NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 191 of 3745

AT-174

< SERVICE INFORMATION >

TR SW, OD SW AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT

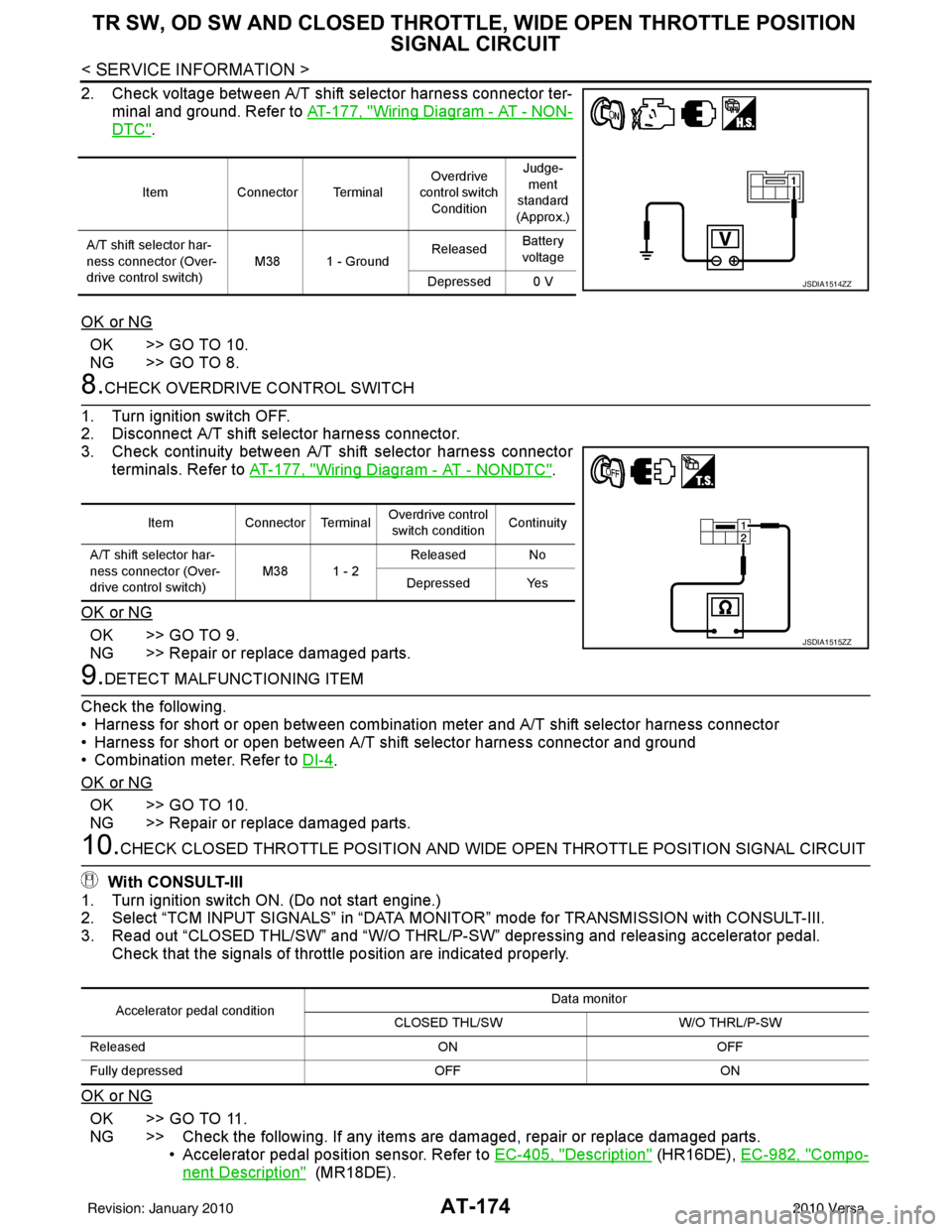

2. Check voltage between A/T shift selector harness connector ter-

minal and ground. Refer to AT-177, "

Wiring Diagram - AT - NON-

DTC".

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8.CHECK OVERDRIVE CONTROL SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T shift selector harness connector.

3. Check continuity between A/T shift selector harness connector terminals. Refer to AT-177, "

Wiring Diagram - AT - NONDTC".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between combination meter and A/T shift selector harness connector

• Harness for short or open between A/T shift selector harness connector and ground

• Combination meter. Refer to DI-4

.

OK or NG

OK >> GO TO 10.

NG >> Repair or replace damaged parts.

10.CHECK CLOSED THROTTLE POSI TION AND WIDE OPEN THROTTLE POSITION SIGNAL CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for TRANSMISSION with CONSULT-III.

3. Read out “CLOSED THL/SW” and “W/O THRL/P-S W” depressing and releasing accelerator pedal.

Check that the signals of throttle position are indicated properly.

OK or NG

OK >> GO TO 11.

NG >> Check the following. If any items are damaged, repair or replace damaged parts. • Accelerator pedal position sensor. Refer to EC-405, "

Description" (HR16DE), EC-982, "Compo-

nent Description" (MR18DE).

Item Connector Terminal Overdrive

control switch

Condition Judge-

ment

standard

(Approx.)

A/T shift selector har-

ness connector (Over-

drive control switch) M38 1 - Ground

Released

Battery

voltage

Depressed 0 V

JSDIA1514ZZ

Item Connector Terminal Overdrive control

switch condition Continuity

A/T shift selector har-

ness connector (Over-

drive control switch) M38 1 - 2

Released No

Depressed Yes

JSDIA1515ZZ

Accelerator pedal condition Data monitor

CLOSED THL/SW W/O THRL/P-SW

Released ONOFF

Fully depressed OFFON

Revision: January 20102010 Versa

Page 192 of 3745

TR SW, OD SW AND CLOSED THROTTLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT

AT-175

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

11 .PERFORM SELF-DIAGNOSIS

Without CONSULT-III

Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III".

