Accelerator NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2252 of 3745

![NISSAN TIIDA 2010 Service Repair Manual DTC P2138 APP SENSOREC-987

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness or connectors.

6.CHECK COM NISSAN TIIDA 2010 Service Repair Manual DTC P2138 APP SENSOREC-987

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness or connectors.

6.CHECK COM](/img/5/57397/w960_57397-2251.png)

DTC P2138 APP SENSOREC-987

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness or connectors.

6.CHECK COMPONENTS

Check the following.

• Crankshaft position sensor (POS) (Refer to EC-798, "

Component Inspection".)

• EVAP control system pressure sensor (Refer to EC-850, "

Component Inspection".)

• Refrigerant pressure sensor (Refer to MTC-38

.)

OK or NG

OK >> GO TO 11.

NG >> Replace malfunctioning component.

7.CHECK APP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between the following; ECM terminal 111 and APP sensor terminal 2,

ECM terminal 104 and APP sensor terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK APP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between the following; ECM terminal 110 and APP sensor terminal 3,

ECM terminal 103 and APP sensor terminal 6.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK APP SENSOR

Refer to EC-988, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> GO TO 10.

10.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-580, "

Accelerator Pedal Released Position Learning".

3. Perform EC-580, "

Throttle Valve Closed Position Learning".

4. Perform EC-580, "

Idle Air Volume Learning".

ECM terminal Sensor terminalReference Wiring Diagram

74 Refrigerant pressure sensor terminal 3 EC-1029, "

Wiring Diagram"

75Crankshaft position sensor (POS) terminal 1 EC-794, "Wiring Diagram"

76EVAP control system pressure sensor terminal 3 EC-853, "Wiring Diagram"

102APP sensor terminal 5 EC-984, "Wiring Diagram"

Continuity should exist.

Continuity should exist.

Revision: January 20102010 Versa

Page 2253 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-988

< SERVICE INFORMATION >[MR18DE]

DTC P2138 APP SENSOR

>>

INSPECTION END

11 .CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Component InspectionINFOID:0000000005532884

ACCELERAT NISSAN TIIDA 2010 Service Repair Manual EC-988

< SERVICE INFORMATION >[MR18DE]

DTC P2138 APP SENSOR

>>

INSPECTION END

11 .CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Component InspectionINFOID:0000000005532884

ACCELERAT](/img/5/57397/w960_57397-2252.png)

EC-988

< SERVICE INFORMATION >[MR18DE]

DTC P2138 APP SENSOR

>>

INSPECTION END

11 .CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Component InspectionINFOID:0000000005532884

ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON.

3. Check voltage between ECM terminals 110 (APP sensor 1 sig-

nal), 103 (APP sensor 2 signal) and ground under the following

conditions.

4. If NG, replace accelerator pedal assembly and go to next step.

5. Perform EC-580, "

Accelerator Pedal Released Position Learning".

6. Perform EC-580, "

Throttle Valve Closed Position Learning".

7. Perform EC-580, "

Idle Air Volume Learning".

Removal and InstallationINFOID:0000000005532885

ACCELERATOR PEDAL

Refer to ACC-4.

Terminal Accelerator pedal Voltage

11 0

(Accelerator pedal position

sensor 1) Fully released

0.6 - 0.9 V

Fully depressed 3.9 - 4.7 V

103

(Accelerator pedal position sensor 2) Fully released

0.3 - 0.6 V

Fully depressed 1.95 - 2.4 V

PBIA9572J

Revision: January 20102010 Versa

Page 2382 of 3745

![NISSAN TIIDA 2010 Service Repair Manual COMPRESSION PRESSUREEM-23

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

COMPRESSION PRESSURE

InspectionINFOID:0000000005398044

1. Warm up engine thoroughly. Then, stop it.

2. Rel NISSAN TIIDA 2010 Service Repair Manual COMPRESSION PRESSUREEM-23

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

COMPRESSION PRESSURE

InspectionINFOID:0000000005398044

1. Warm up engine thoroughly. Then, stop it.

2. Rel](/img/5/57397/w960_57397-2381.png)

COMPRESSION PRESSUREEM-23

< ON-VEHICLE MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

COMPRESSION PRESSURE

InspectionINFOID:0000000005398044

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to

EC-496, "

Inspection".

