

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

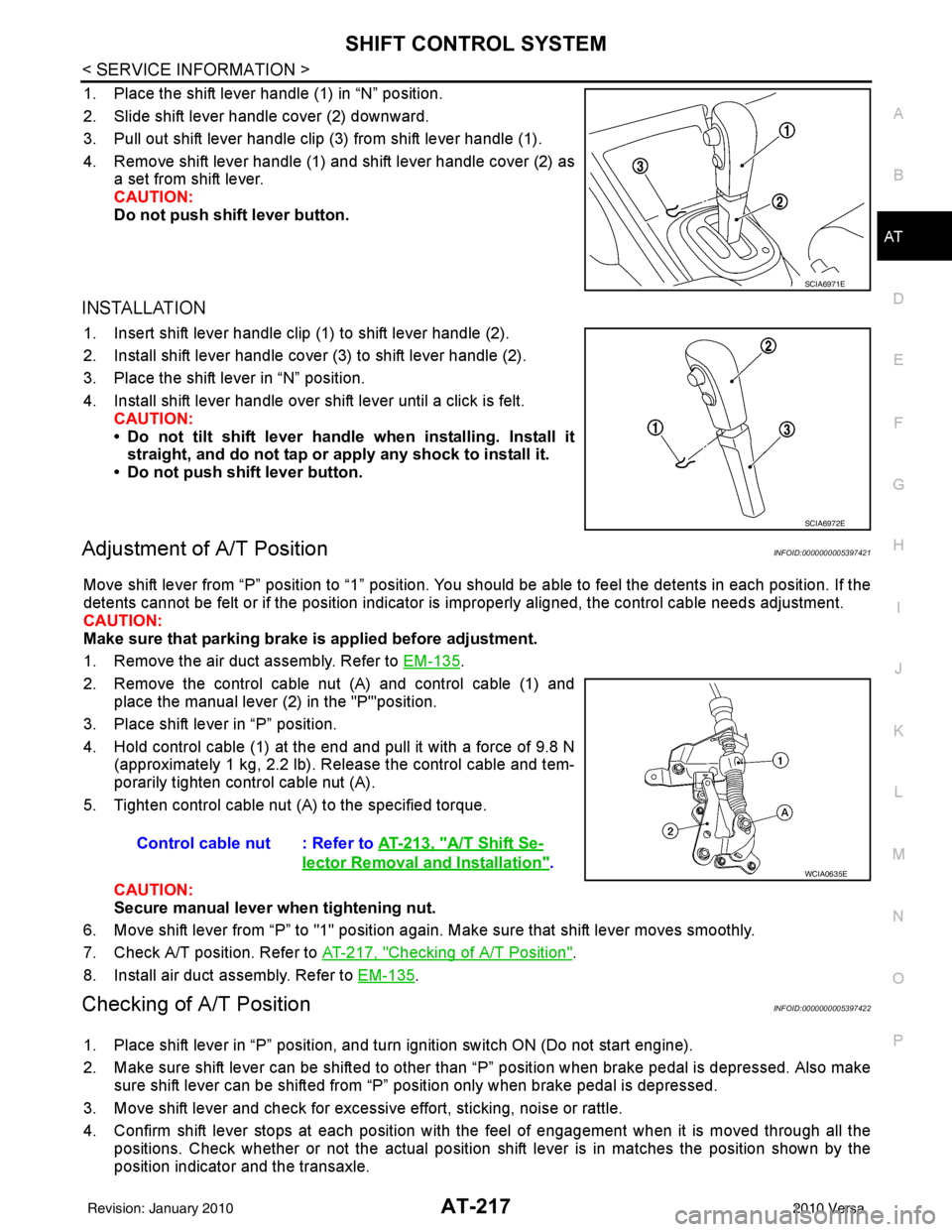

1. Place the shift lever handle (1) in “N” position.

2. Slide shift lever handle cover (2) downward.

3. Pull out shift lever handle clip (3) from shift lever handle (1).

4. Remove shift lever handle (1) and shift lever handle cover (2) as a set from shift lever.

CAUTION:

Do not push shift lever button.