OK or NG

OK >> INSPECTION END

NG − 1 >> Self-diagnosis does not activate: GO TO 12.

NG − 2 >> DTC is displayed: Check the malfunctioning system. Refer to AT-82, "

Diagnosis Procedure with-

out CONSULT-III".

12.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value".

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Component InspectionINFOID:0000000005397388

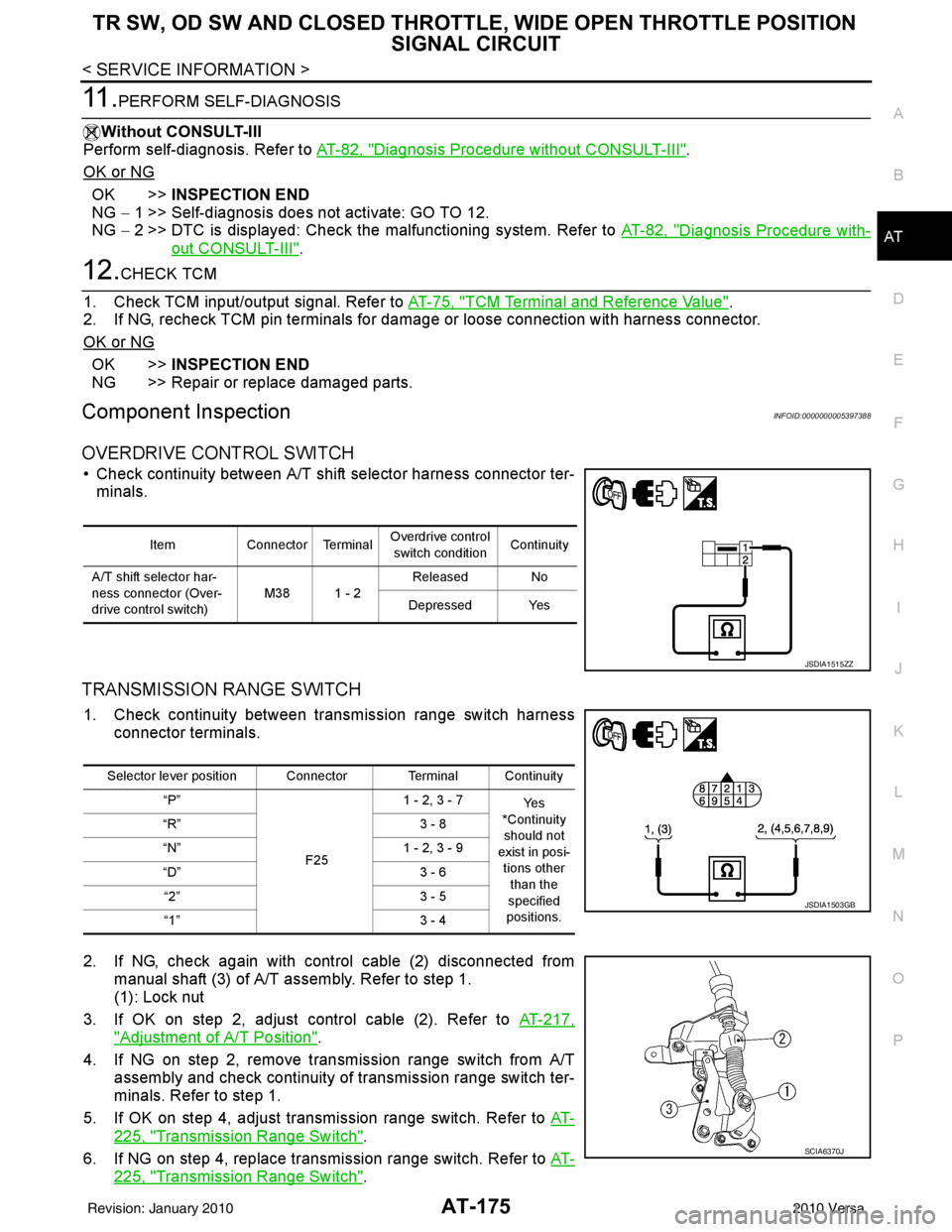

OVERDRIVE CONTROL SWITCH

• Check continuity between A/T shift selector harness connector ter- minals.

TRANSMISSION RANGE SWITCH

1. Check continuity between transmission range switch harness connector terminals.

2. If NG, check again with control cable (2) disconnected from manual shaft (3) of A/T assembly. Refer to step 1.

(1): Lock nut

3. If OK on step 2, adjust control cable (2). Refer to AT-217,

"Adjustment of A/T Position".

4. If NG on step 2, remove transmission range switch from A/T assembly and check continuity of transmission range switch ter-

minals. Refer to step 1.

5. If OK on step 4, adjust transmission range switch. Refer to AT-

225, "Transmission Range Switch".

6. If NG on step 4, replace transmission range switch. Refer to AT-

225, "Transmission Range Switch".

ItemConnector Terminal Overdrive control

switch condition Continuity

A/T shift selector har-

ness connector (Over-

drive control switch) M38 1 - 2Released No

Depressed Yes

JSDIA1515ZZ

Selector lever position Connector Terminal Continuity “P”

F251 - 2, 3 - 7

Ye s

*Continuity

should not

exist in posi- tions other

than the

specified

positions.