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-46, "

Exploded View".

4. Connect an engine tachometer (not required in use of CONSULT-III).

5. Install a compression tester (B) with an adapter (commercial service tool) (A) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plughole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

6. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

CAUTION:

Always use fully a charged battery to obtain the specified engine speed.

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check engine speed again with normal battery gravity.

• If compression pressure is below minimum value, check valve clearances and parts associated with combustion chamber (Valve, valve seat, piston, pi ston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure the compression pressure again.

• If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal- functioning. Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, cylinder head gasket is leaking. In such a case, replace cylinder

head gasket.

7. After inspection is completed, install removed parts.

8. Start the engine, and confirm that the engine runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-106, "

Description".

PBIC3730E

SBIA0533E

Compression Pressure: Refer to E M - 111 , "General Specification".

Revision: January 20102010 Versa

Page 2540 of 3745

![NISSAN TIIDA 2010 Service Repair Manual CYLINDER HEADEM-181

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CYLINDER HEAD

On-Vehicle ServiceINFOID:0000000005398137

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. NISSAN TIIDA 2010 Service Repair Manual CYLINDER HEADEM-181

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CYLINDER HEAD

On-Vehicle ServiceINFOID:0000000005398137

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly.](/img/5/57397/w960_57397-2539.png)

CYLINDER HEADEM-181

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CYLINDER HEAD

On-Vehicle ServiceINFOID:0000000005398137

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to

EC-582, "

Fuel Pressure Check".

3. Disconnect fuel pump fuse (1) to avoid fuel injection during mea- surement.

4. Remove engine room cover.

5. Remove ignition coil and spark plug from each cylinder. Refer to EM-149

.

6. Connect an engine tachometer (not required in use of CONSULT-III).

7. Install a suitable compression tester (B) with an adapter (A) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plughole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

8. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

Compression pressure:

Unit: kPa (bar, kg/cm2 psi) /rpm

CAUTION:

Always use a fully charged battery to obtain the specified engine speed.

: Vehicle front

PBIA9861J

LBIA0459E

SBIA0533E

Standard MinimumDifferential limit between cylinders

1,500 (15.0, 15.3, 217.6) / 250 1,200 (12.0, 12.2, 174) / 250 100 (1.0, 1.0, 15) / 250

Revision: January 20102010 Versa

Page 2836 of 3745

![NISSAN TIIDA 2010 Service Repair Manual CAN COMMUNICATION SYSTEMLAN-27

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN Communication Signal ChartINFOID:0000000005395135

Refer to LAN-16, "How to Use CAN Communication Sig NISSAN TIIDA 2010 Service Repair Manual CAN COMMUNICATION SYSTEMLAN-27

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN Communication Signal ChartINFOID:0000000005395135

Refer to LAN-16, "How to Use CAN Communication Sig](/img/5/57397/w960_57397-2835.png)

CAN COMMUNICATION SYSTEMLAN-27

< SERVICE INFORMATION > [CAN]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

CAN Communication Signal ChartINFOID:0000000005395135

Refer to LAN-16, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

NOTE:

Refer to LAN-22, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Signal name/Connecting unitECM

BCM

EPS

I-KEY M&A

STRG ABS

TCM

*1

TCM

*2

IPDM-E

A/C compressor request signal T R

Accelerator pedal position signal T

R

*3RR

ASCD CRUISE lamp signal T R

ASCD SET lamp signal T R

Closed throttle position signal T R R

Cooling fan motor operation signal T R

Engine coolant temperature signal TR

Engine speed signal TR

R

*3R

Engine status signal T R R R

Fuel consumption monitor signal T R

Malfunction indicator lamp signal TR

Wide open throttle position signal T R R

A/C switch signal R T

Blower fan motor switch signal R T

Buzzer output signal TR

TR

Day time running light request signal

*4TR

Door lock/unlock status signal TR

Door switch signal TR R R

Front wiper request signal T R

High beam request signal TR R

Horn chirp signal T R

Ignition switch signal T R

Low beam request signal T R

Position lights request signal TR R

Rear window defogger switch signal T R

Sleep/wake up signal TRR

R

RT

Theft warning horn request signal T R

Tire pressure signal

*5TR

Trunk open/close status signal TR

Turn indicator signal TR

EPS operation signal TR

EPS warning lamp signal TR

Door lock/unlock/trunk open request signal RT

Hazard request signal RT

Ignition knob switch signal RT

Revision: January 20102010 Versa

Page 3143 of 3745

MA-8

< SERVICE INFORMATION >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-48

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Clutch pedal Make sure the pedal operates smoothly and check that it has the proper free play. CL-6