INSTALLATION

1. Insert shift lever handle clip (1) to shift lever handle (2).

2. Install shift lever handle cover (3) to shift lever handle (2).

3. Place the shift lever in “N” position.

4. Install shift lever handle over shift lever until a click is felt.CAUTION:

• Do not tilt shift lever handle when installing. Install it

straight, and do not tap or ap ply any shock to install it.

• Do not push shift lever button.

Adjustment of A/T PositionINFOID:0000000005397421

Move shift lever from “P” position to “1” position. You should be able to feel the detents in each position. If the

detents cannot be felt or if the position indicator is improperly aligned, the control cable needs adjustment.

CAUTION:

Make sure that parking brake is applied before adjustment.

1. Remove the air duct assembly. Refer to EM-135

.

2. Remove the control cable nut (A) and control cable (1) and place the manual lever (2) in the "P'"position.

3. Place shift lever in “P” position.

4. Hold control cable (1) at the end and pull it with a force of 9.8 N (approximately 1 kg, 2.2 lb). Release the control cable and tem-

porarily tighten control cable nut (A).

5. Tighten control cable nut (A) to the specified torque.

CAUTION:

Secure manual lever when tightening nut.

6. Move shift lever from “P” to "1" position again. Make sure that shift lever moves smoothly.

7. Check A/T position. Refer to AT-217, "

Checking of A/T Position".

8. Install air duct assembly. Refer to EM-135

.

Checking of A/T PositionINFOID:0000000005397422

1. Place shift lever in “P” position, and turn ignition switch ON (Do not start engine).

2. Make sure shift lever can be shifted to other t han “P” position when brake pedal is depressed. Also make

sure shift lever can be shifted from “P” position only when brake pedal is depressed.

3. Move shift lever and check for excessive effort, sticking, noise or rattle.

4. Confirm shift lever stops at each position with the feel of engagement when it is moved through all the positions. Check whether or not the actual position shift lever is in matches the position shown by the

position indicator and the transaxle.