“R”

3 - 8

“N” 1 - 2, 3 - 9

“D” 3 - 6

“2” 3 - 5

“1” 3 - 4

JSDIA1503GB

SCIA6370J

Revision: January 20102010 Versa

Page 193 of 3745

AT-176

< SERVICE INFORMATION >

SHIFT POSITION INDICATOR CIRCUIT

SHIFT POSITION INDICATOR CIRCUIT

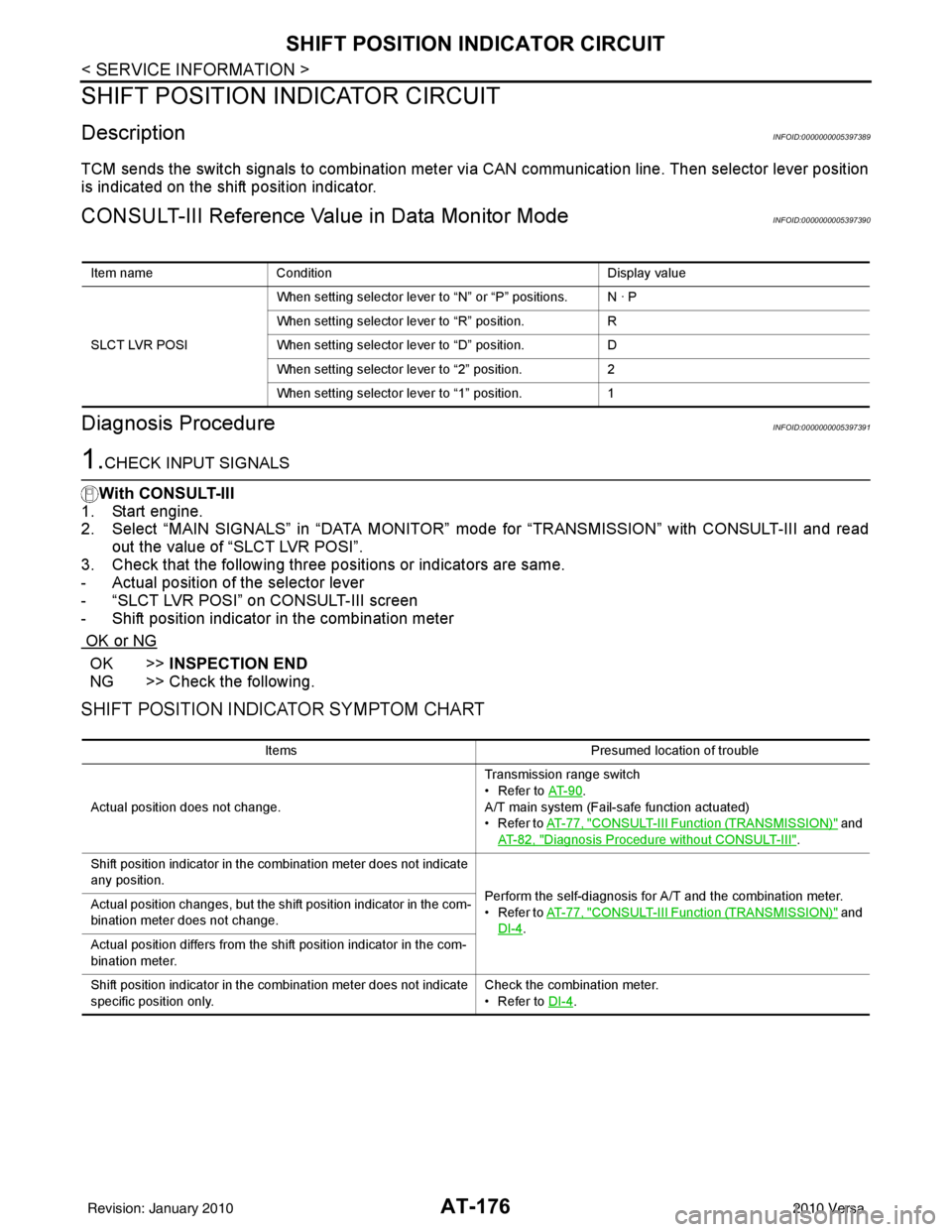

DescriptionINFOID:0000000005397389

TCM sends the switch signals to combination meter via CAN communication line. Then selector lever position

is indicated on the shift position indicator.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397390

Diagnosis ProcedureINFOID:0000000005397391

1.CHECK INPUT SIGNALS

With CONSULT-III

1. Start engine.

2. Select “MAIN SIGNALS” in “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III and read

out the value of “SLCT LVR POSI”.

3. Check that the following three pos itions or indicators are same.

- Actual position of the selector lever

- “SLCT LVR POSI” on CONSULT-III screen

- Shift position indicator in the combination meter

OK or NG

OK >> INSPECTION END

NG >> Check the following.

SHIFT POSITION INDICATOR SYMPTOM CHART

Item name Condition Display value

SLCT LVR POSI When setting selector lever to

“N” or “P” positions. N · P

When setting selector lever to “R” position. R

When setting selector lever to “D” position. D

When setting selector lever to “2” position. 2

When setting selector lever to “1” position. 1

ItemsPresumed location of trouble

Actual position does not change. Transmission range switch

• Refer to

AT- 9 0

.

A/T main system (Fail-safe function actuated)

•Refer to AT- 7 7 , "

CONSULT-III Function (TRANSMISSION)" and

AT- 8 2 , "

Diagnosis Procedure without CONSULT-III".

Shift position indicator in the combination meter does not indicate

any position. Perform the self-diagnosis for A/T and the combination meter.

•Refer to AT- 7 7 , "

CONSULT-III Function (TRANSMISSION)" and

DI-4

.

Actual position changes, but the shift position indicator in the com-

bination meter does not change.

Actual position differs from the shift position indicator in the com-

bination meter.

Shift position indicator in the combination meter does not indicate

specific position only.

Check the combination meter.

• Refer to

DI-4

.