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-6

and

BR-20

Parking brake Check that the lever has the proper travel and make sure that the vehicle is held

securely on a fairly steep hill when only the parking brake is applied. PB-5

Automatic transaxle

“Park” mechanismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the se-

lector lever in the “P” position without applying any brakes. —

CVT P (Park) position

mechanism On a fairly steep hill check that the vehicle is held securely with the selector lever

in the “P” position without applying any brakes.

—

Item

Reference page

ItemReference page

Windshield wash-

er fluid Check that there is adequate fluid in the tank.

—

Engine coolant

level Check the coolant level when the engine is cold. CO-12

(HR)

CO-36

(MR)

A/C condenser,

radiator and hos-

es Check the front of the condenser and radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure the radiator hoses have no cracks, de-

formation, deterioration or loose connections.

—

Brake and clutch

fluid levels Make sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs.

BR-9

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require frequent

checks of the battery fluid level. —

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. EM-14

(HR)

EM-132

(MR)

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turning

off the engine. MA-20

(HR)

MA-30

(MR)

CVT and Automat-

ic transaxle fluid

level Check the level on the dipstick after putting the selector lever in “P” with the engine

idling.

MA-38

MA-43

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the exhaust

seems unusual or there is a smell of exhaust fumes, immediately locate the trouble

and correct it. MA-37, "EXHAUST SYS-

TEM : Checking Exhaust

System HR16DE", MA-38,

"EXHAUST SYSTEM :

Checking Exhaust System

MR18DE"

Underbody

The underbody is frequently exposed to corrosive substances such as those used

on icy roads or to control dust. It is very important to remove these substances, oth-

erwise rust will form on the floor pan, frame, fuel lines and around the exhaust sys-

tem. At the end of winter, the underbody should be thoroughly flushed with plain

water, being careful to clean those areas where mud and dirt can easily accumu-

late. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has

been parked for a while. Water dripping from the air conditioner after use is normal.

If you should notice any leaks or gasoline fumes are evident, check for the cause