SCIA6971E

SCIA6972E

Control cable nut : Refer to AT-213, "A/T Shift Se-

lector Removal and Installation".WCIA0635E

Revision: January 20102010 Versa

Page 518 of 3745

SQUEAK AND RATTLE TROUBLE DIAGNOSESBL-9

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005396545

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: January 20102010 Versa

Page 630 of 3745

INTELLIGENT KEY SYSTEMBL-121

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

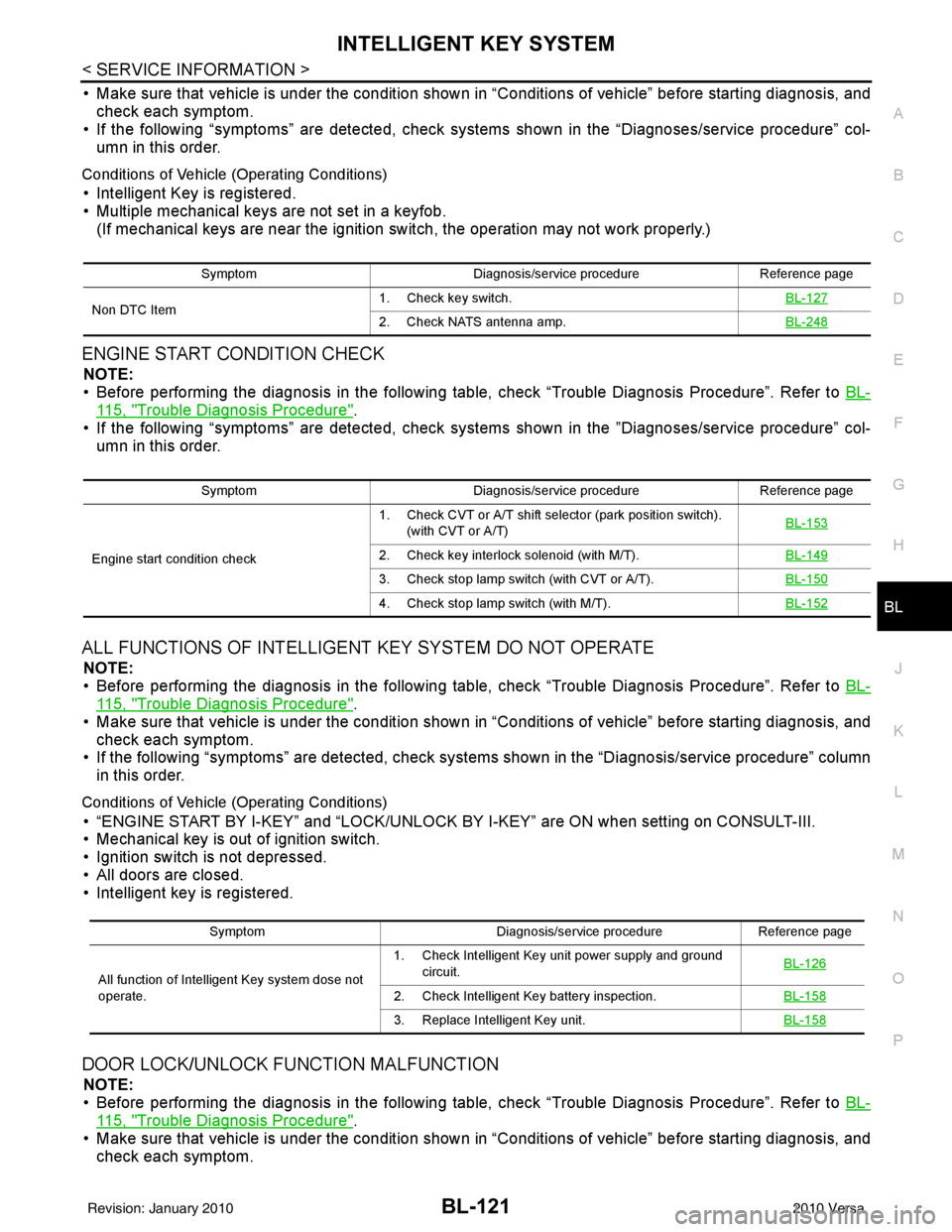

• Make sure that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

• If the following “symptoms” are detected, check syst ems shown in the “Diagnoses/service procedure” col-

umn in this order.

Conditions of Vehicle (Operating Conditions)

• Intelligent Key is registered.

• Multiple mechanical keys are not set in a keyfob. (If mechanical keys are near the ignition switch, the operation may not work properly.)

ENGINE START CONDITION CHECK

NOTE:

• Before performing the diagnosis in the following table, check “Trouble Diagnosis Procedure”. Refer to BL-

115, "Trouble Diagnosis Procedure".

• If the following “symptoms” are detected, check syst ems shown in the ”Diagnoses/service procedure” col-

umn in this order.

ALL FUNCTIONS OF INTELLIGENT KEY SYSTEM DO NOT OPERATE

NOTE:

• Before performing the diagnosis in the following table, check “Trouble Diagnosis Procedure”. Refer to BL-

115, "Trouble Diagnosis Procedure".

• Make sure that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

• If the following “symptoms” are detected, check syst ems shown in the “Diagnosis/service procedure” column

in this order.

Conditions of Vehicle (Operating Conditions)

• “ENGINE START BY I-KEY” and “LOCK/UNLOCK BY I-KEY” are ON when setting on CONSULT-III.

• Mechanical key is out of ignition switch.

• Ignition switch is not depressed.

• All doors are closed.

• Intelligent key is registered.

DOOR LOCK/UNLOCK FUNCTION MALFUNCTION

NOTE:

• Before performing the diagnosis in the following table, check “Trouble Diagnosis Procedure”. Refer to BL-

115, "Trouble Diagnosis Procedure".