Revision: January 20102010 Versa

Page 194 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-177

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

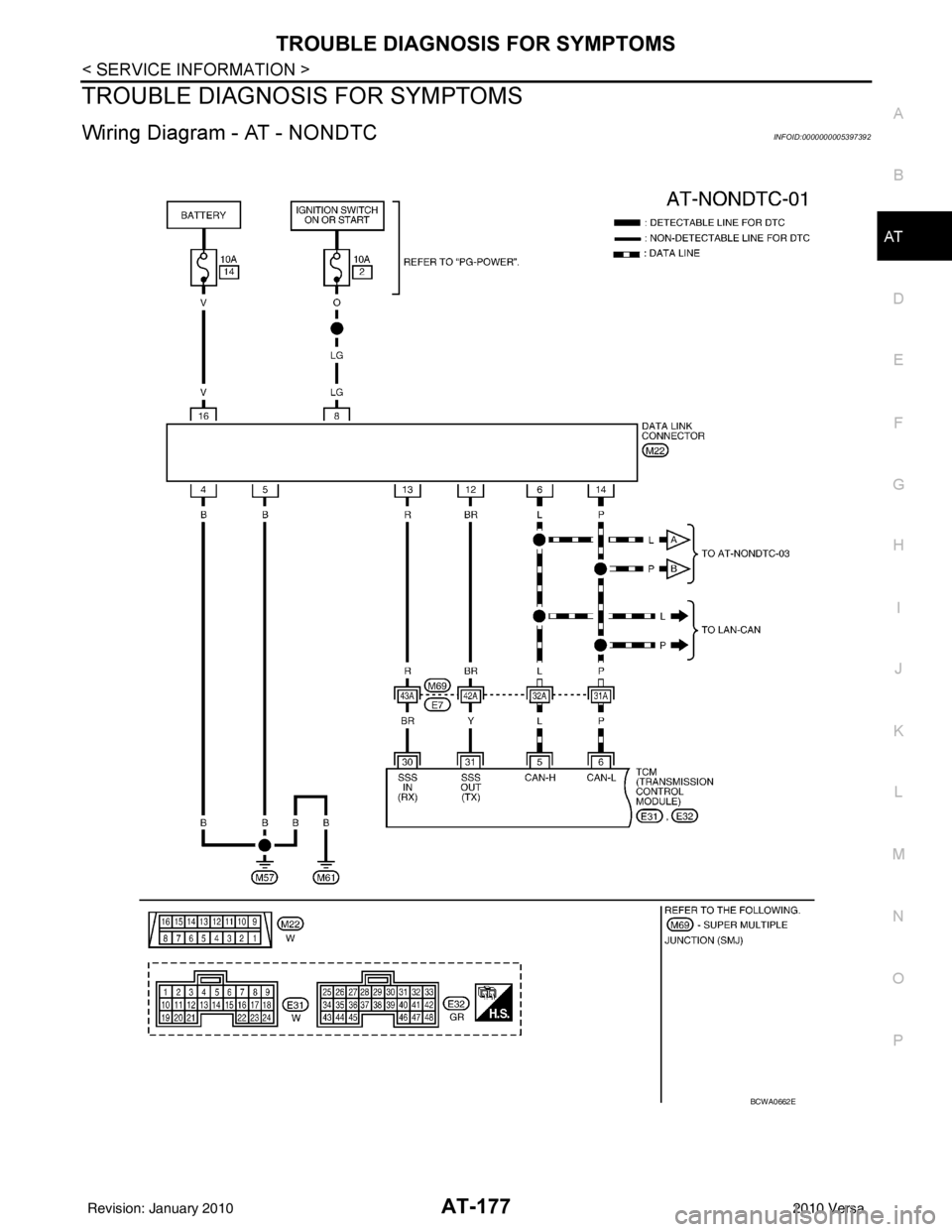

TROUBLE DIAGNOSIS FOR SYMPTOMS

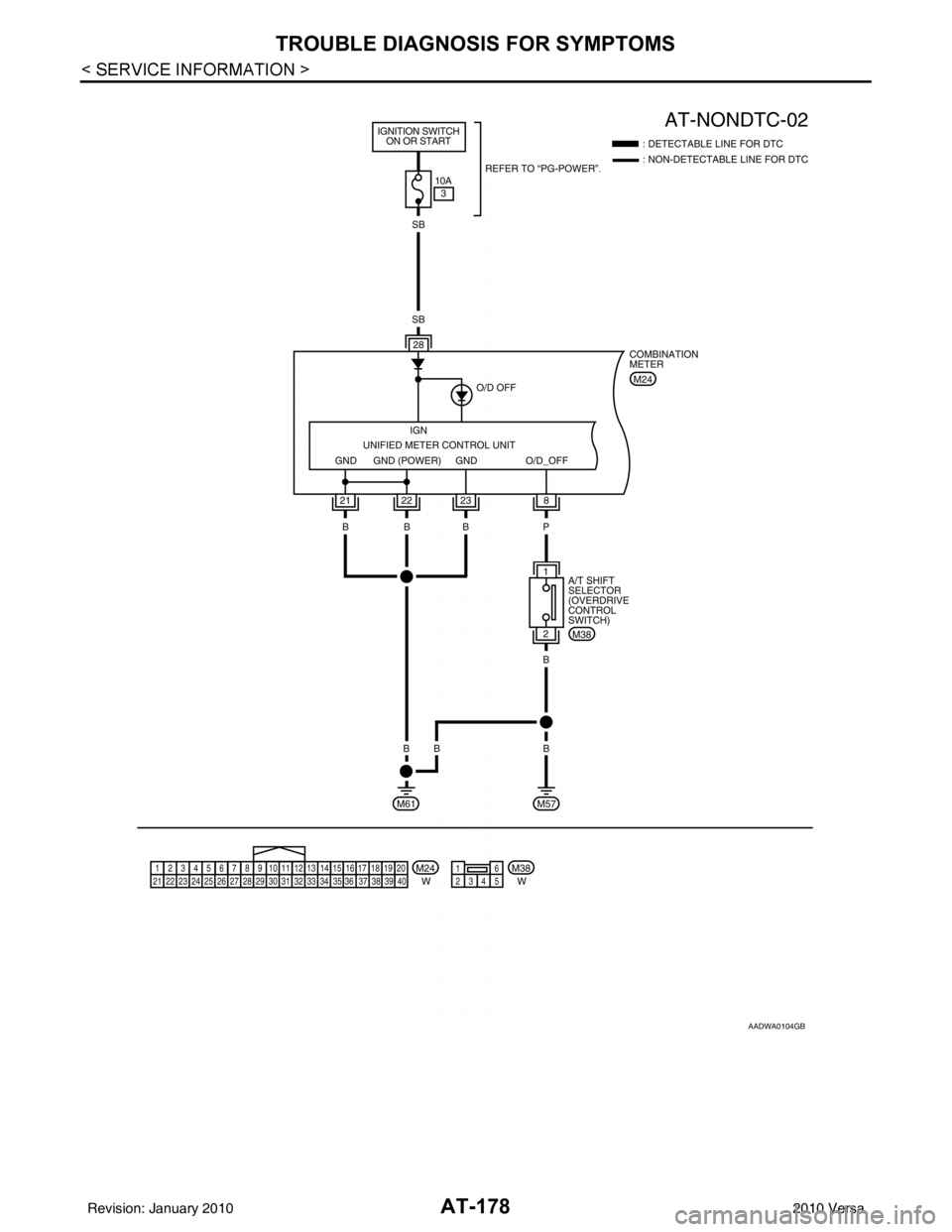