and correct it immediately. —

Revision: January 20102010 Versa

Page 3426 of 3745

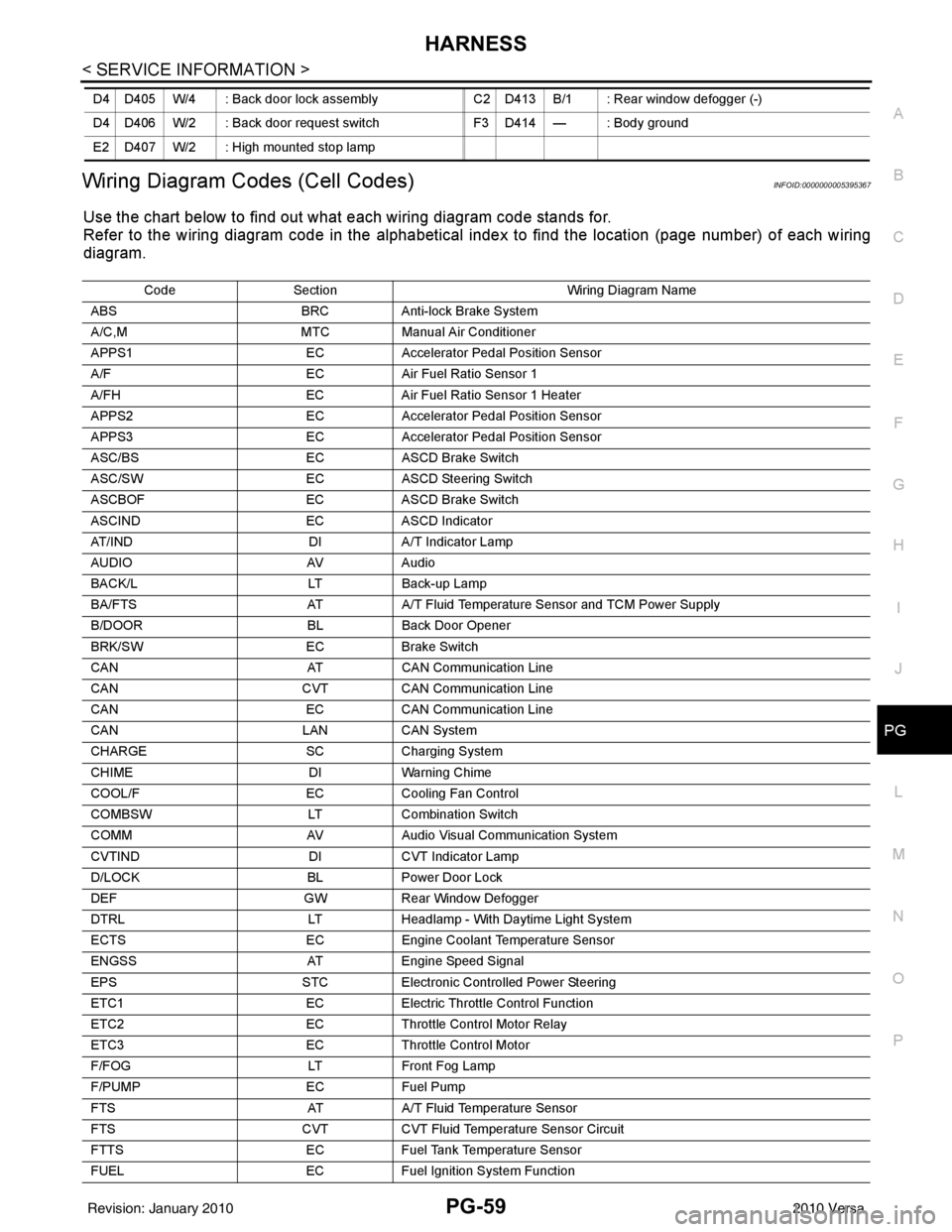

HARNESSPG-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

ENGINE ROOM HARNESS (RH VIEW)

D3 E8 SMJ : To F8 A2 E34 BR/2 : Clutch interlock switch (with M/T)

B4 E9 BR/2 : Fusible link box (battery) A2 E35 BR/2 : ASCD clutch switch

B3 E10 GR/2 : Fusible link box (battery) A2 E36 BR/2 : ASCD brake switch

B1 E11 B/2 : To M78 B4 E40 GR/2 : Brake fluid level switch

A3 E12 B/6 : Accelerator pedal position sensor D3 E42 B/2 : IPDM E/R (intelligent power distribution

module engine room)

A2 E13 B/2 : Stop lamp switch (with M/T) C3 E43 W/16: IPDM E/R (intelligent power distribution

module engine room)

A2 E13 W/4 : Stop lamp switch (without M/T) C3 E44 W/6: IPDM E/R (intelligent power distribution

module engine room)

D3 E14 — : Engine ground (crash zone sensor) D3 E45 BR/12 : IPDM E/R (intelligent power distribution

module engine room)

C2 E15 — : Engine ground D3 E46 W/12: IPDM E/R (intelligent power distribution

module engine room)

B2 E16 B/32 : ECM C3 E47 BR/8: IPDM E/R (intelligent power distribution

module engine room)

C5 E18 B/1 : Horn D3 E48 B/6: IPDM E/R (intelligent power distribution

module engine room)

C4 E19 GR/6 : To F33 D1 E51 B/2 : Front wheel sensor LH

D5 E20 B/1 : Horn D3 E53 B/2 : Front combination lamp LH (parking)

Revision: January 20102010 Versa

Page 3442 of 3745

HARNESSPG-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

Wiring Diagram Codes (Cell Codes)INFOID:0000000005395367

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp

Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pedal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

Revision: January 20102010 Versa