• Make sure that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

Symptom Diagnosis/service procedure Reference page

Non DTC Item 1. Check key switch.

BL-127

2. Check NATS antenna amp.BL-248

SymptomDiagnosis/service procedure Reference page

Engine start condition check 1. Check CVT or A/T shift selector (park position switch).

(with CVT or A/T) BL-153

2. Check key interlock solenoid (with M/T).

BL-149

3. Check stop lamp switch (with CVT or A/T).BL-150

4. Check stop lamp switch (with M/T).BL-152

SymptomDiagnosis/service procedureReference page

All function of Intelligent Key system dose not

operate. 1. Check Intelligent Key unit power supply and ground

circuit. BL-126

2. Check Intelligent Key battery inspection.

BL-158

3. Replace Intelligent Key unit.BL-158

Revision: January 20102010 Versa

Page 855 of 3745

BRAKE PEDALBR-7

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

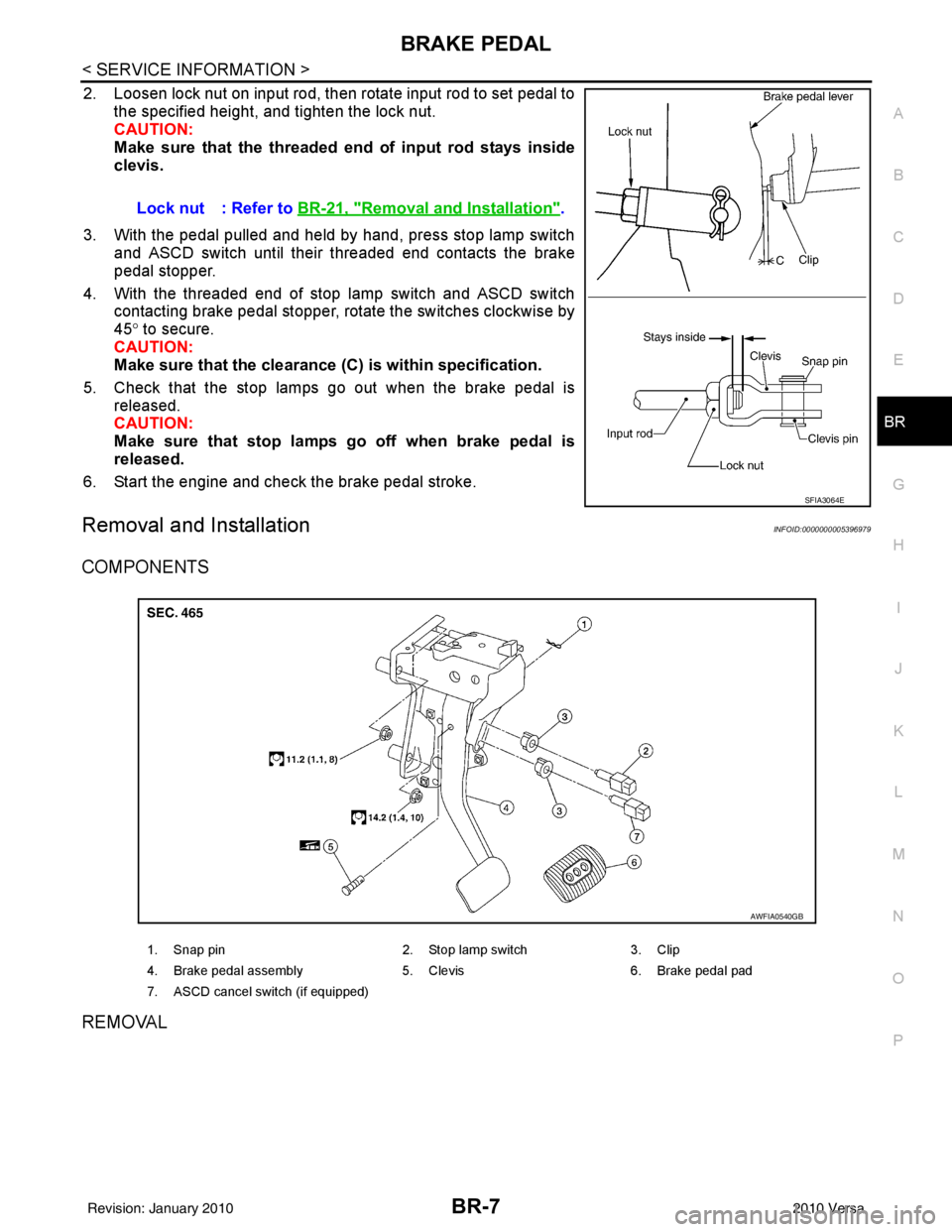

2. Loosen lock nut on input rod, then rotate input rod to set pedal to the specified height, and tighten the lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch and ASCD switch until their threaded end contacts the brake

pedal stopper.

4. With the threaded end of stop lamp switch and ASCD switch contacting brake pedal stopper, rotate the switches clockwise by

45° to secure.

CAUTION:

Make sure that the clearance (C) is within specification.

5. Check that the stop lamps go out when the brake pedal is released.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start the engine and check the brake pedal stroke.

Removal and InstallationINFOID:0000000005396979

COMPONENTS

REMOVAL

Lock nut : Refer to BR-21, "Removal and Installation".