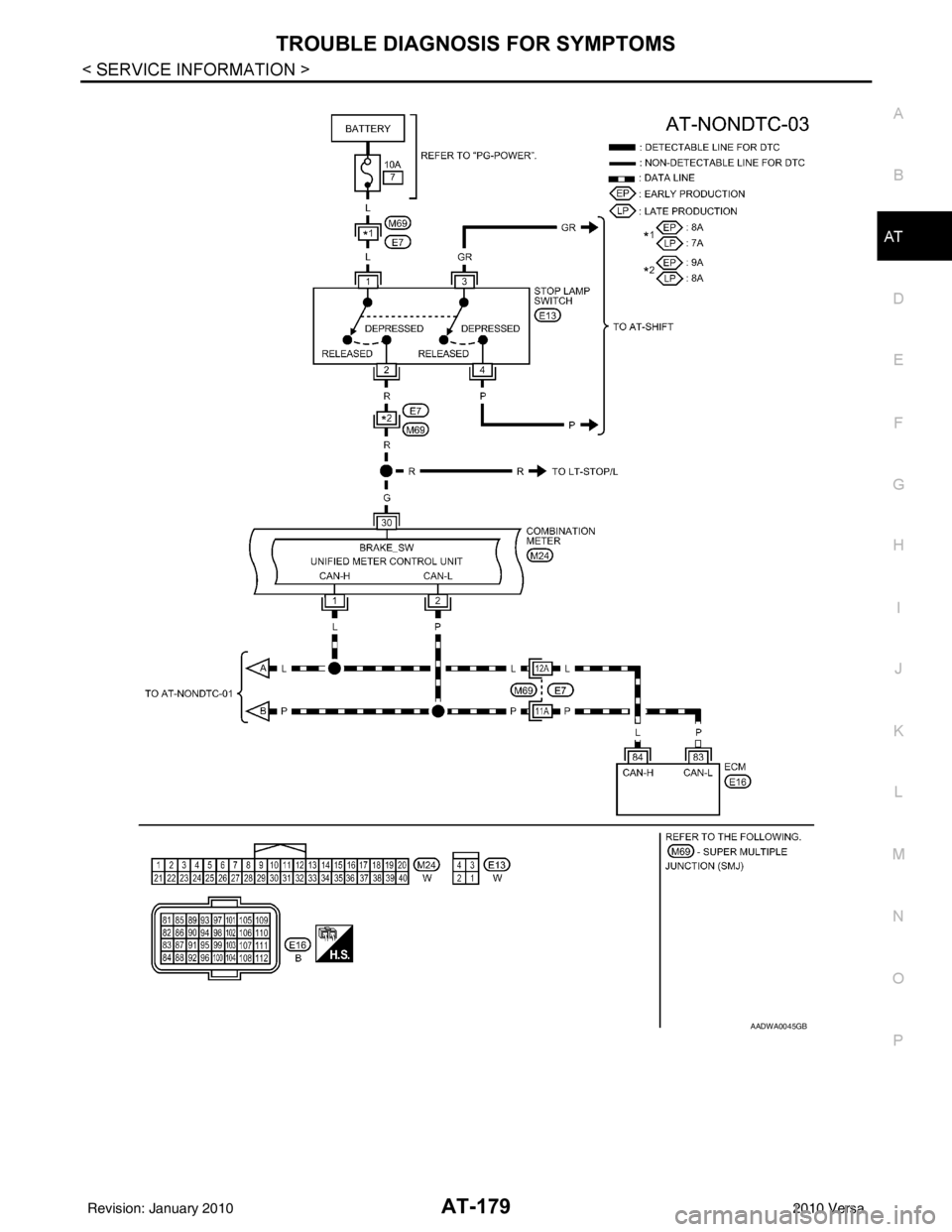

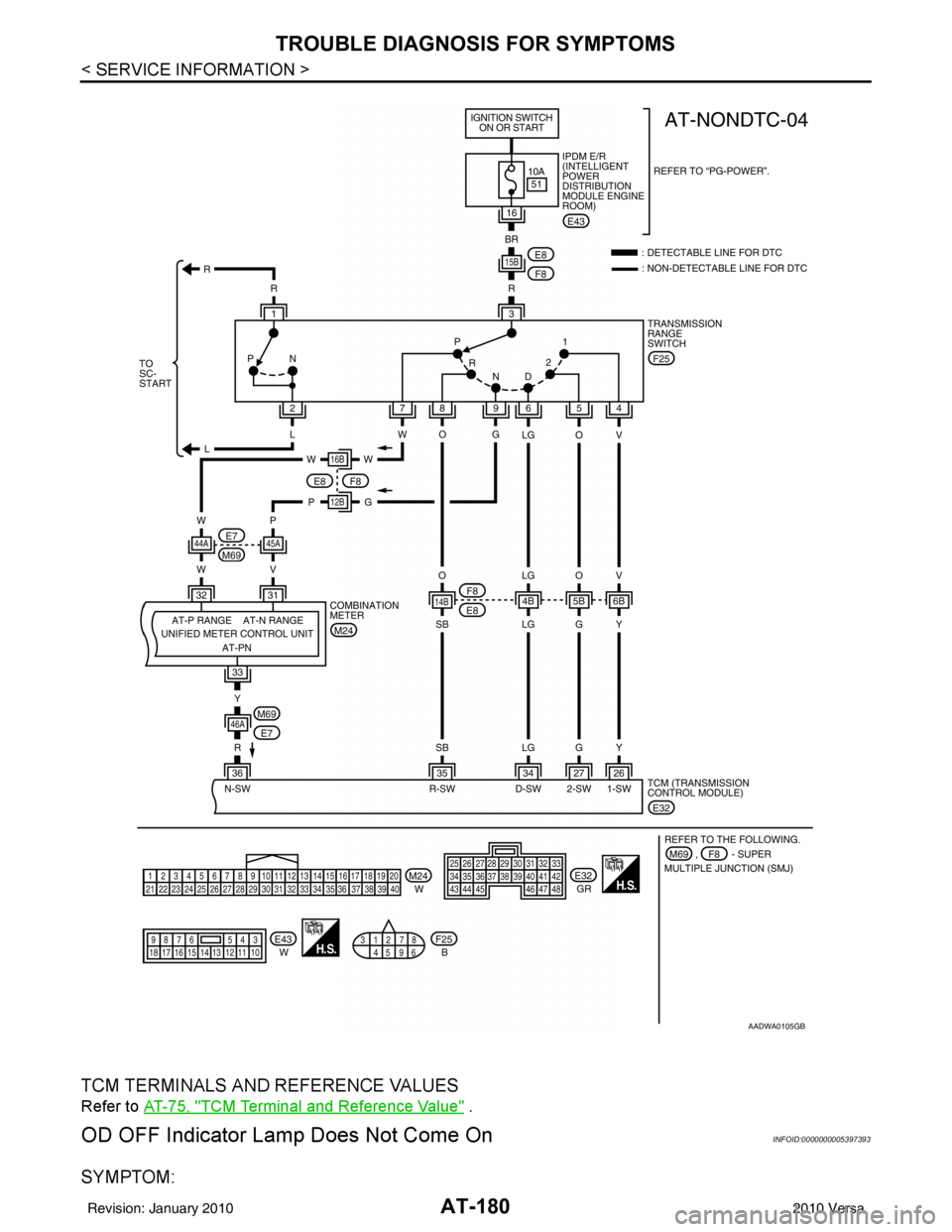

Wiring Diagram - AT - NONDTCINFOID:0000000005397392

BCWA0662E

Revision: January 20102010 Versa

Page 195 of 3745

AT-178

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

AADWA0104GB

Revision: January 20102010 Versa

Page 196 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-179

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

AADWA0045GB

Revision: January 20102010 Versa

Page 197 of 3745

AT-180

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-75, "TCM Terminal and Reference Value" .

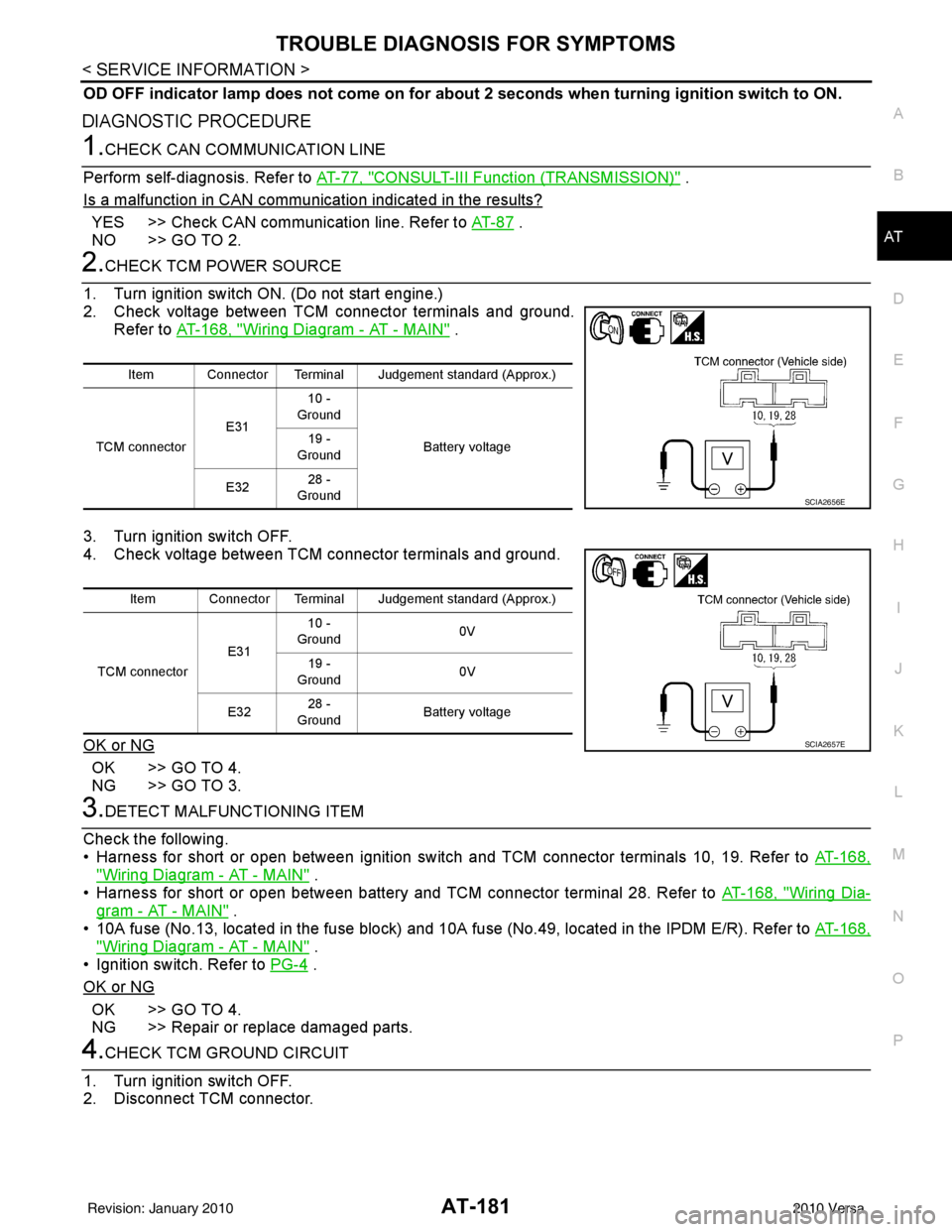

OD OFF Indicator Lamp Does Not Come OnINFOID:0000000005397393

SYMPTOM:

AADWA0105GB

Revision: January 20102010 Versa

Page 198 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-181

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

OD OFF indicator lamp does not come on for abou t 2 seconds when turning ignition switch to ON.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" .

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 8 7 .

NO >> GO TO 2.

2.CHECK TCM POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground. Refer to AT-168, "

Wiring Diagram - AT - MAIN" .

3. Turn ignition switch OFF.

4. Check voltage between TCM connector terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and TCM connector terminals 10, 19. Refer to AT-168,

"Wiring Diagram - AT - MAIN" .

• Harness for short or open between battery and TCM connector terminal 28. Refer to AT-168, "

Wiring Dia-

gram - AT - MAIN" .

• 10A fuse (No.13, located in the fuse block) and 10A fuse (No.49, located in the IPDM E/R). Refer to AT-168,

"Wiring Diagram - AT - MAIN" .

• Ignition switch. Refer to PG-4

.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground

Battery voltage

19 -

Ground

E32 28 -

Ground

SCIA2656E

Item Connector Terminal Judgement standard (Approx.)

TCM connector E3110 -

Ground 0V

19 -

Ground 0V

E32 28 -

Ground Battery voltage

SCIA2657E

Revision: January 20102010 Versa

Page 199 of 3745

AT-182

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

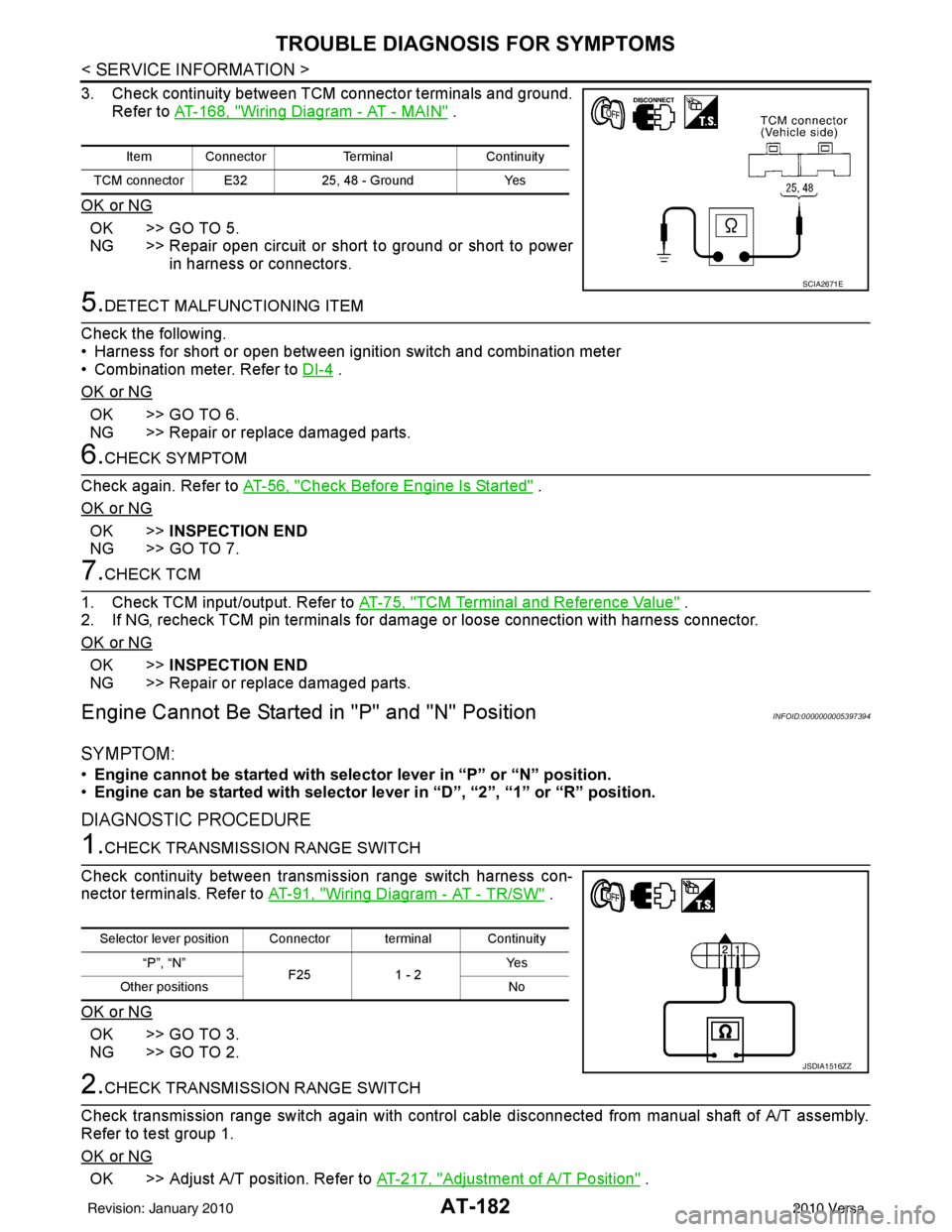

3. Check continuity between TCM connector terminals and ground.Refer to AT-168, "

Wiring Diagram - AT - MAIN" .