SFIA3064E

1. Snap pin 2. Stop lamp switch3. Clip

4. Brake pedal assembly 5. Clevis6. Brake pedal pad

7. ASCD cancel switch (if equipped)

AWFIA0540GB

Revision: January 20102010 Versa

Page 868 of 3745

BR-20

< SERVICE INFORMATION >

BRAKE BOOSTER

BRAKE BOOSTER

On Board InspectionINFOID:0000000005396992

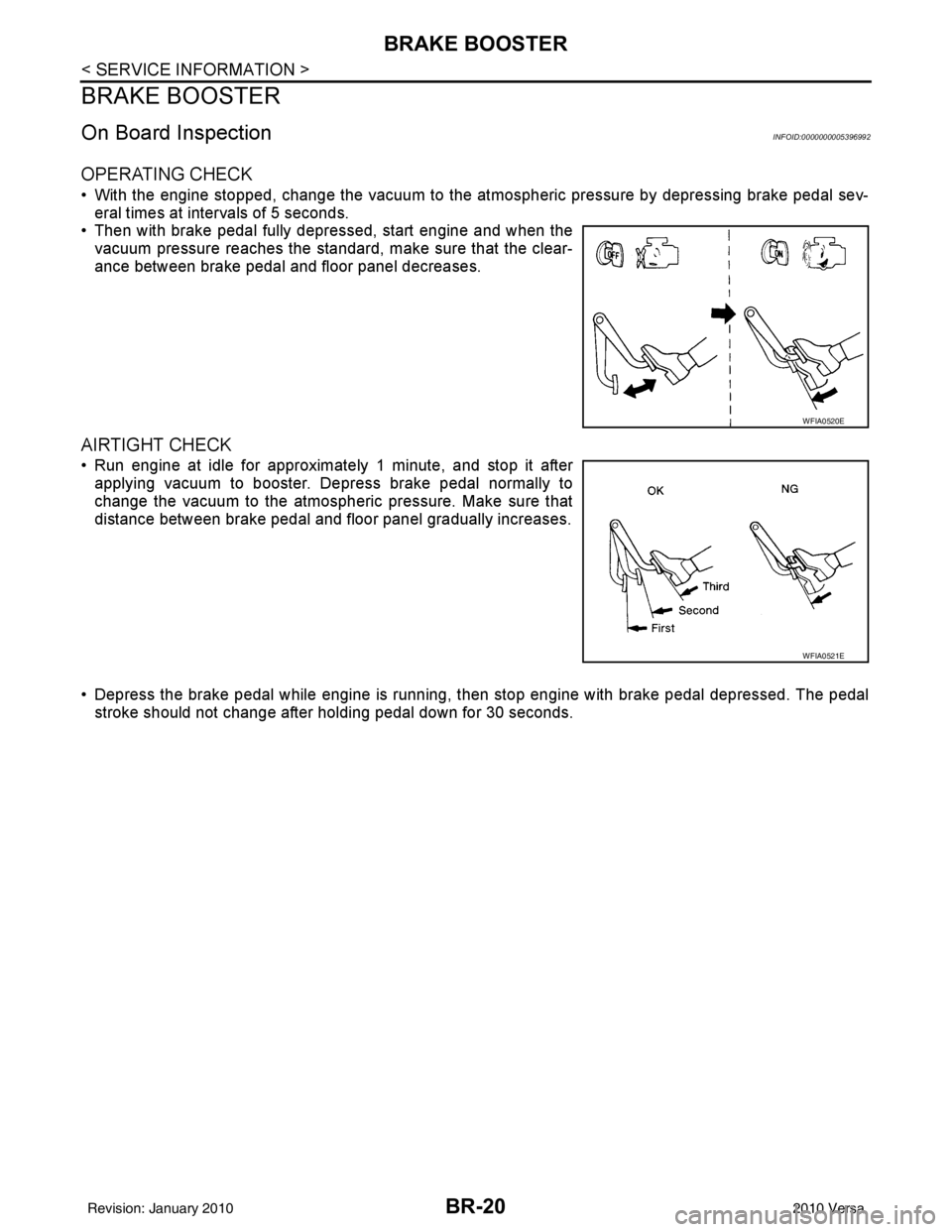

OPERATING CHECK

• With the engine stopped, change the vacuum to the atmospheric pressure by depressing brake pedal sev-

eral times at intervals of 5 seconds.

• Then with brake pedal fully depressed, start engine and when the vacuum pressure reaches the standard, make sure that the clear-

ance between brake pedal and floor panel decreases.

AIRTIGHT CHECK

• Run engine at idle for approximately 1 minute, and stop it afterapplying vacuum to booster. Depress brake pedal normally to

change the vacuum to the atmospheric pressure. Make sure that

distance between brake pedal and floor panel gradually increases.

• Depress the brake pedal while engine is running, then stop engine with brake pedal depressed. The pedal

stroke should not change after holding pedal down for 30 seconds.

WFIA0520E

WFIA0521E

Revision: January 20102010 Versa

Page 894 of 3745

![NISSAN TIIDA 2010 Service User Guide BRC-4

< SERVICE INFORMATION >[ABS]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the st NISSAN TIIDA 2010 Service User Guide BRC-4

< SERVICE INFORMATION >[ABS]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the st](/img/5/57397/w960_57397-893.png)

BRC-4

< SERVICE INFORMATION >[ABS]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Brake SystemINFOID:0000000005397021

CAUTION:

• Refer to MA-14

for recommended brake fluid.

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when removing and installing brake

tube.

• If a brake fluid leak is found, the part must be disassembled without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF an d remove the connector of the

ABS actuator and electric unit (c ontrol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage. Refer to BR-34, "

Brake Burnishing Proce-

dure".

WARNING:

• Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.

Precaution for Brake ControlINFOID:0000000005397022

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning la mp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check brake booster operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the v ehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near t he control module, ABS function may have a malfunction

or error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits or improper wiring.

Precaution for CAN SystemINFOID:0000000005397023

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of test er in use must be less than 7.0V.

• Before checking harnesses, turn ignition sw itch OFF and disconnect battery negative cable.

SBR686C

Revision: January 20102010 Versa

Page 897 of 3745

![NISSAN TIIDA 2010 Service User Guide SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock NISSAN TIIDA 2010 Service User Guide SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock](/img/5/57397/w960_57397-896.png)

SYSTEM DESCRIPTIONBRC-7

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SYSTEM DESCRIPTION

System ComponentINFOID:0000000005397026

ABS FunctionINFOID:0000000005397027

• The Anti-Lock Brake System detects wheel revolution while braking and improves handling stability during sudden braking by electrically preventing wheel lockup. Maneuverability is also improved for avoiding obsta-

cles during emergency braking.

• If the electrical system malfunctions, the Fail-Safe function is activated, t he ABS becomes inoperative and

the ABS warning lamp turns on.

• The electrical system can be diagnosed using CONSULT-III.

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

EBD FunctionINFOID:0000000005397028

• Electronic Brake Distribution is a function that detects subtle slippages between the front and rear wheels during braking, and it improves handling stability by elec tronically controlling the brake fluid pressure which

results in reduced rear wheel slippage.

• If the electrical system malfunctions, the Fail-Safe function is activated, the EBD and ABS become inopera- tive, and the ABS warning lamp and brake warning lamp are turned on.

• The electrical system can be diagnosed using CONSULT-III.

• During EBD operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting the vehicle, the brake pedal may vibrate or motor operating noises may be heard from the

engine compartment. This is normal due to the self check operation.

Fail-Safe FunctionINFOID:0000000005397029

CAUTION:

If the Fail-Safe function is activated, perform the Self Diagnosis for ABS system.

ABS/EBD SYSTEM

In case of an electrical malfunction with the ABS, the ABS warning lamp wi ll turn on. In case of an electrical

malfunction with the EBD system, the brake warni ng lamp and the ABS warning lamp will turn on.

The system will revert to one of the follo wing conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and t he condition of the vehicle is the same condition of

vehicles without ABS system.

WFIA0118E

Revision: January 20102010 Versa

Page 911 of 3745

![NISSAN TIIDA 2010 Service User Guide TROUBLE DIAGNOSISBRC-21

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SELF-DIAGNOSIS

Description

If an error is detected in the system, the ABS warning lamp will turn on. In this ca NISSAN TIIDA 2010 Service User Guide TROUBLE DIAGNOSISBRC-21

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SELF-DIAGNOSIS

Description

If an error is detected in the system, the ABS warning lamp will turn on. In this ca](/img/5/57397/w960_57397-910.png)

TROUBLE DIAGNOSISBRC-21

< SERVICE INFORMATION > [ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SELF-DIAGNOSIS

Description

If an error is detected in the system, the ABS warning lamp will turn on. In this case, perform self-diagnosis as

follows:

Operation Procedure

1. Turn ignition switch OFF.

2. Connect CONSULT-III to the data link connector.

3. Turn ignition switch ON.

4. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping the vehicle, with the engine running, touch “ABS”, “SELF-DIAG RESULTS” in order on the CONSULT-III screen.

6. The self-diagnostic results are displayed. (If necessary, the self-diagnostic results can be printed out by touching “PRINT”.)

• When “NO DTC IS DETECTED” is displayed, check the ABS warning lamp.

7. Conduct the appropriate inspection from the display item list, and repair or replace the malfunctioning

component.

8. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

• When a wheel sensor “short-circuit” is detected, if the vehicle is not driven at 30 km/h (19 MPH)

for at least 1 minute, the ABS warn ing lamp will not turn off even if the malfunction is repaired.

9. Turn ignition switch OFF to prepare for erasing the memory.

10. Start the engine and touch “ABS”, “SELF-DIAG RESULTS”, “ERASE” in order on the CONSULT-III screen to erase the error memory.

If “ABS” is not indicated, go to GI-36, "

CONSULT-III Data Link Connector (DLC) Circuit".

CAUTION:

If the error memory is not erased, re -conduct the operation from step 5.

11. For the final inspection, drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute and

confirm that the ABS warning lamp is off.

Display Item List

FUNCTION TEST Conducted by CONSULT-III in stead of a technician to determine whether each system is "OK" or "NG".

ECU IDENTIFICATION ABS actuator and electric un it (control unit) part number can be read.

Diagnostic mode

Description

Revision: January 20102010 Versa