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.DETECT MALFUNCTIONING ITEM

Check the following.

• Harness for short or open between ignition switch and combination meter

• Combination meter. Refer to DI-4

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check Before Engine Is Started" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 7.

7.CHECK TCM

1. Check TCM input/output. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in "P" and "N" PositionINFOID:0000000005397394

SYMPTOM:

•Engine cannot be started with select or lever in “P” or “N” position.

• Engine can be started with selector lever in “D”, “2”, “1” or “R” position.

DIAGNOSTIC PROCEDURE

1.CHECK TRANSMISSION RANGE SWITCH

Check continuity between transmission range switch harness con-

nector terminals. Refer to AT-91, "

Wiring Diagram - AT - TR/SW" .

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK TRANSMISSION RANGE SWITCH

Check transmission range switch again with control cabl e disconnected from manual shaft of A/T assembly.

Refer to test group 1.

OK or NG

OK >> Adjust A/T position. Refer to AT-217, "Adjustment of A/T Position" .

Item ConnectorTerminalContinuity

TCM connector E32 25, 48 - GroundYes

SCIA2671E

Selector lever position Connector terminal Continuity

“P”, “N” F251 - 2 Ye s

Other positions No

JSDIA1516ZZ

Revision: January 20102010 Versa

Page 200 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-183

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> 1. Check transmission range switch (Refer to test group 1.) again after adjusting transmission

range switch (Refer to AT-225

).

- If OK, INSPECTION END

- If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch" .

3.CHECK STARTING SYSTEM

Check starting system. Refer to SC-9

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

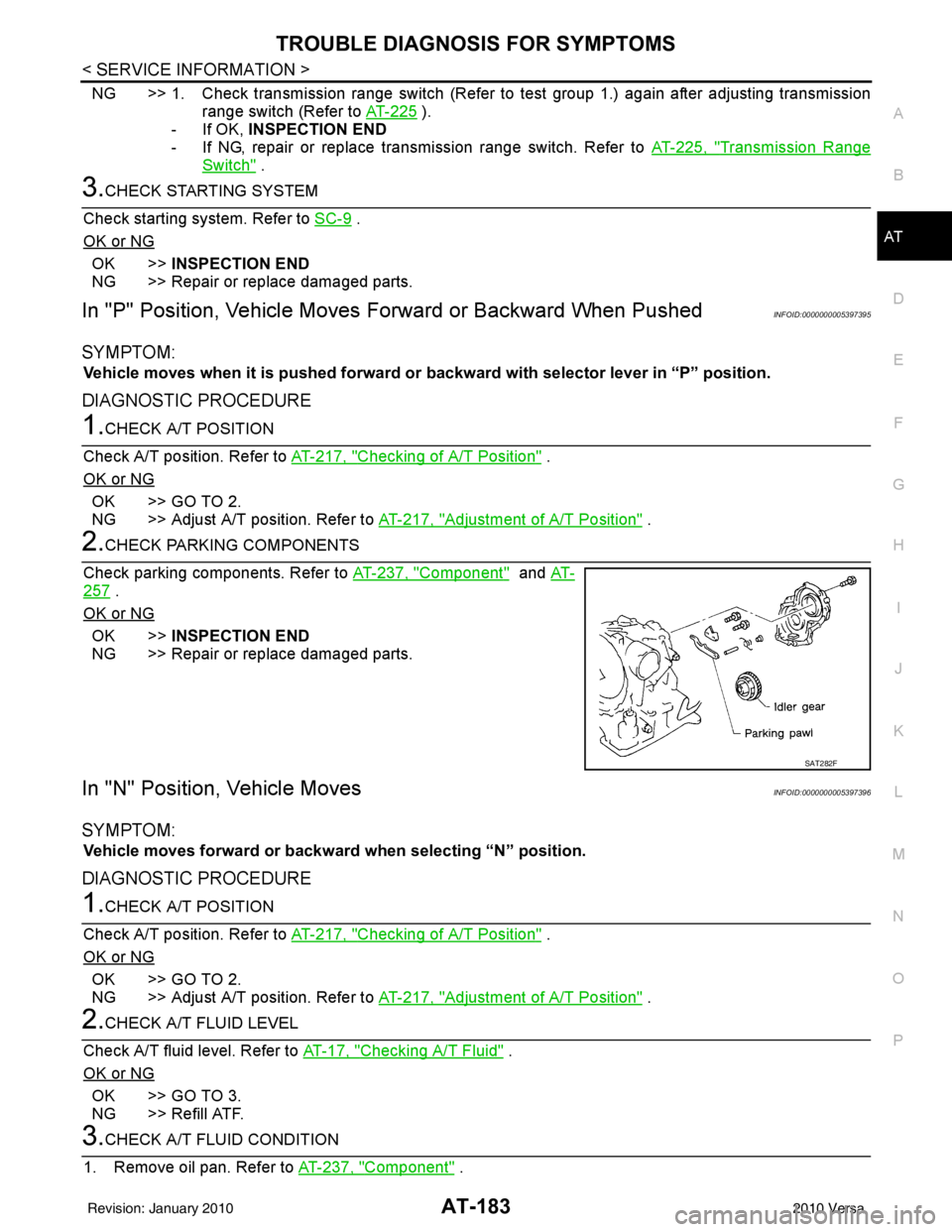

In "P" Position, Vehicle Moves Forward or Backward When PushedINFOID:0000000005397395

SYMPTOM:

Vehicle moves when it is pushed forward or backward with selector lever in “P” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

2.CHECK PARKING COMPONENTS

Check parking components. Refer to AT-237, "

Component" and AT-

257 .

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

In "N" Position, Vehicle MovesINFOID:0000000005397396

SYMPTOM:

Vehicle moves forward or backwar d when selecting “N” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-17, "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

SAT282F

Revision: January 20102010 Versa